Single-chip package part with wafer thinned after bottom fillers cures and manufacture process thereof

A single-chip and package technology, which is applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor/solid-state device components, etc., can solve problems such as easy warpage and unguaranteed packaging reliability, and improve reliability performance, reduced possibility of wafer warpage, and thinner dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

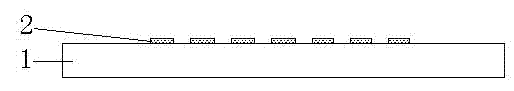

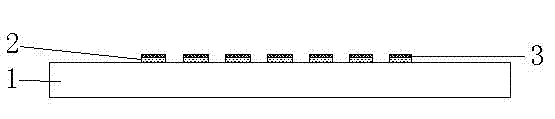

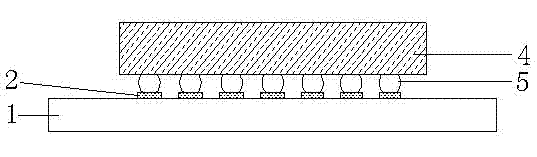

[0024] As shown in the figure, a single-chip package in which the wafer is thinned after the underfill is cured is mainly composed of a substrate 1, a nickel-gold pad 2, a chip 4, a tin-silver bump 5, an underfill 6 and a solder ball 9; The nickel-gold pad 2 is fixedly connected to the substrate 1, and the tin-silver bump 5 is fixedly connected to the chip 4; the tin-silver bump 5 coincides with the center line of the nickel-gold pad 2 and is connected by welding; The filler 6 fills the gap between the substrate 1 and the chip 4 , and surrounds the nickel-gold pad 2 and the tin-silver bump 5 ;

[0025] The chip 4 constitutes a circuit power supply and signal channel through tin-silver bumps 5 , nickel-gold pads 2 , substrate 1 and tin balls 9 .

[0026] As shown in the figure, a manufacturing process of a single-chip package in which the wafer is thinned after the und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com