A helical rotary engine

A rotary engine and solenoid technology, used in rotary piston engines, engine components, combustion engines, etc., can solve the problems that the axial thrust cannot completely cancel each other, affect the service life of the engine bearing, and the structure is complex, so as to reduce heat consumption. The effect of dispersing, easily sealing, and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

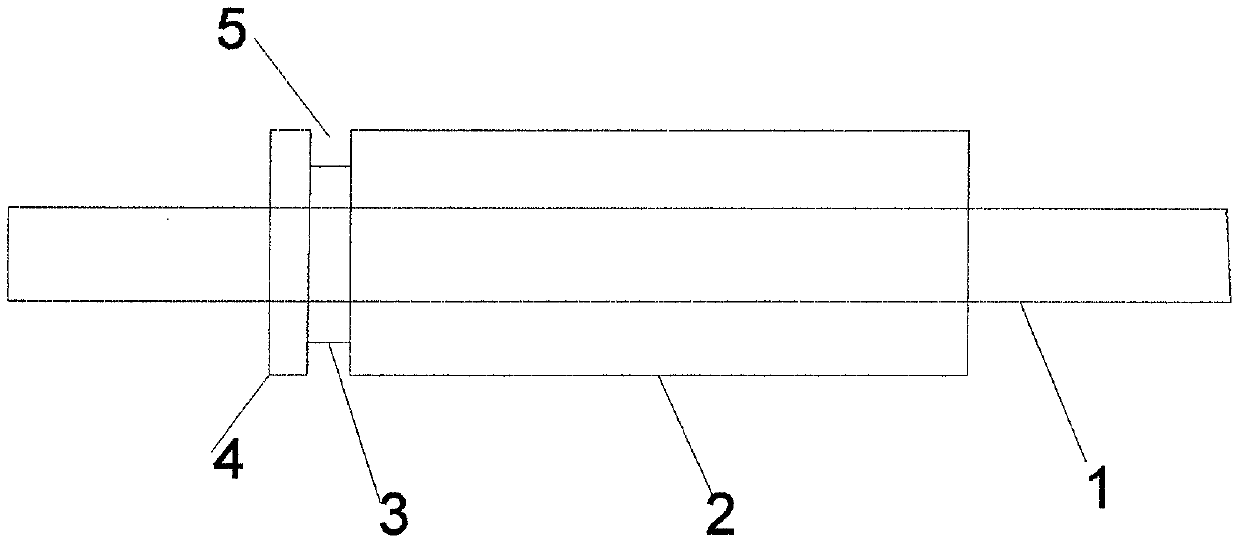

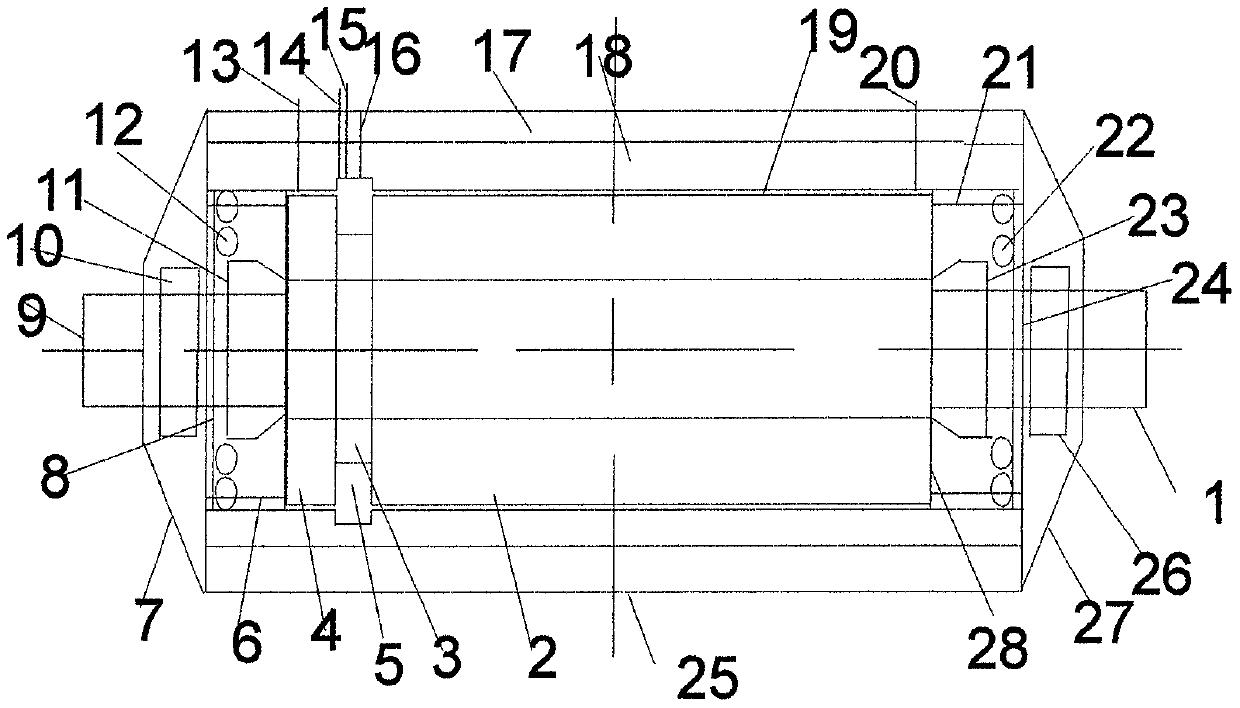

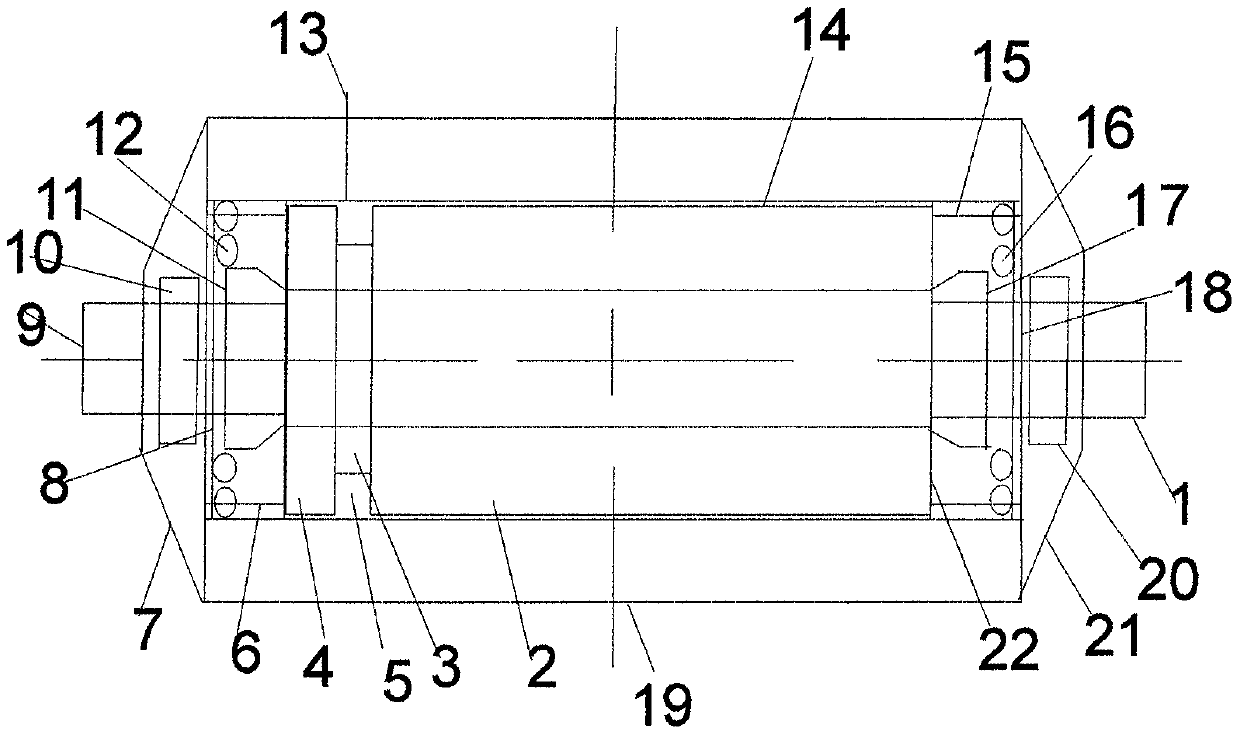

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

[0043] The rotating body of the spiral tube rotor is made on the same cylinder as a whole of the head cylinder, neck cylinder, and built-in spiral tube cylinder, or the left built-in spiral tube cylinder, neck cylinder, and neck are made on the same cylinder. The whole body of the inner cylinder and the right built-in helical tube cylinder, the helical tube for converting fluid energy is arranged on the surface layer of the built-in helical tube cylinder.

[0044] The rotating body of the rotor is a whole made of a head cylinder, a neck cylinder and a built-in solenoid cylinder on the same cylinder, referred to as a single-ended solenoid rotor. Tube rotor engine. The connected head cylinder is mainly used to counteract the axial thrust generated by the fluid in the cavity of the neck cylinder.

[0045] The rotating body of the rotor is made of the left built-in spira...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com