Veneer/aluminum foil composite decorating facing material and manufacturing method thereof

A manufacturing method and technology of aluminum foil, which are used in household decoration, chemical instruments and methods, lamination devices, etc., can solve the problems of easy cracking on the surface and insufficient flexibility, and achieve the effects of strong decoration, various textures, and improved utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

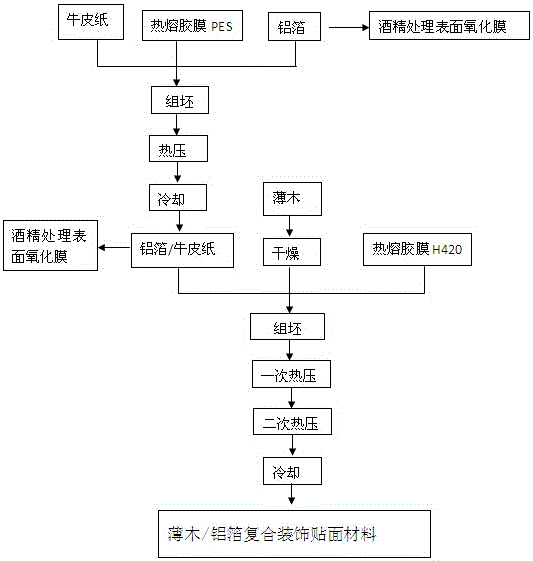

[0041] With reference to the accompanying drawings, a veneer / aluminum foil composite decorative veneer material, its manufacturing method comprises the following process steps:

[0042] Including the following process steps:

[0043] (1) Treat the oxide film on the sizing surface on the 0.018mm thick aluminum foil 3 with alcohol cotton to obtain a good gluing surface;

[0044] (2) Kraft paper 1, copolyester hot-melt adhesive film PES2 and 0.018mm thick aluminum foil 3 are formed into blanks, hot-pressed and cooled to form aluminum foil / kraft paper reinforced materials:

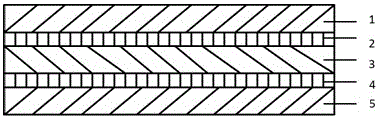

[0045] 1) Blank assembly: kraft paper 1 is used as a reinforcing material, copolyester hot-melt adhesive film PES2 is used as an adhesive and aluminum foil is used for blank assembly (see figure 1 ), the sizing amount of the hot melt adhesive film PES on the upper sizing surface of the aluminum foil 3 is 40g / m 2 , the thickness of the aluminum foil is 0.018mm;

[0046] 2) Hot pressing: continuous rolling me...

Embodiment 2

[0054] With reference to the accompanying drawings, a veneer / aluminum foil composite decorative veneer material, its manufacturing method comprises the following process steps:

[0055] Including the following process steps:

[0056] (1) Treat the oxide film on the sizing surface on the 0.018mm thick aluminum foil 3 with alcohol cotton to obtain a good gluing surface;

[0057] (2) Kraft paper 1, copolyester hot-melt adhesive film PES2 and 0.018mm thick aluminum foil 3 are formed into blanks, hot-pressed and cooled to form aluminum foil / kraft paper reinforced materials:

[0058] 1) Blank assembly: kraft paper layer 1 is used as reinforcing material, copolyester hot melt adhesive film PES2 is used as adhesive and aluminum foil is used for blank assembly (see figure 1 ), the sizing amount of hot melt adhesive film PES is 60g / m 2 , the thickness of the aluminum foil is 0.018mm;

[0059] 2) Hot pressing: adopt continuous rolling method, the hot pressing temperature is 160°C, the...

Embodiment 3

[0067] With reference to the accompanying drawings, a veneer / aluminum foil composite decorative veneer material, its manufacturing method comprises the following process steps:

[0068] Including the following process steps:

[0069] (1) Treat the oxide film on the sizing surface on the 0.018mm thick aluminum foil 3 with alcohol cotton to obtain a good gluing surface;

[0070] (2) Kraft paper 1, copolyester hot-melt adhesive film PES2 and 0.018mm thick aluminum foil 3 are formed into blanks, hot-pressed and cooled to form aluminum foil / kraft paper reinforced materials:

[0071] 1) Blank assembly: kraft paper layer 1 is used as reinforcing material, copolyester hot melt adhesive film PES2 is used as adhesive and aluminum foil is used for blank assembly (see figure 1 ), the sizing amount of hot melt adhesive film PES is 55g / m 2 , the thickness of the aluminum foil is 0.018mm;

[0072] 2) Hot pressing: Continuous rolling method is adopted, the hot pressing temperature is 145°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com