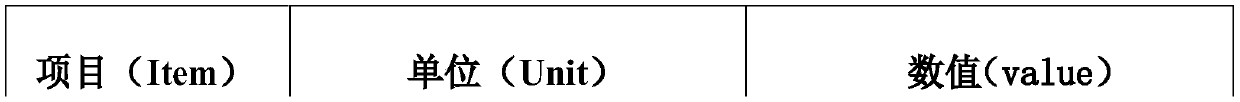

Patents

Literature

68results about How to "Avoid weak bonds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integrally formed 3D flyknitted vamp and making method thereof

The invention discloses an integrally formed 3D flyknitted vamp and a making method thereof.Low-melting yarn and dyed yarn are adopted as raw materials, an upper layer of double-faced jacquard vamp body and a lower layer of double-faced jacquard vamp body with the edges interwoven together are woven on a bidirectional jacquard double-faced loop transfer computer flat knitting machine, openwork figured texture weave is primary weave, different weave structures are adopted in functional zones of the vamp, and then the integrally formed 3D flyknitted vamp is made through hot pressing shaping.The temperature of hot pressing shaping ranges from 170 DEG C to 200 DEG C, and the time of hot pressing shaping ranges from 20 s to 80 s.Each double-faced jacquard vamp body comprises a dyed yarn layer and a low-smelting yarn layer which are interwoven together through yarn coils, and the integrally formed 3D flyknitted vamp is formed by bonding and combining the two layers of double-faced jacquard vamp bodies according to the wave structure of one dyed yarn layer, one low-melting yarn layer, the other low-melting yarn and the other dyed yarn layer through the upper low-melting yarn layer and the lower low-melting yarn layer in a hot pressing and melting mode.The integrally formed 3D flyknitted vamp has the advantages of being soft, comfortable, durable, colorful, attractive, low in cost and the like.

Owner:厦门翔鹭化纤股份有限公司

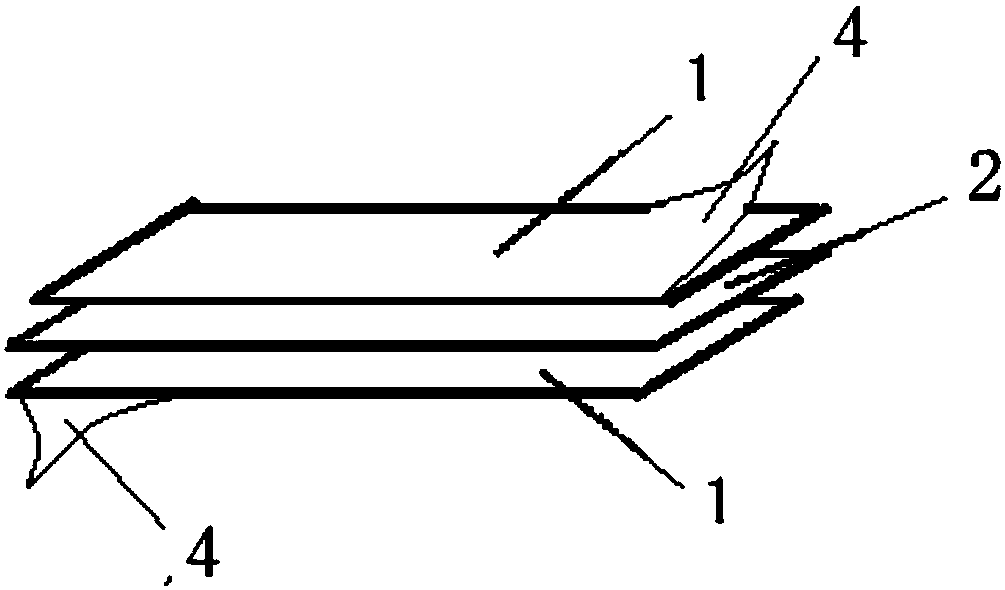

Preparation method of lithium-copper composite negative electrode foil piece

ActiveCN107819104AImprove machinabilityEven contactElectrode rolling/calenderingSecondary cellsLithium metalCopper foil

The invention relates to a preparation method of a lithium-copper composite negative electrode foil piece. An intermittent local pressure enhancement method is adopted for uniformly adhering lithium metal foil pieces on the surface of a copper foil, and a lithium-copper composite negative electrode foil piece is formed. The preparation method comprises the following concrete steps: clamping the copper foil between the lithium metal foil pieces to form a lithium foil / copper foil / lithium foil sandwich layer; adopting common rolling equipment, starting a traction system, and enabling the lithiumfoil / copper foil / lithium foil sandwich layer to pass through a grinding roller, so as to form intermittent local pressure on the lithium foil / copper foil / lithium foil sandwich layer, wherein the pressure range is 0.05-5MPa, and a pre-compounded lithium foil / copper foil / lithium foil sandwich slice is formed; and enabling the pre-compounded lithium foil / copper foil / lithium foil sandwich slice to pass through the grinding roller again, and applying pressure for shaping, wherein the pressure range is 0.02-5MPa, so that the lithium-copper composite negative electrode foil piece is obtained. The preparation method provided by the invention has the beneficial effects that layer-to-layer contact of the prepared lithium-copper composite negative electrode foil piece is uniform, contact of a lithiummetal negative electrode with the copper foil is further improved, and the problem that the lithium metal foil piece and the copper foil are infirmly bonded is avoided, so that outage of lithium metal in a working process of a battery is prevented.

Owner:TIANJIN LISHEN BATTERY +1

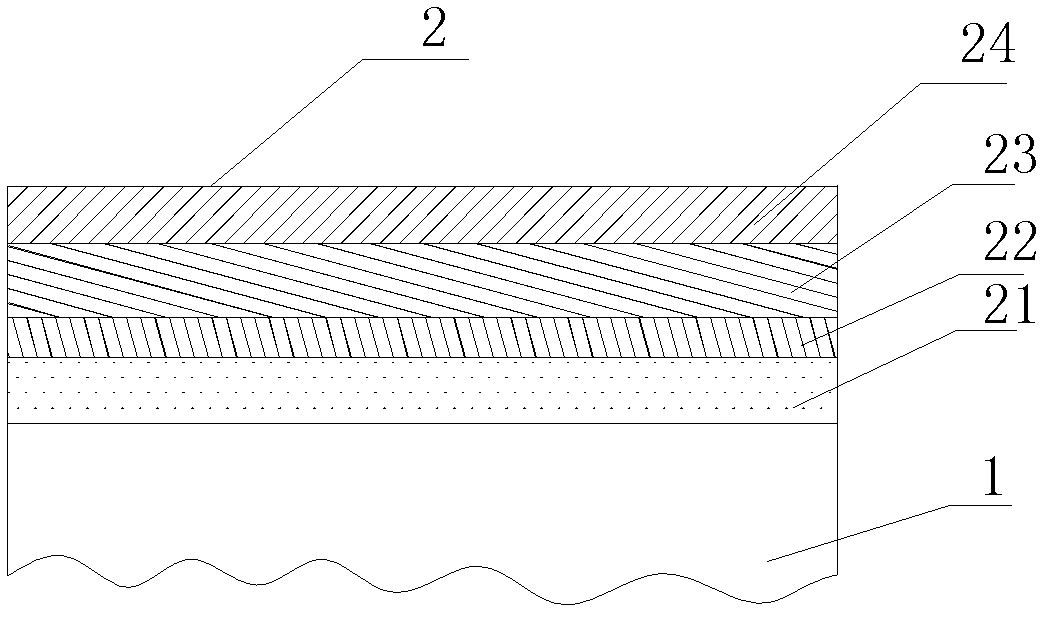

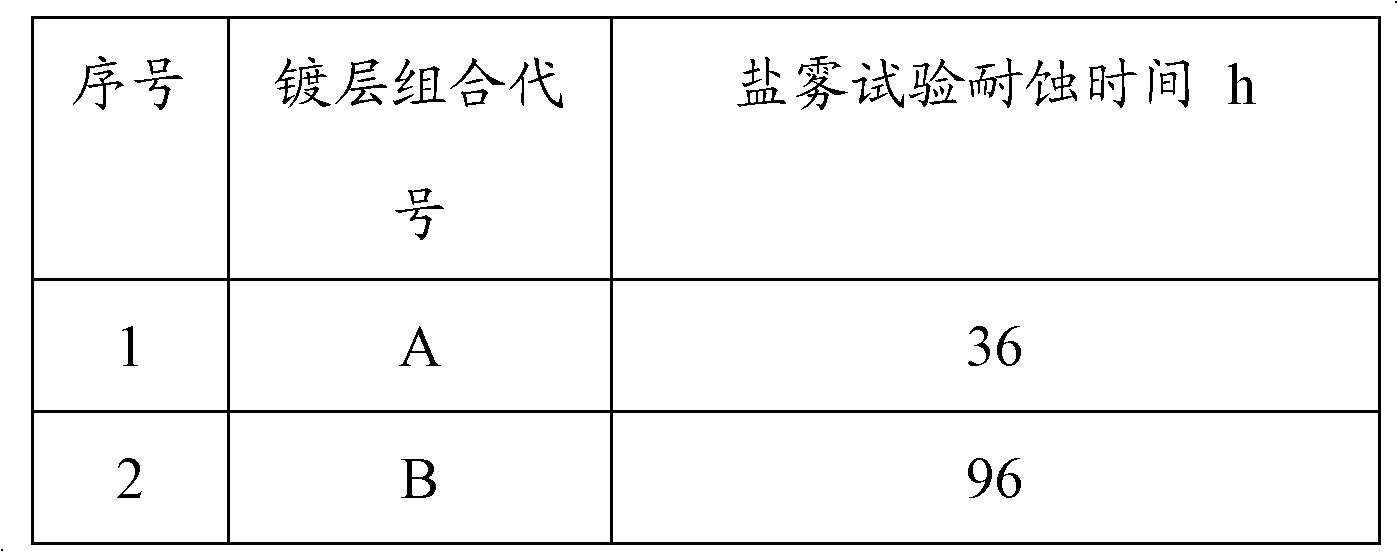

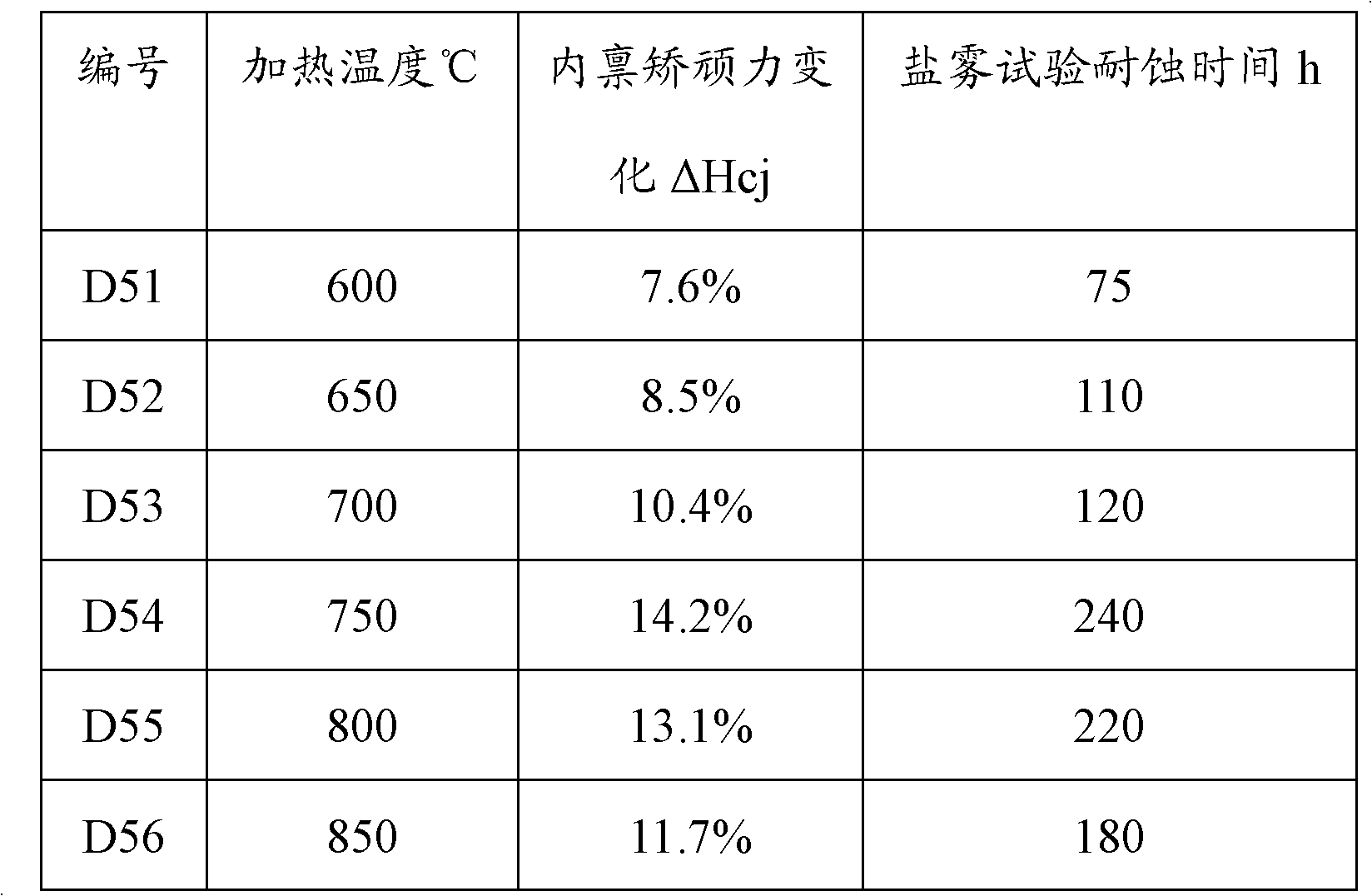

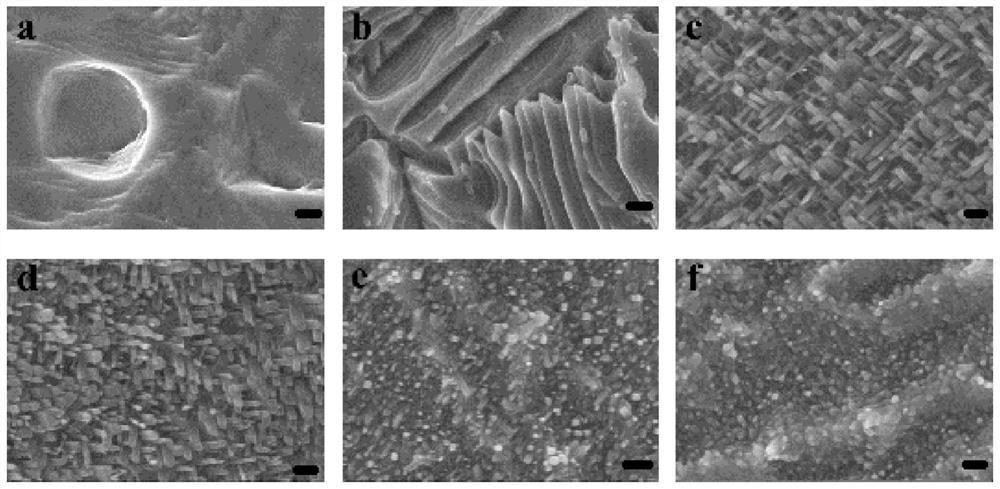

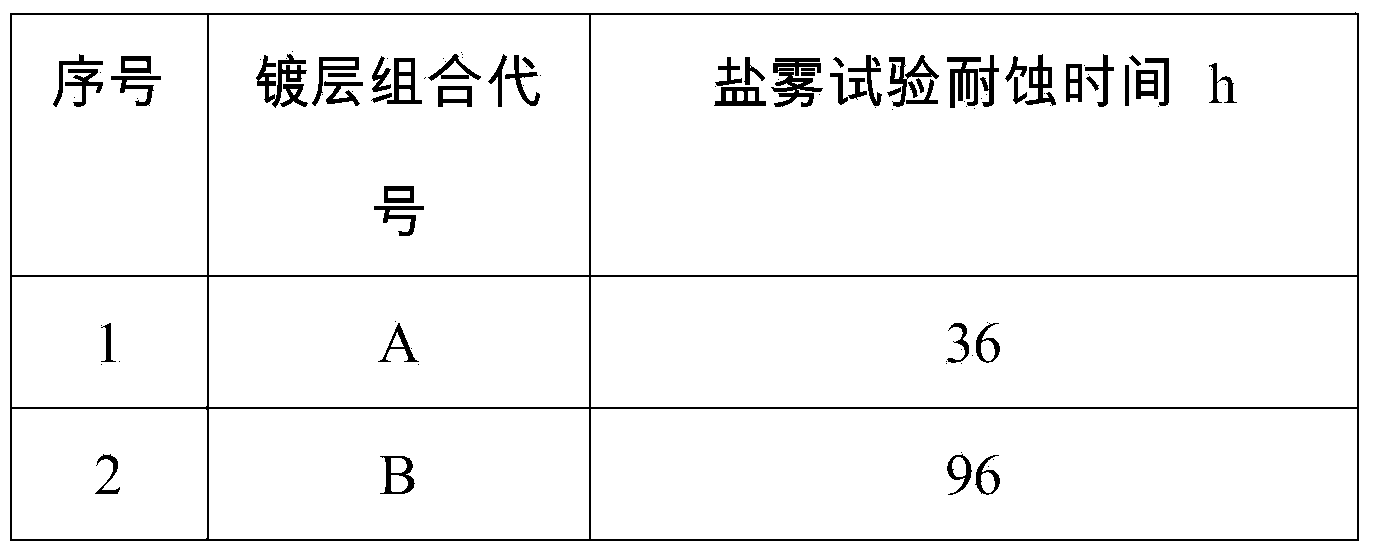

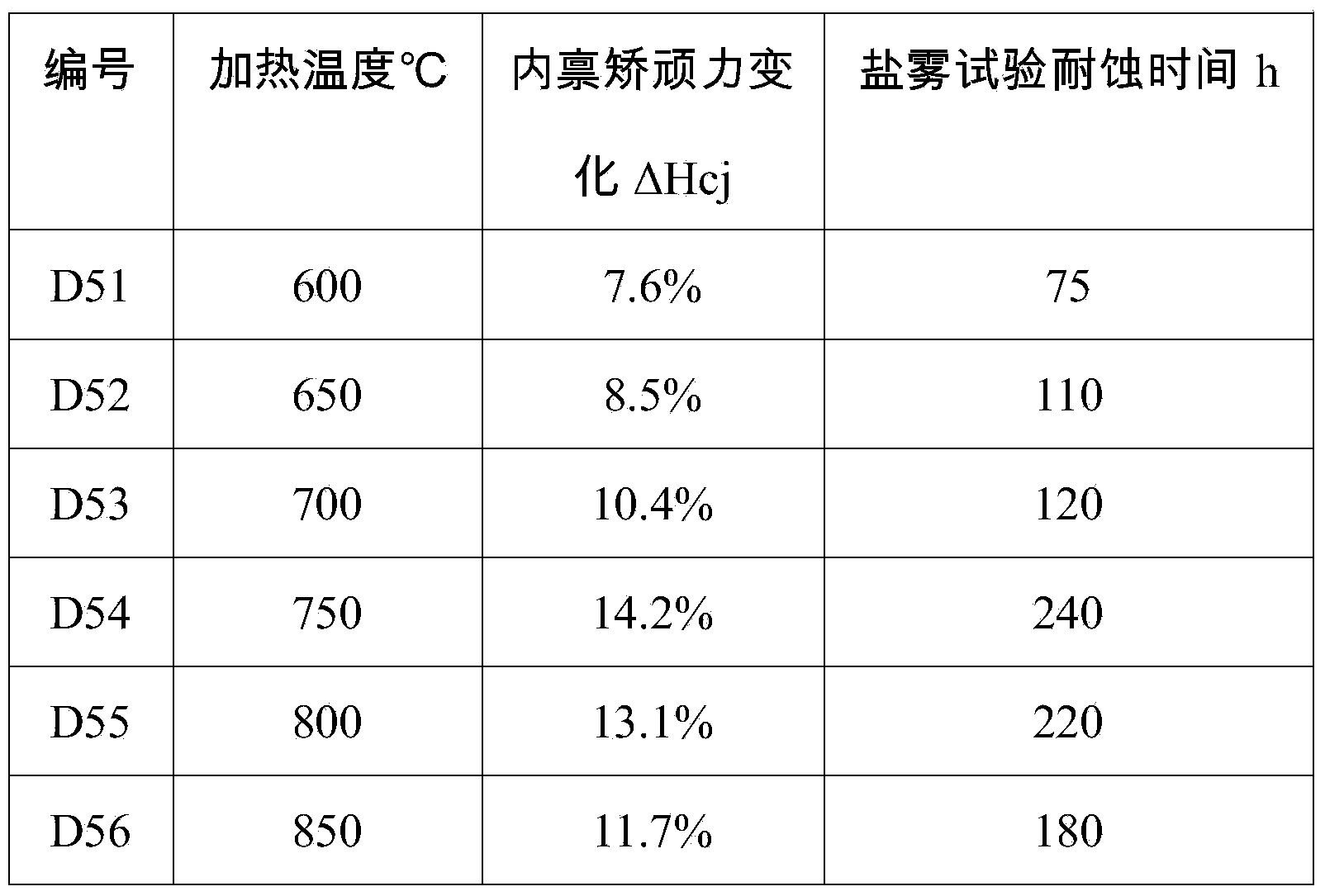

Surface coating process for neodymium iron boron permanent magnetic material and neodymium iron boron permanent magnetic material

ActiveCN102586776AReduce air bubblesImprove adhesionLiquid/solution decomposition chemical coatingMagnetic materialsVacuum furnaceTotal thickness

The present invention relates to a surface coating process for neodymium iron boron permanent magnetic material and a neodymium iron boron permanent magnetic material with coating layers. In the process, an electroplated bottom surface nickel layer, a chemically-coated nickel layer, an electroplated copper layer and an electroplated external nickel layer are sequentially coated on the substrate surface of the neodymium iron boron permanent magnetic material from inside to outside, and after coating, the neodymium iron boron permanent magnetic material is subjected to heat treatment in a vacuum furnace. The total thickness of the coating layers on the neodymium iron boron permanent magnetic material prepared with the process is 15-30mum, the thickness of electroplated bottom surface nickel layer is 5-10mum, the thickness of the electroplated copper layer is 5-10mum, the thickness of the electroplated external nickel layer is 5-10mum and the thickness of the chemically-coated nickel layer is 3-10mum. The coating process provided by the invention reduces the bubble formation, looseness and rust stains, enhances the adhesion of the coating layers, reduces the porosity and obtains compact coating layers, thus significantly improving the quality of the electroplated coating layers on the magnet surface, improving the indicates of a salt spray test and increasing the qualification rate of products.

Owner:SHENYANG GENERAL MAGNETIC

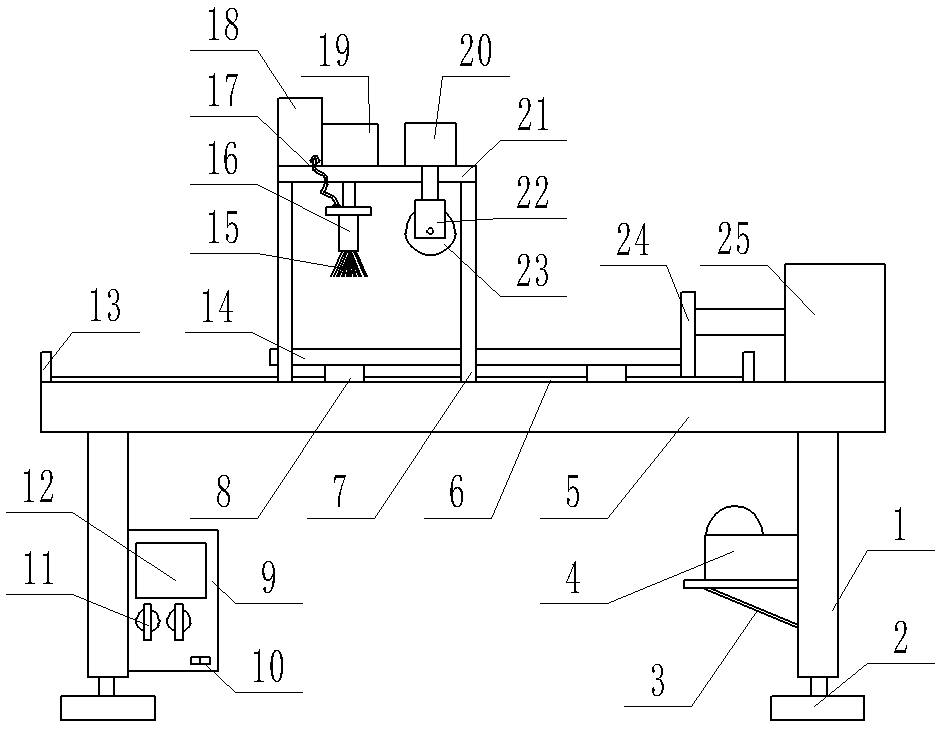

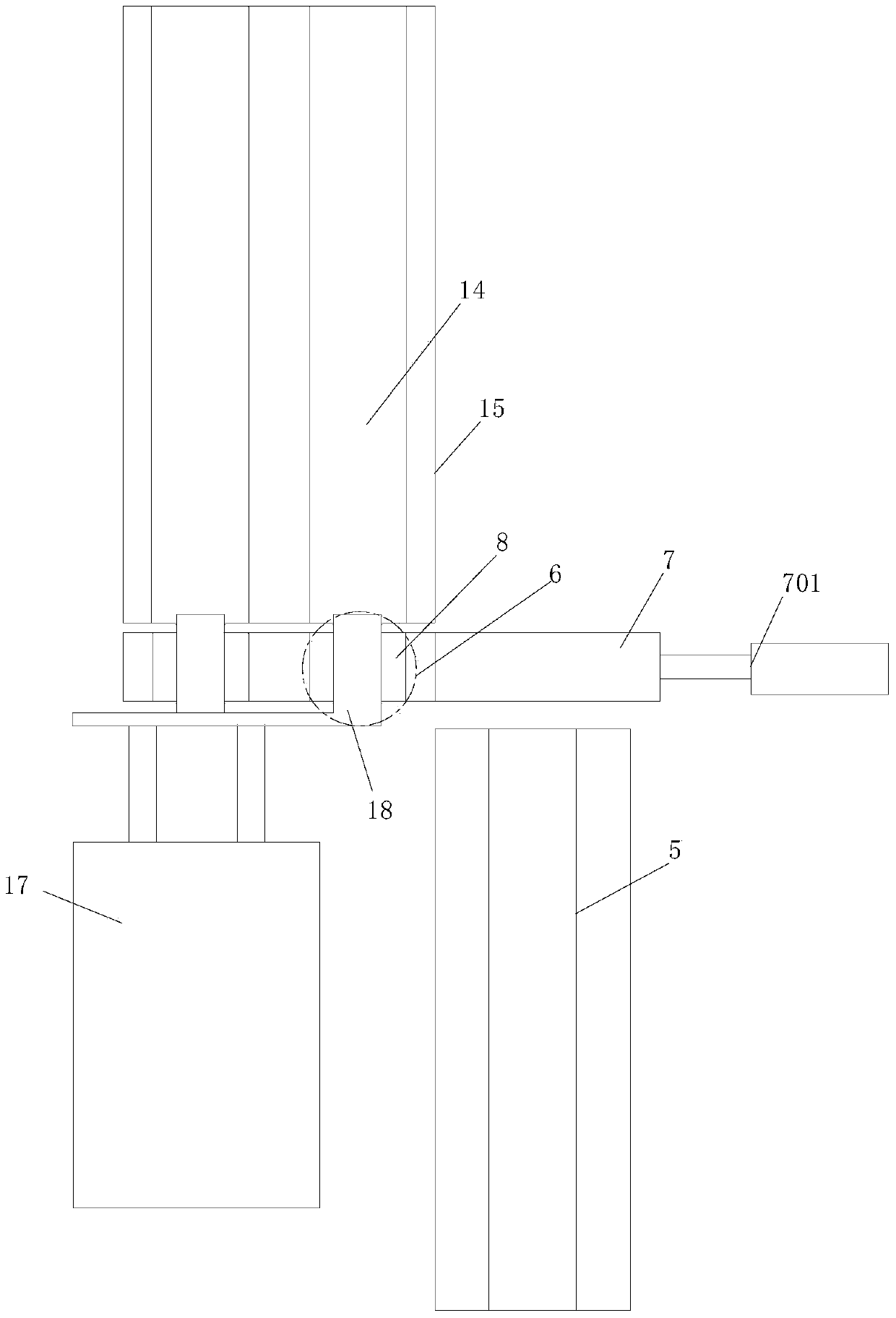

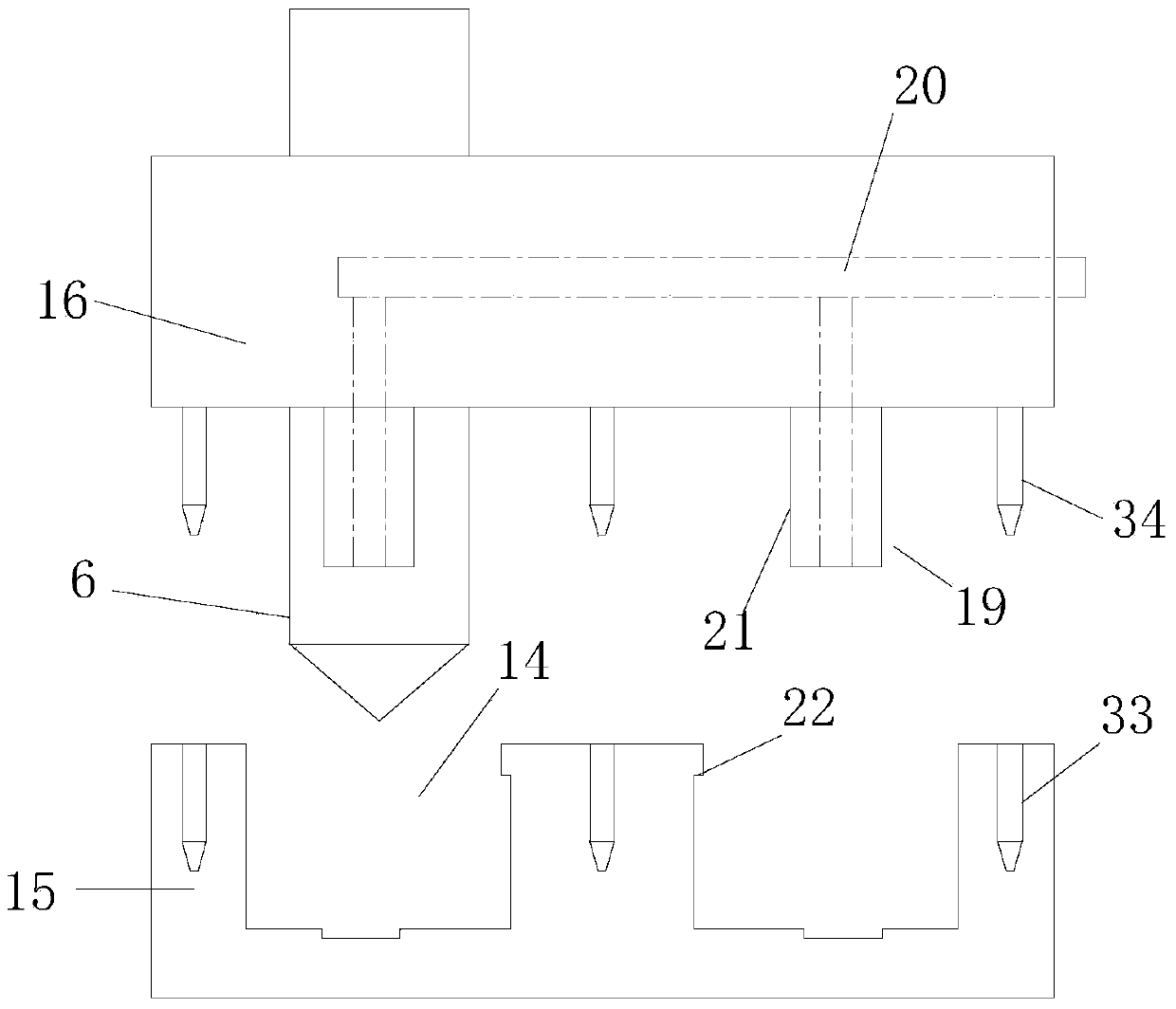

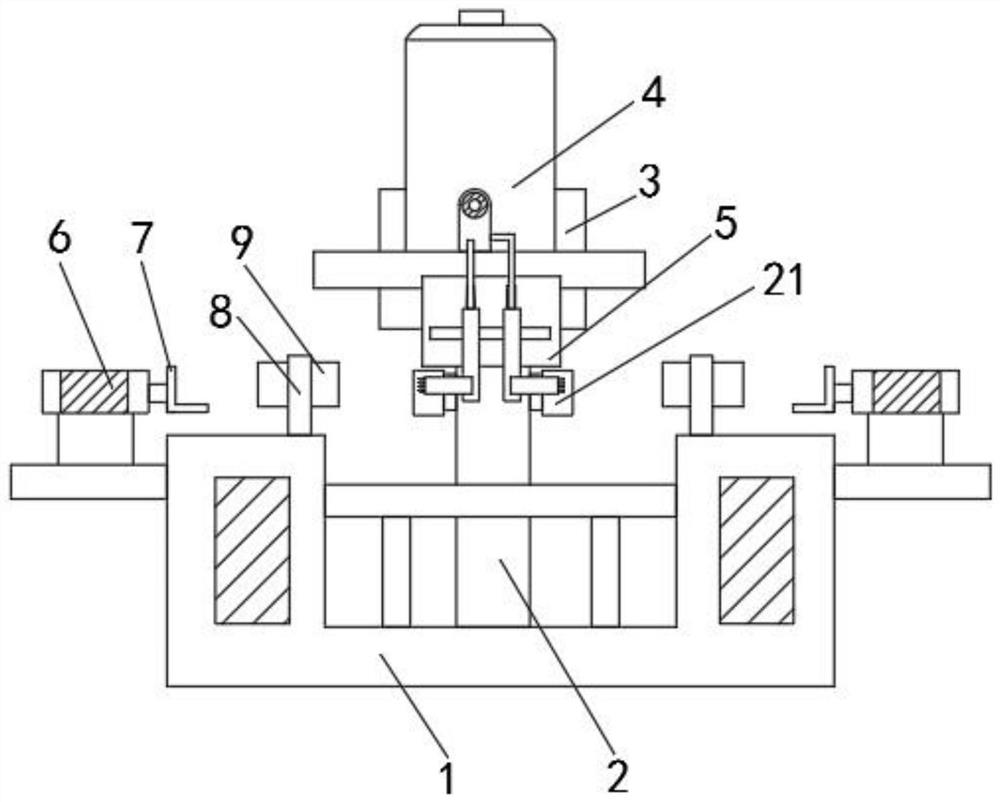

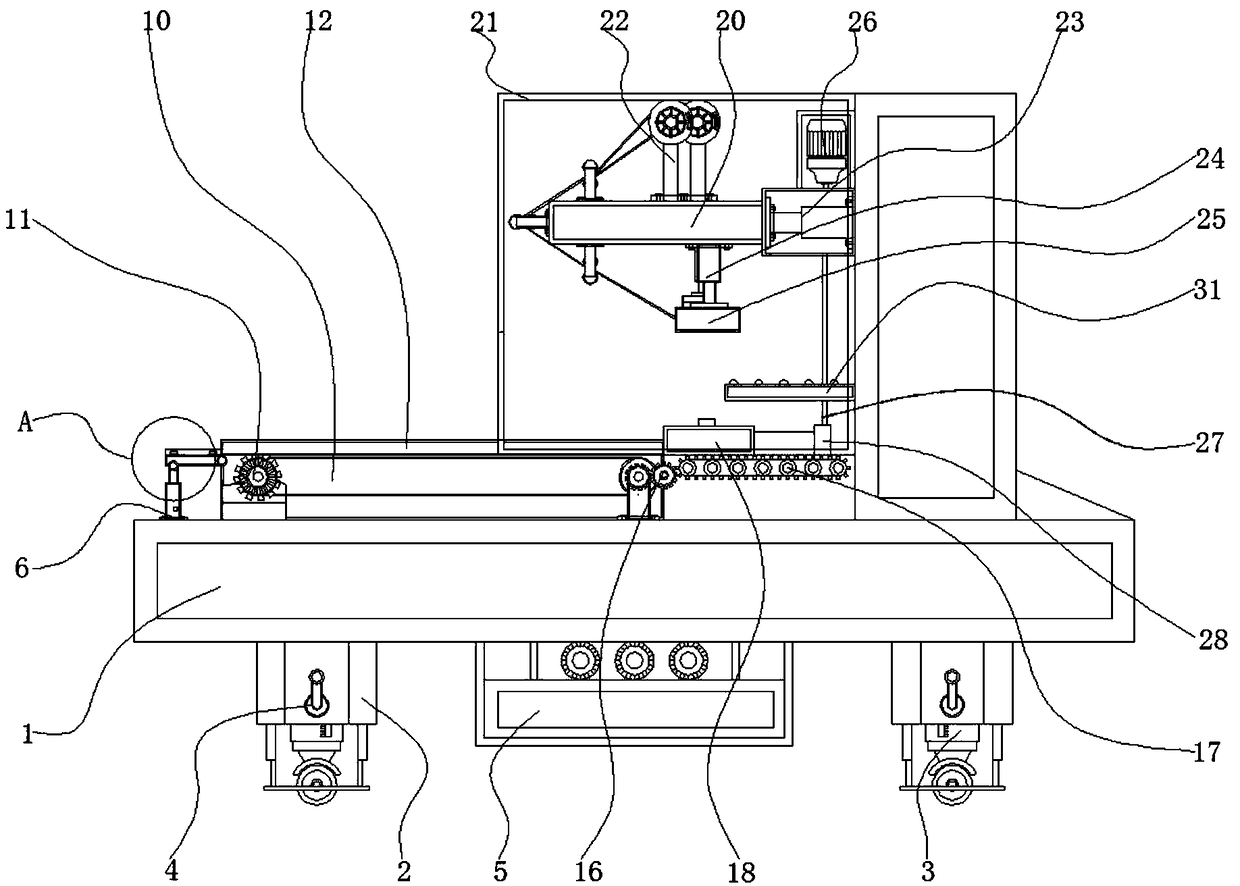

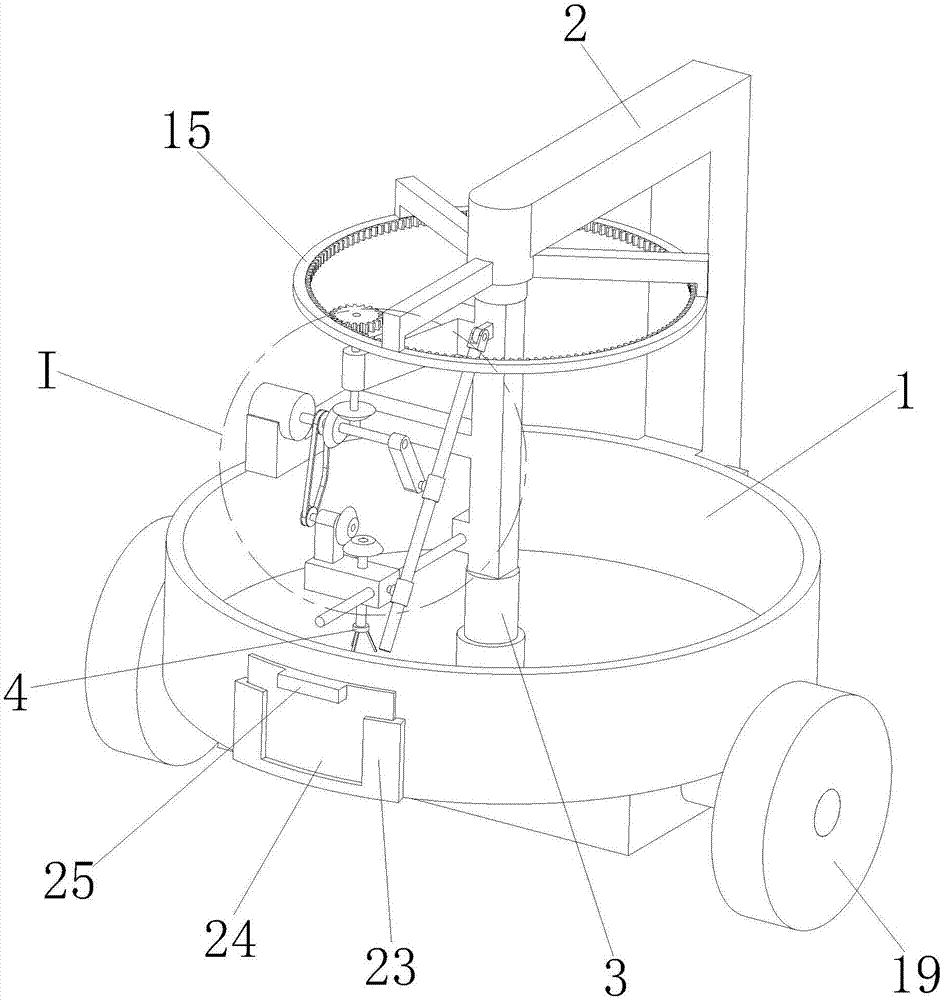

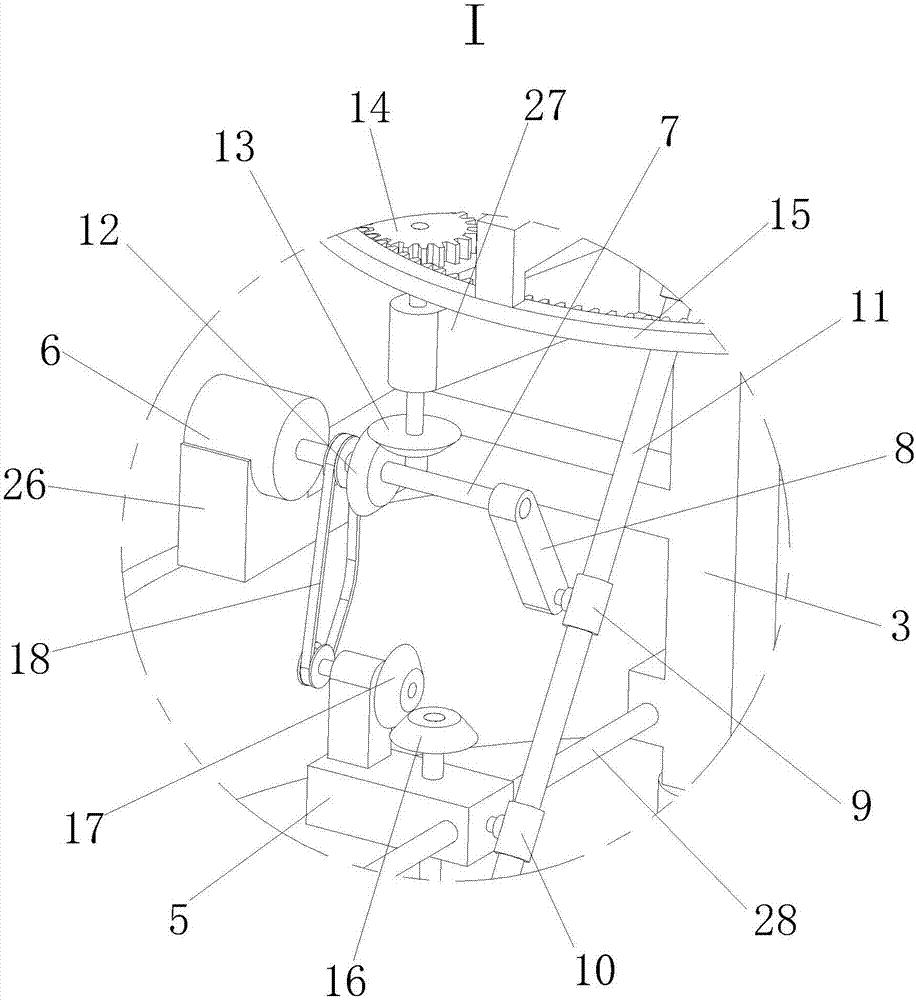

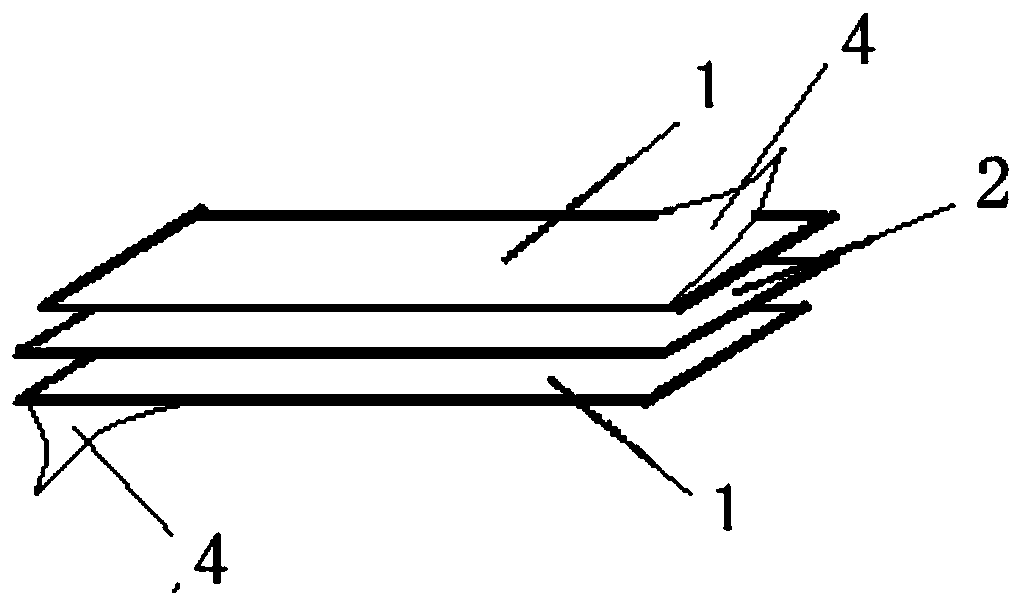

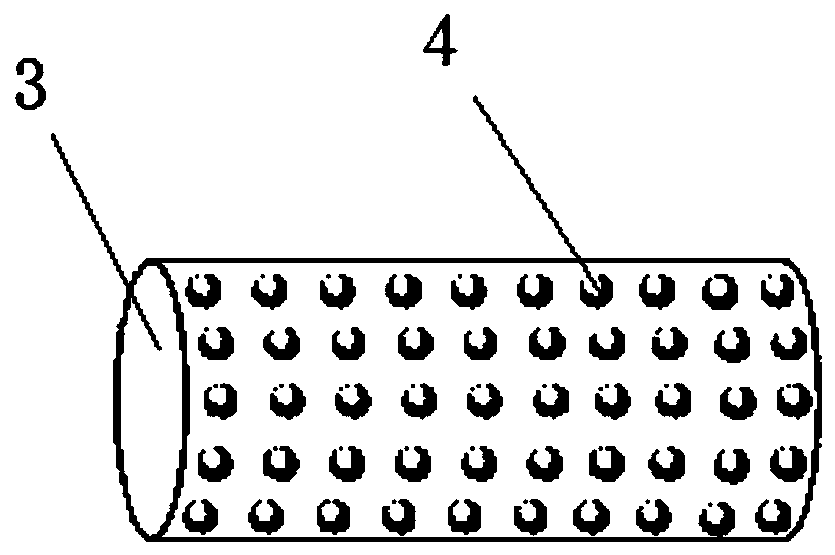

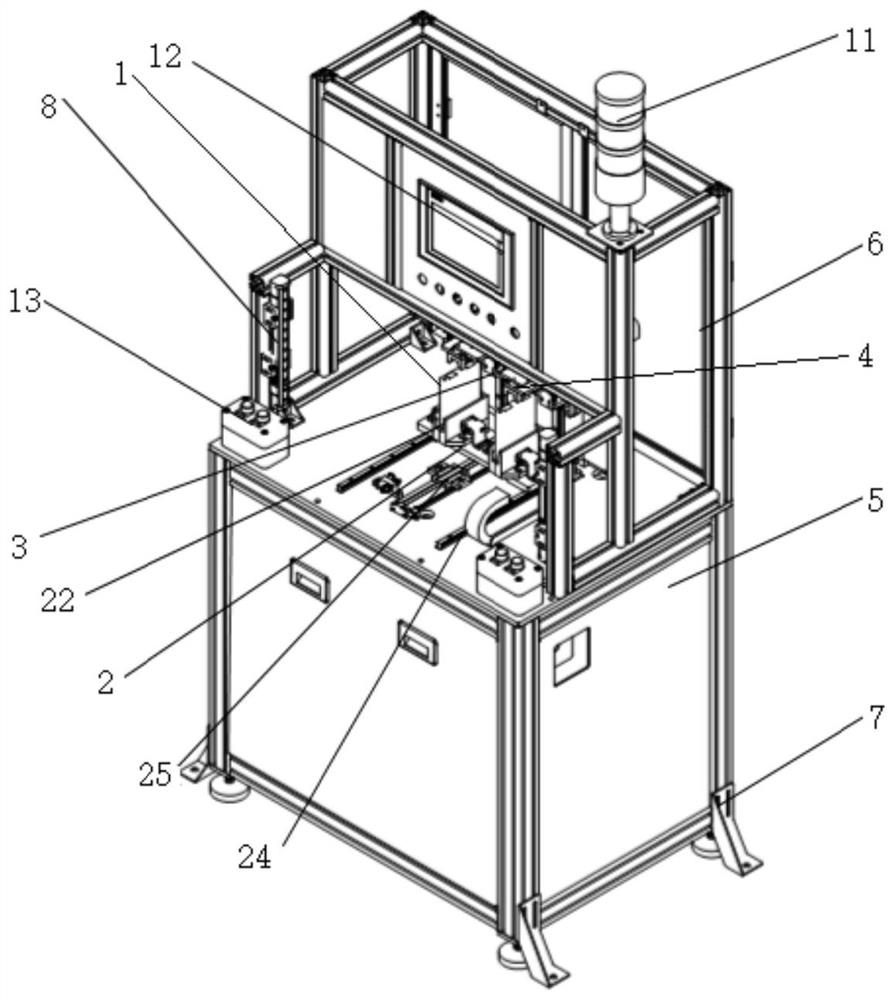

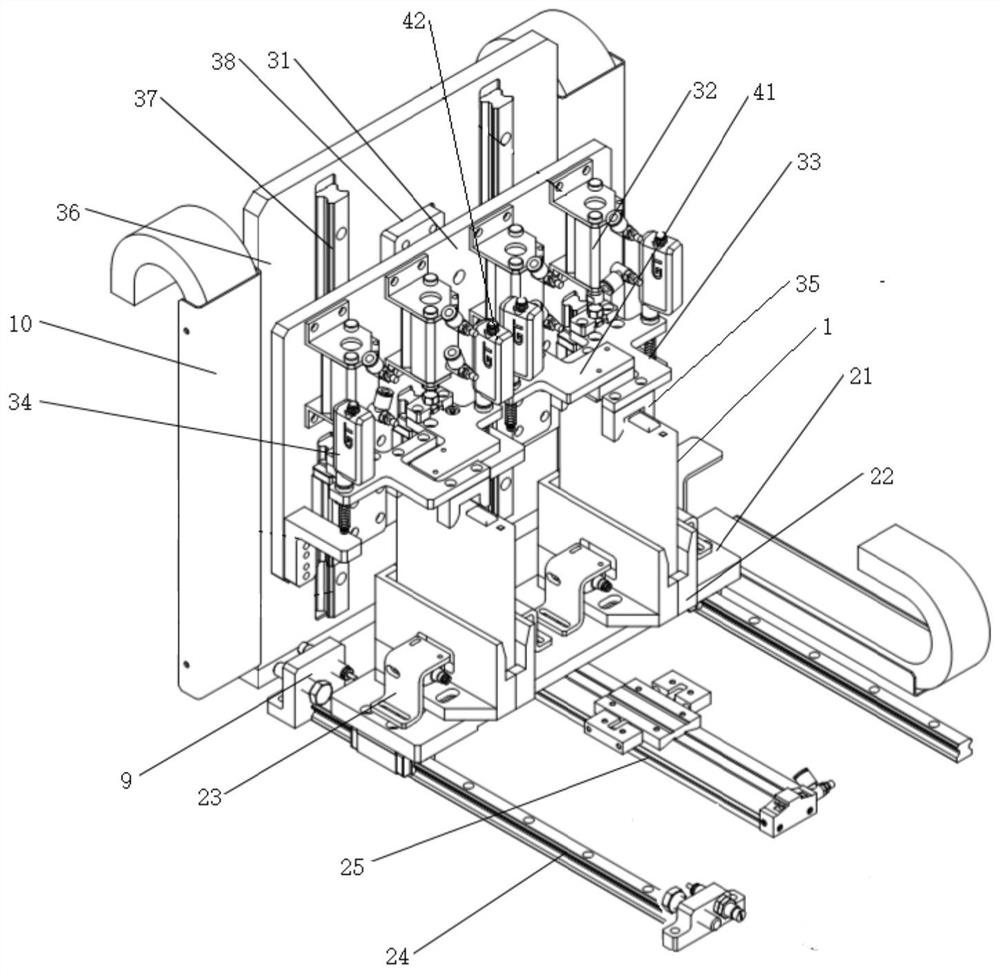

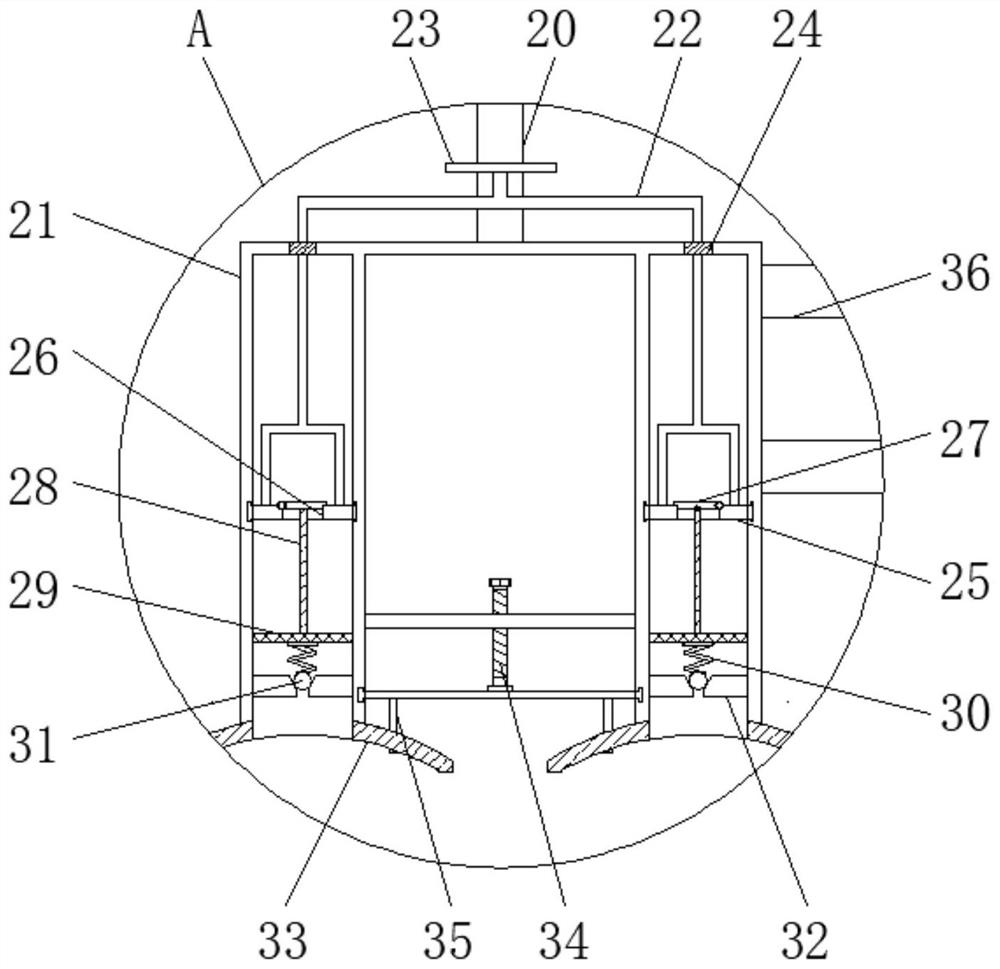

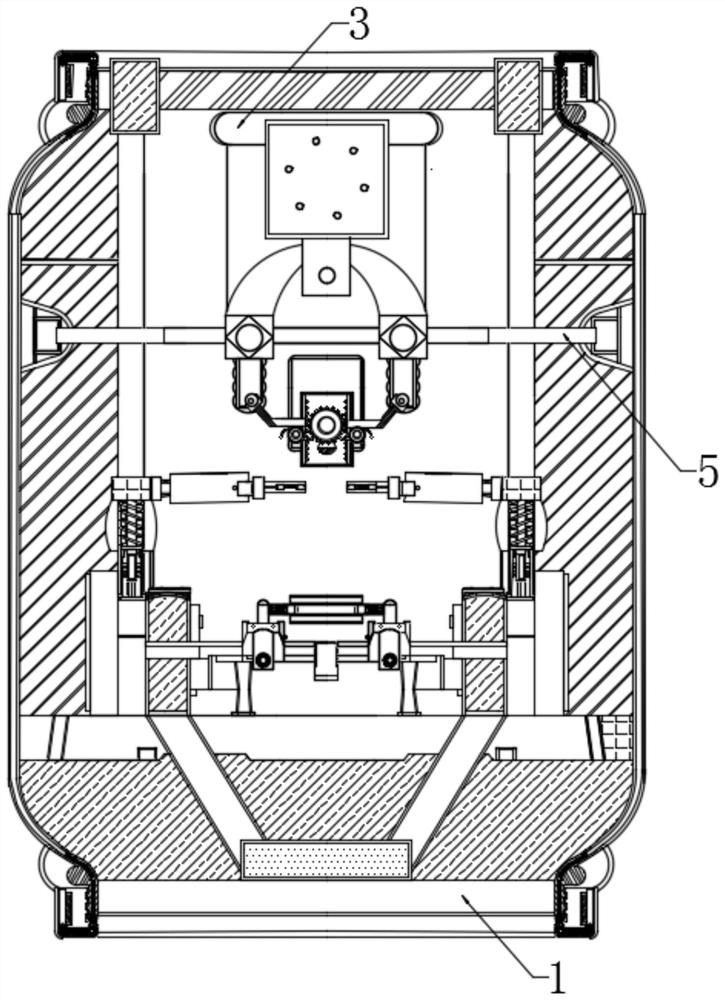

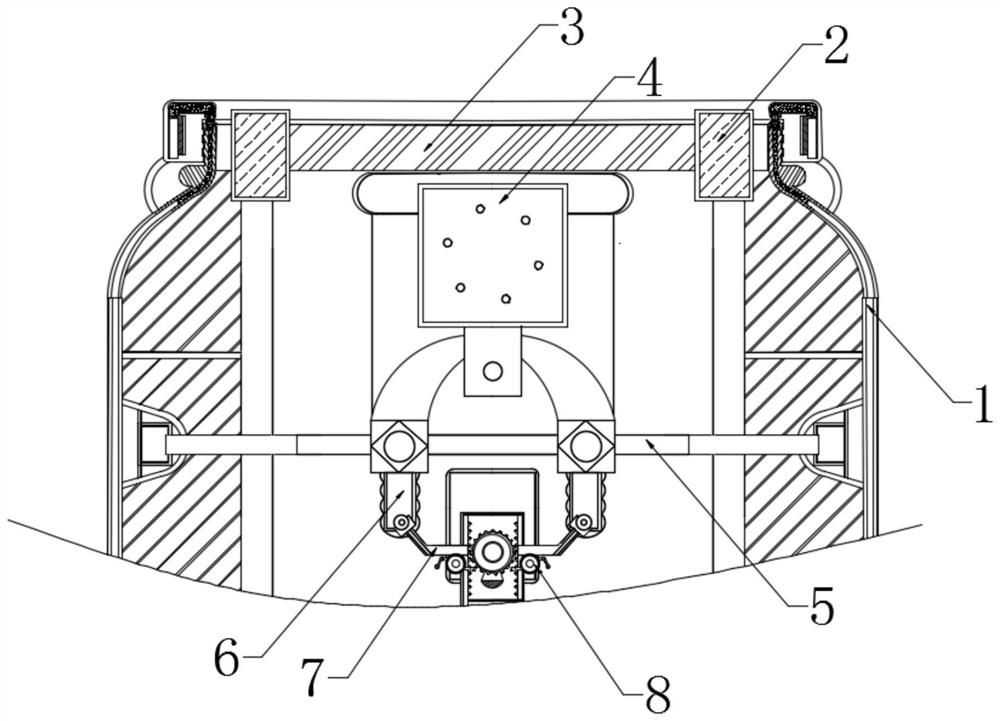

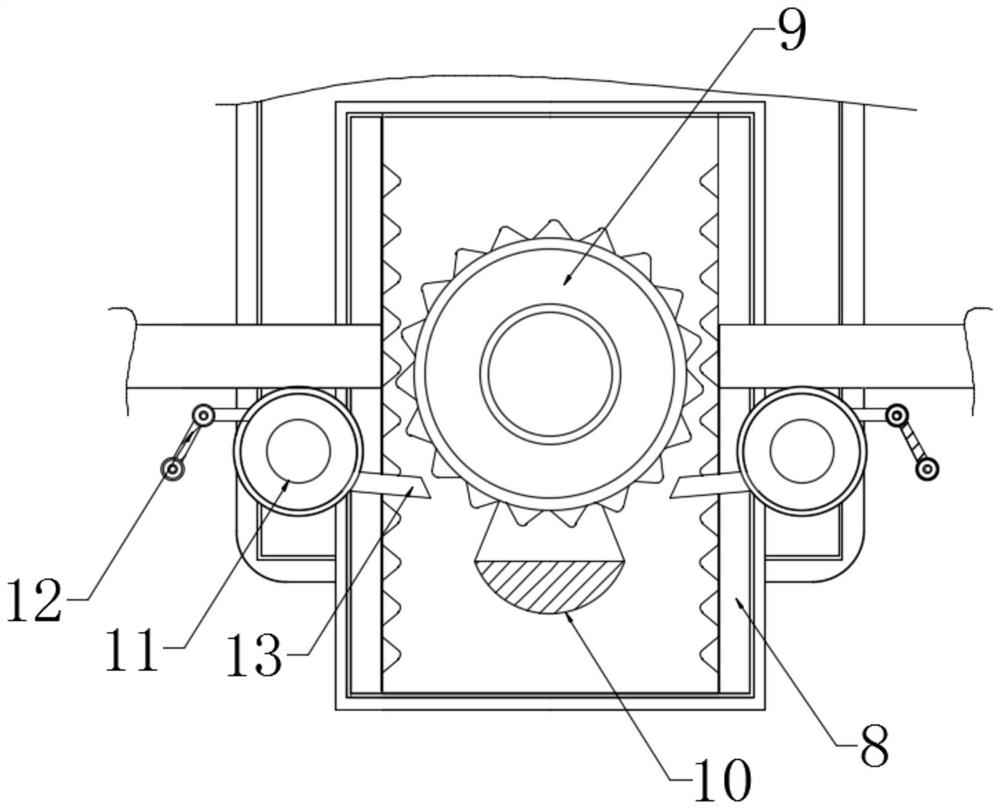

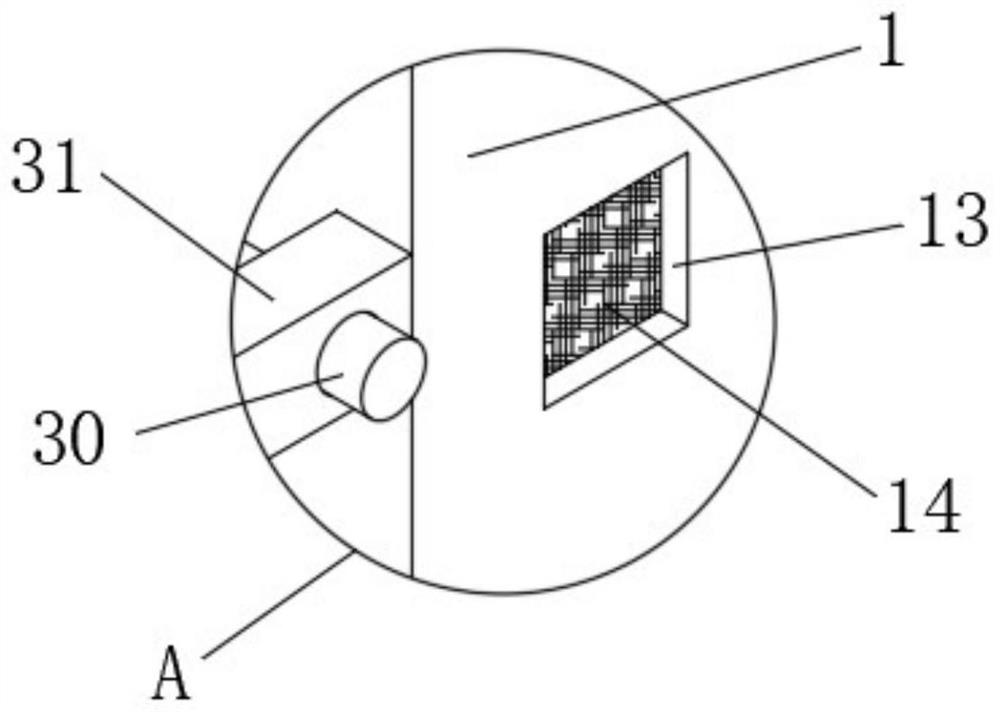

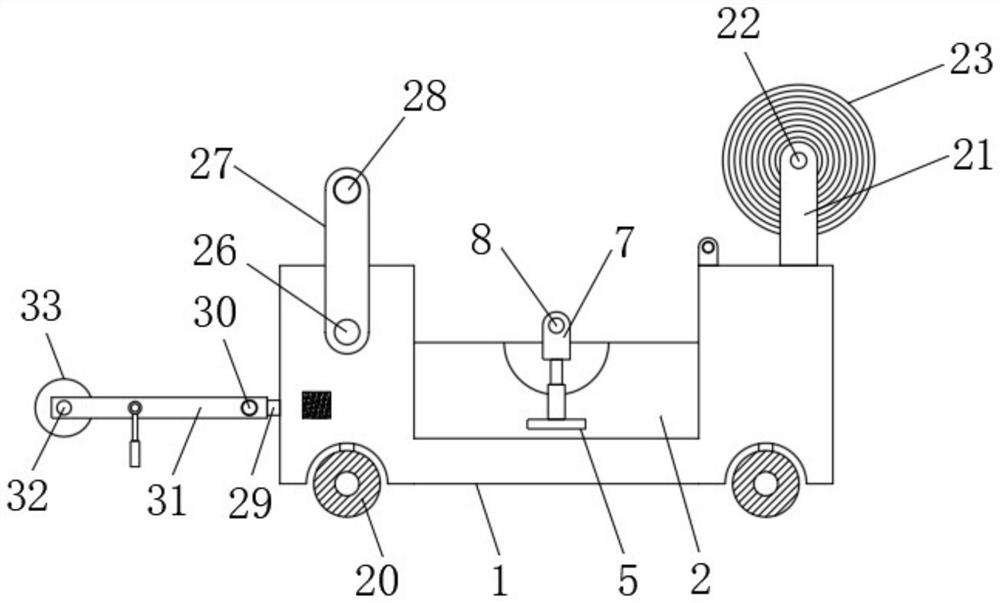

Slab forming device for multi-layer solid wood floors

InactiveCN108687920AGuarantee processing qualityAvoid weak bondsPlywood pressesVeneer pressesSolid woodPulp and paper industry

The invention discloses a slab forming device for multi-layer solid wood floors. The slab forming device comprises supporting columns, bases, a supporting frame and an air pump. The bases are arrangedat the lower ends of the supporting columns. The supporting frame is arranged on one side of one supporting column. The air pump is arranged on the supporting frame. A workbench is arranged at the upper ends of the supporting columns. A pushing plate cylinder is arranged at one end of the workbench. A pushing plate is arranged at one end of the pushing plate cylinder. A movable plate is arrangedat one end of the pushing plate. Sliding blocks are arranged under the movable plate. A guide rail is arranged under the sliding blocks. Limiting baffles are arranged at the two ends of the guide rail. Upper supports are arranged on the workbench. The slab forming device has the beneficial effects that the slab forming device is manly used for processing multi-layer solid wood floors, and gluing and hot-pressing are independently conducted between single layers, so that insecure bonding caused by integral hot-pressing is avoided, and the processing quality of the multi-layer solid wood floorsis ensured; and the slab forming device is simple in overall structure and convenient to operate.

Owner:泗阳县顺意木材制品厂

Water-resistant abrasive base paper and production method thereof

ActiveCN105297526AGood waterproof and oil-proof performanceImprove toughnessWater-repelling agents additionPaper coatingSolventPaper sheet

The invention discloses water-resistant abrasive base paper and a production method thereof. The water-resistant abrasive base paper is prepared from the following raw materials in parts by weight: 32-35 parts of softwood pulp fibers, 32-35 parts of hardwood pulp fibers, 5-10 parts of polyester fibers, 10-15 parts of modified thermoplastic resin, 3-5 parts of a water-proofing agent and 3-5 parts of an oil-proofing agent. The preparation method comprises the following steps: (1) mixing, crushing, pulping and repulping the softwood pulp fibers, the hardwood pulp fibers and the polyester fibers in parts by weight; (2) starching by a fourdrinier machine; (3) molding and drying a paper sheet on the fourdrinier machine, and carrying out gumming treatment once online, wherein the glue quantity is 10%-15%; (4) after drying the glue obtained in the step (3), carrying out secondary gumming on the front surface of the paper sheet, wherein the glue quantity is 6%-10%; and (5) calendaring the paper sheet which is gummed for the second time in the step (4) by a soft calendar. The Water-resistant abrasive paper prepared from the water-resistant abrasive base paper has the advantages of good waterproofness, softness, solvent resistance, dimension stability, high dry strength, good high temperature resistance and good weathering resistance.

Owner:SHANDONG LUNAN NEW MATERIALS

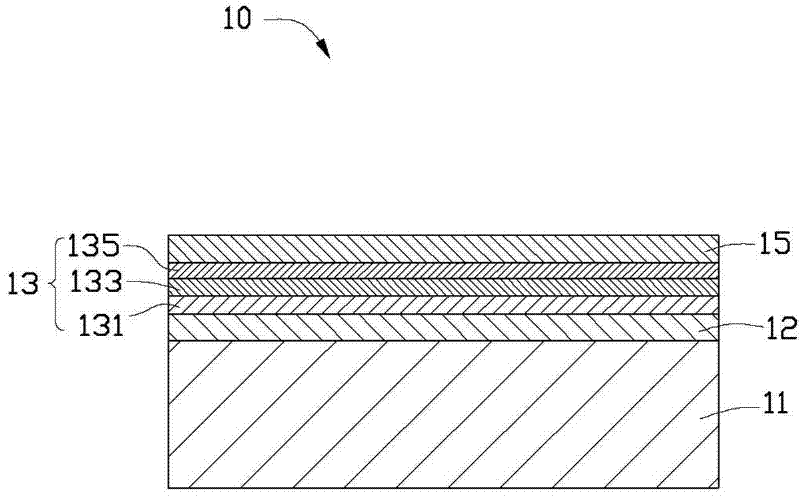

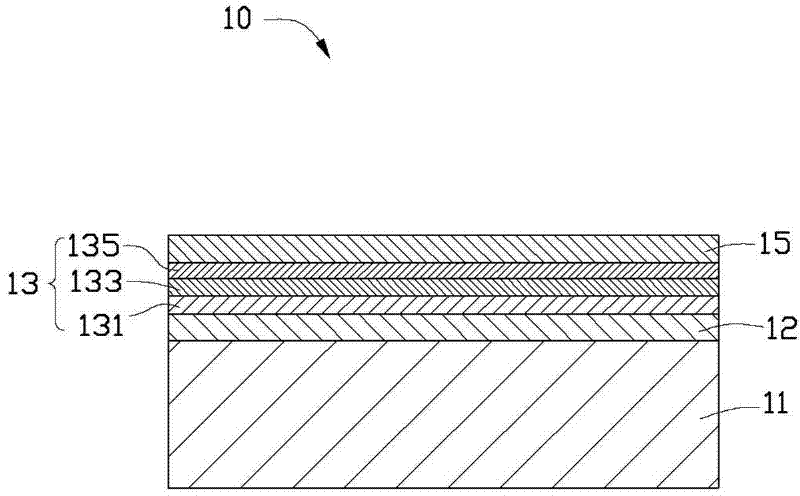

Film coating part and preparation method thereof

InactiveCN102676989AEasy transitionAvoid weak bondsVacuum evaporation coatingSputtering coatingAlloy substrateNitrogen

The invention provides a film coating part and a preparation method of the film coating part. The film coating part comprises an aluminum alloy substrate, and a gradient combination layer and a decoration layer which are formed on the surface of the aluminum alloy substrate in sequence, wherein the gradient combination layer comprises a plurality of aluminum-oxygen-nitrogen layers, the atomic percentage composition of aluminum in the aluminum-oxygen-nitrogen layers is gradually reduced from a direction close to the aluminum alloy substrate to a direction far away from the aluminum alloy substrate, the atomic percentage compositions of oxygen and nitrogen are gradually increased from a direction close to the aluminum alloy substrate to a direction far away from the aluminum alloy substrate, and the decoration layer is a nonmetallic layer. The preparation method of the film coating part comprises the following steps: providing the aluminum alloy substrate; spluttering the aluminum-oxygen-nitrogen layers on the aluminum alloy substrate by a vacuum spluttering method so as to form the gradient combination layer, spluttering the gradient combination layer by taking an aluminum target as a target material, and oxygen and nitrogen as reaction gas; and spluttering the decoration layer on the surface of the gradient combination layer by the vacuum spluttering method, and the decoration layer is the nonmetallic layer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

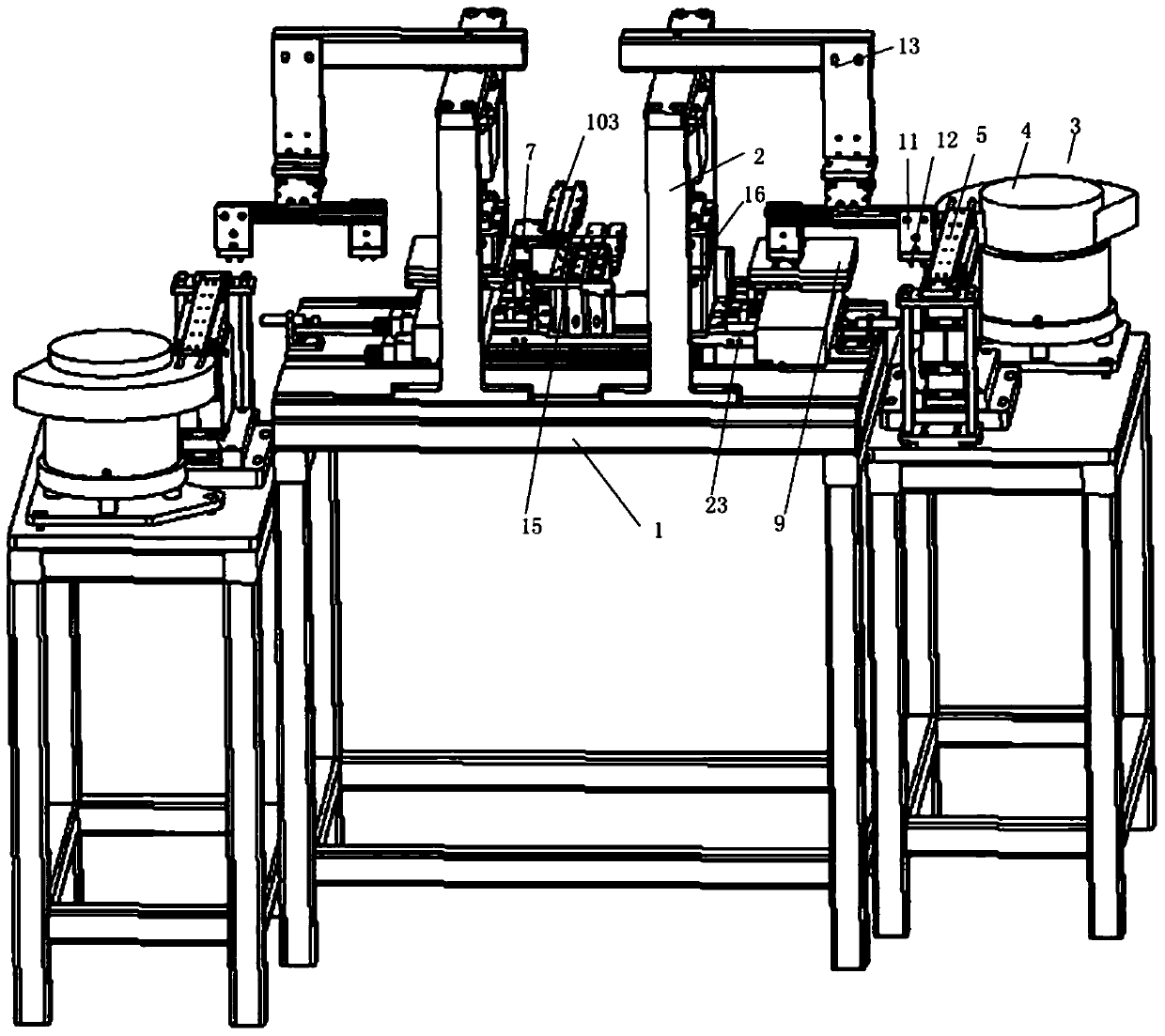

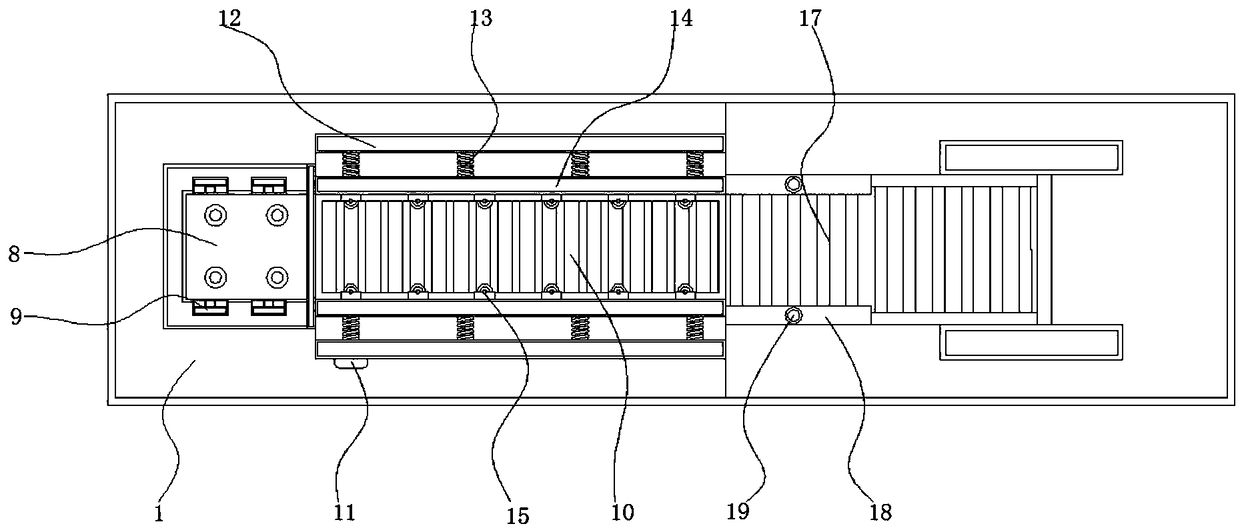

Full-automatic surface mounting machine of ultrasonic sensor

ActiveCN103742498AAuto pasteIncrease productivityFastening meansSurface mountingStructural engineering

The invention relates to a full-automatic surface mounting machine of an ultrasonic sensor. The full-automatic surface mounting machine comprises a housing, a ceramic chip vibration feeding mechanism, a dispensing machine, the feeding tail end and a mobile block; the housing is arranged on one side of a base; the dispensing machine is arranged on the base; the feeding tail end is located on a housing vibration feeding mechanism; the mobile block is arranged on the base and horizontally moves; the mobile block is provided with a limiting groove which is communicated with the feeding tail end of the housing vibration feeding mechanism; the base is provided with a bearing block; the tail end of the ceramic chip vibration feeding mechanism is provided with a rotating suction block; the base is provided with a limiting block and a pressing block; the limiting block comprises an accommodating channel and can horizontally move; the pressing block is located above the limiting block and can move up and down to be matched with the limiting block; one side of the mobile block is provided with a pushing mechanism which is used for pushing housings arranged in the limiting groove into the accommodating channel; the pressing block is provided with the adsorption end which is used for adsorbing and pressing ceramic chips located in the accommodating channel to the housings arranged in the accommodating housing. According to the full-automatic surface mounting machine of the ultrasonic sensor, vibration conveying is performed on the housings and the ceramic chips automatically, the housings and the ceramic chips are conveyed to the specified position, the ceramic chips are adsorbed to the housings through respective adsorption, and the pressure is maintained to enable the ceramic chips and the housings to be pressed together firmly.

Owner:BESTAR HLDG +1

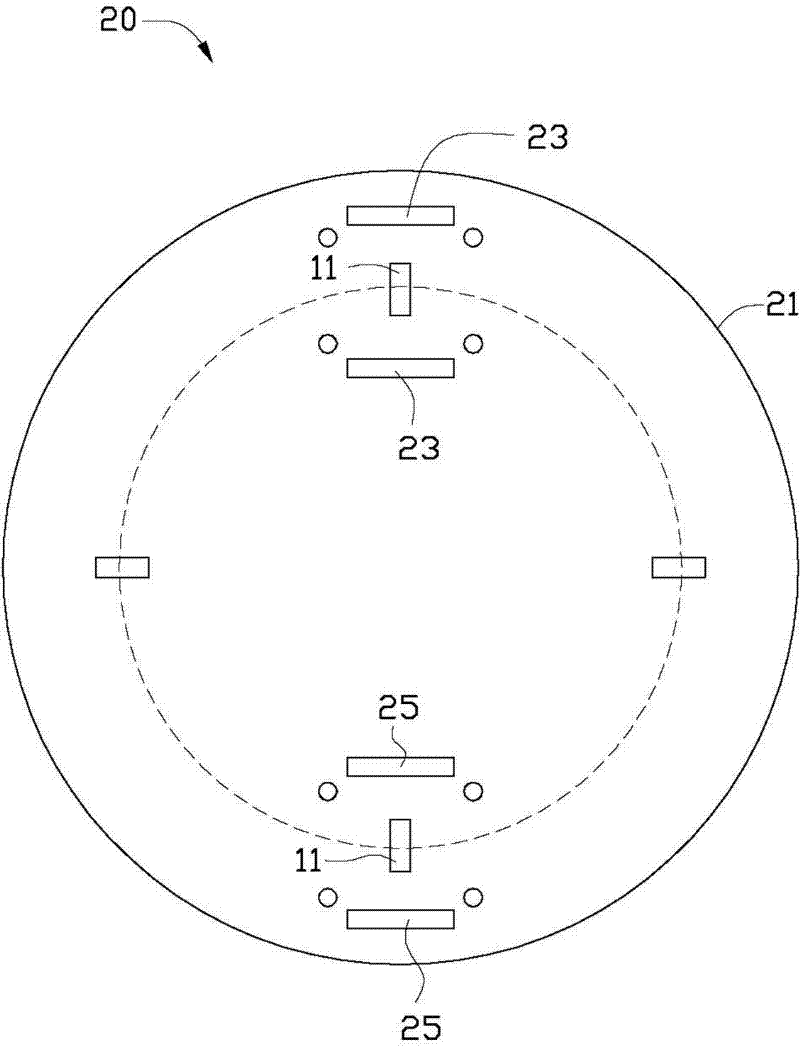

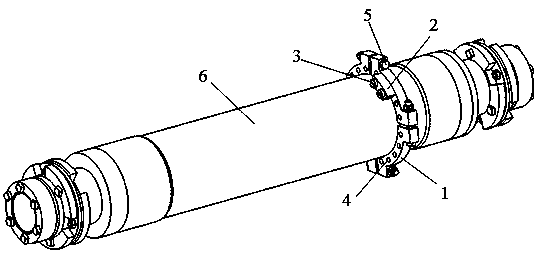

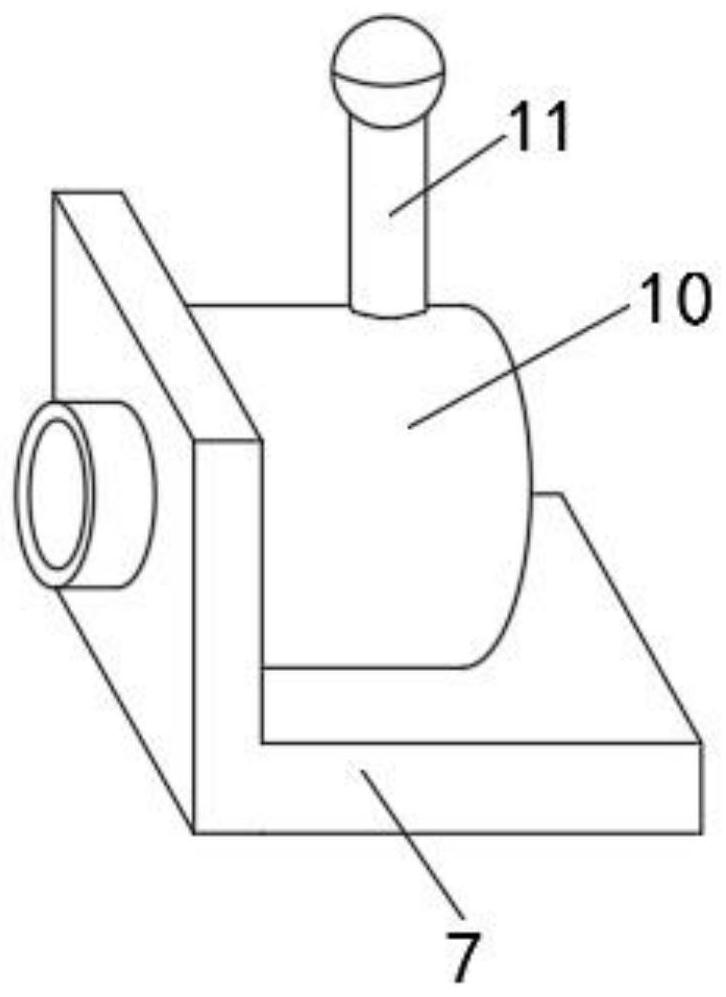

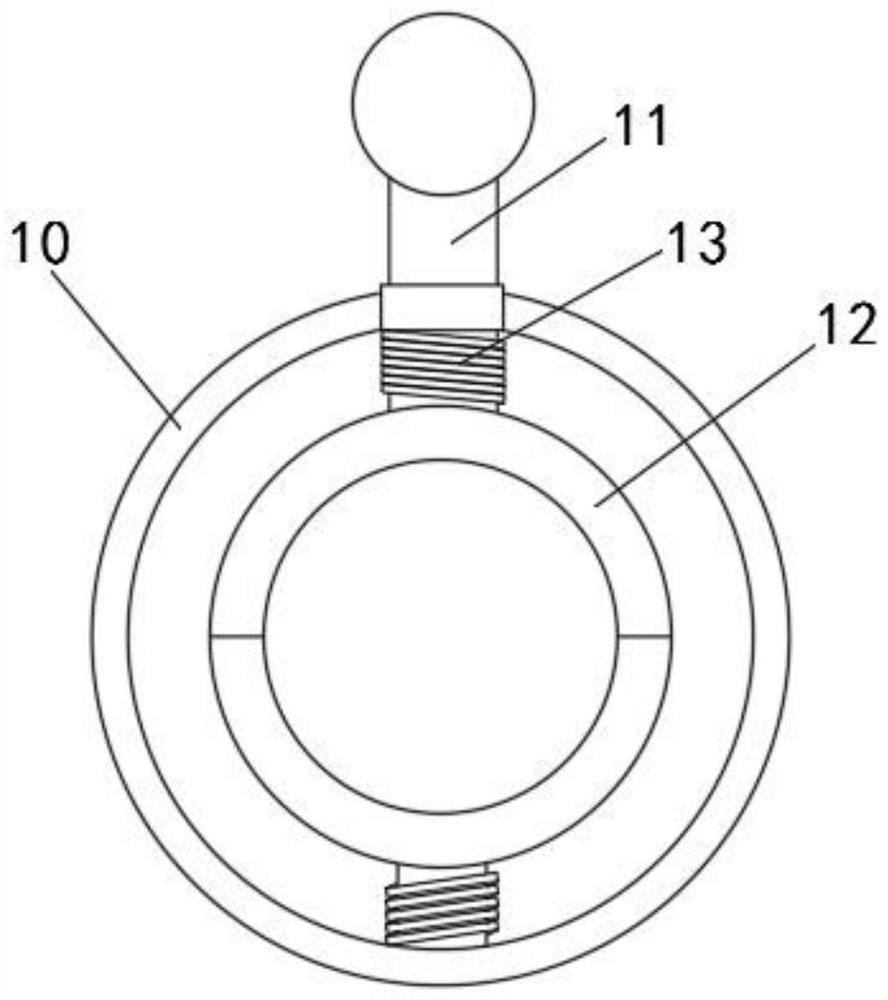

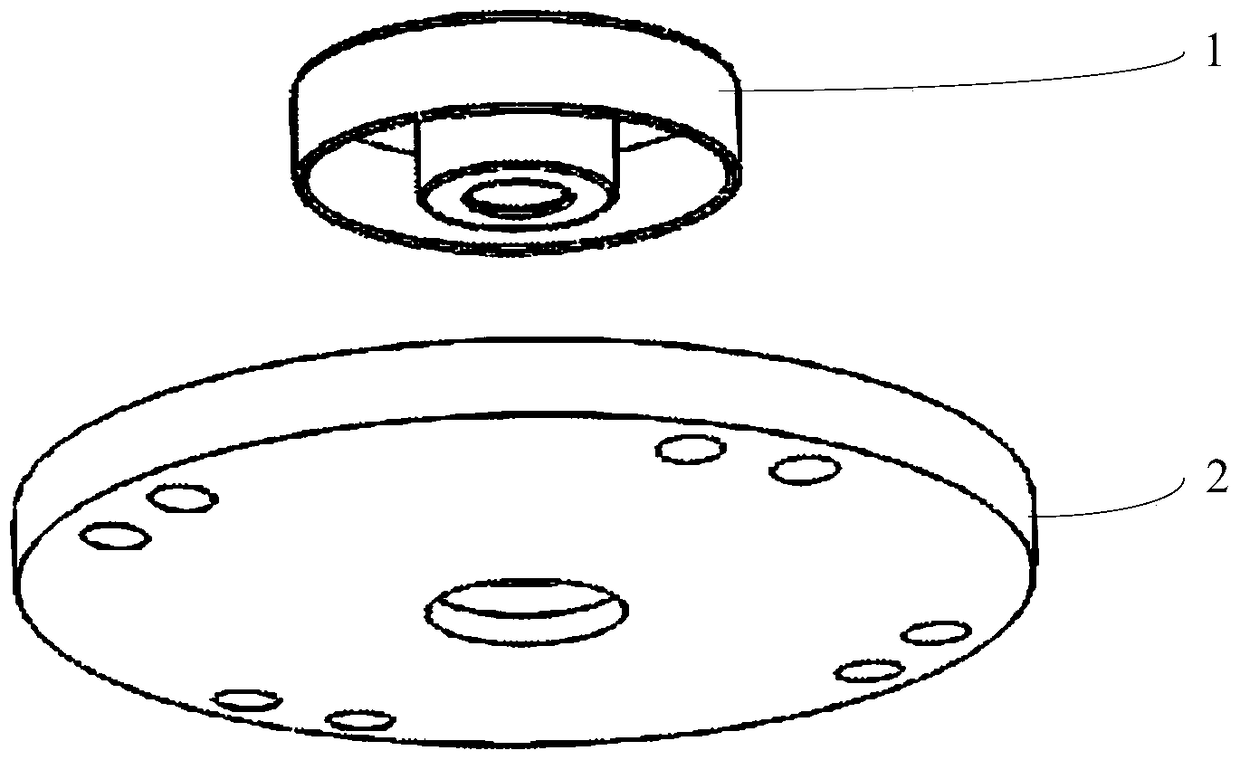

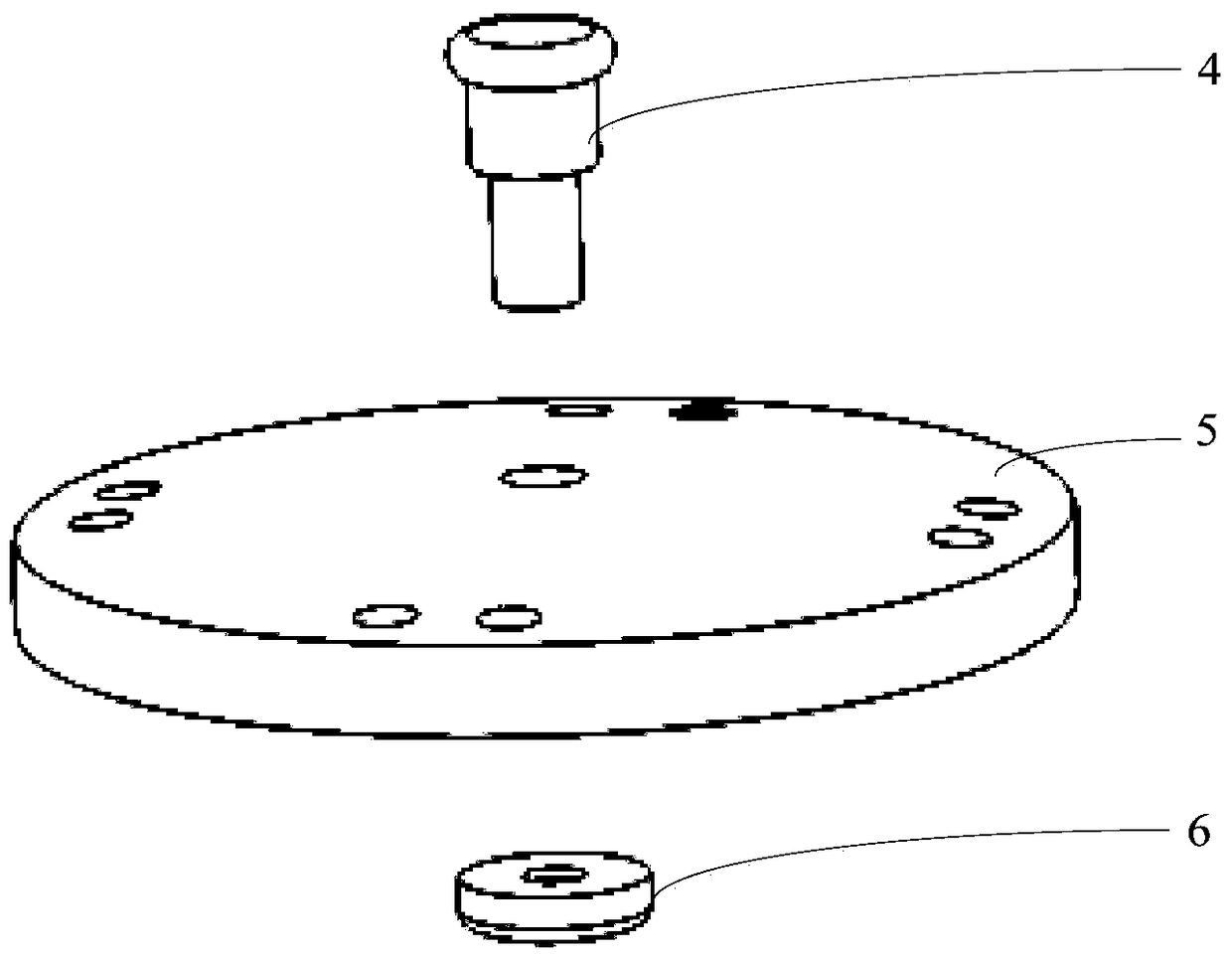

Dynamic balance process method of carbon fiber composite transmission shaft tube and combined dynamic balance clamping hoop

InactiveCN110206851ASimple manufacturing processAvoid weak bondingVibration dampersSpringsCarbon fiber compositeFibrous composites

The invention discloses a process method for achieving dynamic balance of a carbon fiber composite transmission shaft and a used combined dynamic balance clamping hoop device. The dynamic balance device comprises a clamping hoop, bolts, nuts, spring gaskets, balancing weights and balancing weight set screws. The clamping hoop is composed of four quarter round clamping hoop bodies which are connected through the bolts, the nuts and the spring gaskets. The integrated round clamping hoop is formed on a carbon fiber composite tube in the circumferential direction. Threaded holes used for fixing the balancing weights are uniformly distributed in the circumference of the round clamping hoop. The device is simple in structure, the carbon fiber composite transmission shaft can be dynamically balanced by adopting a weight increment method or a weight decrement method by means of the process method, in addition, operation is convenient when the axial and circumferential positions of the balancing weights are adjusted, drilling weight-decrement is not needed in the carbon fiber composite transmission shaft, the balancing weights do not need to be bonded to the shaft, and dynamic balance of the carbon fiber composite shaft tube can be easily and effectively achieved.

Owner:WUHAN UNIV OF TECH

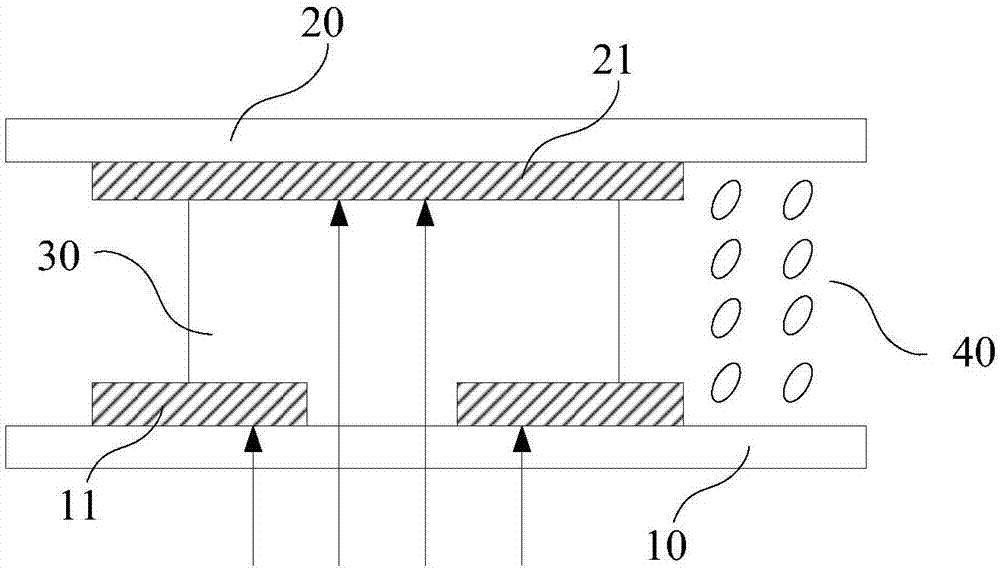

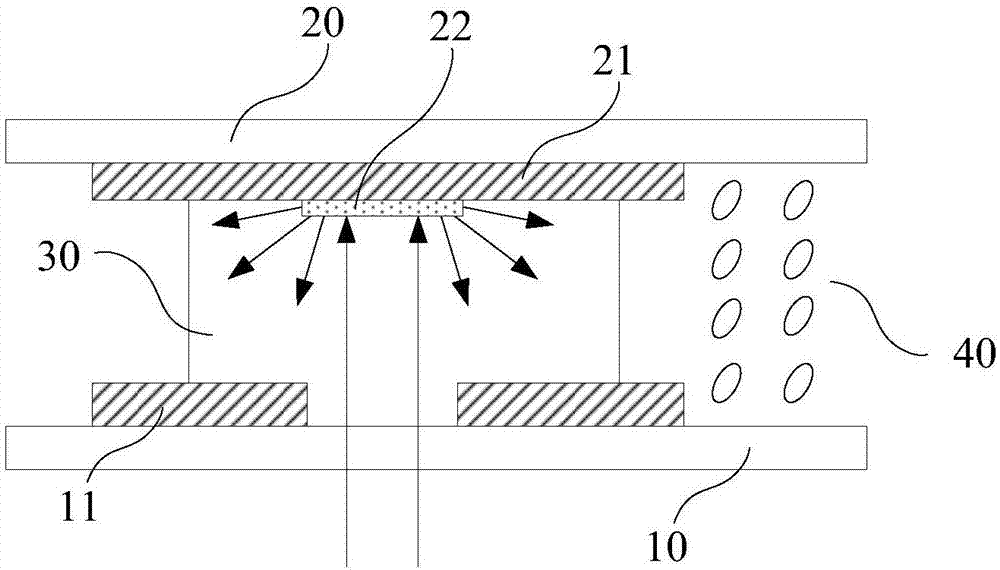

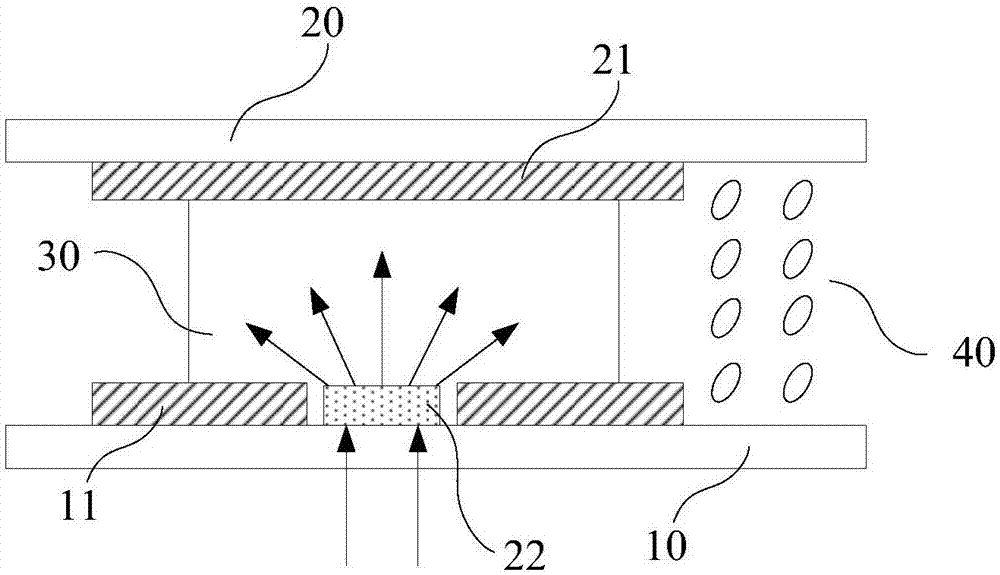

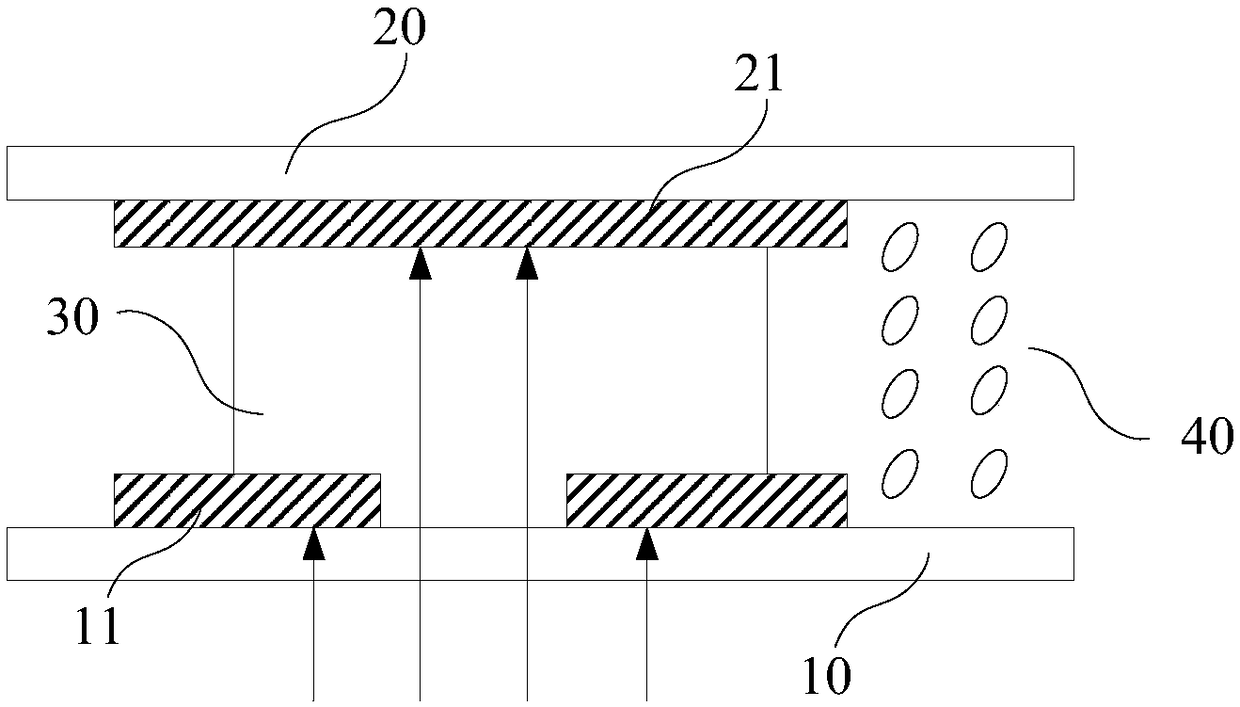

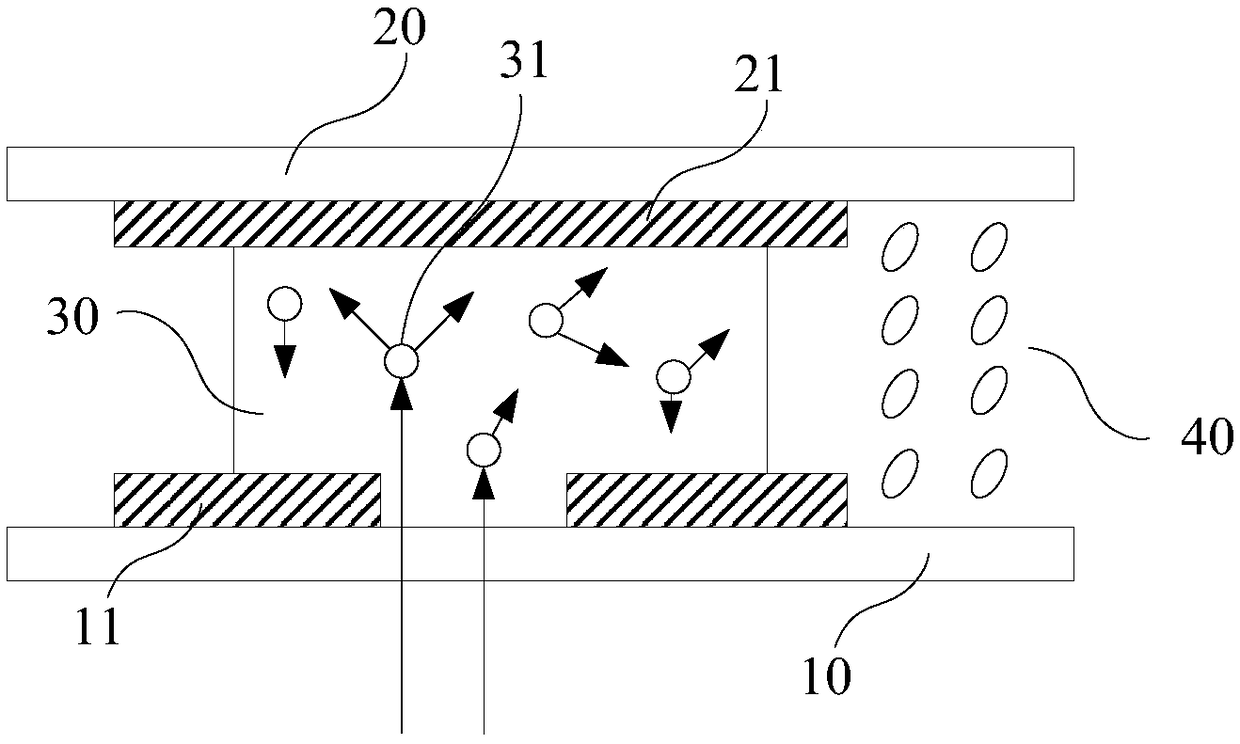

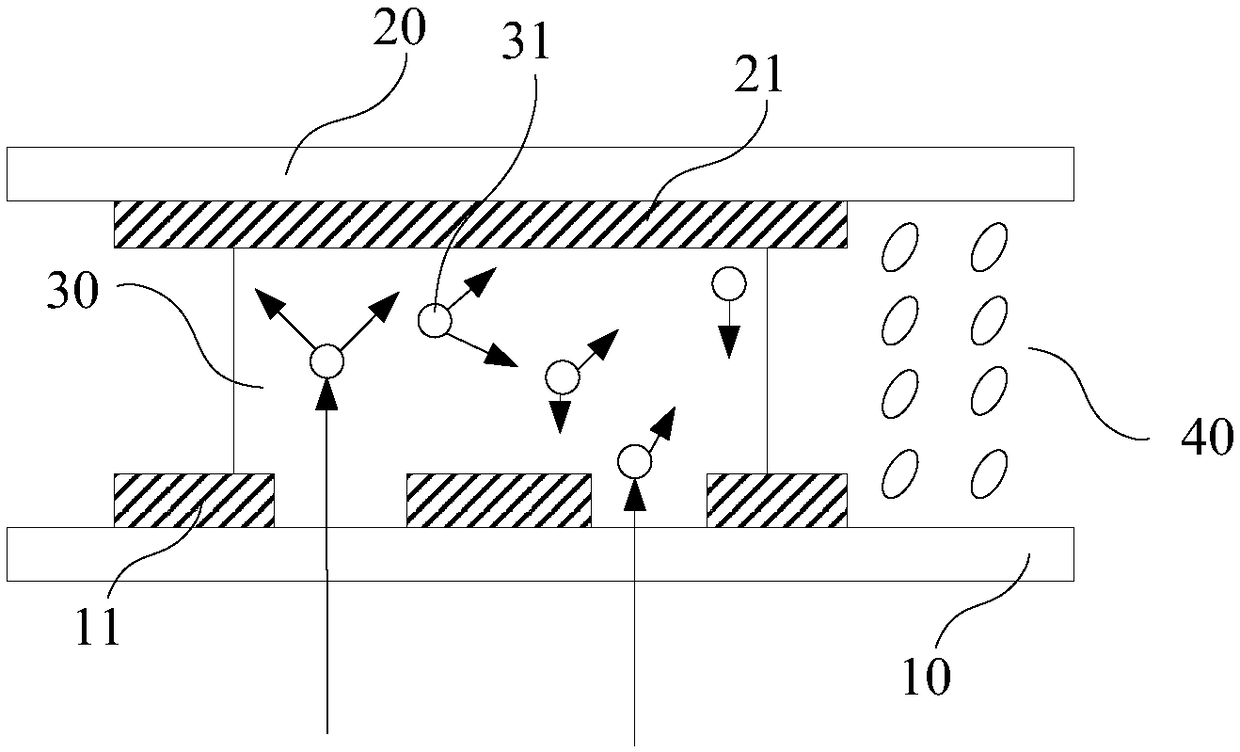

Liquid crystal display panel and production method thereof as well as liquid crystal display device

InactiveCN107991813AGuaranteed connectionAvoid weak bondsNon-linear opticsLiquid-crystal displayLiquid crystal

The invention discloses a liquid crystal display panel and a production method thereof as well as a liquid crystal display device. The liquid crystal display panel comprises an array substrate, a colored film substrate, a frame adhesive for connecting the array substrate and the colored film substrate, and a liquid crystal between the array substrate and the colored film substrate, wherein photoluminescence substances are arranged at positions, corresponding o the frame adhesive, of the array substrate and / or the colored film substrate; the photoluminescence substances are used for sending outsecond light under the stimulation of first light; the second light is used for curing the frame adhesive; at least part of the photoluminescence substances are arranged on a light path of the firstlight. With the adoption of the manner, the problems of an existing display panel that that the light is shielded when the frame adhesive is cured and the frame adhesive cannot be completely irradiated so that the frame adhesive is not completely cured can be solved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

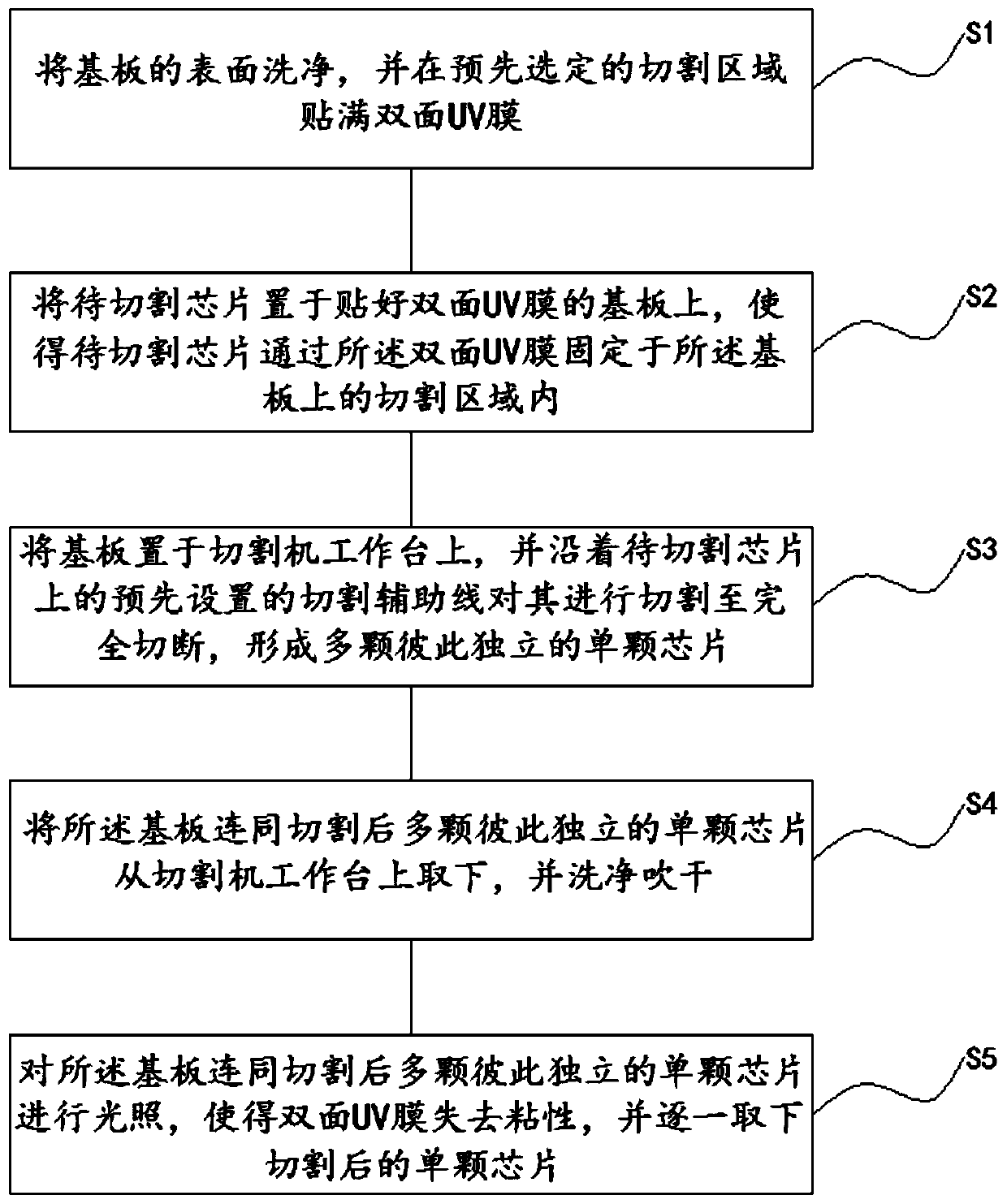

Efficient chip cutting method

ActiveCN110648908AShort cycleGuaranteed cutting accuracySemiconductor/solid-state device manufacturingSingle chipMechanical engineering

The invention relates to an efficient chip cutting method, which comprises the following steps: cleaning the surface of a substrate, and fully pasting a double-sided UV film onto a cutting area; placing a to-be-cut chip on the substrate and fixing the to-be-cut chip in the cutting area through the double-sided UV film; placing the substrate on a workbench of a cutting machine, and cutting the to-be-cut chip along a cutting auxiliary line on the to-be-cut chip until the to-be-cut chip is completely cut off; taking the substrate down from the workbench of the cutting machine, and cleaning and blow-drying the substrate; illuminating the substrate to make the double-sided UV film lose viscosity, and taking down single chips after cutting one by one. Because the double-sided UV film is arrangedon the substrate, the to-be-cut chip can be fixed on the substrate, and it is ensured that the position of the chip is relatively fixed during cutting. After cutting is completed, the double-sided UVfilm loses viscosity through illumination, and single chips are directly taken down and do not need to be cleaned through a chemical solvent. Therefore, the period of the cutting process is shortened, the cutting efficiency is improved, and the cutting precision and the cutting quality can be guaranteed.

Owner:WUHAN YILUT TECH CO LTD

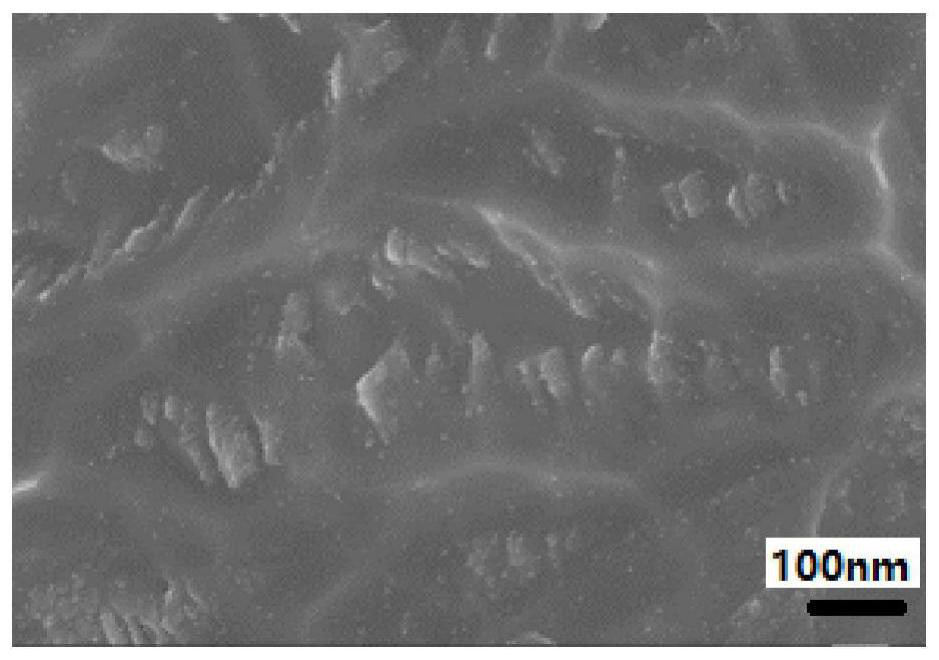

Metal material with modified surface and preparation method and application thereof

ActiveCN112111733AGood biocompatibilitySpecial light absorption propertiesMaterial nanotechnologyPharmaceutical delivery mechanismMetallic materialsBiocompatibility

The invention relates to a metal material with the modified surface and a preparation method and application thereof. The metal material with the modified surface comprises a metal material matrix andan oxidation film which is formed on the surface of the matrix in an in-situ manner and provided with a nanometer topological structure. According to the preparation method of the metal material, themetal material and an acid solution are mixed and then subjected to a hydrothermal reaction, and thus the metal oxidation film provided with the nanometer topological structure is formed on the surface of the metal material in an in-situ manner. By means of formation of the oxidation film, biocompatibility of the material can be improved remarkably, and the material has a good tissue growth induction ability and good antibacterial performance. The oxidation film is formed on the metal matrix in an in-situ manner, an obvious interface between the oxidation film and the matrix material is avoided, the risk that the oxidation film falls off from the matrix is reduced greatly, bonding strength between a decorating layer and a substrate material is ensured, and the application range of the metal material is enlarged.

Owner:SHENZHEN INST OF ADVANCED TECH

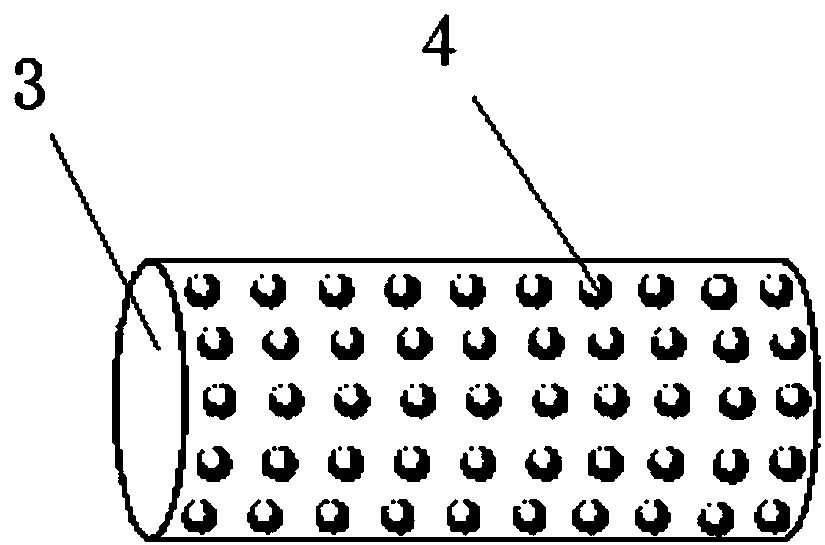

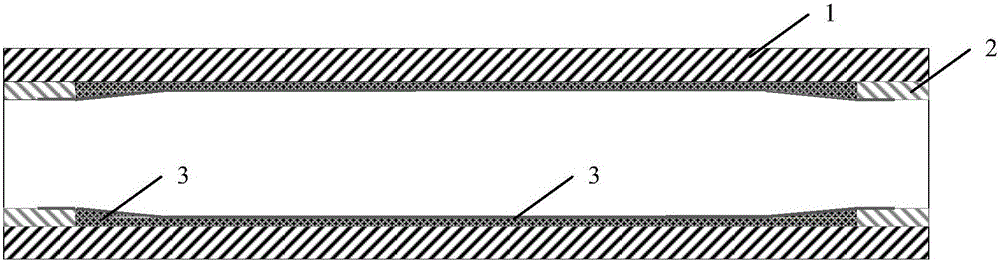

Corrosion-resistance composite pipe and manufacturing method thereof

InactiveCN105927822AExtended service lifeReduce gapPretreated surfacesCorrosion preventionHot TemperatureMetal

The invention relates to a corrosion-resistance composite pipe and a manufacturing method thereof and belongs to the technical field of pipeline connection. The corrosion-resistance composite pipe comprises a pipe material base body and a lining corrosion-resistance layer arranged on the inner wall of the pipe material base body. The lining corrosion-resistance layer comprises metal corrosion-resistance layers arranged on the inner walls of the two ends of the pipe material base body and a non-metal corrosion-resistance layer arranged between the metal corrosion-resistance layers. By means of the corrosion-resistance composite pipe, the lining corrosion-resistance layer composed of the metal corrosion-resistance layers and the non-metal corrosion-resistance layer is arranged on the inner wall of the steel pipe base body, high-temperature heating is not needed in the manufacturing process of the lining corrosion-resistance layer, the phenomena that the steel pipe base body expands due to heating, and a gap exists between the lining corrosion-resistance layer and the steel pipe base body due to or contraction are avoided, corrosion at the combined position of the lining corrosion-resistance layer and the steel pipe base body is relieved, and the service life of the composite pipe is prolonged.

Owner:中石化河南油建工程有限公司

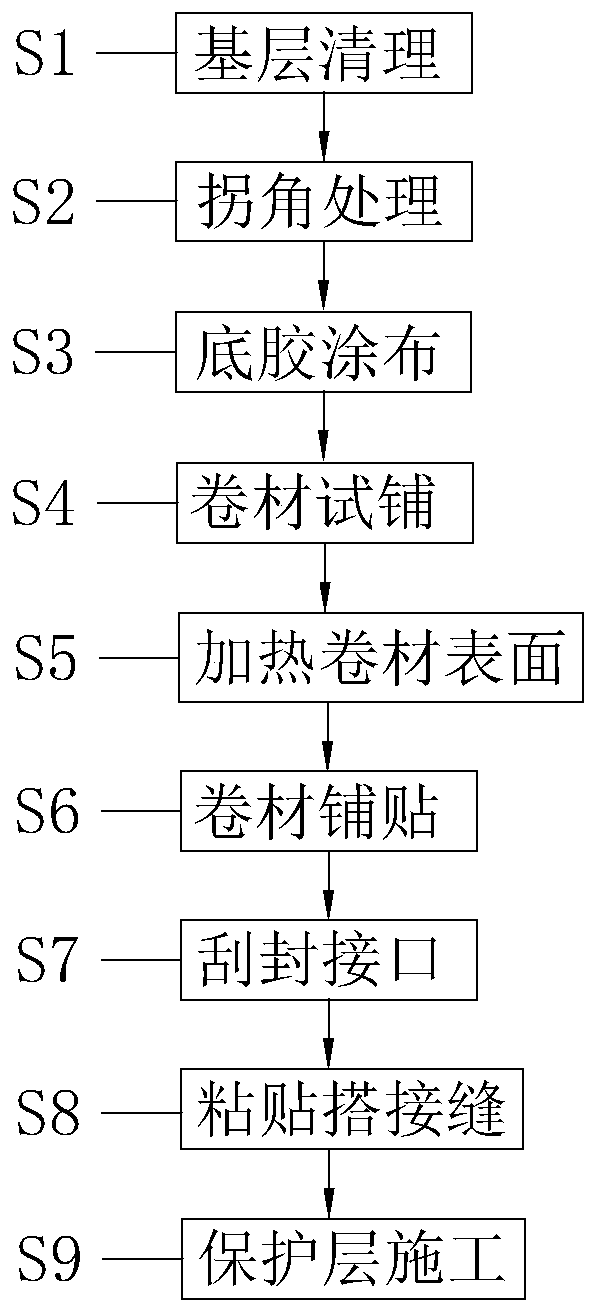

Waterproof construction process for basement

InactiveCN111535368AImprove waterproof effectAvoid weak bondsProtective foundationMechanical engineeringCement mortar

The invention discloses a waterproof construction process for a basement, and relates to the field of building construction. The waterproof construction process for the basement comprises the following steps of S1, cleaning a base layer; S2, performing corner treatment; S3, conducting primer coating; S4, trial laying of a coiled material; S5, heating the surface of the coiled material; S6, pavingand pasting the coiled material; S7, scraping and sealing an interface; S8, pasting lap seams; and S9, constructing a protective layer. The waterproof construction process for the basement has the following advantages that cement mortar is made into a circular arc or a 135-degree break angle at the corner position, so that the waterproof coiled material can be flatly attached to the surface of thebase layer, the phenomena of hollowing and wrinkling are avoided, perfect sealing of all positions is achieved, and the waterproof effect of the whole basement is improved.

Owner:中力建设集团有限公司

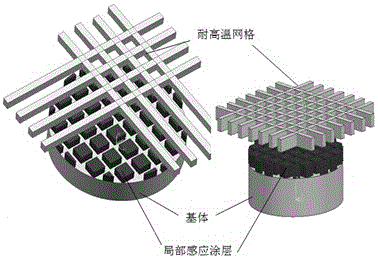

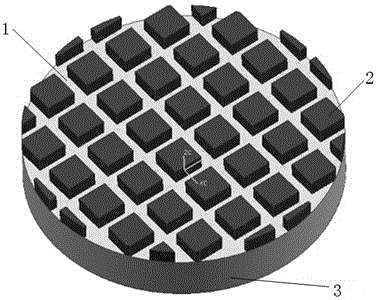

Method for preparing composite coating through electromagnetic induction heating

InactiveCN105821368AImprove adhesionNot easy to warp and deformMolten spray coatingThermal sprayingElectromagnetic induction

The invention discloses a method for preparing a composite coating through electromagnetic induction heating, and belongs to the technical field of electromagnetic induction heating. The method comprises specific steps that a base body surface is subject to roughening and cleaning treatment, a to-be-sprayed surface of a base body is covered with or pasted with a hollow-out screen, thermal spraying is carried out, and after the screen is removed, an electromagnetic induction heating composite coating evenly divided by grooves is obtained; or the base body surface is directly subject to thermal spraying, then, mechanical cutting is carried out, and the electromagnetic induction heating composite coating which is evenly divided by the grooves is obtained; the thermal spraying coating is separated into a plurality of electromagnetic induction heat source coating blocks, the base body is more evenly heated, and stress is more dispersed; and after dividing is carried out, even if the part of a heating layer falls off or is damaged, continuous using of other parts of coating and a whole product is not affected, and a repairing technology is simple.

Owner:KUNMING UNIV OF SCI & TECH

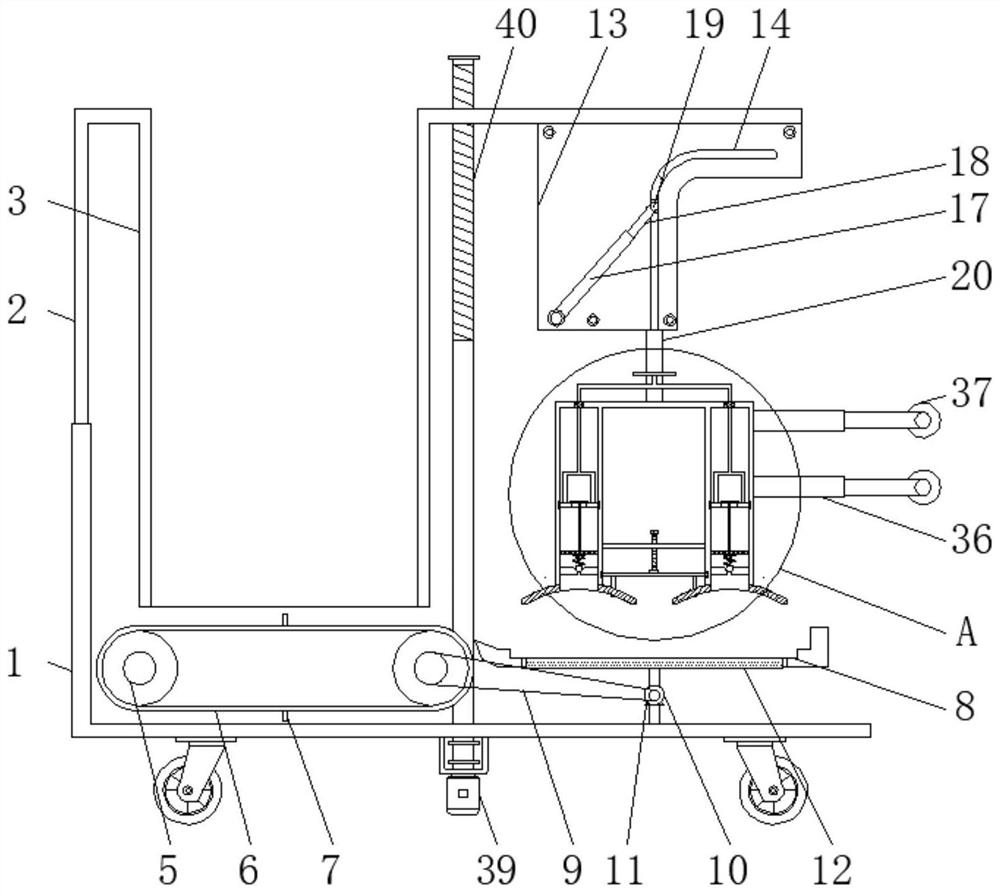

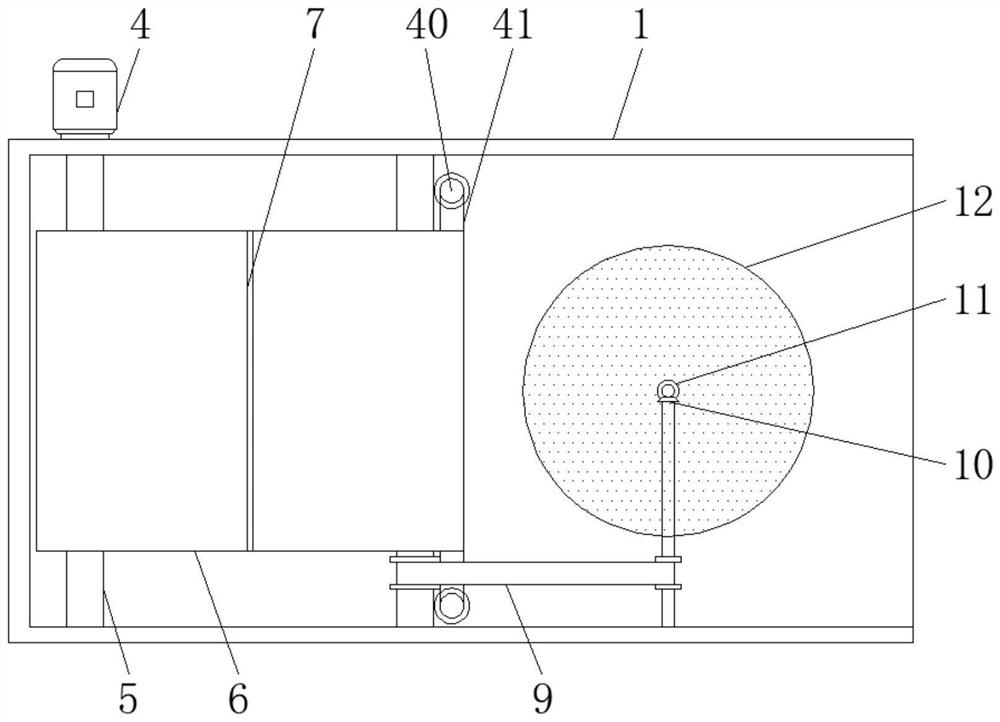

Pipeline gluing fixing device and using method thereof

InactiveCN111878492AEffectively fixedAvoid fixationEdge grinding machinesGrinding drivesLever pressingRetainer (device)

The invention discloses a pipeline gluing fixing device, which comprises a supporting underframe, a bearing frame is mounted in the middle of the top of the supporting underframe, a fixing frame is mounted in the middle of the rear end of the supporting underframe, a glue conveying tank is mounted at the top of the fixing frame, a glue feeding plate is mounted at the position, close to bottom, ofthe front end of the glue conveying tank, polishing parts are mounted on the two sides of the fixing frame correspondingly, air cylinders are mounted on the two sides of the supporting underframe correspondingly, push plates are mounted at the opposite ends of the two sets of air cylinders correspondingly, two sets of fixing rods are mounted at the top of the supporting underframe, limiting cylinders are mounted on the inner sides of the fixing rods, a guiding cylinder is mounted on one side of each push plate, a pressing rod is mounted in the mode of penetrating through the top of each guiding cylinder, and each guiding cylinder is internally provided with two sets of oppositely-arranged arc-shaped sheets. An end opening of a pipeline can be polished, meanwhile, a good limiting function is achieved, uniform distribution of glue can be further maintained when the pipeline is glued, and thus the fixing effect is improved.

Owner:钱佳钰

Safety type corner edge sealing machine capable of preventing hands from being clamped

ActiveCN109366682AShorten the timePrevent movementWood working apparatusDomestic articlesEngineeringEdge banding

The invention relates to a safety type corner edge sealing machine capable of preventing hands from being clamped. The machine comprises a main body, an extending-out rotating arm, an air pump and a material pushing air rod, a support is arranged below the main body, and a moving wheel is arranged in the support, the main body and the support are connected through screws, the support is movably connected with the moving wheel, the extending-out rotating arm penetrates through the front end of the support, and extends out of the rotating arm and is movably connected with the bracket, the air pump is arranged on the inner side of the support, and the air pump is connected with the main body through the screw, the pushing air rod is arranged above the main body, and a discharging plate is arranged above the pushing air rod, and the pushing air rod is connected with the main body through the screw. The safety type corner edge banding machine has the advantages of being capable of preventing hands from being clamped, an anti-collision layer is arranged, so that the possibility of collision between the sealed object and the material clamping plate can be prevented, so that the possibility that the cut-out of the object to be sealed is expanded is reduced, and the sealing opening of the glue is reduced, and the probability of defective products produced by the device is also reduced.

Owner:杨辉

Surface coating process for neodymium iron boron permanent magnetic material and neodymium iron boron permanent magnetic material

ActiveCN102586776BReduce generationImprove qualityLiquid/solution decomposition chemical coatingMagnetic materialsPorositySalt spray test

The present invention relates to a surface coating process for neodymium iron boron permanent magnetic material and a neodymium iron boron permanent magnetic material with coating layers. In the process, an electroplated bottom surface nickel layer, a chemically-coated nickel layer, an electroplated copper layer and an electroplated external nickel layer are sequentially coated on the substrate surface of the neodymium iron boron permanent magnetic material from inside to outside, and after coating, the neodymium iron boron permanent magnetic material is subjected to heat treatment in a vacuum furnace. The total thickness of the coating layers on the neodymium iron boron permanent magnetic material prepared with the process is 15-30mum, the thickness of electroplated bottom surface nickel layer is 5-10mum, the thickness of the electroplated copper layer is 5-10mum, the thickness of the electroplated external nickel layer is 5-10mum and the thickness of the chemically-coated nickel layer is 3-10mum. The coating process provided by the invention reduces the bubble formation, looseness and rust stains, enhances the adhesion of the coating layers, reduces the porosity and obtains compact coating layers, thus significantly improving the quality of the electroplated coating layers on the magnet surface, improving the indicates of a salt spray test and increasing the qualification rate of products.

Owner:SHENYANG GENERAL MAGNETIC

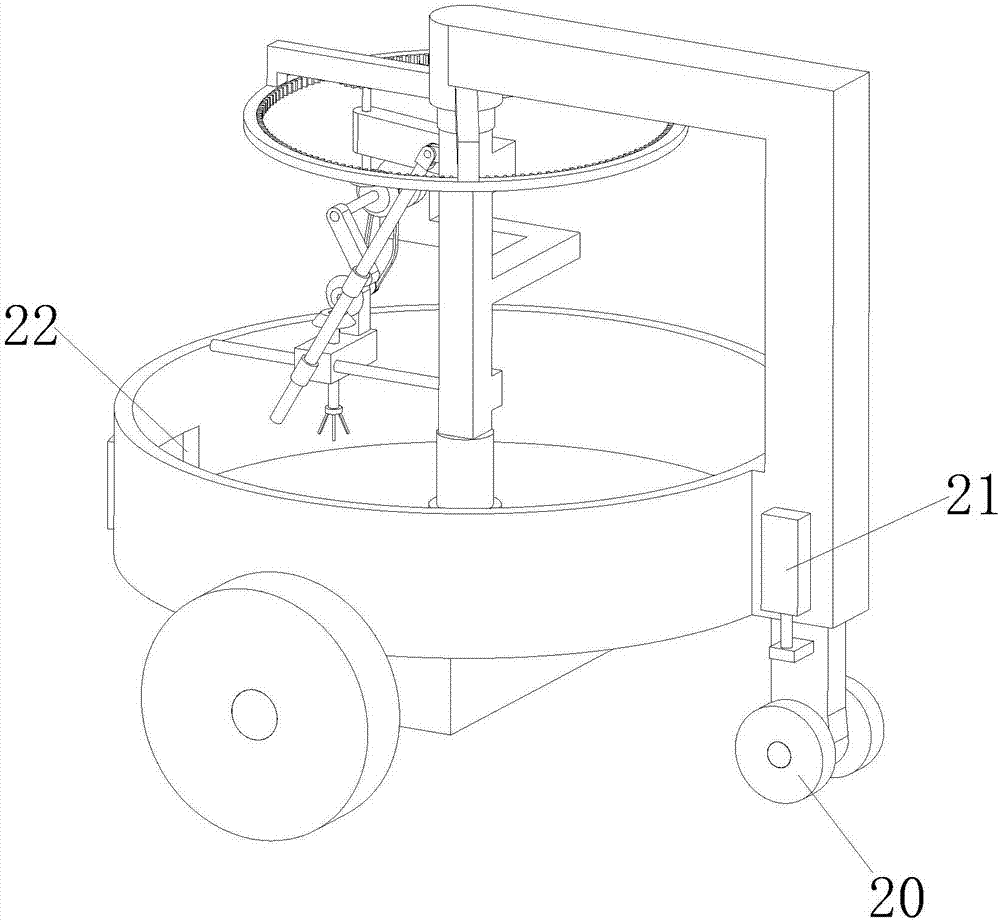

Stirring equipment suitable for small-scale operation

InactiveCN107160562AWon't hurtStir wellDischarging apparatusCement mixing apparatusEngineeringCantilever

The invention relates to stirring equipment suitable for small-scale operation. The stirring equipment comprises a cylinder body, a cantilever installing column is fixed to the outer side of the cylinder body, a rotary column is installed between the cantilever installing column and the cylinder body and is provided with a sliding block, the sliding block slides in a manner of being vertical to the rotary column and is connected with a stirring rod, and a swing rod mechanism is connected between the sliding block and the rotary column; and a motor is connected to the rotary column, a rotating long shaft is connected to the motor, a rotating mechanism is installed between the motor and the rotary column, a linkage mechanism is arranged between the motor and the stirring rod, and an unloading mechanism is arranged on the cylinder body. By means of the stirring equipment, manual operation can be replaced with mechanical operation under small-scale operation, sufficient stirring of materials such as cement can be achieved, the size is small, energy consumption is low, and the stirring equipment is suitable for large-scale application and popularization.

Owner:汪建文

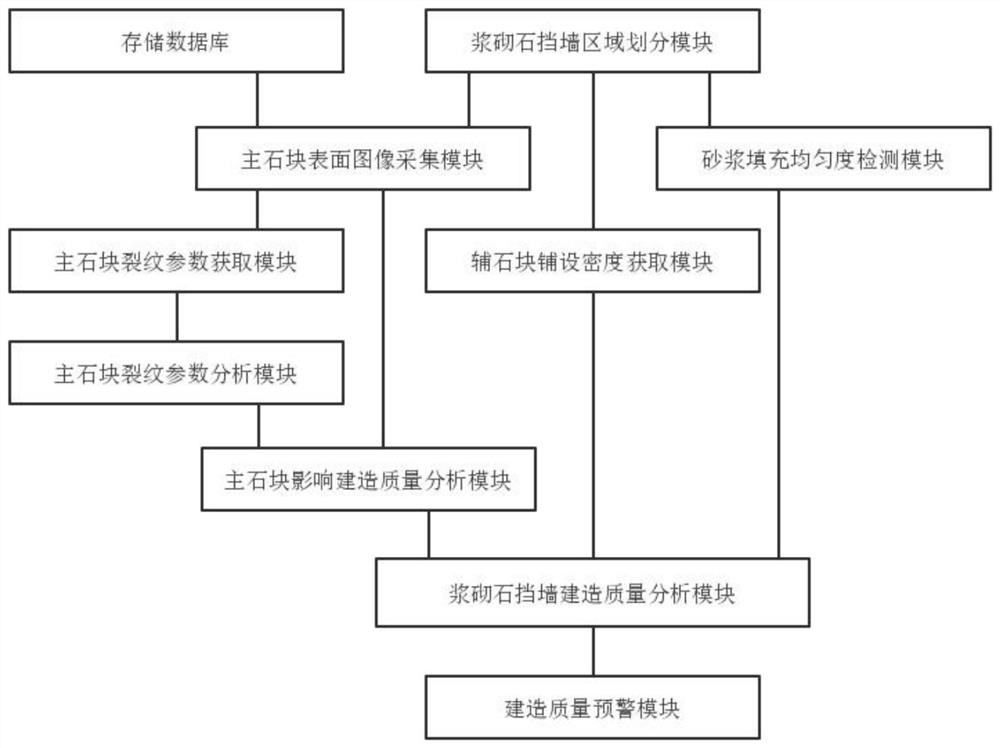

Water conservancy project grouted rubble retaining wall construction quality intelligent analysis system based on big data analysis

InactiveCN114398705AImprove exterior build qualityEasy to useGeometric CADArtificial islandsHydraulic engineeringRetaining wall

The invention discloses a hydraulic engineering grouted rubble retaining wall construction quality intelligent analysis system based on big data analysis, and the system comprises the steps: obtaining main stone hardness and main stone crack parameters of each stone sub-region in a to-be-monitored hydraulic engineering grouted rubble retaining wall, and analyzing a main stone influence construction quality coefficient of each stone sub-region; the method comprises the following steps: monitoring a to-be-monitored hydraulic engineering grouted rubble retaining wall, detecting laying density of auxiliary stones and mortar filling uniformity in each stone sub-area, analyzing a grouted rubble construction quality coefficient of the to-be-monitored hydraulic engineering grouted rubble retaining wall, and if the grouted rubble construction quality coefficient of the to-be-monitored hydraulic engineering grouted rubble retaining wall is smaller than a preset safe grouted rubble construction quality coefficient threshold, performing safety early warning reminding. Therefore, the construction quality detection index diversity of the grouted rubble retaining wall is realized, potential safety hazards of the quality of the hydraulic engineering grouted rubble retaining wall are avoided, the appearance construction quality of the hydraulic engineering grouted rubble retaining wall is improved, and the use performance of the later hydraulic engineering grouted rubble retaining wall is guaranteed.

Owner:宁波烁安网络科技有限公司

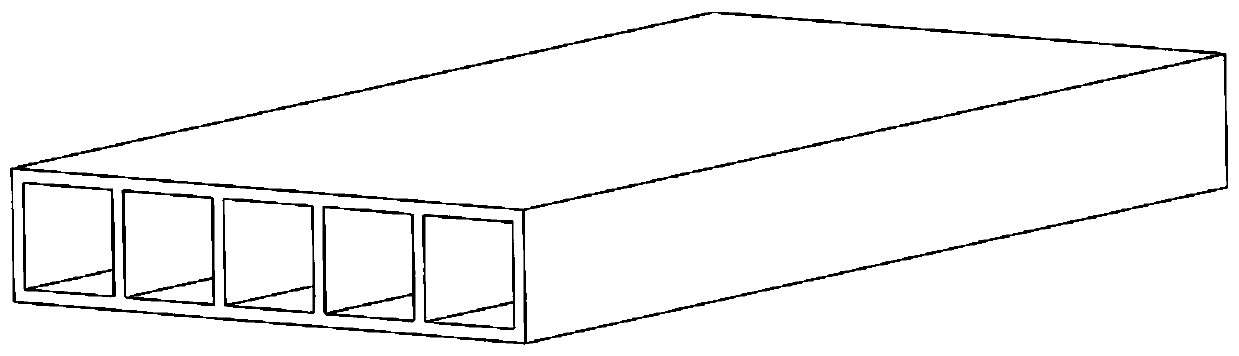

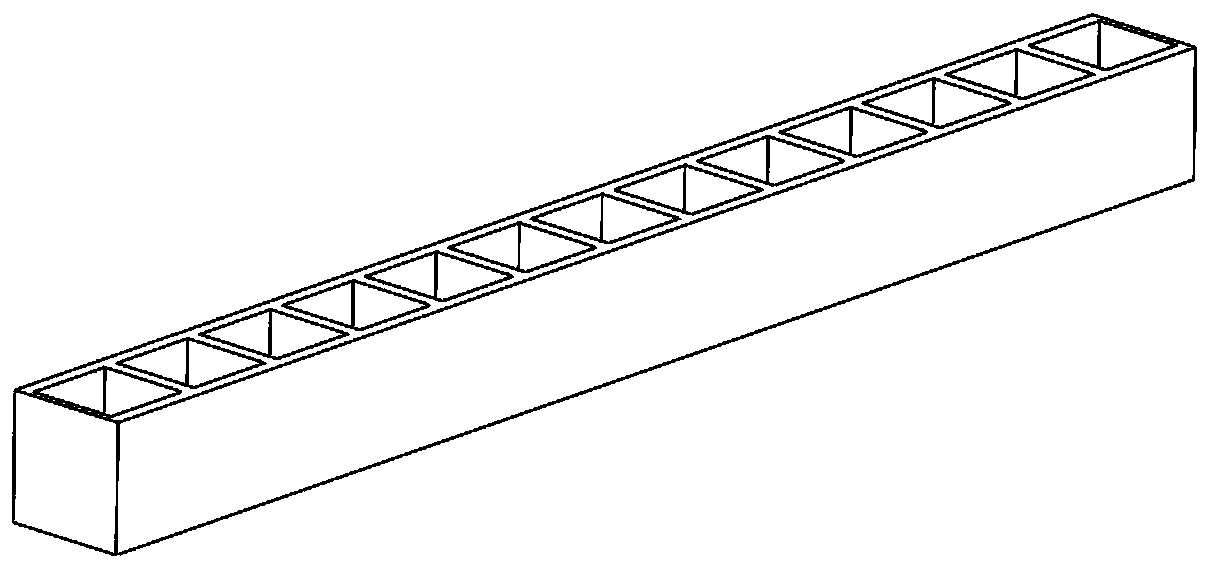

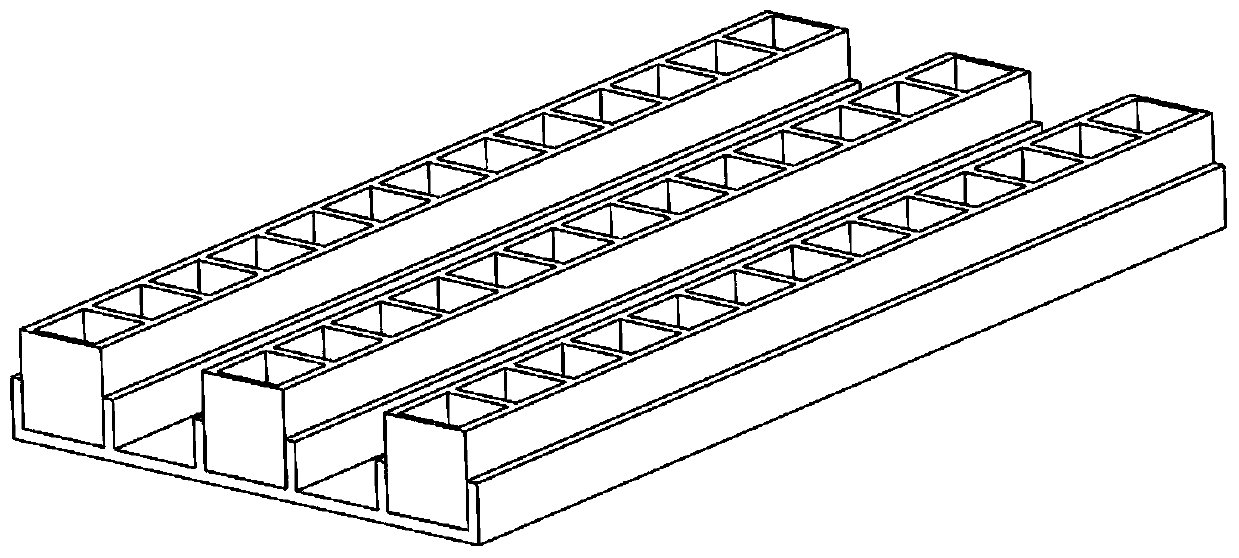

Lightweight high-strength composite material structure and preparation method thereof

ActiveCN109732952AImprove mechanical propertiesSolve the problem of insufficient longitudinal strengthDomestic articlesFiberHigh intensity

The invention discloses a lightweight high-strength composite material structure. The lightweight high-strength composite material structure comprises a hollow box girder structure and a supporting core arranged in the inner cavity of the hollow box girder structure; the size of the supporting core is consistent with the size of the inner cavity of the hollow box girder structure; and the hollow box girder structure and the supporting core are made by curing continuous fibers impregnated in resin glue. The composite material structure has good mechanical properties in both the planar directionand the vertical direction, achieves the performance characteristics of light weight and high strength, has high preparation efficiency, and stable and reliable structure, and is suitable for applications requiring high strength and low density.

Owner:WUHAN UNIV OF TECH

Liquid crystal display panel and manufacturing method thereof, display device and frame sealant mixture

InactiveCN108333839AFirmly connectedAvoid incomplete curingNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a liquid crystal display panel and a manufacturing method thereof, a display device and a frame sealant mixture. The liquid crystal display panel comprises an array substrate,a color filter substrate, a frame sealant connecting the array substrate and the color filter substrate, and a liquid crystal between the array substrate and the color filter substrate; a photoluminescent material is disposed in the frame sealant, and the photoluminescent material is used to emit a second light under excitation of a first light, and the second light is used to cure the frame sealant. In the above manner, the present application can solve the problem that the existing display panel can not completely illuminate the frame sealant when the frame sealant is cured, and the light isblocked, resulting in incomplete curing of the frame sealant.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Preparation method of lithium copper composite negative electrode foil

ActiveCN107819104BImprove machinabilityEven contactElectrode rolling/calenderingSecondary cellsMetallurgyElectrical battery

The invention relates to a preparation method of a lithium-copper composite negative electrode foil piece. An intermittent local pressure enhancement method is adopted for uniformly adhering lithium metal foil pieces on the surface of a copper foil, and a lithium-copper composite negative electrode foil piece is formed. The preparation method comprises the following concrete steps: clamping the copper foil between the lithium metal foil pieces to form a lithium foil / copper foil / lithium foil sandwich layer; adopting common rolling equipment, starting a traction system, and enabling the lithiumfoil / copper foil / lithium foil sandwich layer to pass through a grinding roller, so as to form intermittent local pressure on the lithium foil / copper foil / lithium foil sandwich layer, wherein the pressure range is 0.05-5MPa, and a pre-compounded lithium foil / copper foil / lithium foil sandwich slice is formed; and enabling the pre-compounded lithium foil / copper foil / lithium foil sandwich slice to pass through the grinding roller again, and applying pressure for shaping, wherein the pressure range is 0.02-5MPa, so that the lithium-copper composite negative electrode foil piece is obtained. The preparation method provided by the invention has the beneficial effects that layer-to-layer contact of the prepared lithium-copper composite negative electrode foil piece is uniform, contact of a lithiummetal negative electrode with the copper foil is further improved, and the problem that the lithium metal foil piece and the copper foil are infirmly bonded is avoided, so that outage of lithium metal in a working process of a battery is prevented.

Owner:TIANJIN LISHEN BATTERY +1

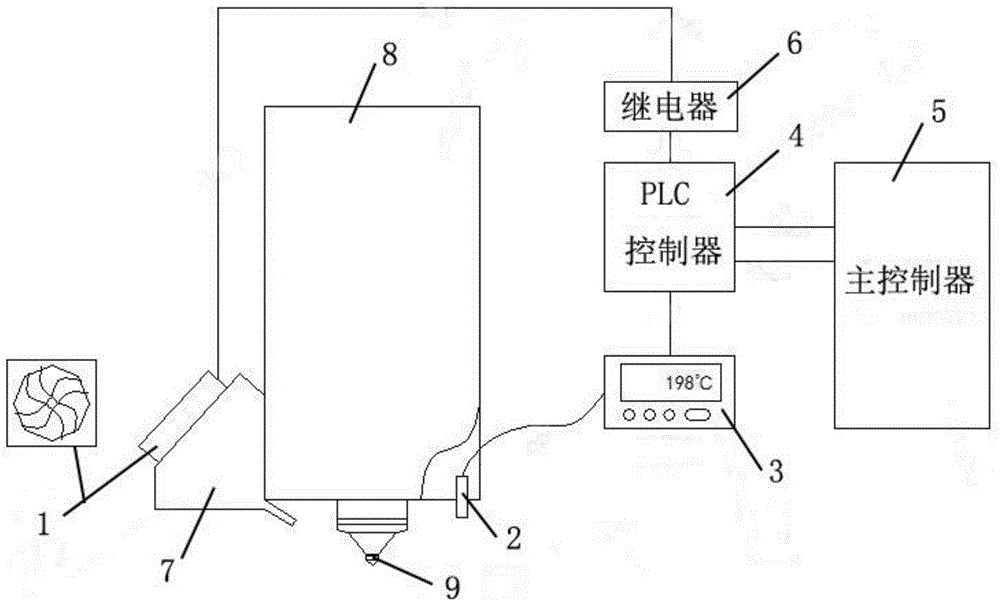

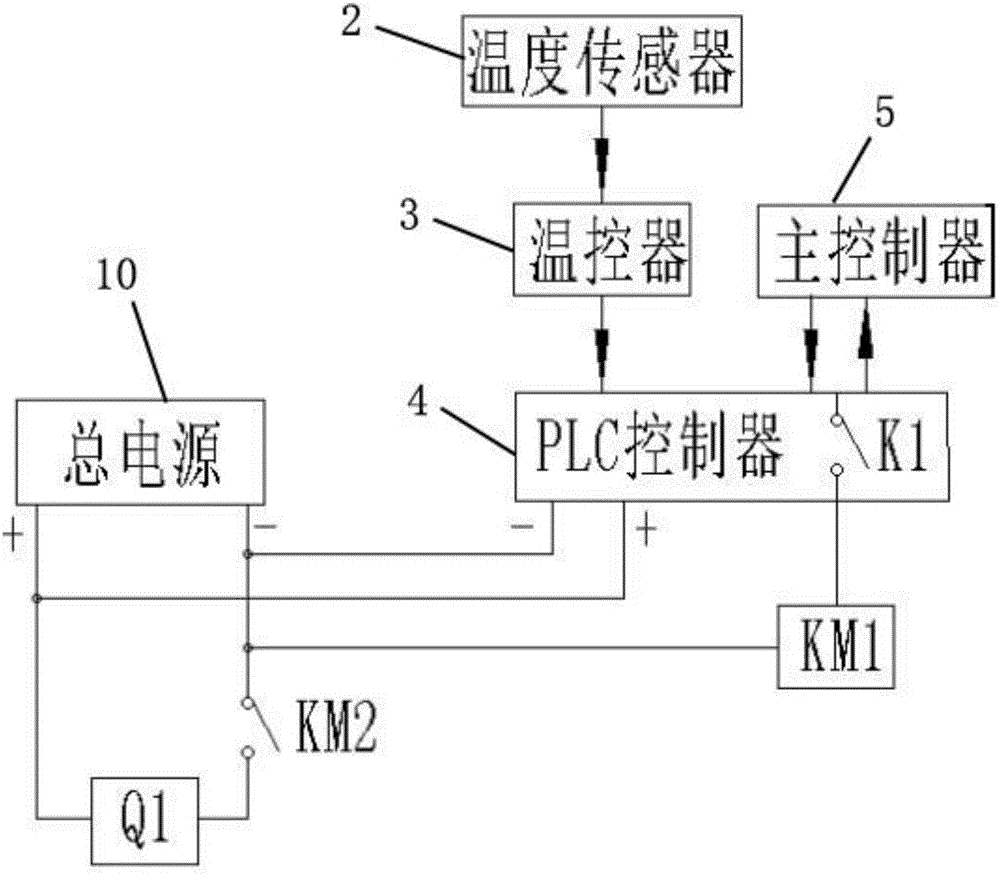

Device for printing model cooling automatic controlling in FDM printing process

InactiveCN106799832AWon't crackWill not soften, collapse and deformAdditive manufacturing apparatus3D object support structuresAutomatic controlEngineering

The invention relates to the technical field of FDM printing moulds, in particular to a device for printing model cooling automatic controlling in the FDM printing process. According to the device, a timely-cooling model material is provided, and it is ensured that a model is not cracked, softened, collapsed and deformed in the FED printing process. According to the technical scheme, the device for printing model cooling automatic controlling in the FDM printing process comprises a cooling fan, a temperature sensor, a temperature controller, a PLC, a master controller and a relay; and the temperature sensor is in electric connection with the temperature controller, the temperature controller is in electric connection with the PLC, the PLC is in electric connection with the master controller, and the relay is in electric connection with the cooling fan. The device for printing model cooling automatic controlling in the FDM printing process is applicable to the field of FDM printing.

Owner:NINGXIA KOCEL MOLD

Battery cell height measuring device

PendingCN112857237AAvoid Weld Quality IssuesImprove efficiencyUsing optical meansReal time displayElectrical and Electronics engineering

The invention discloses a battery cell height measuring device. The device comprises a battery cell fixing mechanism used for fixing a battery cell, a pole detection mechanism used for detecting the height from the pole face of the battery cell to the bottom of the battery cell and a cover plate detection mechanism used for detecting the height from the cover plate face of the battery cell to the bottom of the battery cell, one end of the battery cell is fixed to the battery cell fixing mechanism, and the other end of the battery cell is propped against the pole detection mechanism and the cover plate detection mechanism. The battery cell height measuring device can automatically measure the height from the pole face of the battery cell to the bottom of the battery cell, and the measured value can be displayed on a display screen in real time; meanwhile, the height from the cover plate surface of the battery cell to the bottom of the battery cell is automatically measured, the measured value is displayed in real time, and the problems that the welding quality of a PACK module is poor due to height inconsistency and the module is not firmly bonded with glue of a battery shell are solved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

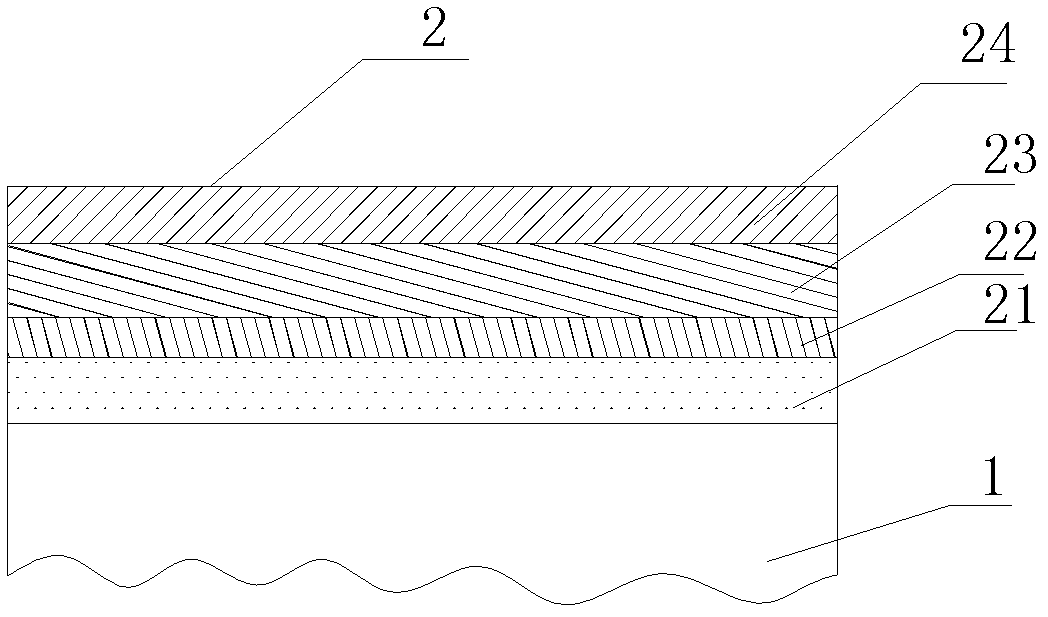

A kind of integrally formed 3D flying woven shoe upper and its preparation method

The invention discloses an integrally formed 3D flyknitted vamp and a making method thereof.Low-melting yarn and dyed yarn are adopted as raw materials, an upper layer of double-faced jacquard vamp body and a lower layer of double-faced jacquard vamp body with the edges interwoven together are woven on a bidirectional jacquard double-faced loop transfer computer flat knitting machine, openwork figured texture weave is primary weave, different weave structures are adopted in functional zones of the vamp, and then the integrally formed 3D flyknitted vamp is made through hot pressing shaping.The temperature of hot pressing shaping ranges from 170 DEG C to 200 DEG C, and the time of hot pressing shaping ranges from 20 s to 80 s.Each double-faced jacquard vamp body comprises a dyed yarn layer and a low-smelting yarn layer which are interwoven together through yarn coils, and the integrally formed 3D flyknitted vamp is formed by bonding and combining the two layers of double-faced jacquard vamp bodies according to the wave structure of one dyed yarn layer, one low-melting yarn layer, the other low-melting yarn and the other dyed yarn layer through the upper low-melting yarn layer and the lower low-melting yarn layer in a hot pressing and melting mode.The integrally formed 3D flyknitted vamp has the advantages of being soft, comfortable, durable, colorful, attractive, low in cost and the like.

Owner:厦门翔鹭化纤股份有限公司

A three-dimensional suspended frame structure with multi-directional construction attached to building wall bricks

ActiveCN111456390BAvoid weak bondsIncrease the use of diversityGrinding drivesBuilding constructionsHydraulic cylinderBrick

Owner:江苏九天建设集团有限公司

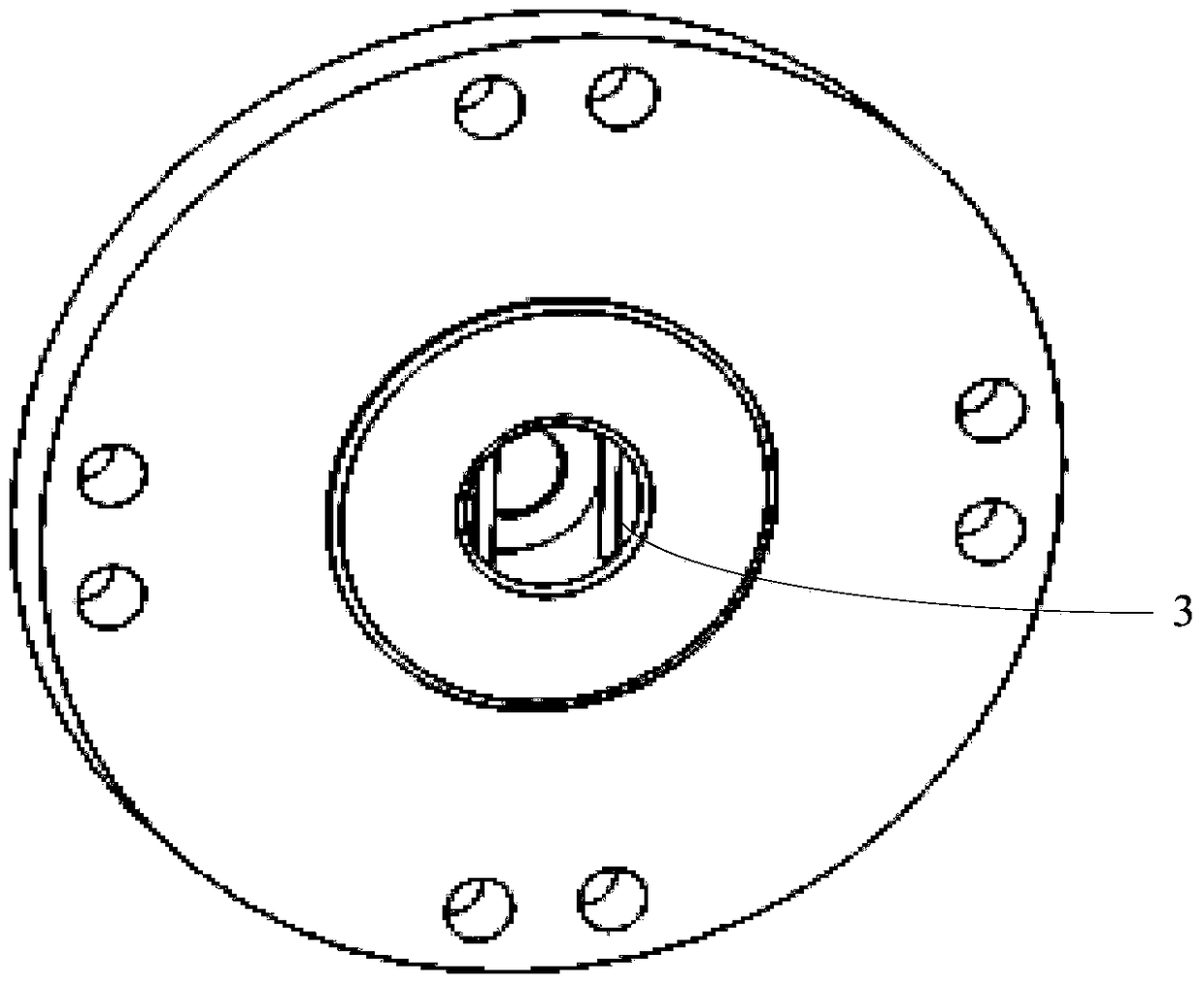

Combination buckle and manufacturing method thereof

ActiveCN105077858BAvoid weak bondsFeatures to avoid sheddingSnap fastenersButtonsBiochemical engineeringNatural material

The present application discloses a combination clasp, which includes a female clasp and a male clasp, the female clasp includes a slingshot cup and a first meson, the slingshot cup is riveted with the first meson, and the male clasp includes a convex bead and a first meson As for the second meson, the protruding bead is riveted to the second meson. The present application also discloses a method for making a combination buckle, which includes: riveting a slingshot cup to the first meson to form the female buckle; riveting a protruding bead to the second meson to form the male buckle. The above combined buckle and its production method avoid the problem of chemical glue not being firmly bonded in the high temperature process, and also avoid the characteristic of natural materials shrinking and falling off, and one less meson part than in the prior art, so that it can improve The combination fastness of the product improves the combination efficiency and reduces the production cost.

Owner:ZHEJIANG WEIXING IND DEV

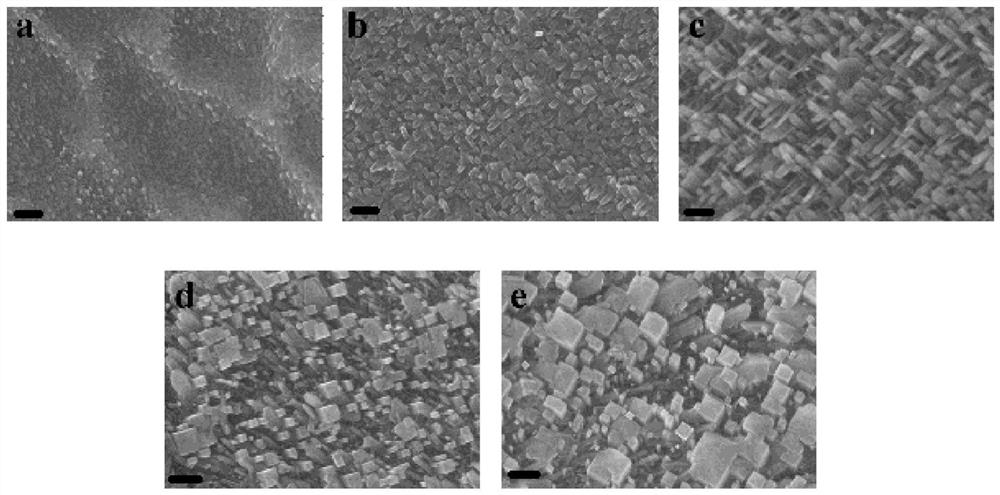

Growth method of graphene and graphene

ActiveCN102181924BAvoid weak bondsSimple manufacturing processPolycrystalline material growthFrom chemically reactive gasesRoom temperatureCvd graphene

The invention discloses a growth method of graphene, which comprises the following steps of: providing an III-nitride substrate; placing the III-nitride substrate in a central area of a flat heater; introducing non-oxidizing gas to the surface of the III-nitride substrate; heating the III-nitride substrate; introducing carbonaceous materials to the surface of the III-nitride substrate as a carbon source for growing the graphene; and stopping introducing the carbon source, and continuing to introduce the non-oxidizing gas for protection and reducing the temperature to the room temperature.

Owner:SUZHOU NANOWIN SCI & TECH +1

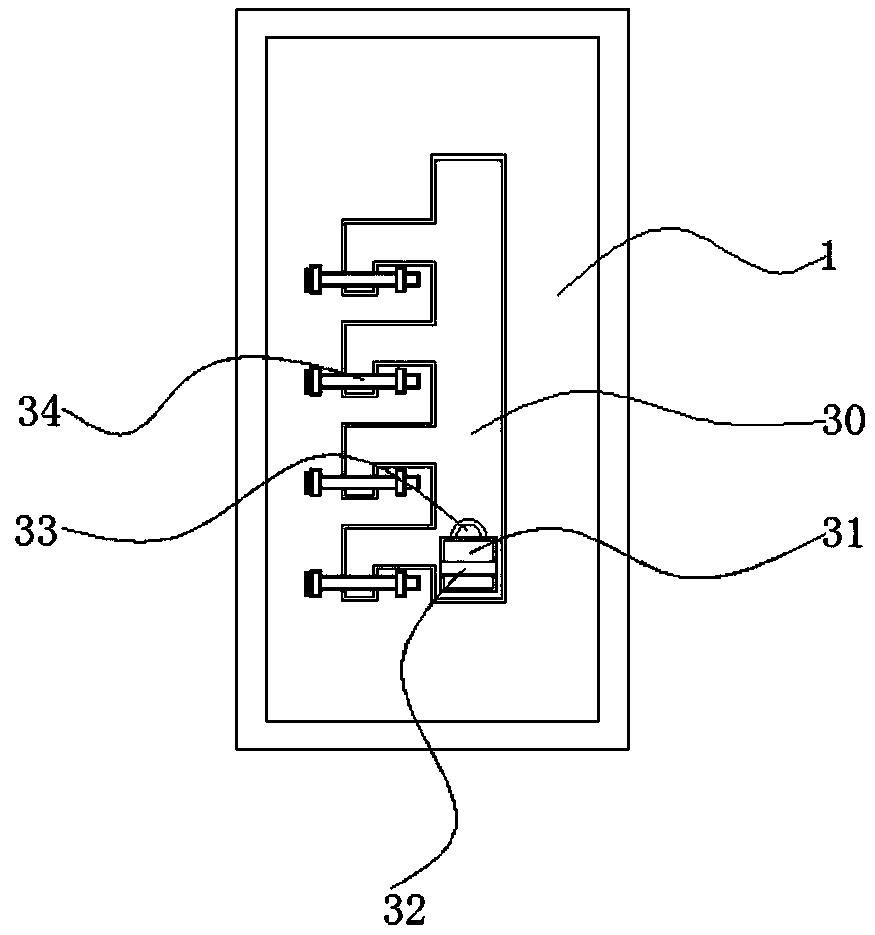

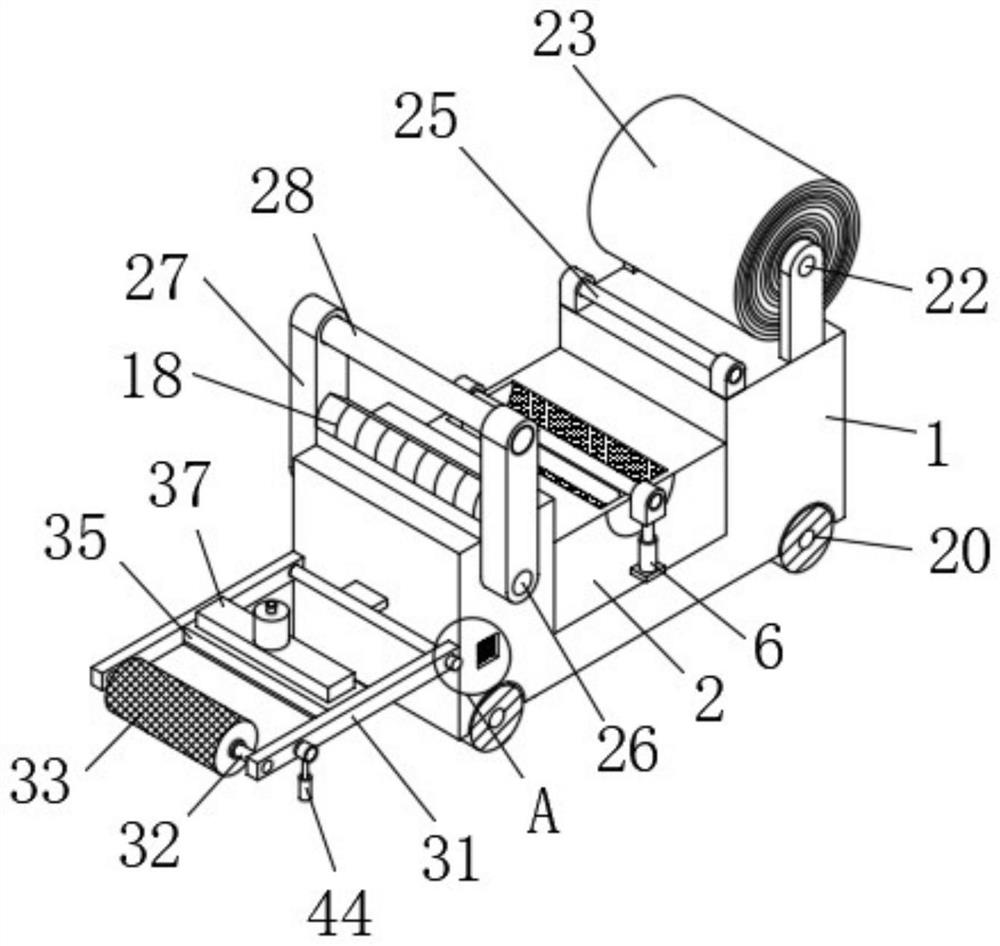

Intelligent manufacturing equipment for industrial automatic box sealing and capable of preventing adhesive tape from being bonded weakly

PendingCN112407448AEquipment efficiencyImprove equipment efficiencyWrapper twisting/gatheringPackaging machinesMechanical engineeringAutonomation

The invention relates to the technical field of industrial automation, and discloses intelligent manufacturing equipment for industrial automatic box sealing and capable of preventing an adhesive tapefrom being bonded weakly. A screw rod is movably connected to the inner side of a sliding block, a metal base is movably connected to the bottom end of the screw rod, and a stabilizing piece is movably connected to the bottom end of the metal base. According to the intelligent manufacturing equipment for industrial automatic box sealing and capable of preventing the adhesive tape from being bonded weakly, an auxiliary component is erected above a conveying belt to achieve the preliminary limiting effect, the screw rod is powered on to rotate anticlockwise, the metal base runs along a track matched with the front end of a main body and forms a moving trend in the direction close to a circular shaft, the circular shaft drives a swing rod to rotate, the swing rod deflects to roll the adhesive tape that is cocked, a supporting piece is used for knocking the adhesive tape, and therefore the adhesive tape is prevented from falling off, then the adhesive tape is bonded in place in the key box sealing process, the firmness of the adhesive tape is deepened, the equipment is high in efficiency, the effect is improved, and the embarrassing situation that the adhesive tape falls off in a later period is avoided.

Owner:广州盘肯商贸有限公司

Waterproof roll laying device with adhesive glue immersed

ActiveCN112627443AAvoid excessive wasteEasy height adjustmentDispersed particle filtrationRoof toolsAdhesive glueElectric heating

The invention discloses a waterproof roll laying device with adhesive glue immersed in the field of waterproof roll laying devices. The waterproof roll laying device comprises a base, wherein a glue storage box is fixedly mounted at the top of the base; a backflow groove is formed in the top of the glue storage box; a through hole is formed in the bottom of the backflow groove; mounting plates are fixedly connected to the two sides of the glue storage box; air cylinders are fixedly connected to the tops of the mounting plates; connecting blocks are fixedly mounted at the output ends of the air cylinders; and rotating rods are movably connected to the inner surfaces of the connecting blocks. According to the waterproof roll laying device, part of overflowing adhesive glue makes contact with the bottom of a waterproof roll and is evenly smeared at the bottom of the waterproof roll, the other part of the adhesive glue is recycled through the backflow groove, and the working efficiency is improved; and after an electric heating wire is powered on, heat is generated, air is heated, the hot air is conveyed to the surface of the waterproof roll containing the adhesive glue through an exhaust plate, the temperature of the adhesive glue and the temperature of the waterproof roll rise, and the problem that the adhesive glue is rapidly solidified, and consequently bonding of the waterproof roll and the surface of a building is not firm can be solved.

Owner:襄阳市攀源建筑防水材料实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com