Air exhausting device for motor hydrostatic test tank for deepwater submersible electric pump

A technology for submersible electric pumps and hydraulic tests, which is applied to valve devices, packaging, mechanical equipment, etc. It can solve the problems of poor sealing performance, weak pressure resistance, and short service life, and achieve good sealing, not easy to wear and tear damage, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention will be further described, but the present invention is not limited to these examples, under the premise of departing from the gist of the present invention, any improvement made falls within the protection scope of the present invention.

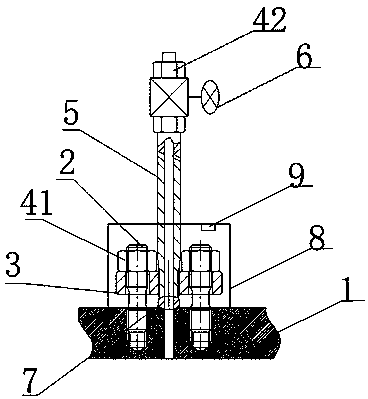

[0014] As shown in the figure, an exhaust device for a motor hydraulic test tank for a deep-water submersible electric pump according to the present invention includes an end cover 1, a stud bolt 2, a flange 3, a nut, a high-pressure pipe 5, and a stop valve 6. Lens pad 7, protective cover 8, the high-pressure pipe 5 is provided with a flange 3 at the lower end of a cylindrical structure, and the flange 3 is provided with mounting holes formed by an array, and the nuts include first nuts 41, the second nut 42, the stud bolt 2 is installed in the mounting hole on the flange 3, the lower end is installed on the end cover 1 through threaded connection, and the upper end is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com