Method for coating positive electrode material by using organic silicon coupling agent

A technology of organic silicon coupling agent and positive electrode material, which is applied in battery electrodes, electrode manufacturing, structural parts, etc., can solve problems such as insufficient binding force, dissolution of lithium cobaltate metal, gas production, etc., and achieve high temperature and high pressure performance improvement , The effect of improving the cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

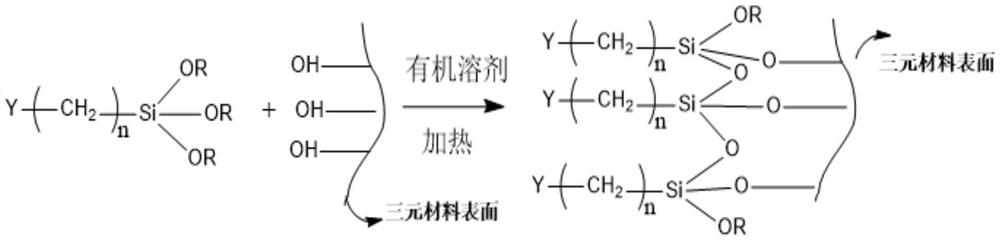

Method used

Image

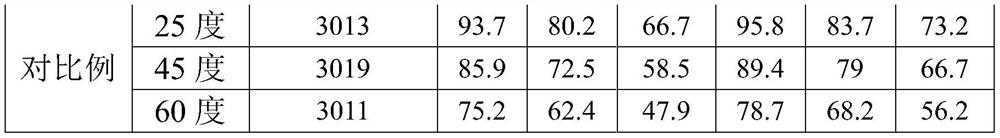

Examples

Embodiment 1

[0023] The organosilicon coupling agent was added to a methanol solution containing 1% deionized water, and then the organosilicon coupling agent was added to prepare a reaction solution. The content of the organosilicon coupling agent in the reaction solution was 0.2%. Then, the high-nickel ternary material (nickel-cobalt-manganese ternary material) to be treated is poured into the reaction solution, and the mass ratio of the added amount to the organic solvent is 1:1. Mix uniformly with a mixer, the stirring speed is 50r / min, and the stirring time is controlled between 1h. After stirring, turn on the heating button, control the temperature to 110°C, stir while heating for 3 hours, and then stop heating and stirring. Take a piece of filter paper with a clean and dry surface, filter out the high-nickel ternary material, and dry it in an oven at a temperature of 110 °C for 7 hours. The treated high-nickel ternary material is taken out, and the modified high-nickel ternary mate...

Embodiment 2

[0025] The mass fraction of deionized water in methanol solution is 2%, the content of organosilicon coupling agent in the reaction solution is 0.4%, and the mass ratio of high nickel ternary material to organic solvent is 1:2. Other parameters and experimental procedures are the same as in Example 1.

Embodiment 3

[0027] The mass fraction of deionized water in methanol solution is 4%, the content of organosilicon coupling agent in the reaction solution is 0.8%, and the mass ratio of high nickel ternary material to organic solvent is 1:4. Other parameters and experimental procedures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com