Full-automatic surface mounting machine of ultrasonic sensor

A sensor, fully automatic technology, applied in the field of sensors, can solve the problems of high defect rate, different strength, low work efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

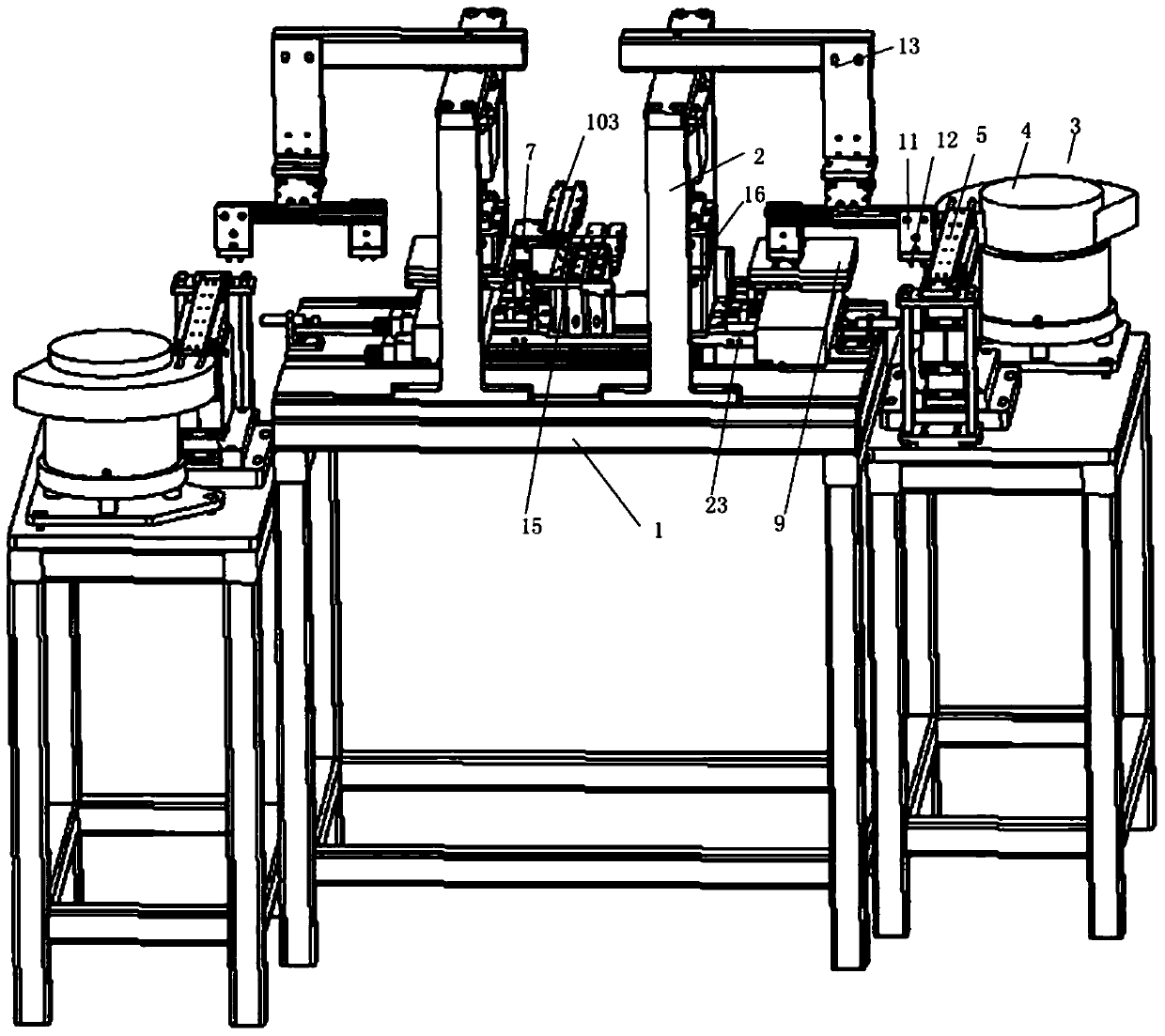

[0020] The drawings given in the embodiments show a schematic diagram of combining two full-automatic placement machines of a type of ultrasonic sensor, which can improve work efficiency.

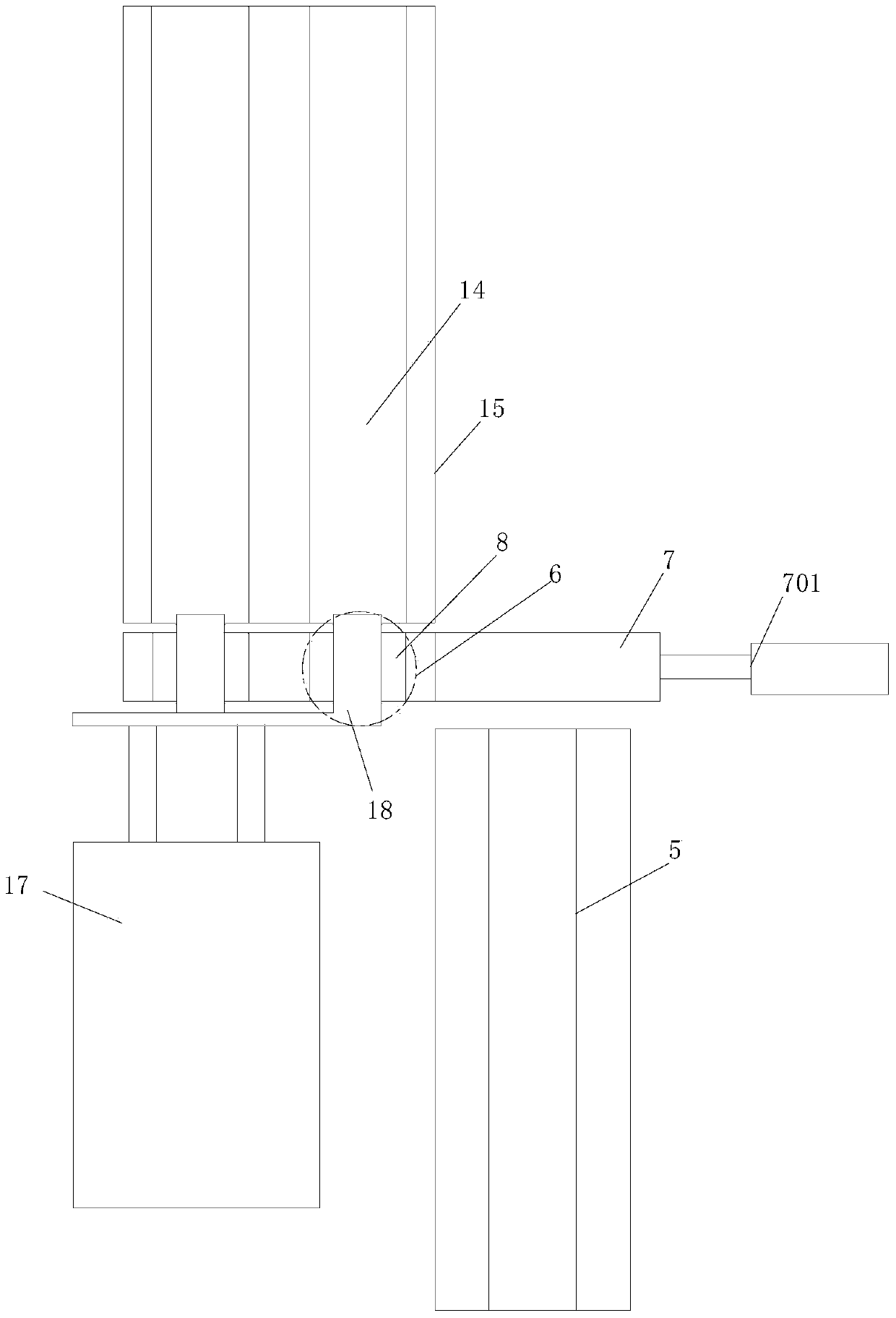

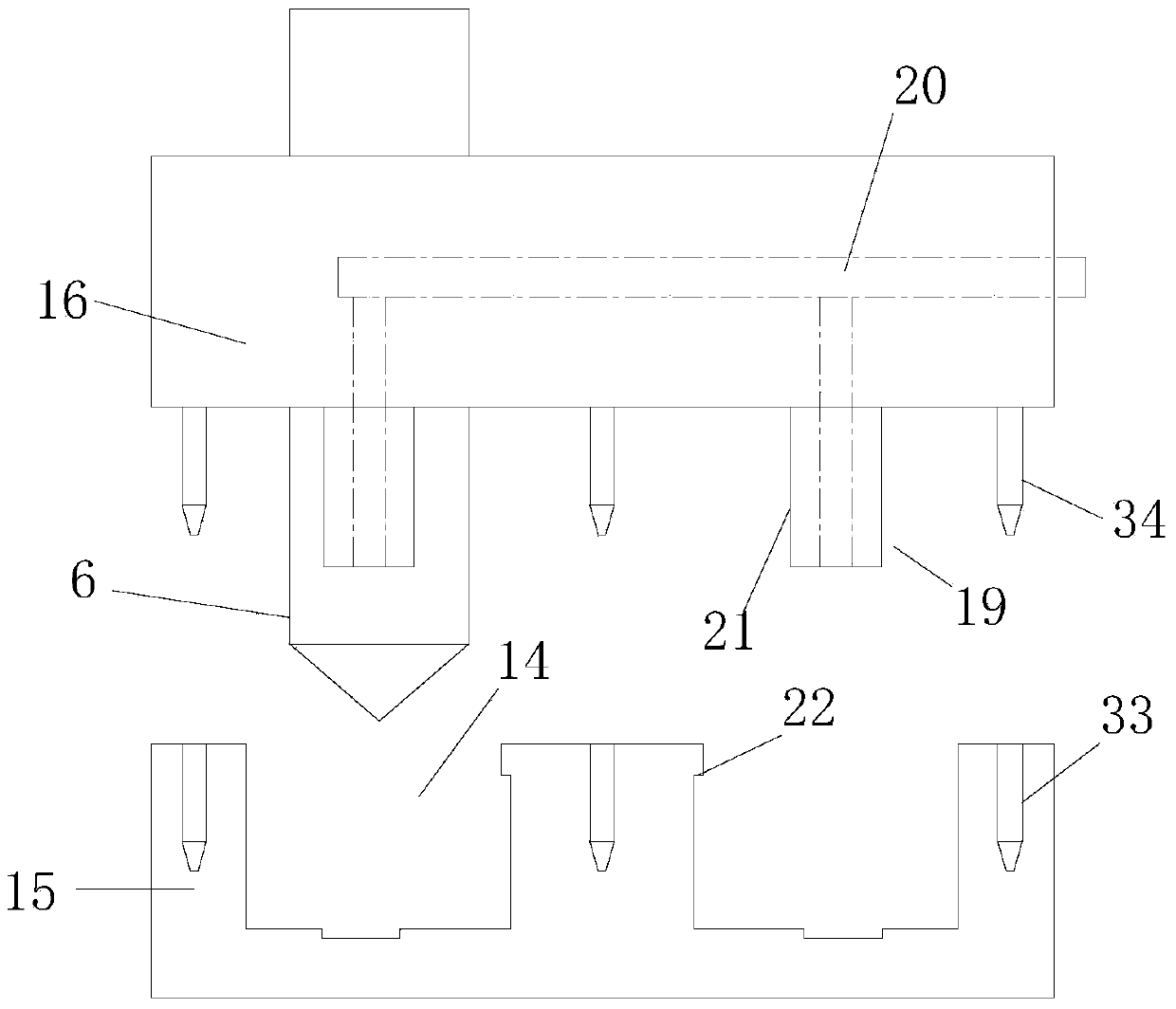

[0021] see Figure 1-5 , an ultrasonic sensor full-automatic placement machine, comprising a machine base 1, a bracket 2 is fixedly arranged on the machine base, a shell 101 vibration feeding mechanism, a tile 102 vibration feeding mechanism 3 are arranged on one side of the machine base, figure 1 The shell vibrating feeding mechanism is not shown in the figure, which is located at the rear of the entire device during specific assembly. The shell and ceramic chip vibrating feeding mechanisms are vibrating feeding equipment available on the market, including a vibrating plate 4 with an accommodating cavity. The spiral vibrating passage in the vibrating plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com