Pilot-operated type electromagnetic valve capable of resisting high temperature and high pressure

A high-temperature and high-pressure, pilot-operated technology, applied in the field of solenoid valves, can solve the problems of safety accidents, poor high temperature resistance, poor pressure resistance, etc., and achieve the effect of improving sealing performance, good effect, and enhancing high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

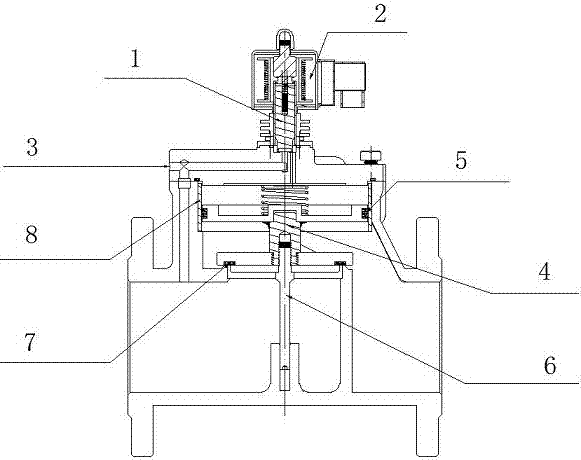

[0012] In a preferred embodiment of the present invention, a pilot-operated high-temperature and high-pressure solenoid valve is provided, which adopts a pilot-operated structure, including a pilot part 1, a coil part 2, a moving iron core, a pilot hole 3, a main valve part 4, and an elastic piston ring 5 , main valve positioning rod 6 and seal 7 and other main parts, the pilot part 1 is provided with a moving iron core, the cylinder surface above the moving iron core is wound with a coil part 2, and the pilot part 1 is also provided with a pilot hole 3; There is a certain gap between the main valve part 4 and the valve wall 8, the main valve part 4 is symmetrically provided with a sealing groove, and the elastic piston ring 5 is placed in the sealing groove; the material of the sealing member 7 is increased by metals such as silver base and copper base. Material; the main valve positioning rod 6 is located directly below the main valve part 4 .

[0013] see figure 1 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com