Method for preparing composite coating through electromagnetic induction heating

A technology of electromagnetic induction heating and composite coating, applied in coating, metal material coating process, fusion spraying and other directions, can solve the problems of coating peeling, warping deformation, cracking, etc. strong knot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Specific embodiments of the present invention prepare the preparation scheme of multilayer coating as follows, specifically comprise the following steps:

[0050] (1) First use white corundum, brown corundum or zirconium corundum (the particle size of the sand is 18-25μm) to sandblast the substrate; after spraying, use compressed dry air to blow off the remaining sand and impurities in the pits on the surface of the substrate .

[0051] (2) Using the thermal spraying system, put the substrate to be sprayed on the spraying platform of the spraying system, make preparations before spraying, and spray.

[0052] (3) Carry out mechanical processing and treatment of the coating surface according to the requirements to meet the corresponding use requirements.

[0053] (4) Spray the protective layer and decorative layer on the surface of the coating according to the requirements of use, cool to room temperature, and remove the sample.

[0054] There are 2 methods of physicall...

Embodiment 1

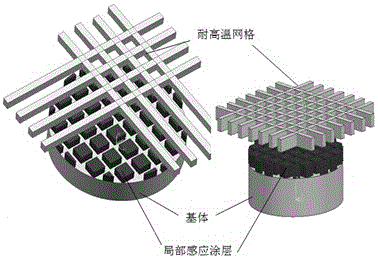

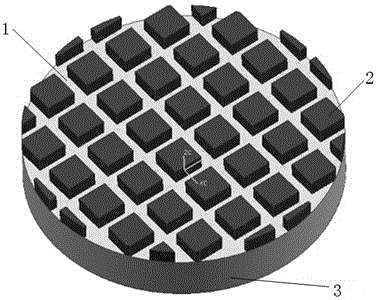

[0058] In this embodiment, the aluminum alloy is used as the base, and the 316L stainless steel coating is sprayed on the aluminum alloy base. Plate (the material is high temperature resistant molybdenum wire, the thickness of molybdenum wire is 0.1mm), the shape of the mesh plate is honeycomb, and the area of each honeycomb is 0.01mm 2 . Thermal spraying is carried out by arc spraying technology, the distance between the grid and the surface to be sprayed is 4mm, the spray voltage is 32V, the current is 180A and the spray pressure is 0.6MPa, the distance between the spray gun and the grid is 200mm, and the spraying speed is 6mm / s. The distributed electromagnetic induction heating composite coating has a thickness of about 100 μm.

[0059] The coating prepared in this embodiment is distributed in a honeycomb shape, and the area of each grid is 0.01mm 2 , the distance between the grids is 0.1mm. Microhardness tester MC010-HVS-1000Z coating was used for hardness test, and...

Embodiment 2

[0063] In this embodiment, the aluminum alloy is used as the substrate, and the Ni-Al coating is sprayed on the aluminum alloy substrate. The specific method is: after the surface of the aluminum alloy substrate is roughened and cleaned, the surface to be sprayed is hollowed out Stencil (the material is high temperature resistant chrome wire, the thickness of chrome wire is 10mm), the shape of the stencil is grid, and the area of each grid is 10000mm 2 . Plasma spraying is used for thermal spraying, the distance between the grid and the surface to be sprayed is 4mm, and the distance between the spray gun and the grid is 200mm; current 410A; voltage 320V; N 2 Flow 230L / min; Ar flow 100L / min; H 2 The flow rate is 15L / min; the powder feeding voltage is 18V, the moving speed of the spray gun is 6mm / s, and the thickness of the prepared coating is about 700μm.

[0064] The coating prepared in this example is distributed in a grid shape, and the area of each grid shape is 10000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com