Corrosion-resistance composite pipe and manufacturing method thereof

A composite pipe and corrosion-resistant technology, which is applied in the direction of pipes/pipe joints/fittings, pipeline protection, mechanical equipment, etc., can solve the problems of easy corrosion, poor anti-corrosion effect, and reduced service life of composite pipes, so as to reduce corrosion, Corrosion prevention and service life improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

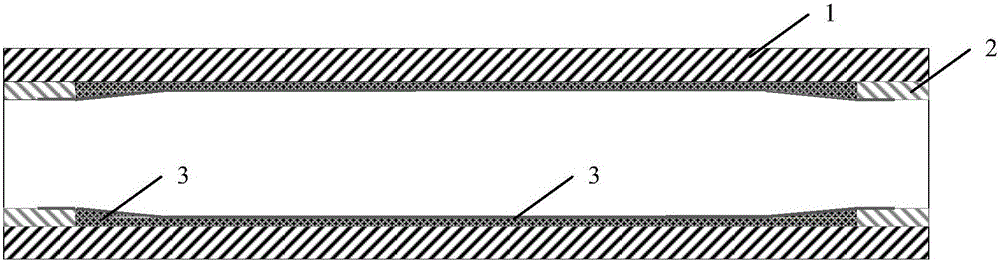

[0030] like figure 1 As shown, the corrosion-resistant composite pipe of this embodiment includes a pipe matrix 1, which is a carbon steel pipe to ensure the requirements of strength and pressure resistance. The inner wall of the steel pipe base is attached with a lining anti-corrosion layer, and the inner liner anti-corrosion layer includes a metal anti-corrosion layer 2 and a non-metallic anti-corrosion layer 3; The inner side of the end is melted and welded, the metal anti-corrosion layer is cylindrical, and its outer wall is attached to the inner wall of the steel pipe substrate. The material is nickel-based corrosion-resistant alloy, and the nickel-based corrosion-resistant alloy is Ni-Cr-Mo alloy; the material of the non-metallic anti-corrosion layer is epoxy resin, and the epoxy resin layer 3 is sprayed and fixed on the inner wall of the steel pipe matrix, and the epoxy resin layer It includes a main body part arranged between two metal anti-corrosion layers and an ann...

Embodiment 2

[0037] The corrosion-resistant composite pipe of this embodiment includes a pipe matrix, and the pipe matrix is a carbon steel pipe to ensure the requirements of strength and pressure resistance. The inner wall of the steel pipe matrix is attached with a lining anti-corrosion layer. The inner anti-corrosion layer includes a metal anti-corrosion layer and a non-metallic anti-corrosion layer; The outer wall of the layer is attached to the inner wall of the steel pipe substrate, and the end face of the metal anti-corrosion layer facing the outside of the steel pipe substrate is flush with the end face of the steel pipe substrate. The material of the metal anti-corrosion layer is 316L stainless steel; the material of the non-metallic anti-corrosion layer is epoxy resin The epoxy resin layer is sprayed and fixed on the inner wall of the steel pipe base, and the epoxy resin layer includes a main part arranged between two metal anti-corrosion layers and a metal anti-corrosion laye...

Embodiment 3

[0045] The corrosion-resistant composite pipe of this embodiment includes a pipe matrix, and the pipe matrix is a carbon steel pipe to ensure the requirements of strength and pressure resistance. The inner wall of the steel pipe matrix is attached with a lining anti-corrosion layer. The inner anti-corrosion layer includes a metal anti-corrosion layer and a non-metallic anti-corrosion layer; It is attached to the inner wall of the steel pipe base, and the end face of the metal anti-corrosion layer facing the outside of the steel pipe base is flush with the end face of the steel pipe base. The material of the metal anti-corrosion layer is 316L stainless steel; the material of the non-metallic anti-corrosion layer is epoxy resin, epoxy The resin layer is sprayed and fixed on the inner wall of the steel pipe matrix, and the epoxy resin layer includes a main body part arranged between two metal anti-corrosion layers and an annular covering part integrally arranged on the main bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com