Patents

Literature

77results about How to "Not easy to warp and deform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium cement fireproof board having excellent water-resistance and preparation thereof

InactiveCN101250062ASmall coefficient of thermal expansionNot easy to warp and deformFiberThermal expansion

The invention reltes to a fireproof board, belonging to the technical field of building material, decorative material, traffic facility, fireproof product, abrasive, abrasive tool and wood furniture. According to the formula of the invention, a preparation method comprises adding 80 portions of magnesium sulfate and 1 portion of tartaric acid into a mixer, adding water of suitable amount, mixing and adjusting the Baume degree of the magnesium sulfate and tartaric acid to 26, adding 150 portions of 85% light magnesium oxide, 12 portions of perlite, 120 portions of heavy calcium carbonate and 22 portions of sawdust, mixing for 5min, emptying, shaping the materials on a fireproof board product line provided with two layers of dual fiber net bags, removing mould and cutting when the product reaches a suitable strength, to obtain the magnesium cement fireproof board with better water resistance. The inventive fireproof board has low thermal expansion factor, non warping deformation, softening factor higher than 0.9, non recurrent halogen, non frost mist, better freezing resistance and non combustibility.

Owner:李锦富

Lightweight plastic-wood composite sheet and preparation method thereof

The invention relates to a lightweight plastic-wood composite sheet and a preparation method thereof. The preparation method comprises the following steps of: firstly stirring PVC particles and tribasic lead sulfate evenly in a stirred tank, and then adding wood flour, LDPE-g-GMA, hollow glass beads, chlorinated polyethylene, ethylene bisstearamide and hard fatty acid butyl ester to the tank, heating up and stirring evenly, cooling and taking out the mixture, and then stirring the mixture evenly with baking soda and citric acid at room temperature, extruding out and molding. The lightweight plastic-wood sheet has the advantages of convenient production and manufacture, high degree of mechanization in the production process, low production cost, low density, light weight, easy installation and maintenance, less use of timber and plastic, turning waste into treasure, being recyclable and not destroyed by insects, no aging and discoloration as well as cracking, no buckling deformation and high impact strength, with the function of adsorbing gas. The lightweight plastic-wood sheet can be applied to a plurality of occasions such as office buildings, hotels and home offices, can be made into products such as photo frames, picture frames, foot lines, and hoisting and fastening boards, and can also be used as suspended beams, pergolas, and the like.

Owner:江苏森诺塑胶科技有限公司

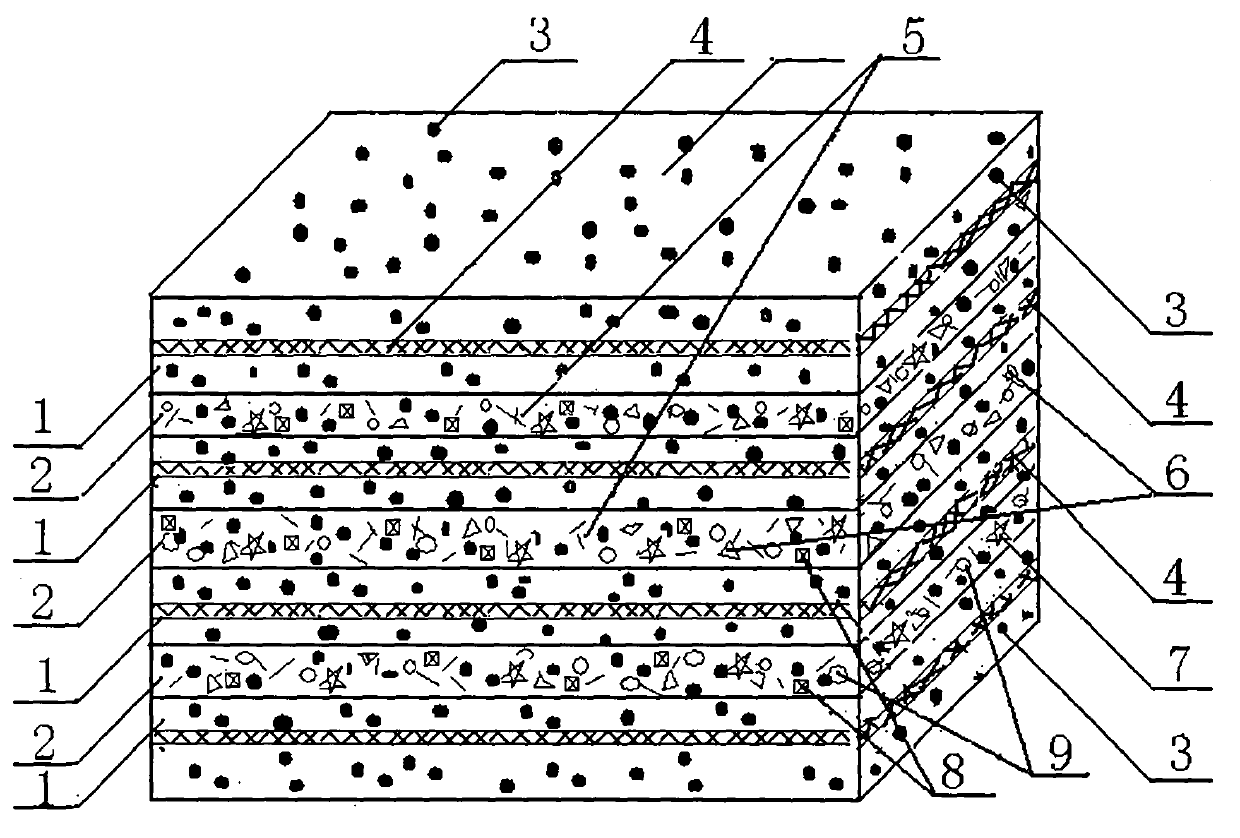

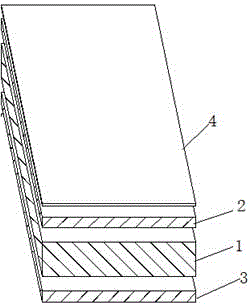

Sandwich material plate and preparation method thereof

InactiveCN102001200ASimple structureReasonable designSynthetic resin layered productsLaminationFiberPlasticizer

The invention discloses a sandwich material plate and a preparation method thereof, relates to a composite material, an environment-friendly material and a preparation method thereof, and is applied to manufacturing door plates, instrument panel frames, trunk liners, rear shelf panels for vehicles and the like of automobiles, airplanes and other means of transportation, building templates, clapboards, seaside floors, industrial floors and the like in the field of buildings, outdoor open tables and chairs, storage tanks, movable shelves and the like in the furniture industry, and pavement plates, flower boxes and the like in municipal landscape engineering. The sandwich material plate consists of 2 to 4 layers of flax fabric reinforced plastic layers and wood plastic composite material layers, wherein 3 to 5 wood plastic composite material layers are pressed between two adjacent flax fabric reinforced plastic layers; the flax fabric reinforced plastic layers are formed by pressing flaxfabrics treated by plastic particles and silane coupling agents; and the wood plastic composite material layers are prepared by drying, mixing and rolling the plastic particles, wood powder, interface solubilizers, calcium carbonate, lubricating agents and plasticizers.

Owner:NANJING FORESTRY UNIV

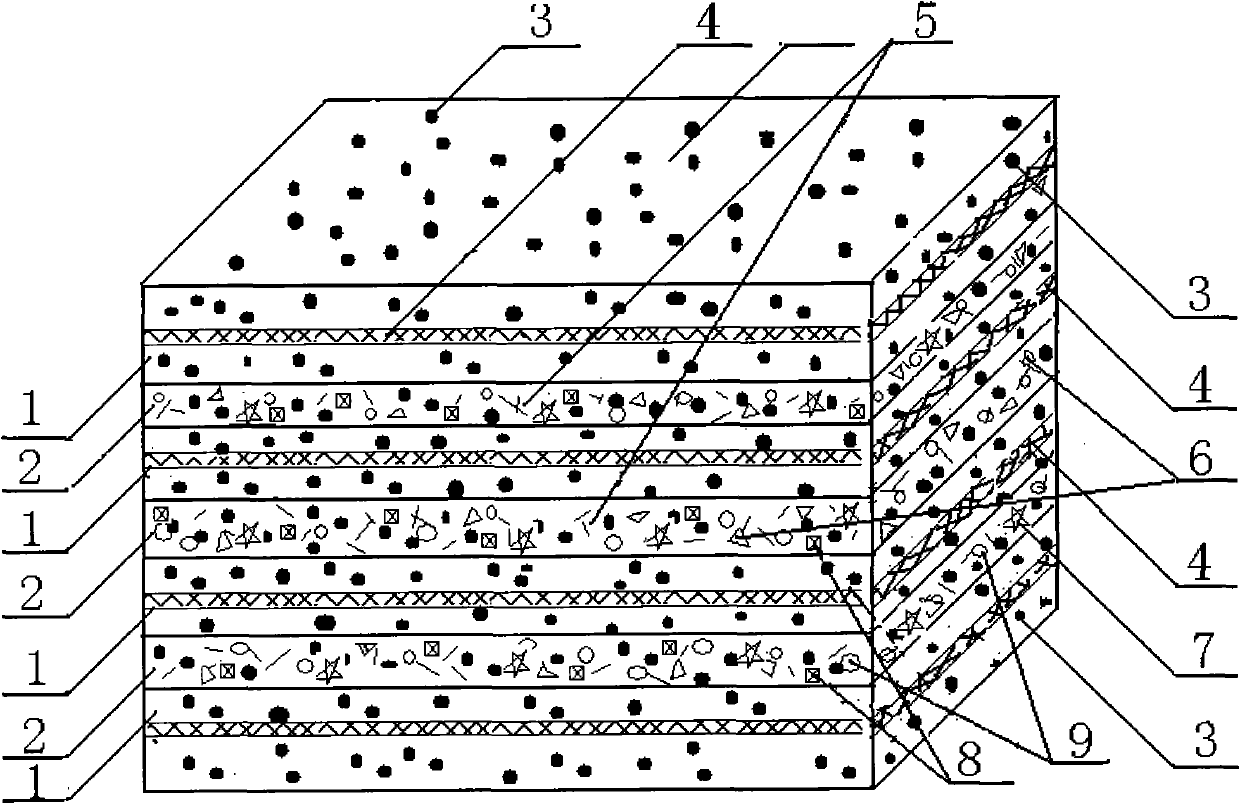

High-structural-strength three-dimensional solid wood composite board and forming method thereof

The invention discloses a high-structural-strength three-dimensional solid wood composite board which comprises a hard base layer and further comprises a first capacity layer group, a second capacity layer group and a surface layer, wherein the first capacity layer group and the second capacity layer group are arranged on the two sides of the base layer, wherein each of the first capacity layer group and the second capacity layer group is provided with at least one flexible capacity layer; the surface layer is arranged on the surface of the first capacity layer; a decoration groove is formed in the surface layer; and the bottom of the decoration groove is embedded into the first capacity layer group. The hard base layer can provide enough mechanical strength for the whole board and support the capacity layers and the surface layer in the board, so as to prevent the board from deforming in the process of making the decoration groove under high pressure. The solid wood composite board provided by the invention has a brand-new structure different from that of a conventional board, has the characteristics of stereoscopic vision, high mechanical strength and long service life, further has the advantages of low formaldehyde release amount and environment friendliness in use and can be widely applied to the fields of home decoration, artwork processing, commercial place decoration and municipal construction.

Owner:SHENZHEN SONGBOYU TIMBERING

Anti-aging wood-plastic composite material board and preparation method thereof

The invention relates to an anti-aging wood-plastic composite material board and a preparation method of the board. The preparation method comprises the steps of: firstly, evenly stirring plastic particles, diisopropylbenzene peroxide, nano-titanium dioxide, antioxidant, antioxidant synergist, light stabilizer, basic magnesium sulfate whisker, stearic acid and oxidized polyethylene; carrying out melt blending and pelleting by adopting an extruder to obtain modified plastic particles; and then stirring the modified plastic particles, wood powder and pigment, and carrying out melt blending and extruding forming by adopting the extruder to obtain the anti-aging wood-plastic composite material board. The anti-aging wood-plastic composite material board is convenient to produce and manufacture, low in cost, less in plastic consumption and wood consumption, environment-friendly and high in modulus and rigidity, does not easily cause buckling deformation, and is free from cracking and damage by worms, resistant in ultraviolet light and thermal oxidizing aging, free from color fading and decomposition and long in service life. The anti-aging wood-plastic composite material board can be used as an open-air table and chair, a stool, a picnic table, a flower box, a guardrail, a sign and the like to be widely applied to occasions such as a park, a court, municipal administration, a dock and the like.

Owner:G&S HUZHOU ENTERPRISES

Preparation method of polyurethane-modified organic silicon resin

ActiveCN106810664AImprove mechanical propertiesHigh mechanical strengthAdditive manufacturing apparatusEpoxySilanes

The invention provides a preparation method of an ultraviolet-curing polyurethane-modified organic silicon resin for 3D printing. The method comprises the following steps: carrying out hydrolysis reaction on epoxy-group-containing alkoxy silane to obtain an epoxy-group-containing hydroxyl-terminated silicone resin, carrying out reaction on the epoxy-group-containing hydroxyl-terminated silicone resin, diisocyanate and polyether dibasic alcohol to obtain a prepolymer, and reacting to obtain an epoxy-group-containing polyurethane-modified organic silicon resin; uniformly mixing the epoxy-group-containing polyurethane-modified organic silicon resin with an ultraviolet photosensitizer, and carrying out vacuum degassing to obtain the ultraviolet-curing polyurethane-modified organic silicon resin for 3D printing. After the polyurethane-modified organic silicon resin is printed by an ultraviolet 3D printer, the obtained product has low buckling deformation tendency, the Shore hardness is 35-65A, the tensile strength is 0.3-2.5 MPa, the water absorptivity is 1-4.5%, and the linear expansion coefficient is 0.4-1.4%.

Owner:HANGZHOU LEYI NEW MATERIAL TECH CO LTD

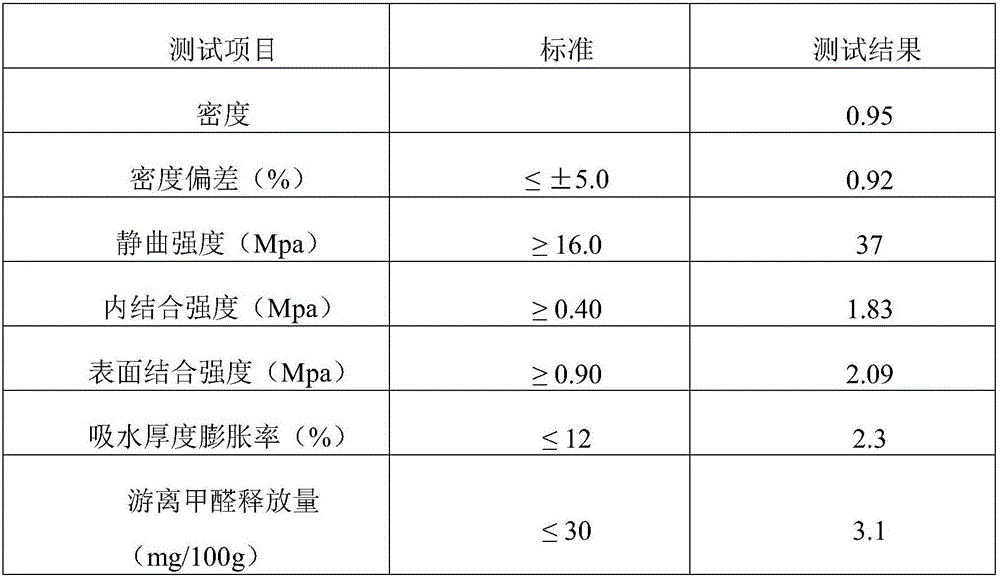

Method for preparing fiber particle board

InactiveCN102350721ANot easy to warp and deformLow costDomestic articlesFlat articlesFiberOptoelectronics

The invention relates to a method for preparing a fiber particle board and aims to provide a method for preparing the fiber particle board which has high wood utilization rate, is difficult to warp or deform, has a flat panel and is easy to realize mechanical production by processes of drying, sizing, paving and the like. In the technical scheme disclosed by the invention, the method for preparing the fiber particle board is characterized by comprising the following steps of: (1) small-diameter wood milling; (2) wafer grinding; (3) pipeline sizing; (4) fiber fine wood wool drying; (5) paving (6) prepressing; (7) hot pressing; and (8) post processing. The method for preparing the fiber particle board is suitable for the industries of furnitures, decoration and the like.

Owner:ZHEJIANG FORESTRY UNIVERSITY

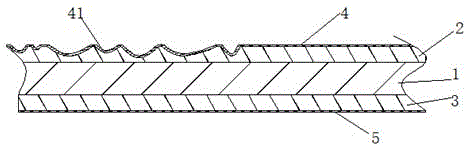

Carbon fiber paper reinforced thermoplastic resin sandwich composite material and preparation method thereof

InactiveCN106313782APromote formationPlay a conductive functionSynthetic resin layered productsLaminationCarbon fibersElectromagnetic shielding

The invention discloses a carbon fiber paper reinforced thermoplastic resin sandwich composite material. The composite material is formed through compounding two resin skin layers and a core layer positioned between the two resin skin layers, every resin skin layer is a thermoplastic resin composite material layer, and the core layer is a carbon fiber paper reinforcement. The invention also discloses a preparation method of the composite material. Clamping of the carbon fiber paper reinforcement between resins is similar to the effect of steel bars in concrete, so the carbon fiber reinforcement effect of carbon fiber papers is guaranteed, the continuity and the load transmission and dispersion property of the fiber reinforcement are guaranteed, the material is isotropic, and the integral performances of the composite material are improved; and the continuously distributed carbon fibers are in favor of forming effective channels among the carbon fibers in order to well show the conductive, antistatic and electromagnetic shielding functions.

Owner:HEFEI GENIUS NEW MATERIALS

Wood-plastic flooring structure convenient and quick to install

InactiveCN106049807AEffective moisture-proofEasy to installFlooring insulationsEngineeringMechanical engineering

Owner:ANHUI GUOFENG WOOD PLASTIC COMPOSITE

Preparing method for environment-friendly composite floor base material

ActiveCN106272844AFill in the gapsIncrease contact areaNon-macromolecular adhesive additivesImpregnation spraying apparatusWood fibrePre treatment

The invention discloses a preparing method for an environment-friendly composite floor base material. The preparing method includes the following steps that firstly, early wood and late wood are selected, and first raw materials and second raw materials are obtained; secondly, the first raw materials and the second raw materials are stacked respectively, and a pretreated first raw material is obtained; thirdly, the pretreated first raw material is put into a cooking tank to be cooked and is then subjected to fiber separation through an overheating mill, and first wood fiber is obtained; fourthly, a pretreated second raw material is treated according to the method in the third step, and second wood fiber is obtained; fifthly, the first wood fiber and the second wood fiber are mixed to obtain mixed fiber, then glue applying and hot pressing are conducted, and a floor base material is obtained; and sixthly, the floor base material is subjected to cooling hardening and tempering and sanding sawing, and the composite floor base material is obtained. The prepared composite floor base material has the beneficial effects of being high in strength, resistant to impacts, good in humidity resistance, environment-friendly and high in popularization value.

Owner:上海亚美利加实业有限公司

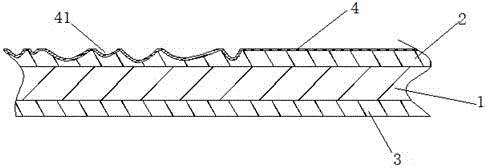

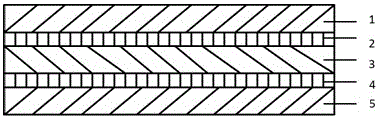

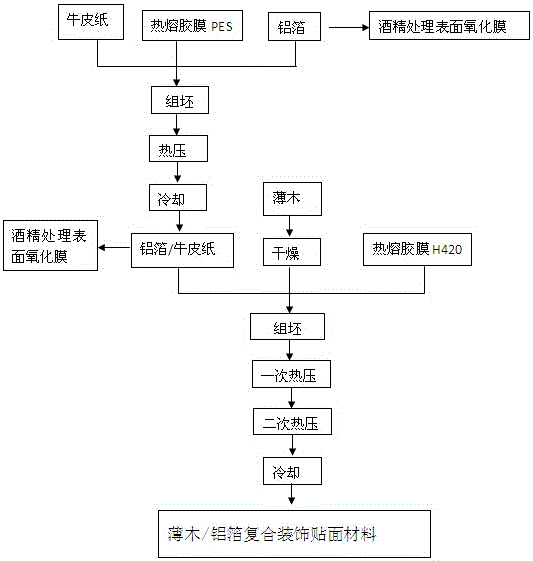

Veneer/aluminum foil composite decorating facing material and manufacturing method thereof

ActiveCN105818490AImprove the decorative effectAbundant raw materialsDomestic upholsteryLaminationPolyesterHot melt

The invention relates to a veneer / aluminum foil composite decorating facing material which structurally comprises kraft paper, a copolyester hot-melt glue film PES, aluminum foil, a holt-melt glue film H420 and veneer. The upper glue applying surface of the aluminum foil is bonded to the kraft paper through the copolyester hot-melt glue film PES, and the lower glue applying surface of the aluminum foil is bonded to the veneer through the holt-melt glue film H420. A manufacturing method of the veneer / aluminum foil composite decorating facing material comprises the following steps that firstly, the upper glue applying surface of the aluminum foil is treated; secondly, the kraft paper, the copolyester hot-melt glue film PES and the aluminum soil are subjected to the assembling, hot pressing and cooling process to form an aluminum foil / kraft paper enhanced material; thirdly, the lower glue applying surface of the aluminum foil is treated; fourthly, the dried veneer, the holt-melt glue film H420 and the aluminum foil / kraft paper enhanced material are subjected to the assembling, hot pressing and cooling process treatment to form the veneer / aluminum foil composite decorating facing material. The veneer / aluminum foil composite decorating facing material has the advantages of being high in decoration performance, environmentally friendly, free of pollution and superior to a natural veneer facing material on physical and mechanical properties such as static bending intensity and bending resistance.

Owner:NANJING FORESTRY UNIV

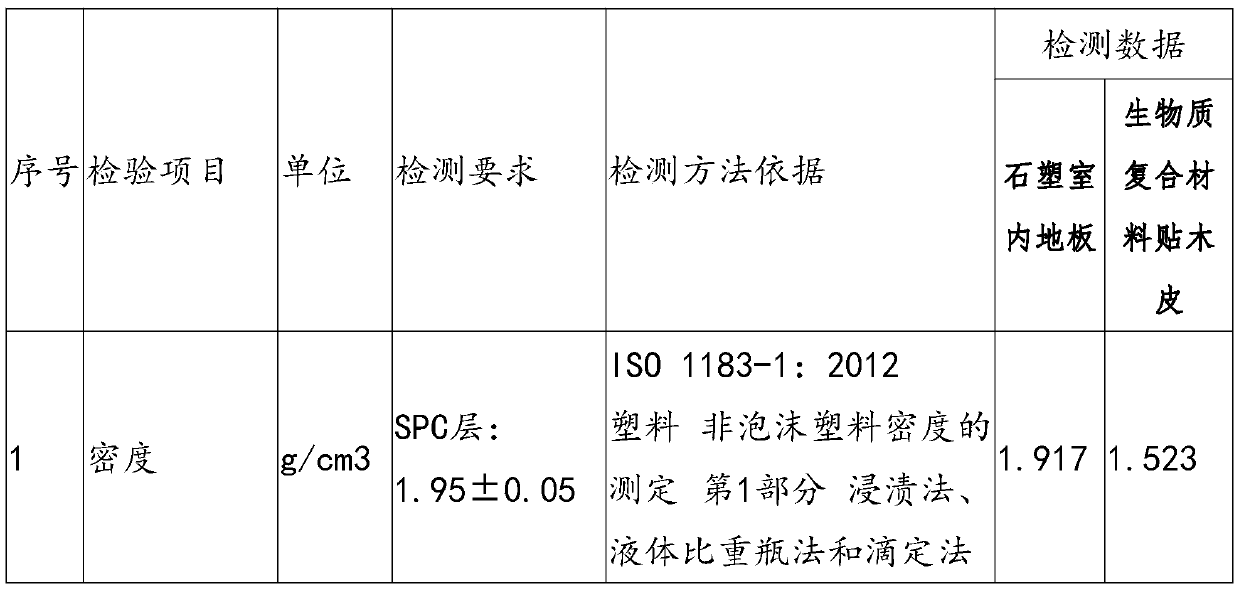

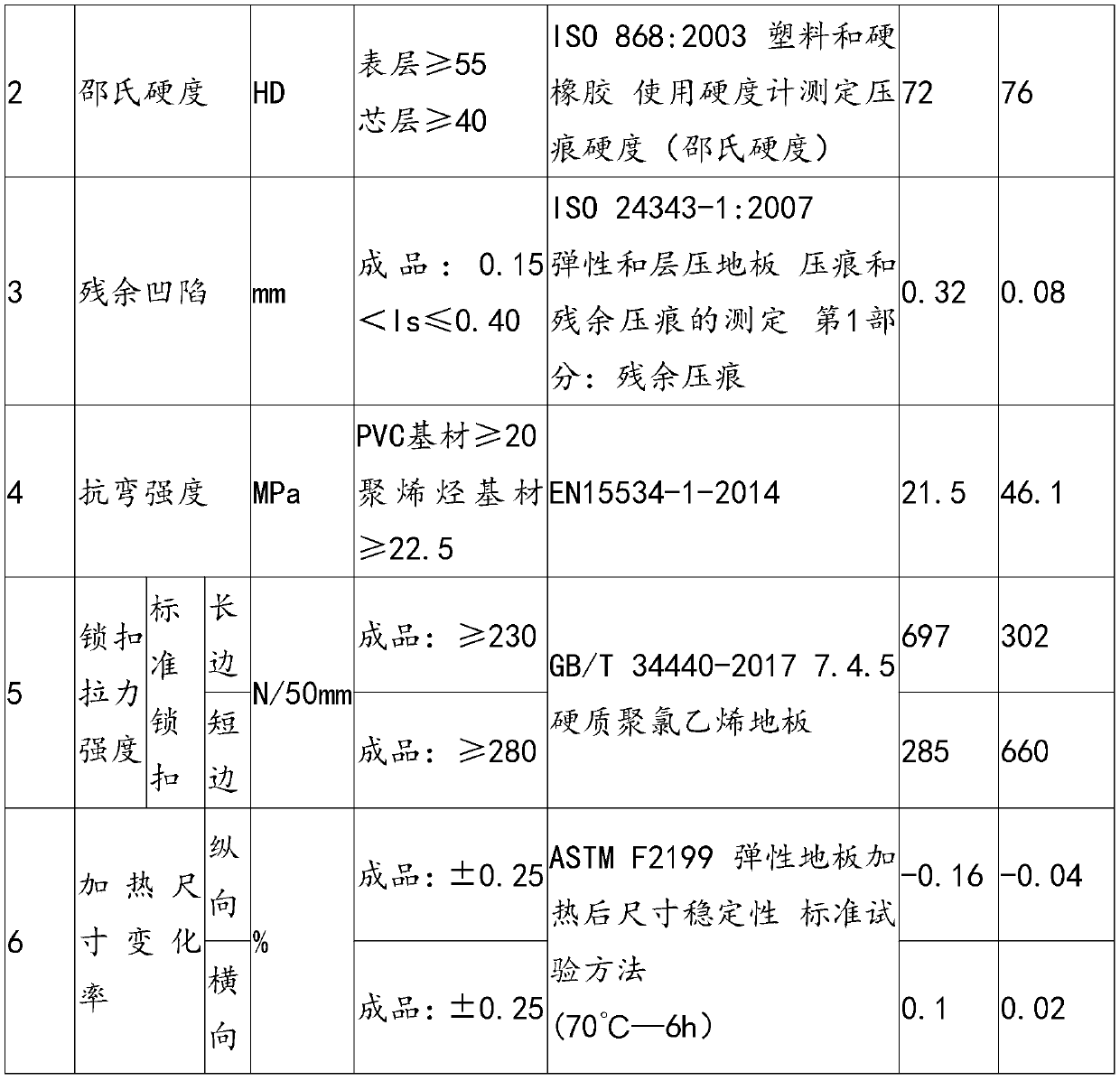

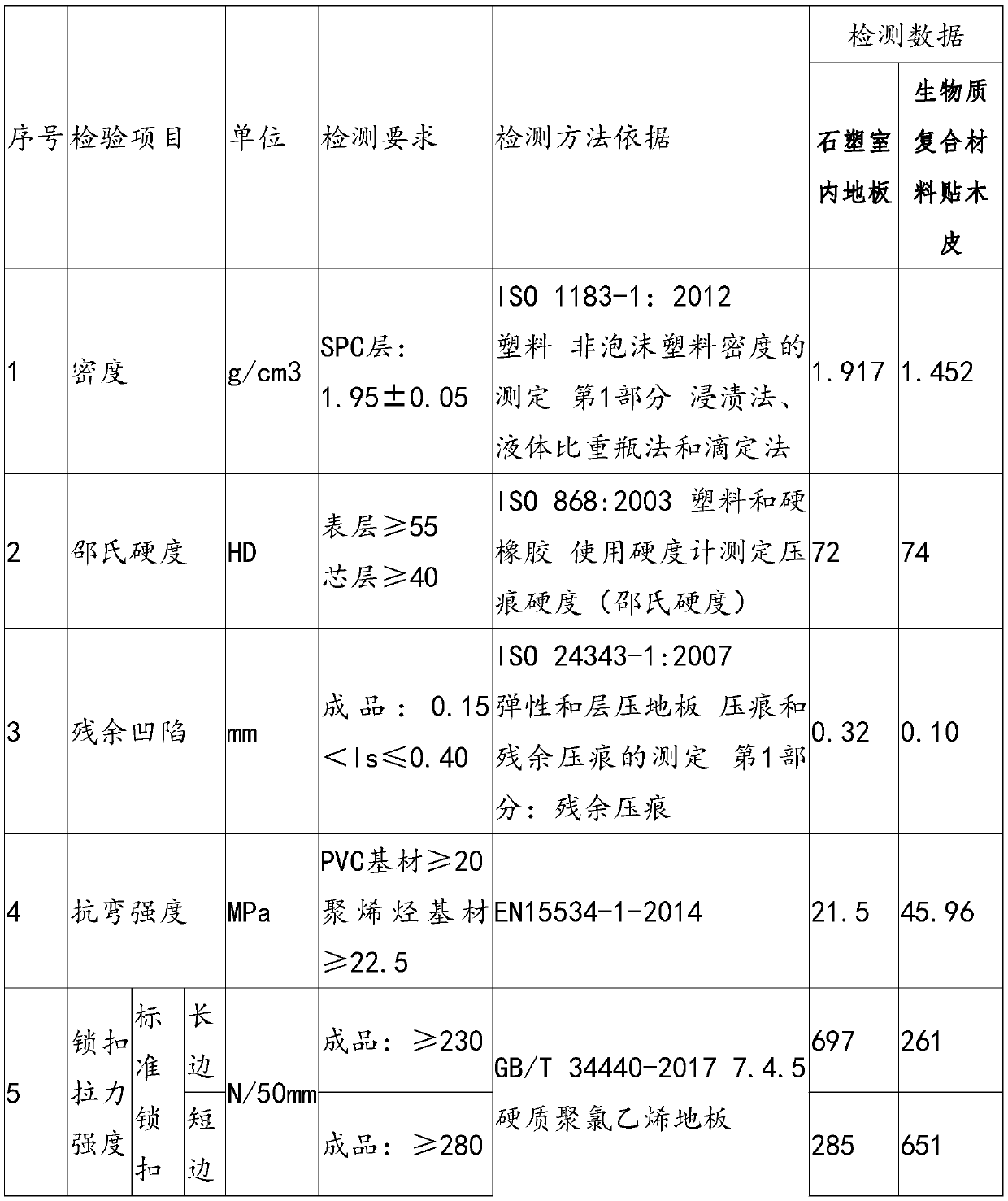

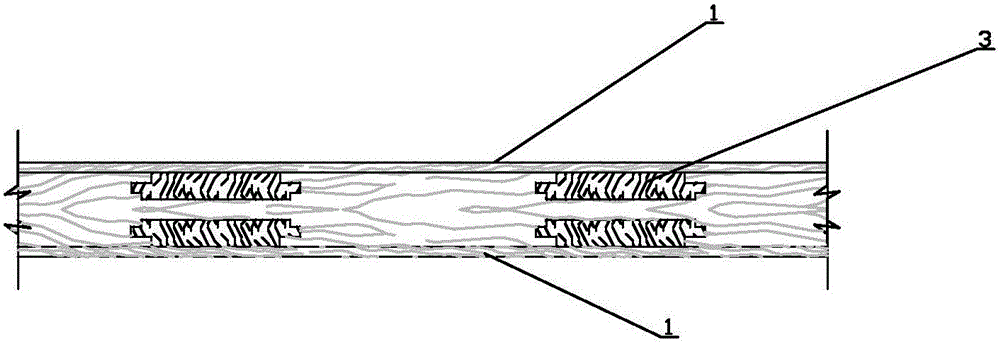

Biomass composite gluing veneer floor technology and composite floor, used base material

InactiveCN110593518AReduce deforestationSave woodSynthetic resin layered productsLaminationSolid woodPolyolefin

The invention provides a biomass composite gluing veneer floor technology and a composite floor, a used base material. The base material is a polyolefin basic level with 1%-60% of biomass. The technology includes the following steps: the veneer is glued onto the polyolefin basic level through polyurethane glue, and press fitting is carried out for 8-15 hours at normal temperature after gluing; aconnecting part is machined at the side of the obtained product; the composite floor is obtained. According to the invention, the polyolefin basic level with biomass is used for replacing solid wood core layer, only veneer is adopted for the surface layer, a plenty of wood is saved, cutting of wood is reduced, and resources are protected; only the 2-layer gluing structure is adopted for the composite floor, and the entire floor is not easy to deform without the balance layer; as the polyolefin basic level has a plenty of biomass close to the property of the solid wood veneer, the linear expansion coefficient is consistent with the veneer, and the entire floor is not easy to cause buckling deformation after gluing, and compared with the other composite floors, the balance layer is not needed.

Owner:ANHUI SENTAI WPC TECH FLOOR CO LTD

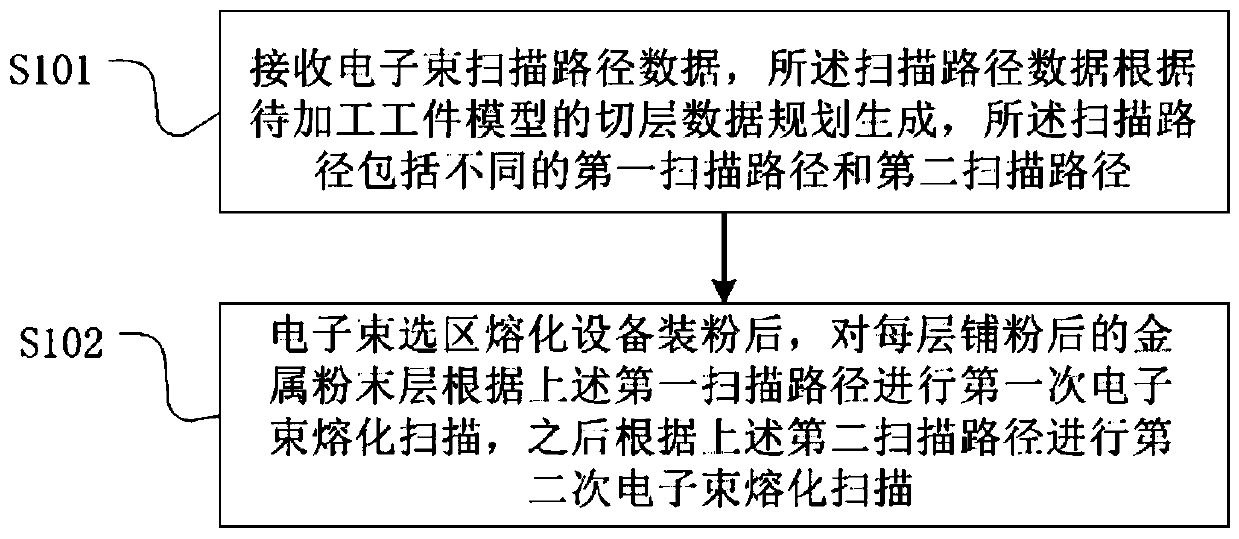

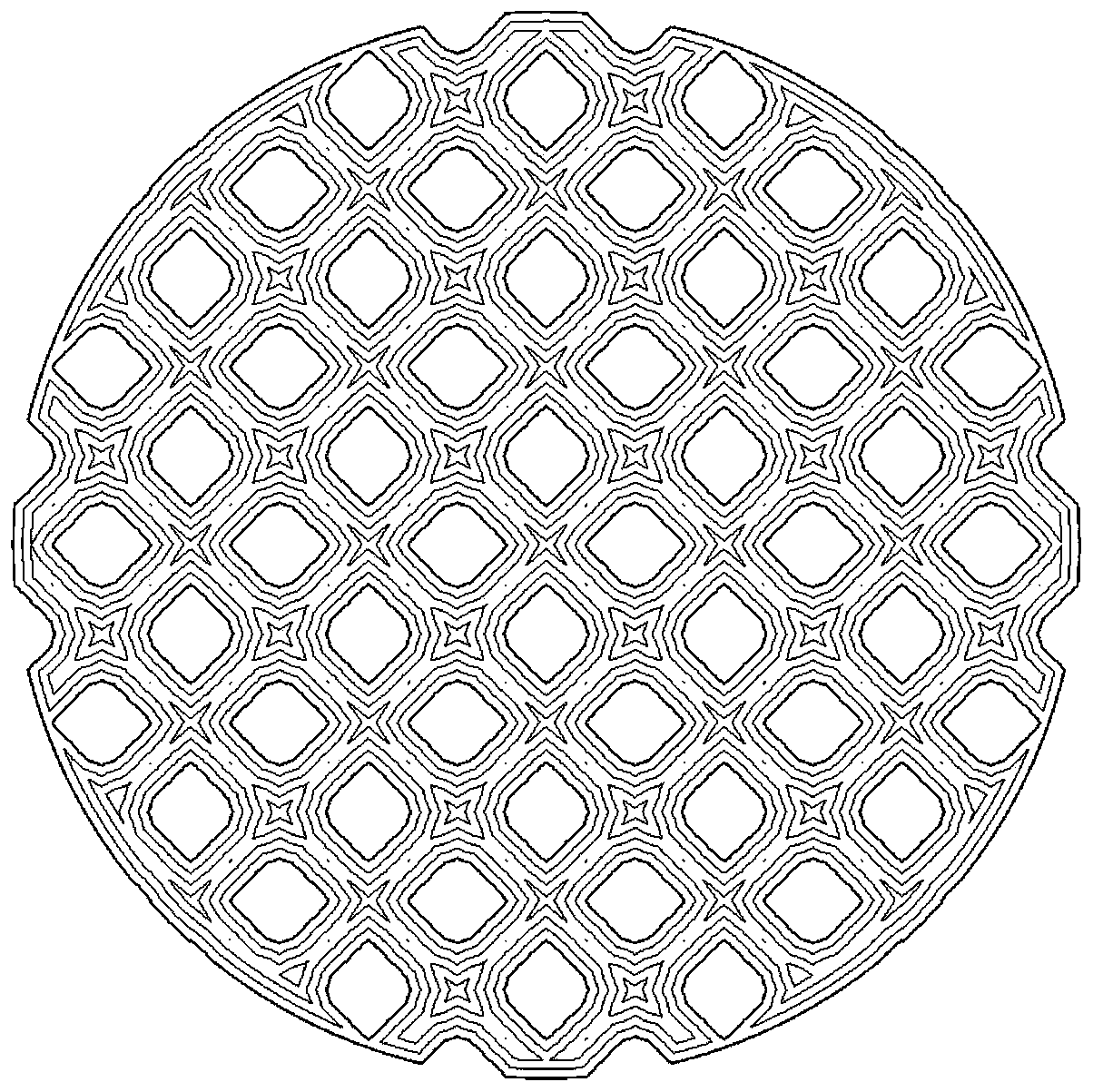

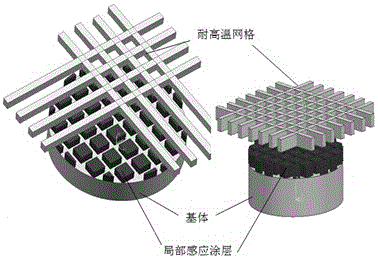

Electron beam scanning method, refractory metal member and electron beam selective melting device

ActiveCN110918990AUniform thermal stress distributionNot easy to warp and deformAdditive manufacturing apparatusIncreasing energy efficiencyOpticsElectron bunches

An embodiment of the invention relates to an electron beam scanning method, a refractory metal member and an electron beam selective melting device. The electron beam scanning method includes the steps of receiving electron beam scanning path data, wherein the scanning path data are generated by planning according to slice data of a to-be-processed workpiece model and comprise a first scanning path and a second scanning path which are different; and after the electron beam selective melting device is filled with powder, conducting first electron beam melting scanning on a metal powder layer obtained powder paving according to the first scanning path, and then conducting second electron beam melting scanning according to the second scanning path. By means of the embodiment, the two different scanning paths are used for conducting electron beam selective melting scanning on the metal powder layer by using the two different scanning paths, on one aspect, thermal stress distribution is more uniform, and part layer warpage and deformation are not prone to being caused; and on the other hand, the metal powder layer is subjected to two times of electron beam selective melting scanning insequence, and therefore the defect of poor fusion of part layers is overcome to a certain extent.

Owner:西安赛隆增材技术股份有限公司

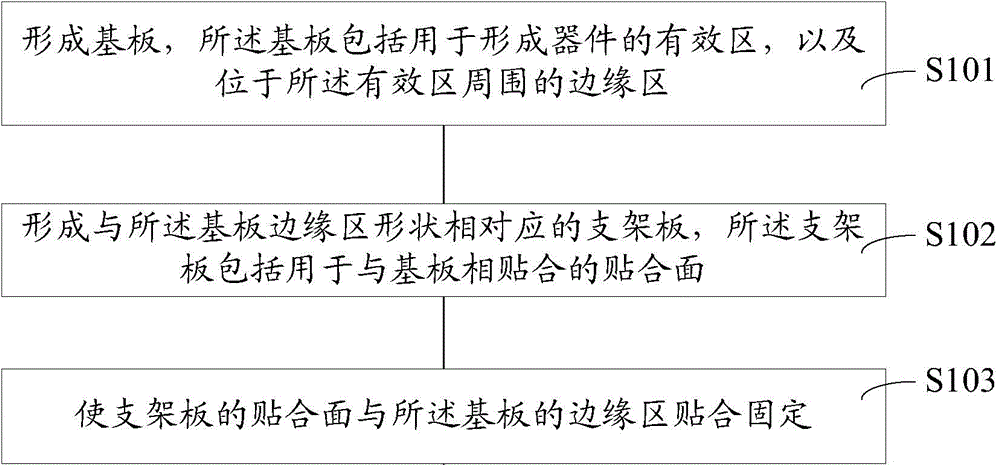

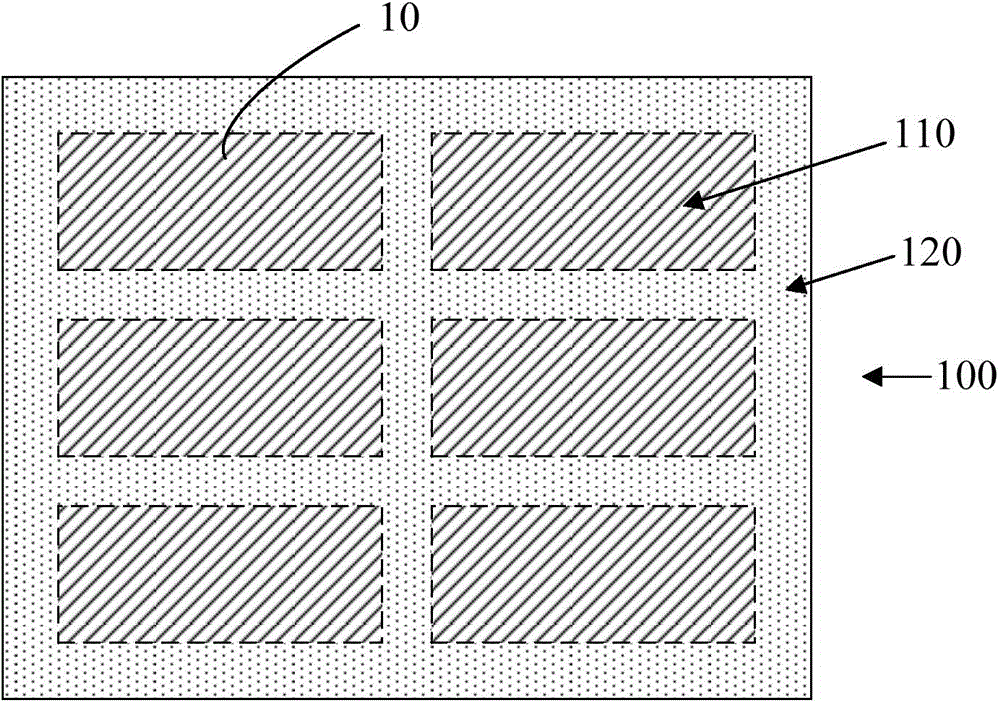

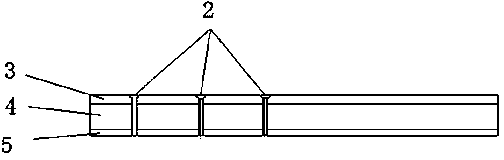

Making method of substrate with support

InactiveCN104411100AAvoid warpingAvoid damageMechanical/acoustic circuit processingCooling/ventilation/heating modificationsState of artEngineering

Owner:NANTONG FUJITSU MICROELECTRONICS

High-temperature rough epoxy resin and preparation method of rapidly formed carbon fiber prepreg thereof

The invention discloses high-temperature rough epoxy resin and a preparation method of a rapidly formed carbon fiber prepreg thereof. The preparation method is characterized by comprising the following steps: preparing a high-temperature rough epoxy resin matrix containing polyurethane soft segments and rigid five-membered rings, synthesizing isocyanate-terminated polyurethane prepolymer from diisocyanate and polyhydric alcohols, and carrying out a ring-opening reaction on the epoxy resin so as to obtain the high-temperature rough epoxy resin matrix; kneading a rapid curing system and a liquidepoxy resin to prepare a curing agent master batch component, and adding the curing agent master batch component into the high-temperature rough epoxy resin to be uniformly mixed so as to obtain a resin system for prepreg; preparing a resin adhesive film according to a hot-melt method, and compounding with carbon fibers or fabrics, thereby obtaining the rapidly formed prepreg. The resin system prepared from the high-temperature rough epoxy resin can realize curing within 5 minutes at 150 DEG C, the glass-transition temperature is high, and the prepared prepreg is excellent in manufacturability, excellent in breaking tenacity, applicable to rapid forming of a composite material, easy for high-temperature demolding and difficult in buckling deformation and can be applied to the field of rapid forming of the carbon fiber composite material on a large scale.

Owner:BEIJING UNIV OF CHEM TECH

Tempered glass and preparation method thereof

InactiveCN107663025AImprove toughnessHigh strengthGlass tempering apparatusWater basedShock resistance

The invention discloses tempered glass which comprises the following raw materials: water-base resin, kaolin, barium sulfate, potassium pyrophosphate, water glass, strontium carbonate, silicon dioxide, nano-silver, molybdenum oxide, calcium oxide, magnesium carbonate, zirconium dioxide, yttrium oxide, ferric oxide, plant starch, copper powder, kieselguhr, manganese oxide, silicon nitride, potassium feldspar, glass fiber, zinc sulfate, medical stone, sodium borate and aluminum powder. The toughness and strength of the tempered glass disclosed by the invention are greatly promoted, the temperedglass cannot be cracked and damaged easily, the use of the glass is safer and more convenient, the tempered glass cannot warp and deform easily and the shock resistance is higher.

Owner:滕州市丰华玻璃有限公司

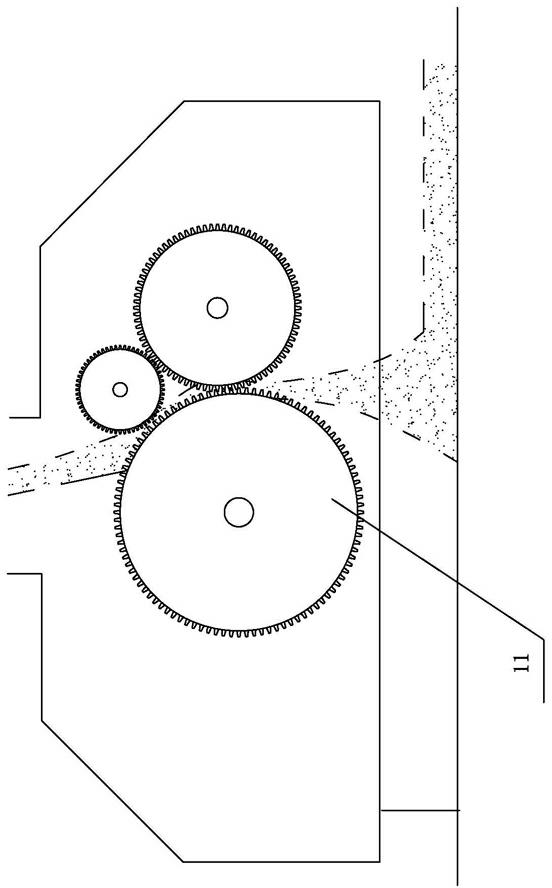

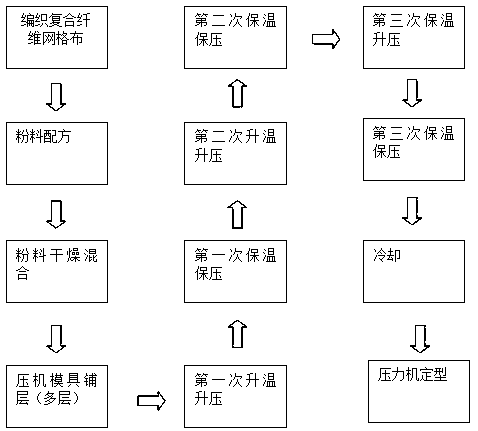

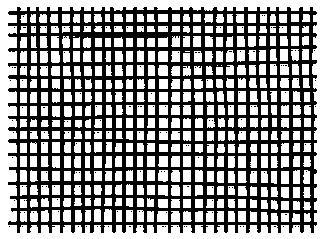

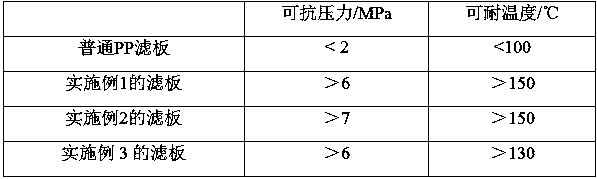

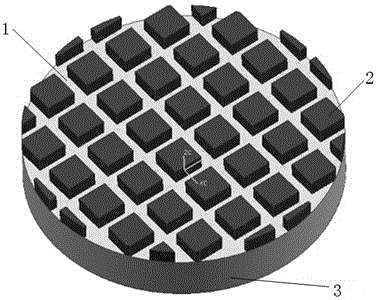

Hybrid fiber grid fabric reinforced polypropylene compound filtering plate and preparation method thereof

ActiveCN109224630AImprove high temperature and high pressure performanceImprove thermal stabilityFiltration separationPolypropyleneInternal stress

The invention provides a hybrid fiber grid fabric reinforced polypropylene compound filtering plate and a preparation method thereof. A complex fiber reinforced polypropylene, which is formed by weaving inorganic fiber with organic fiber, is taken as a main material of the filtering plate. The filtering plate is prepared from the following components in parts by weight in the manner of die-cast formation: polypropylene resin, inorganic mineral powder, continuous inorganic fiber, continuous organic fiber, coupling agent, antioxidant and lubricating oil. According to the preparation method provided by the invention, due to the compound components and structure characteristics of gridding cloth, the whole structure and mechanical properties of the filtering plate are isotropic. A molding method of gradually increasing pressure and temperature and maintaining pressure and temperature is adopted and pressing molding under room temperature is performed, so that the internal stress of the filtering plate is relieved and the compactness, density and size of the filtering plate are stable and uniform.

Owner:ZHONGYUAN ENGINEERING COLLEGE

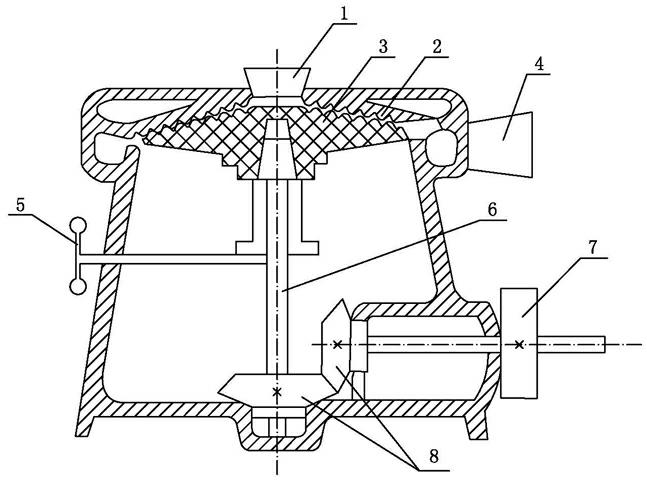

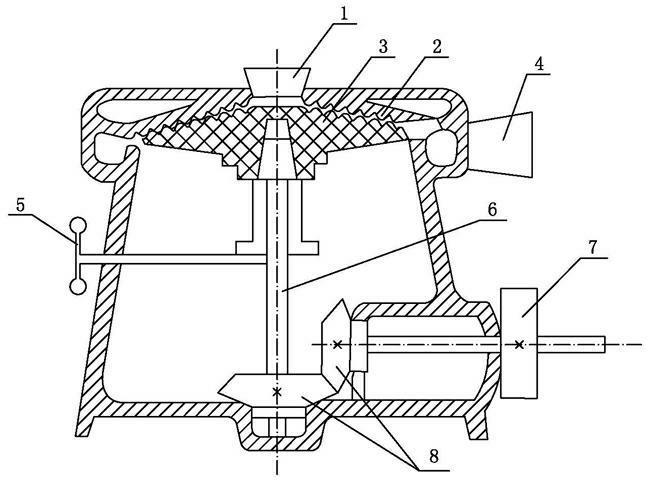

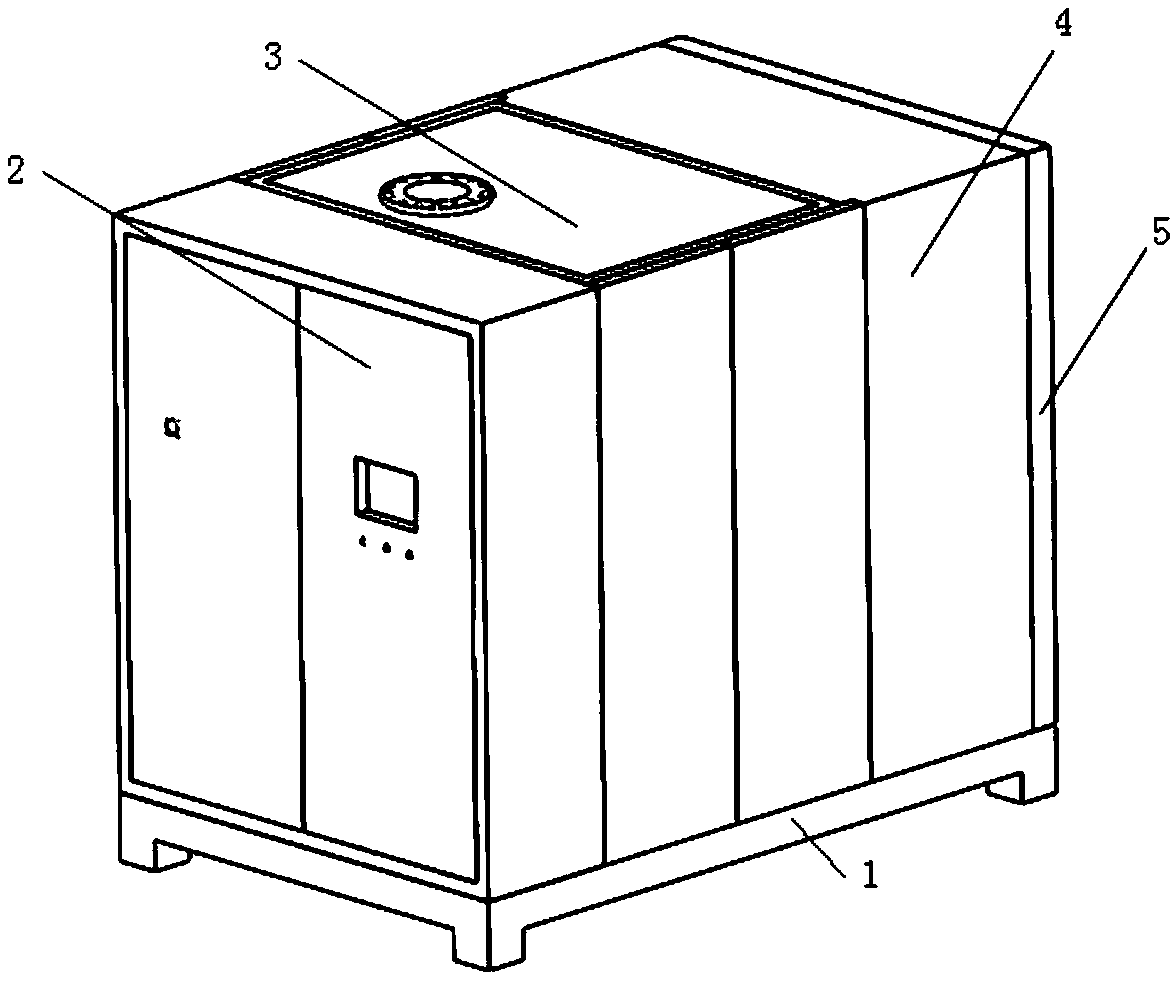

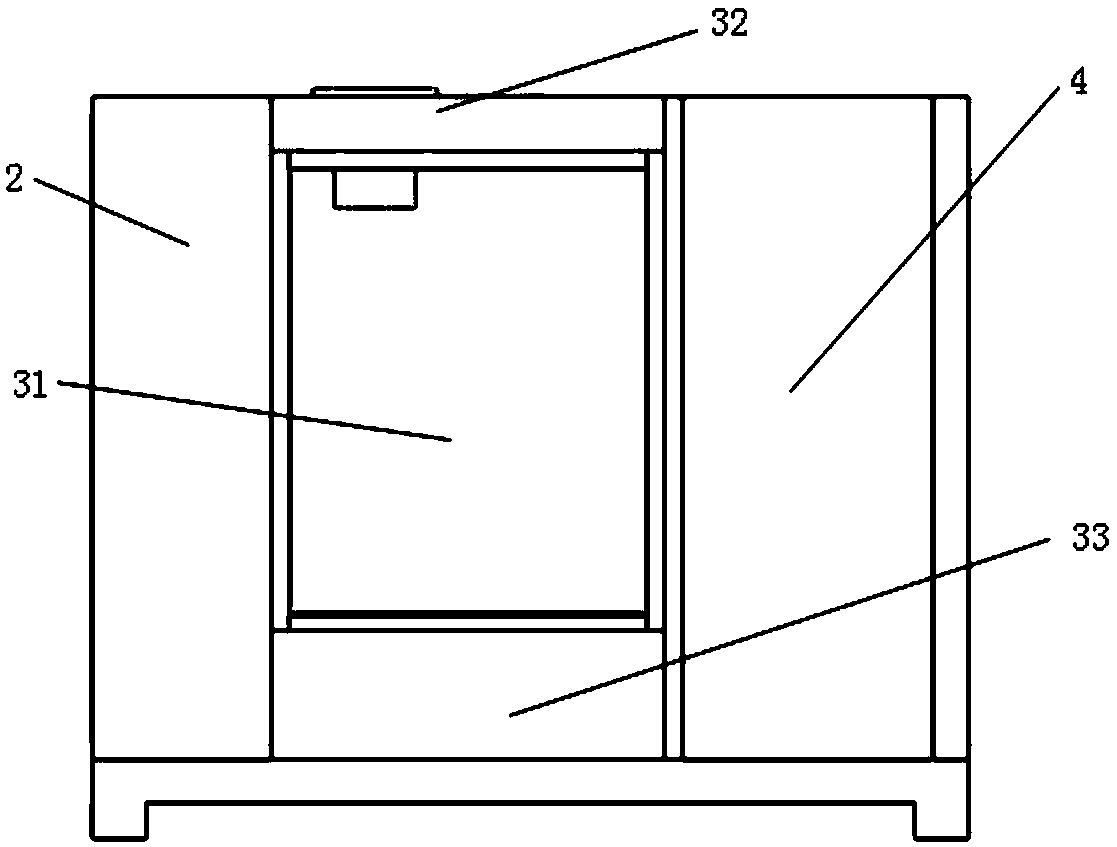

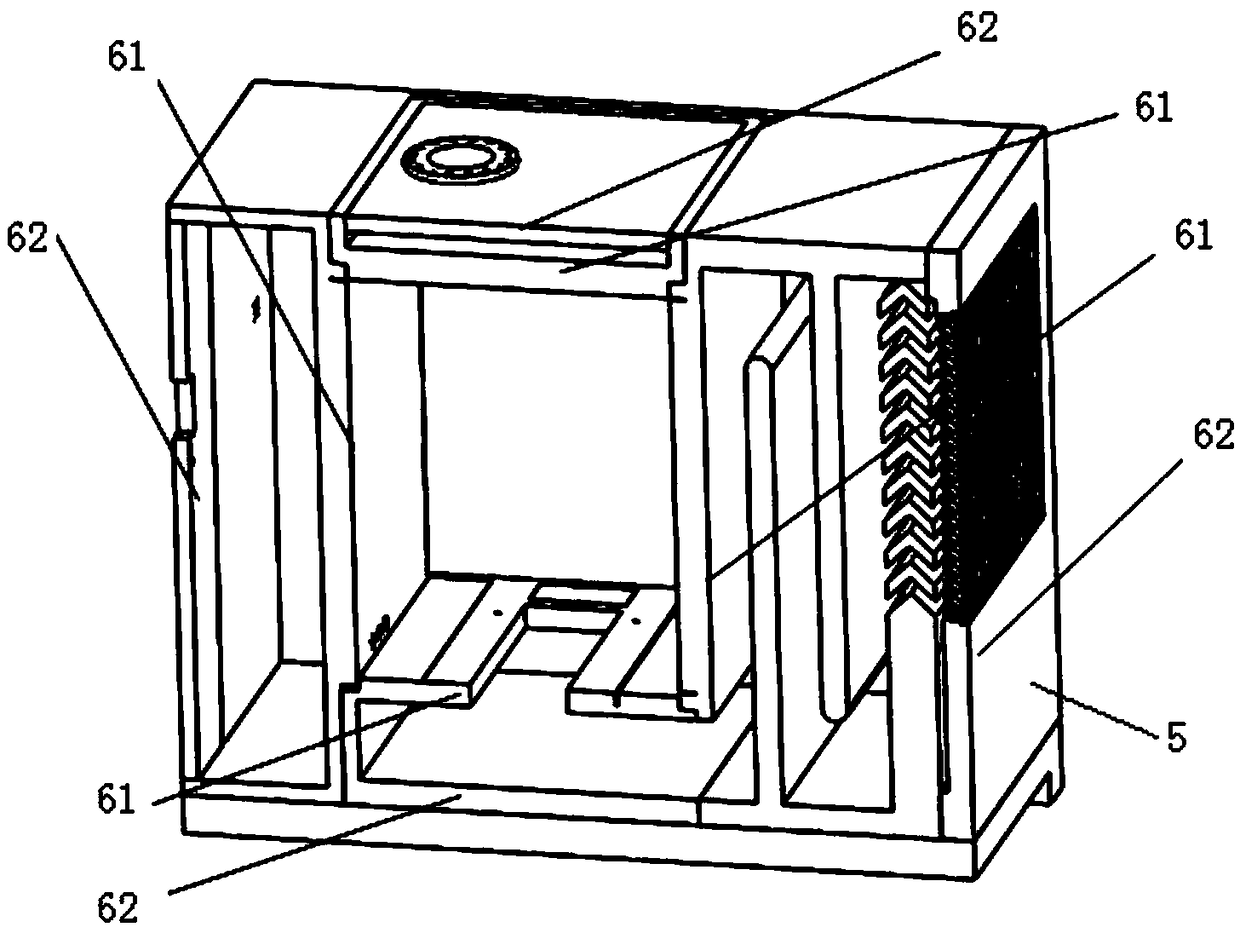

Modular box-type assembly-structure low-noise cabinet

PendingCN109026851ASimple and elegant appearanceOptimize layoutPump componentsPump installationsLow noiseEngineering

The invention discloses a modular box-type assembly-structure low-noise cabinet. The cabinet comprises a chassis, an electric control cabinet, a host cabinet, a main silencing cabinet and a filteringcabinet, wherein the electric control cabinet, the host cabinet, the main silencing cabinet and the filtering cabinet are sequentially arranged on the chassis from left to right. The host cabinet is of a rectangular structure and comprises a host cabinet body, a main top cabinet and a main bottom cabinet, the main top cabinet and the main bottom cabinet are fixed at the upper end and the lower endof the host cabinet body respectively, and an inner cavity of the host cabinet body correspondingly communicates with an inner cavity of the main top cabinet and an inner cavity of the main bottom cabinet. Sound insulation board units are arranged in the directions of the six side faces of the host cabinet body respectively, and each sound insulation board unit comprises an inner layer sound insulation board and an outer layer sound insulation board. The front and back surfaces of each inner layer sound insulation board are each provided with silencing cotton, and silencing cotton is attachedto the inner side of each outer layer sound insulation board. During assembly, the working space is easy to arrange, the operation is convenient, warping deformation is not likely to happen, the structural strength is good, and the sealing surface can be easily ensured to be flat. Noise of a host needs to penetrate through three layers of sound insulation cotton when spreading in any direction, so that the sound insulation effect is good.

Owner:NANJING CIGU TECH CORP LTD

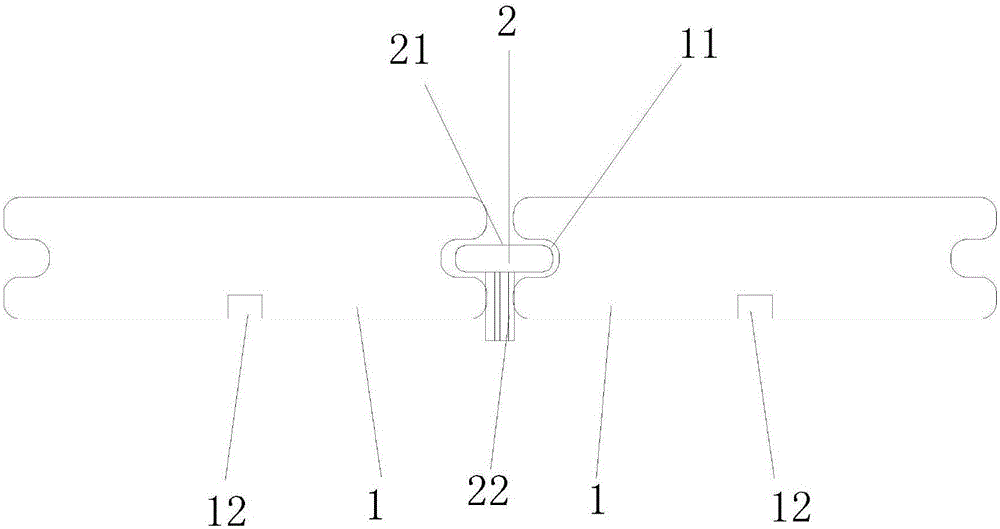

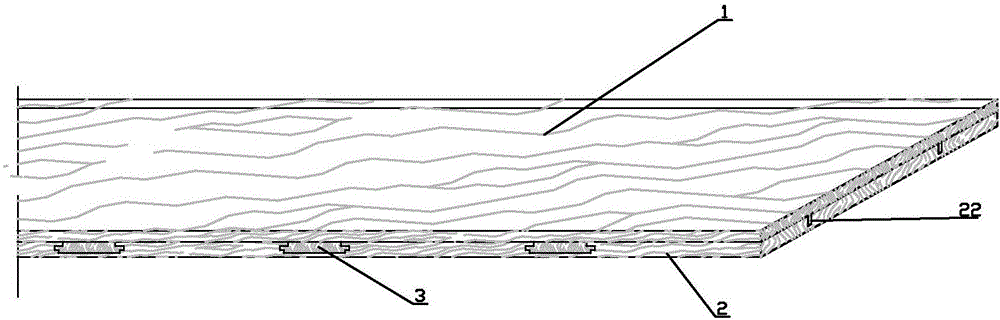

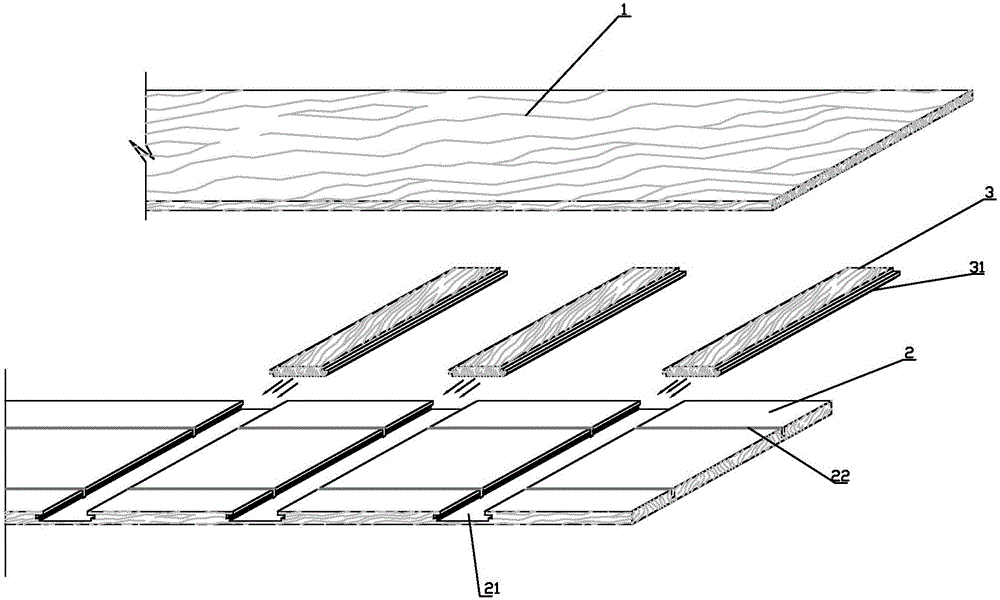

Anti-deformation solid wood composite board and processing method thereof

InactiveCN106193523APrevent telescopic deformationNot easy to warp and deformWood veneer joiningConstructions elementsTongue and grooveSolid wood

The invention relates to an anti-deformation solid wood composite board and a processing method thereof. The solid wood composite board comprises a solid wood base layer and a surface layer. The solid wood composite board is characterized in that a plurality of transverse tenons are embedded into the solid wood base layer at intervals in the width direction of the solid wood base layer, balance tenon edges protruding outwards are arranged on the two sides of each tenon, a plurality of tenon grooves are formed in the solid wood base layer correspondingly, a certain distance is reserved between the inner bottom face of each tenon groove and the lower surface of the solid wood base layer, and the upper surface of each transverse tenon and the upper surface of the solid wood base layer are on the same plane. According to the anti-deformation solid wood composite board and the processing method thereof, in the using process, fibers in the solid wood base layer is cut off through the transverse tenons, therefore the solid wood base layer is prevented from contracting and deforming due to the changes of external environment, transverse and longitudinal tension is balanced through the transverse tenons, and therefore the solid wood base layer is not liable to crimp and deform. Because a processing method that grooving and keel adding are conducted on the upper face and the lower face of the same solid wood plate blank and the solid wood plate blank is sawed in half into two anti-deformation solid wood composite boards is adopted, the anti-deformability of the solid wood composite board is further ensured.

Owner:孙建新

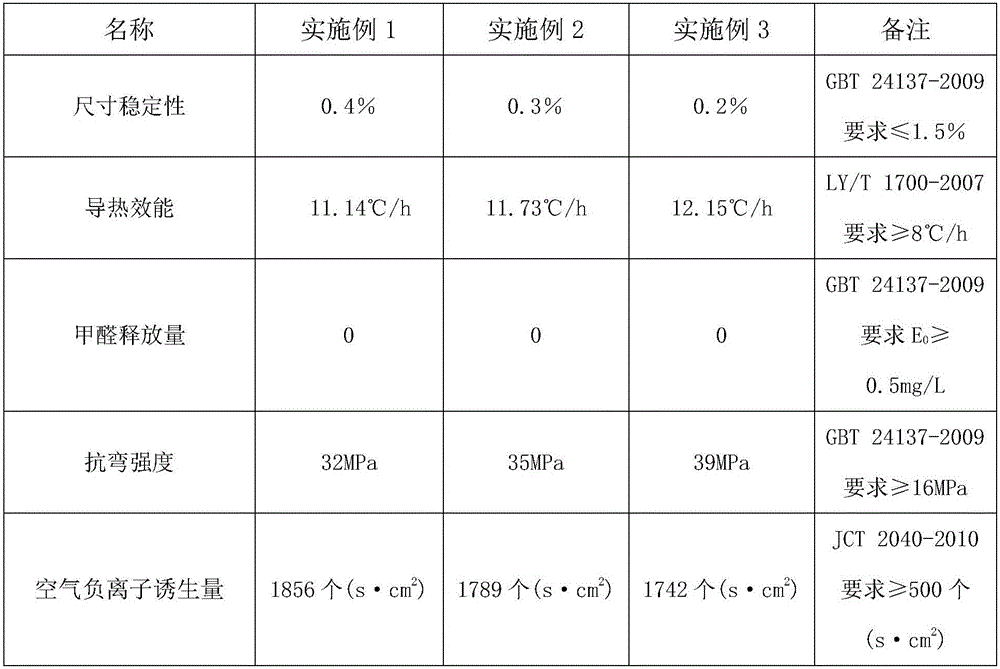

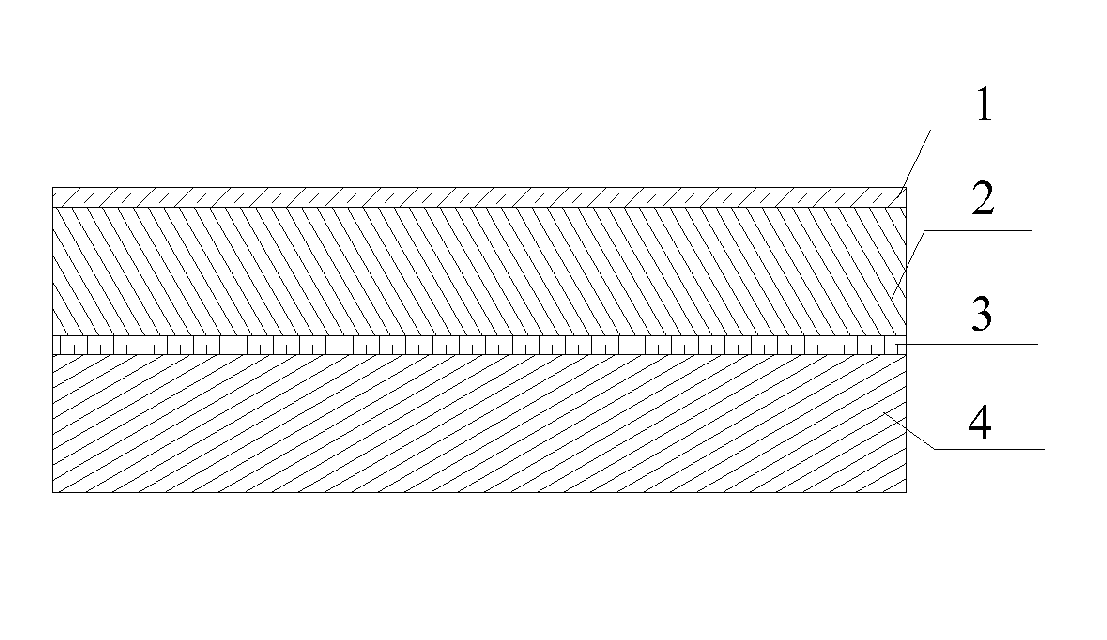

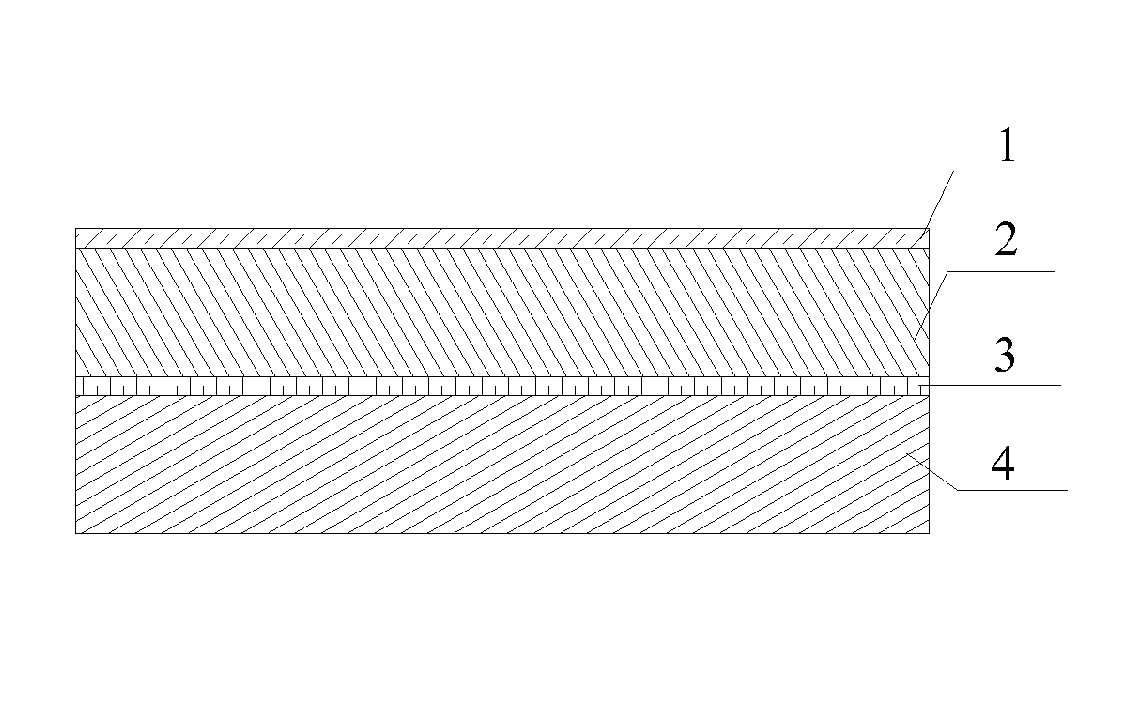

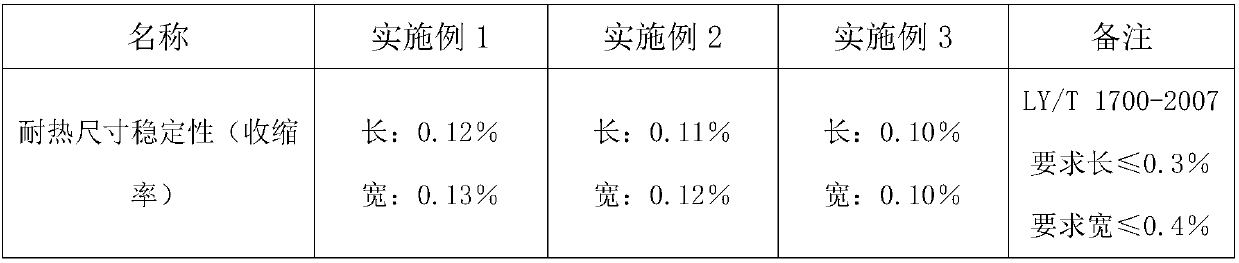

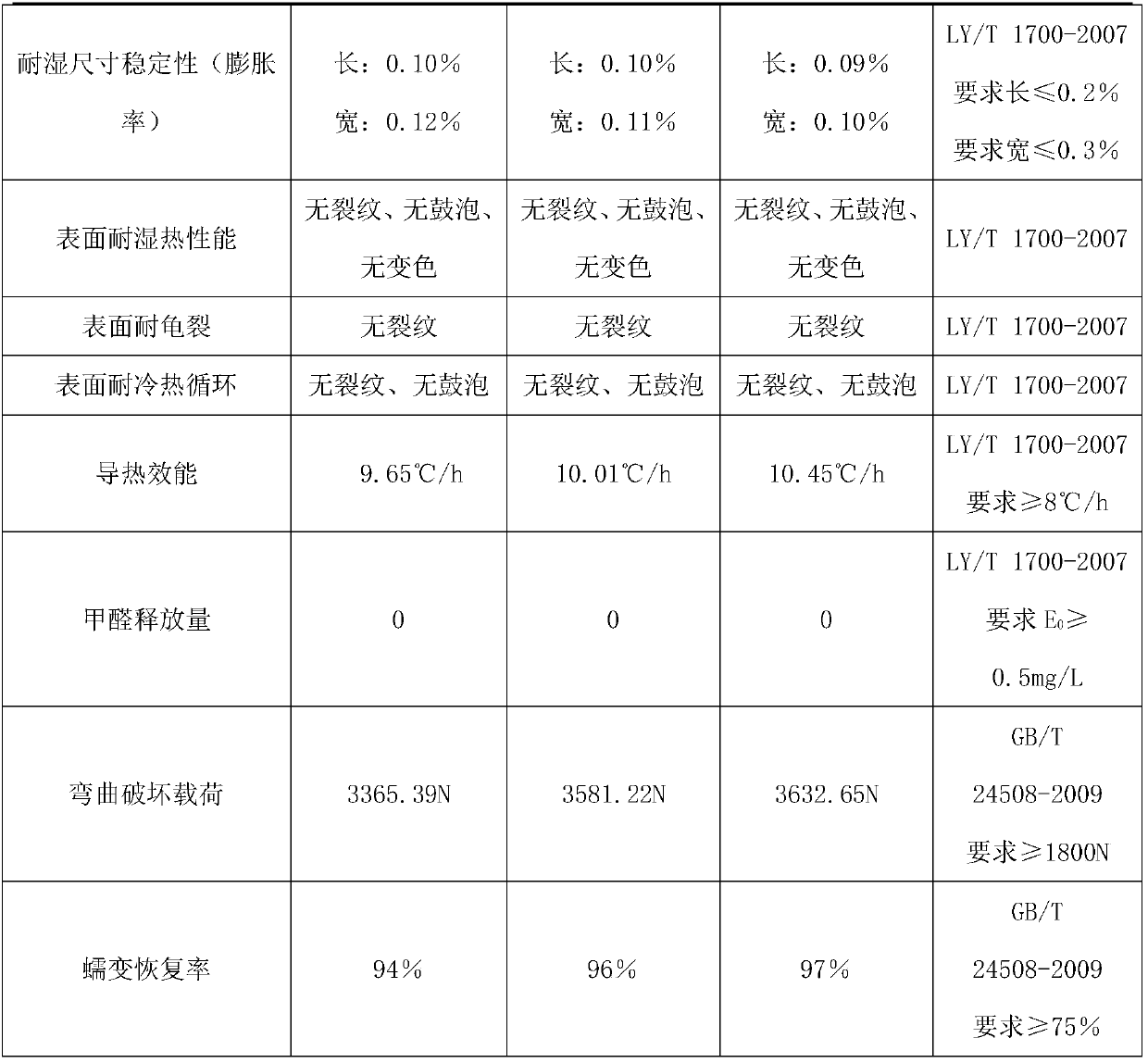

Facing bamboo plastic heat conduction wallboard with negative ions and processing method thereof

ActiveCN105754361AImprove thermal efficiencyHigh heat resistance and dimensional stabilityThermoplasticGlass fiber

The invention discloses a facing bamboo plastic heat conduction wallboard with negative ions and a processing method thereof. The facing bamboo plastic heat conduction wallboard is characterized by comprising a bamboo plastic wallboard substrate layer, a glass fiber cloth layer, and a reconsolidated bamboo veneer layer. The bamboo plastic wallboard substrate layer comprises the following components by mass: 20-25% of bamboo powder, 30-35% of a PVC and polyether block amide blend, 8-10% of nanoscale bamboo charcoal powder, 2-4% of a lubricant, 1-3% of a foaming agent, 2-3% of a coupling agent, and the balance germanite powder. The wallboard provided by the invention adopts bamboo processing waste, germanite powder, thermoplastic plastics (PVC and polyether block amide blend) as the main raw materials, and the facing bamboo plastic heat conduction wallboard with negative ions is manufactured by crushing, pretreatment, high-speed mixing, extrusion, curing, gluing, assembling compounding, cold pressing, sanding, painting, slotting and other processes. The wallboard has natural texture, high negative ions and heat conduction efficiency, and low thermal expansion coefficient, is not easy to warp, can be widely used in the field of functional wallboards, and has good market prospects.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Composite optical reflective film and preparation method therefor

ActiveUS9732233B2Reduce reflectivityEasy to transformMirrorsOptical filtersOptical reflectionAdhesive

The present invention provides a composite optical reflective film for a backlight source system and a preparation method therefor. The composite optical reflective film comprises a transparent diaphragm and a reflective diaphragm, wherein the reflective diaphragm is spliced to the transparent diaphragm through an adhesive, and the other face of the reflective diaphragm is coated with a reflective coating. The composite optical reflective film has good dimension stability, is not easy to warp and deform, has a higher reflectivity, has a simple preparation process and is easy to operate.

Owner:NINGBO CHANGYANG TECH

Method for preparing composite coating through electromagnetic induction heating

InactiveCN105821368AImprove adhesionNot easy to warp and deformMolten spray coatingThermal sprayingElectromagnetic induction

The invention discloses a method for preparing a composite coating through electromagnetic induction heating, and belongs to the technical field of electromagnetic induction heating. The method comprises specific steps that a base body surface is subject to roughening and cleaning treatment, a to-be-sprayed surface of a base body is covered with or pasted with a hollow-out screen, thermal spraying is carried out, and after the screen is removed, an electromagnetic induction heating composite coating evenly divided by grooves is obtained; or the base body surface is directly subject to thermal spraying, then, mechanical cutting is carried out, and the electromagnetic induction heating composite coating which is evenly divided by the grooves is obtained; the thermal spraying coating is separated into a plurality of electromagnetic induction heat source coating blocks, the base body is more evenly heated, and stress is more dispersed; and after dividing is carried out, even if the part of a heating layer falls off or is damaged, continuous using of other parts of coating and a whole product is not affected, and a repairing technology is simple.

Owner:KUNMING UNIV OF SCI & TECH

Method for producing stair tread

InactiveCN109016032ANot easy to warp and deformNot easy to hangRadiation/waves wood treatmentWood treatment detailsAlcoholCarbonization

The invention discloses a method for producing a stair tread. The method comprises the following steps that a, a board made of beech materials is cut into a panel for making the stair tread, and a product A is obtained; b, planning of the product A is carried out, and a product B is obtained; c, two aluminum plates are placed on the front and back two sides of the product B to achieve tight clamping, and a product C is obtained; d, the product C is placed into a kiln to be carbonized, the carbonization temperature is 180-210 DEG C, the carbonization time is 1-2 h, ultrasonic treatment of the product C is carried out while carbonization is carried out, the frequency of ultrasonic waves is 40-45 KHz, and a product D is obtained; e, the aluminum plates on the product D are removed, then the product D is placed into a resurgence chamber, the moisture content of the product D rises to 7%-9%, and a product E is obtained; f, the product E is subjected to paint treatment, and a product F is obtained; g, the product F is covered with tea to be then put into the kiln for heat preservation, and a product G is obtained; h, phenol is used for fumigation of the product G, and a product H is obtained; and i, ethyl alcohol is used for scrubbing the surface of the product H, the surface of the product H is made clean and tidy, and a finished product is obtained. The stair tread manufactured through the method has the advantages of being not prone to generating noise and being small in paint odor.

Owner:湖州南浔登越家居有限公司

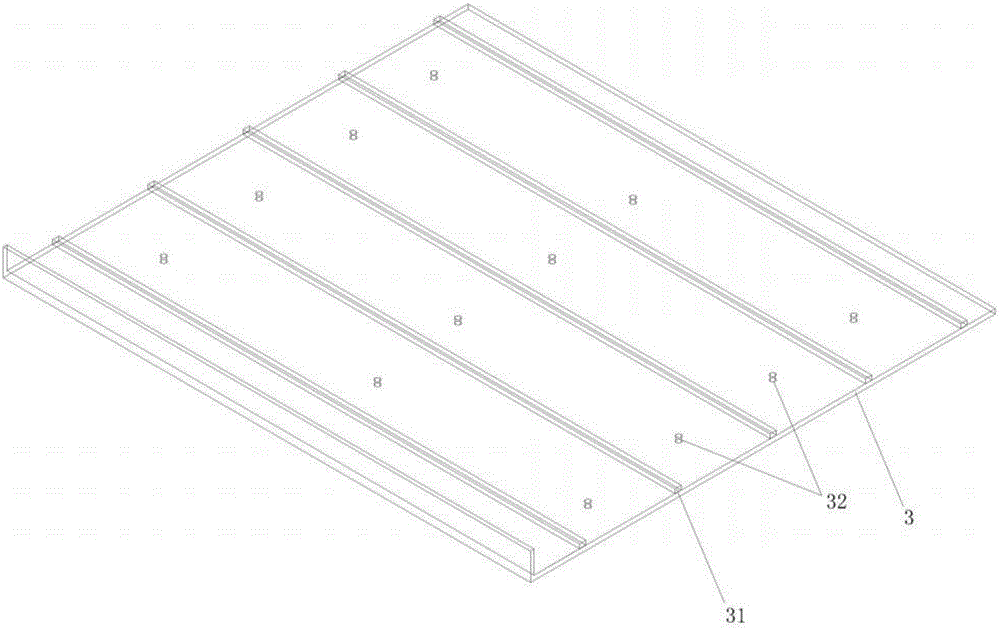

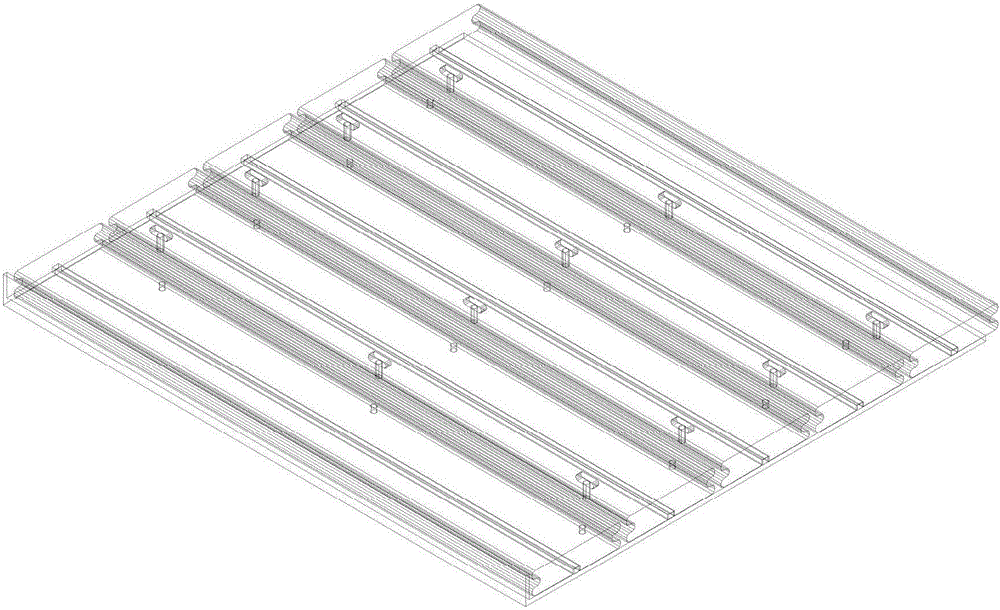

Nail embedded floor heating floor

InactiveCN104264943AFast conductionAvoid warpingLighting and heating apparatusElectric heating systemSolid woodSurface layer

The invention discloses a nail embedded floor heating floor. The nail embedded floor heating floor comprises a body and a metal heat conduction nail; the metal heat conduction nail is embedded in the body and penetrates the body; the body comprises a floor surface layer, a floor core layer and a floor substrate from top to bottom in turn; the floor surface layer, the floor core layer and the floor substrate can be formed by solid wood or plastic materials. The heat of a floor lower layer can be rapidly transmitted above the floor through the metal heat conduction nail and accordingly the temperature of the upper side and the lower side of the solid wood floor can be rapidly balanced and accordingly the floor deformation and warp caused by the too large upper and lower temperature difference of the floor is avoided. The nail embedded floor heating floor can be combined with the traditional manufacturing process of solid wood floors, the heat conduction is good, the warp and the deformation are not easy to cause, the cleaning is easy, and the attractive and environment-friendly effect is achieved.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

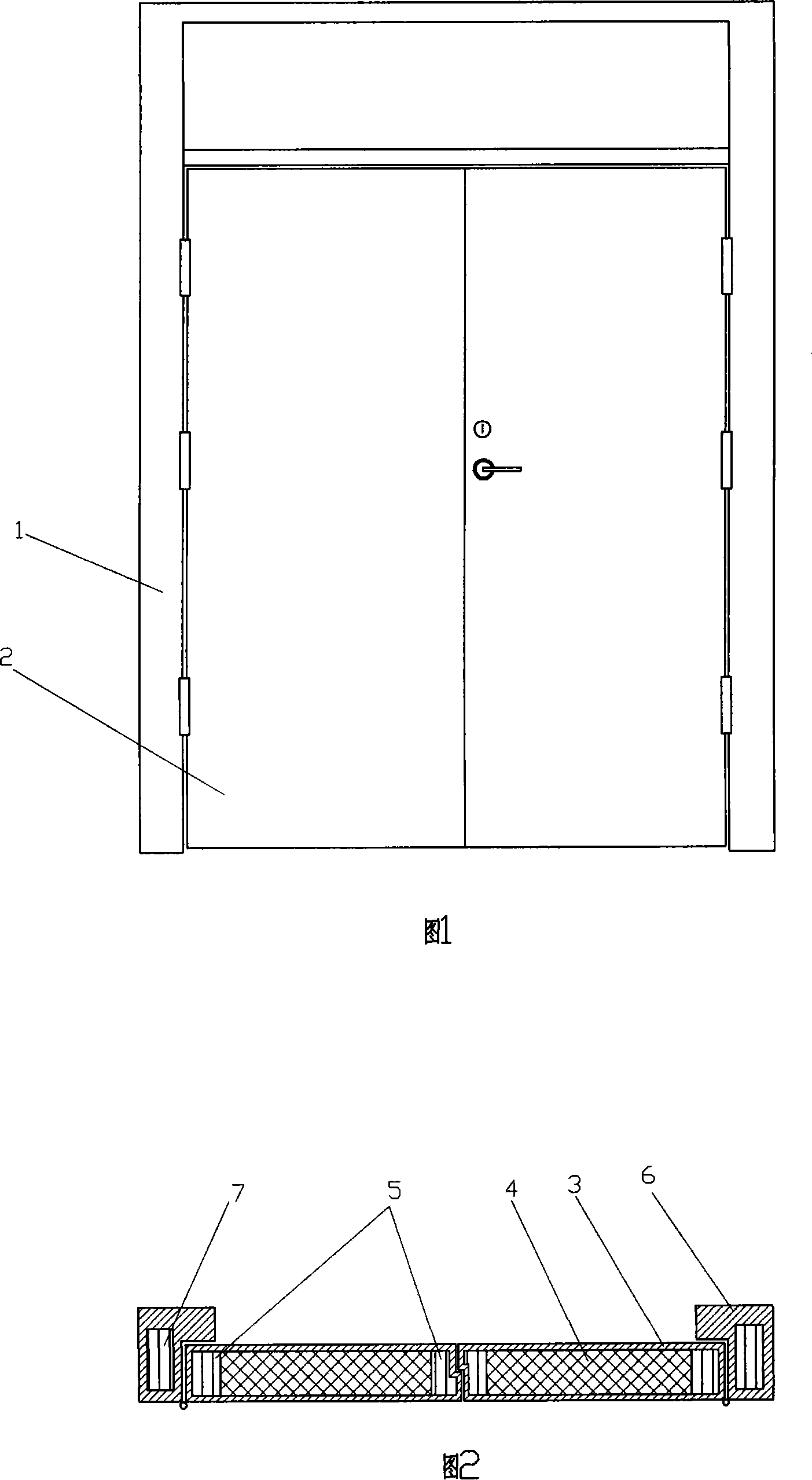

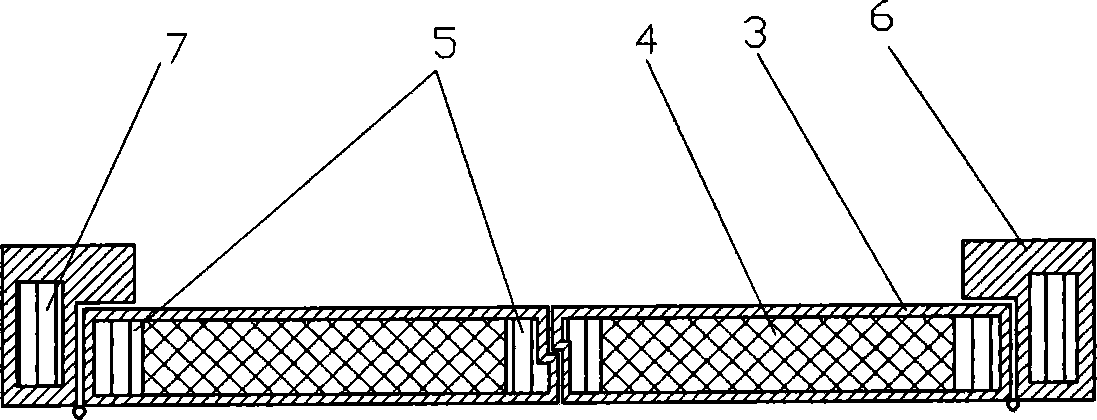

Fire-proof door

InactiveCN101210472BReasonable structureImprove fire performanceFireproof doorsCeramic layered productsEngineeringJamb

The invention discloses a fire door comprising a door panel, which includes an external covering layer, an inner core layer and a framework. The external covering layer completely covers the framework and the inner core layer; the external covering layer, the inner core layer and the framework of the door panel are wholly shaped by pouring molding; the external covering layer of the door panel ismade from inorganic fireproof materials, the framework is made from plywood, and the inner core layer of the door panel is made from one or two of the following materials: rock wool, expanded perlite, and expanded magnesia material; the frame of the fire door is of two-layered structure, wherein the outer layer is made of inorganic fireproof materials and the inner core layer is made of plywood. The invention represents a significant improvement in the fire-protecting performance as well as the overall performance of the fire doors among fire-protecting products and is widely used in industrial and civil buildings.

Owner:重庆民生建材厂

Pottery flying disk target and method for producing same

InactiveCN101493303AEasy to useImprove economyCeramic shaping apparatusMovable targetsDecompositionMaceral

The invention relates to improvement of clay target used for environment-friendly shooting sports, in particular to a ceramic clay target. The clay target is characterized in that the clay target is mainly formed by press forming of mineral mixed powder, then the mineral mixed powder is subject to soft burning to achieve proportion of 1.5-2.5g / cm, water absorbing capacity of 10-20% and breaking resistance of 50-80N. The ceramic clay target can not only meet the requirement for proportion, strength and easy shattering in the use requirement of clay targets, but also lead the clay target to absorb sufficient water or goes through weathering after being shattered, so that the clay target can be naturally decomposed to natural matter inorganic mineral powder to be returned to the nature; as a result, possible pollution to the environment caused by pieces of the clay target is completely avoided, and no artificial cleaning and collection of pieces is needed, thereby offsetting the defects of difficulty in natural decomposition of the clay target into powder after being shattered and the need for artificial cleaning and recovery and being an environment-friendly ceramic clay target with convenient use.

Owner:宜兴新宝工艺礼品有限公司

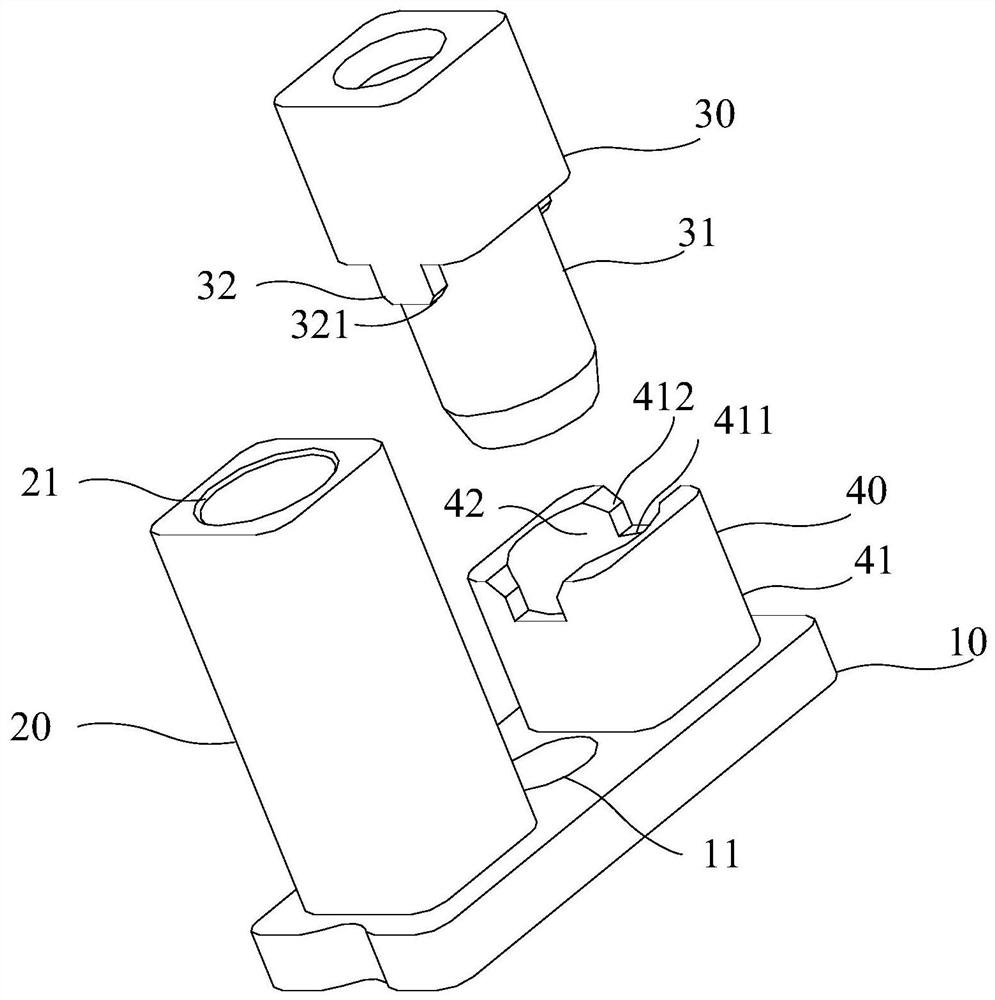

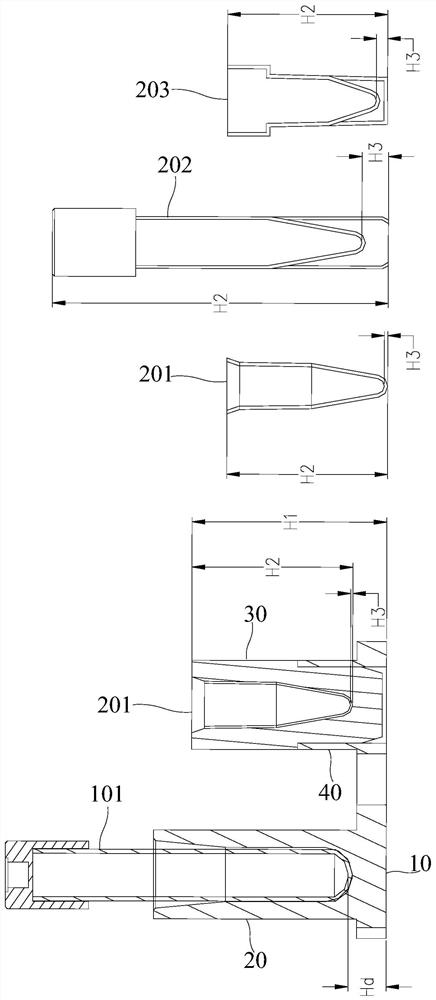

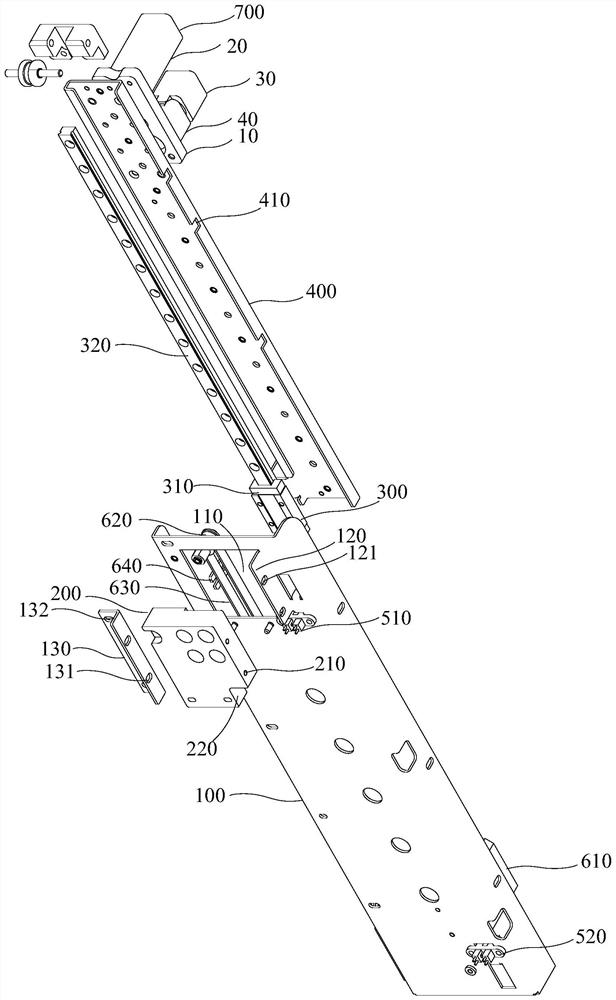

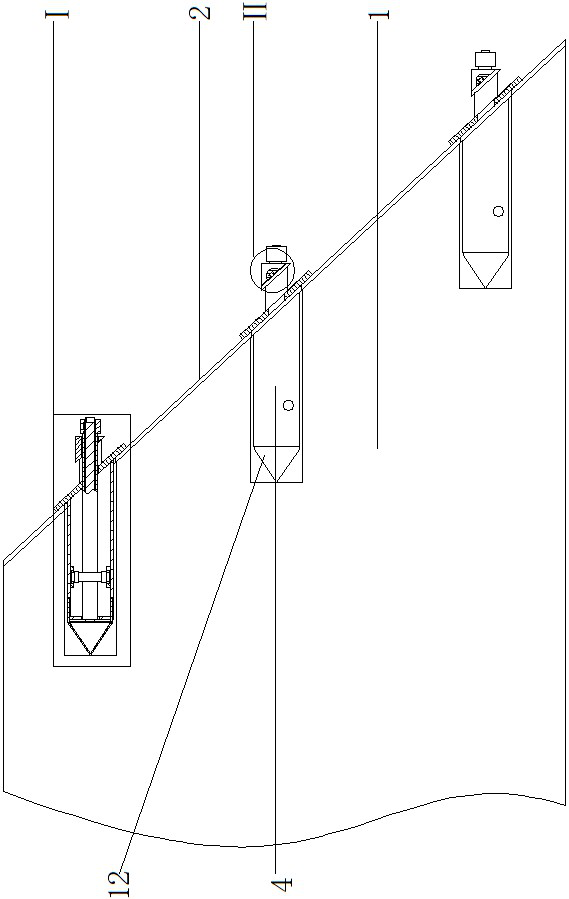

Sample analyzer and test tube transmission relay assembly

PendingCN114062702AStable deliveryEnsure normal delivery of test tubesMaterial analysisEngineeringStructural engineering

The invention provides a relay assembly which comprises a bottom plate, a supporting block, a sliding block, a sliding rail and a panel, wherein the bottom plate is provided with an opening part, the supporting block is fixed to the bottom plate at the opening part of the bottom plate, the sliding block is assembled through the supporting block, the sliding rail is in sliding fit with the sliding block, and the panel is fixed to the sliding rail. The supporting block is arranged at the bottom of the sliding block, the sliding block and the supporting block serve as fulcrums in the sliding process of the sliding rail, the compressive strength of the fulcrums is enhanced, the sliding rail is not prone to buckling deformation, and thus it is guaranteed that the relay assembly conveys test tubes normally.

Owner:SHENZHEN DYMIND BIOTECH

Rapid reinforcing device for river dam roadbed protective slope

ActiveCN111945662ANot easy to looseNot easy to slideCoastlines protectionThreaded pipeStructural engineering

The invention provides a rapid reinforcing device for river dam roadbed protective slope. The rapid reinforcing device comprises a slope and a metal net covering the slope surface of the slope, wherein the metal net is fixed to the slope surface of the slope through a plurality of evenly-distributed fixing devices; and each fixing device comprises a pressing plate, wherein the left side inclined face of the pressing plate is in contact fit with the right side face of the metal net, the left side wall of the pressing plate is fixedly connected with a barrel with an opening in the right side, the middle of the left side wall of the barrel and the middle of the plate face of the pressing plate are each provided with a first through hole located in the same horizontal straight line, the two first through holes are internally connected with the same transverse outer threaded pipe through sealing bearings, and the right end of the outer threaded pipe is fixedly connected with a bolt head. The rapid reinforcing device is compact in structure and reasonable in design, the metal net is pressed on the slope through the multiple fixing devices and is not prone to sliding, the pressing platesof the fixing devices play a role in attaching the metal net to the slope, the metal net is not prone to warping deformation, after a pressing block presses tarpaulin, the gap between the tarpaulin and the pressing plates and the gap between the tarpaulin and the slope cannot be too large, and rainwater is not prone to scouring the protective slope.

Owner:HUNAN INSTITUTE OF ENGINEERING

Special low-warpage composite material for notebook computer and preparation method thereof

InactiveCN101875766BImprove cooling effectNot easy to warp and deformDigital processing power distributionProcedure AgentsAntioxidant

The invention discloses a special low-warpage composite material for a notebook computer and a preparation method thereof. The composite material is prepared from the following main raw materials of PC (Polycarbonate) resin, ABS (Acrylonitrile Butadiene Styrene) resin, a flexibilizer, a fire retardant, an assistant fire retardant, a compatilizer, a wrapage preventing agent, an antioxidant and a processing aid. The preparation method comprises the following steps of: (1) firstly, placing the PC resin at 110-130 DEG C for drying for 2-4h; (2) uniformly mixing the dried PC resin with the ABS resin, the flexibilizer, the fire retardant, the assistant fire retardant, the compatilizer, the wrapage preventing agent, the antioxidant and the processing aid; and (3) fusing and extruding the mixed raw materials in the step (2) to prill to obtain a low-warpage composite material. The invention provides the special low-warpage composite material for a notebook computer, which is not easy to warp or deform and improves the product molding rate and the installing rate, and the preparation method thereof.

Owner:SHENZHEN KEJU NEW MATERIAL

A kind of decorative bamboo plastic geothermal floor and its cold pressing processing method

ActiveCN105804369BSave resourcesEliminate pollutionLaminationLamination apparatusGlass fiberAdhesive

The invention provides a facing bamboo-plastic heating floor and a cold-pressing processing method thereof. The facing bamboo-plastic heating floor is formed by combining a bamboo-plastic floor base material layer, a glass fiber cloth layer and a heavy bamboo veneer layer. The bamboo-plastic floor base material layer comprises, by mass, 20%-25% of polyvinyl chloride (PVC) and polyether block amide blends, 6%-8% of nanoscale bamboo charcoal powder, 25%-30% of chinastone powder, 7%-9% of lubricating agents, 2%-3% of coupling agents and the balance bamboo powder. A manufacturing method of the facing bamboo-plastic heating floor comprises the steps that firstly, bamboo materials are pulverized and mixed with the chinastone powder at a high temperature after being subjected to fluoridation, then other components are placed into a high-speed mixing and dispersing machine jointly and mixed for 20 minutes after the temperature is increased to 125-130 DEG C, afterwards the temperature is decreased to 45 DEG C through cooling, and finally, the mixture is extruded through an extruding machine, so that a bamboo-plastic floor base material is obtained; and then the bamboo-plastic floor base material, the glass fiber cloth and the heavy bamboo veneer are assembled and combined after being coated with adhesives, and the facing bamboo-plastic heating floor is obtained through the procedures such as cold pressing. The floor has the natural material texture, high heat-conducting efficiency, low thermal expansivity and good mechanical performance, is not prone to buckling deformation and can be widely used in the heating floor field.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com