Dynamic balance process method of carbon fiber composite transmission shaft tube and combined dynamic balance clamping hoop

A composite material and process method technology, applied in the field of shaft dynamic balance, to achieve the effects of strong operability, avoidance of weak bonding, and simple processing and manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but is not limited to the content described below.

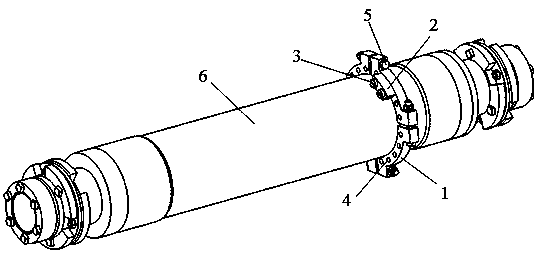

[0021] Referring to Fig. 1, it is a diagram of the overall structure of the hoop involved in a method for realizing the dynamic balance of the carbon fiber composite shaft tube of the present invention, including the hoop 1, bolts, nuts and spring washers 5. Among them, the clamp 1 is composed of four quarter-circle clamps, and the quarter-circle clamps are composed of bolts, nuts and spring washers 5 (the spring washers are placed between two adjacent quarter-circle clamps). The bolts of a round clamp and then fastened with nuts) are connected to form a complete circular clamp 1.

[0022] On the circumference of the complete circular clamp 1 (the side or axial surface of the clamp 1), some threaded holes 4 are evenly arranged (the axis of the threaded hole is parallel to the axis of the clamp), and the number of threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com