Biomass composite gluing veneer floor technology and composite floor, used base material

A composite material and composite floor technology, applied in the field of flooring, can solve the problems of high maintenance costs, physical health threats, and high prices of solid wood floors, and achieve the effects of less glue consumption, resource protection, and not easy to warp and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: This embodiment provides a polyolefin biomass composite material laminated veneer production flooring process, the specific steps are as follows:

[0035] The base material is a polyolefin base layer containing;

[0036] The polyolefin base layer includes 1%-60% biomass, 4%-10% filler, 10-15% color material, 2-5% processing aid, and the rest is polyolefin, which is heated and extruded.

[0037] The above components satisfy 100%.

[0038] The extrusion molding process is: the mixing process, the materials are mixed according to the formula, stirred at high speed by the mixer, frictional heat is generated, and the set process temperature is 110 ° C ~ 125 ° C, then discharged into the cold mix, until the set process Discharge after 40°C;

[0039] In the granulation process, the above-mentioned raw materials are added into the hopper in proportion, and the steps of heating, kneading, and bonding are carried out in the granulator. The granulation temperature ...

Embodiment 2

[0052] Example 2: The polyolefin base layer includes 30% biomass, 10% filler, 15% colorant, 5% processing aid, and 40% polyolefin is heated and extruded;

[0053] (40% biomass polyolefin base + glue + veneer solution)

[0054] Experimental equipment: electronic density meter, Shore hardness tester, residual dent testing machine, universal testing machine, constant temperature and humidity test chamber, constant temperature blast drying oven, height vernier caliper

[0055] Experimental environment: temperature 23°C, humidity 50% equilibrium treatment for 24h, heating at 80°C for 6h, room temperature 23°C for 24h.

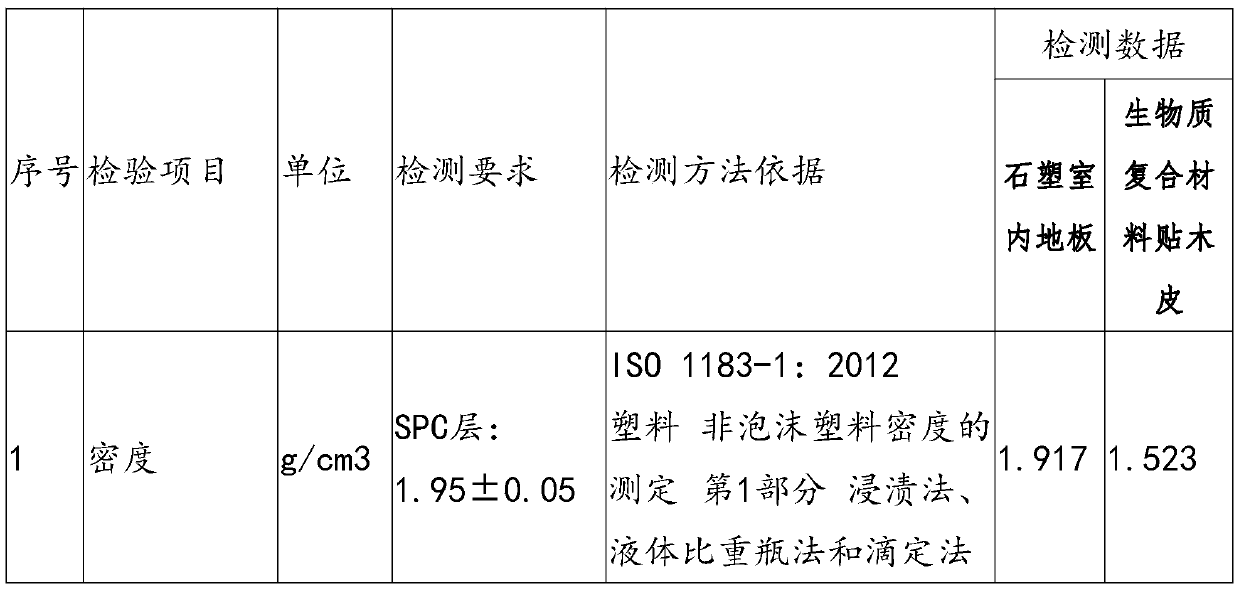

[0056] Test method: GB / T 4085-2015 Semi-rigid polyvinyl chloride block floor, EN15534-1-2014 Composite materials based on fibrous materials and thermoplastics (commonly known as wood-plastic composites or natural fiber composites) Part 1 Test methods for formulation and product performance characterization, GB / T34440-2017 Rigid polyvinyl chloride flooring

[0057]...

Embodiment 3

[0060] Example 3: The base material selection includes 60%, 4% filler, 10% color material, 2% processing aid, and 24% polyolefin heated extrusion molding;

[0061] Experimental equipment: electronic density meter, Shore hardness tester, residual dent testing machine, universal testing machine, constant temperature and humidity test chamber, constant temperature blast drying oven, height vernier caliper

[0062]Experimental environment: temperature 23°C, humidity 50% equilibrium treatment for 24h, heating at 80°C for 6h, room temperature 23°C for 24h.

[0063] Test method: GB / T 4085-2015 Semi-rigid polyvinyl chloride block floor, EN15534-1-2014 Composite materials based on fibrous materials and thermoplastics (commonly known as wood-plastic composites or natural fiber composites) Part 1 Test methods for formulation and product performance characterization, GB / T34440-2017 Rigid polyvinyl chloride flooring

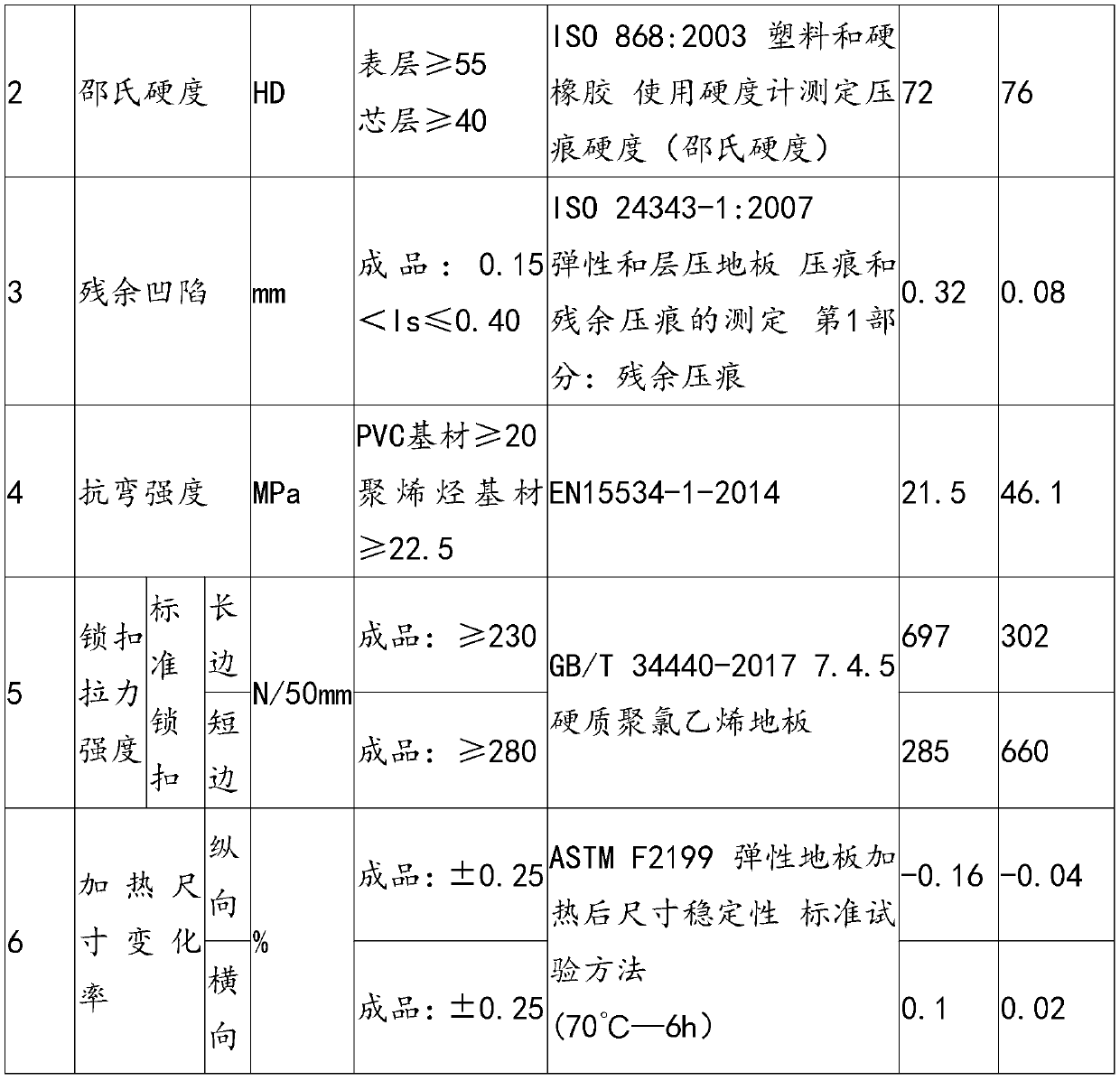

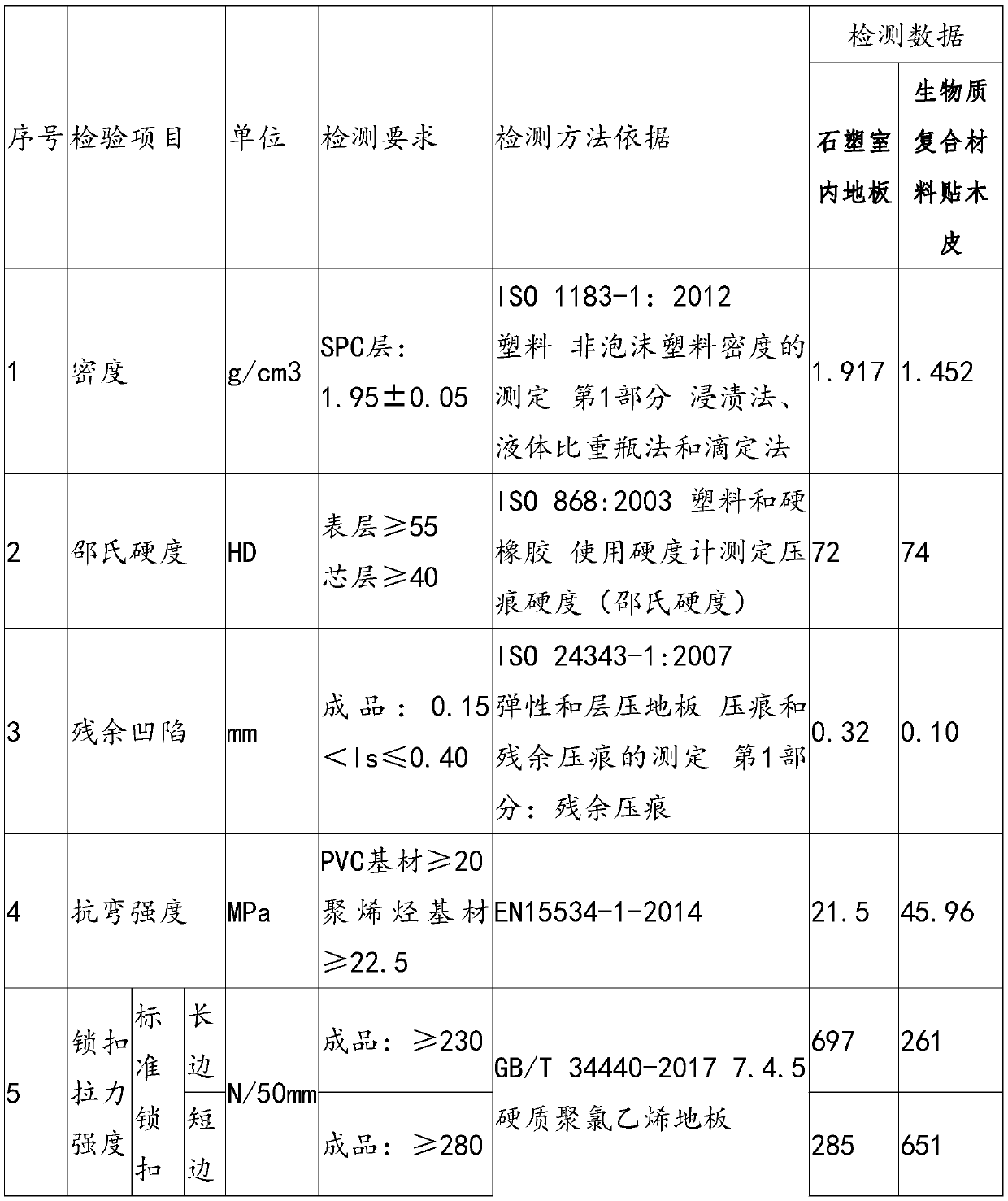

[0064] Experimental data: the following table:

[0065]

[0066] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com