Hybrid fiber grid fabric reinforced polypropylene compound filtering plate and preparation method thereof

A fabric-reinforced and mixed-fiber technology, applied in the field of mixed-fiber grid fabric-reinforced polypropylene composite filter plate and its preparation, can solve problems such as insufficient strength and insufficient stability of the filter plate, achieve reduced thickness and quality, and good industrial application Foreground, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

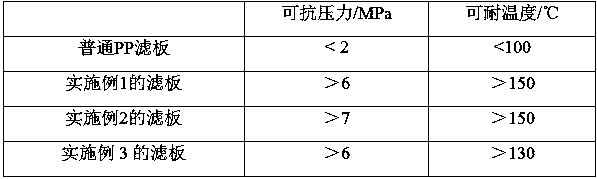

Embodiment 1

[0035] A hybrid fiber mesh fabric-reinforced polypropylene composite filter plate, which contains the following components in die-cast molding, and the weight ratio of each component is as follows:

[0036] Polypropylene resin 60;

[0037] Inorganic mineral powder 14;

[0038] Continuous inorganic fiber 12;

[0039] Continuous organic fiber 12;

[0040] Coupling agent 1.5;

[0041] Antioxidant 0.25;

[0042] Lubricant 0.25.

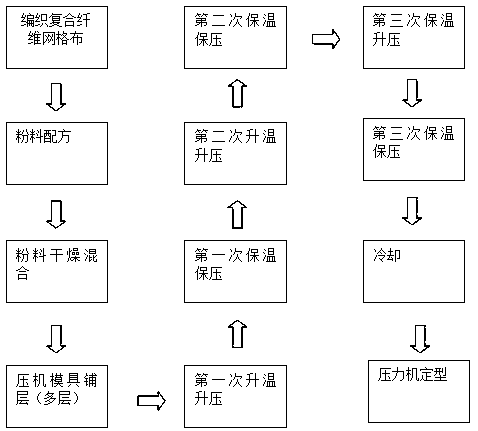

[0043] A preparation method of hybrid fiber mesh fabric reinforced polypropylene composite filter plate includes the following steps:

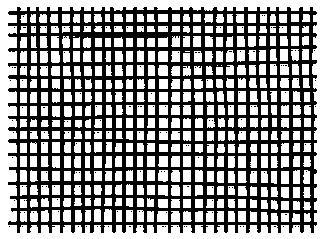

[0044] Step 1. Weaving and impregnation: Inorganic fiber and organic fiber are compositely woven into a mesh cloth in a certain proportion, impregnated with coupling agent, and dried for later use;

[0045] Step 2. Reclaiming: Take the other components in parts by weight, mix them evenly, dry and remove water to obtain the mixture;

[0046] Step 3. Die casting molding:

[0047] 1) Put a piece of glass inorganic fiber and organic fiber com...

Embodiment 2

[0052] A hybrid fiber mesh fabric-reinforced polypropylene composite filter plate, which contains the following components in die-cast molding, and the weight ratio of each component is as follows:

[0053] Polypropylene resin 50;

[0054] Inorganic mineral powder 18;

[0055] Continuous inorganic fiber 15;

[0056] Continuous organic fiber 15;

[0057] Coupling agent 1.5;

[0058] Antioxidant 0.25;

[0059] Lubricant 0.25.

[0060] A preparation method of hybrid fiber mesh fabric reinforced polypropylene composite filter plate includes the following steps:

[0061] Step 1. Weaving and impregnation: Inorganic fibers and organic fibers are compositely woven into a composite mesh cloth in a certain proportion, impregnated with coupling agent, and dried for later use;

[0062] Step 2. Reclaiming: Take the other components in parts by weight, mix them evenly, dry and remove water to obtain the mixture;

[0063] Step 3. Die casting molding:

[0064] 1) Put a piece of inorganic fiber and organic fib...

Embodiment 3

[0069] A hybrid fiber mesh fabric-reinforced polypropylene composite filter plate, which contains the following components in die-cast molding, and the weight ratio of each component is as follows:

[0070] Polypropylene resin 70;

[0071] Inorganic mineral powder 8;

[0072] Continuous inorganic fiber 10;

[0073] Continuous organic fiber 10;

[0074] Coupling agent 1.5;

[0075] Antioxidant 0.25;

[0076] Lubricant 0.25.

[0077] A preparation method of hybrid fiber mesh fabric reinforced polypropylene composite filter plate includes the following steps:

[0078] Step 1. Weaving and impregnation: Inorganic fibers and organic fibers are compositely woven into a mesh cloth in a certain proportion, and the coupling agent is impregnated at room temperature for 12 hours, and dried for later use;

[0079] Step 2. Reclaiming: Take the other components in parts by weight, mix them evenly, dry and remove water to obtain the mixture;

[0080] Step 3. Die casting molding:

[0081] 1) Put a piece of com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com