Magnesium cement fireproof board having excellent water-resistance and preparation thereof

A technology of fireproof board and magnesium cement, applied in the field of magnesium cement fireproof board, can solve the problems such as the inherent problems of magnesium oxychloride cement and increase the cost that cannot be fundamentally solved, and achieve excellent non-combustibility, no warping deformation, and low thermal expansion coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

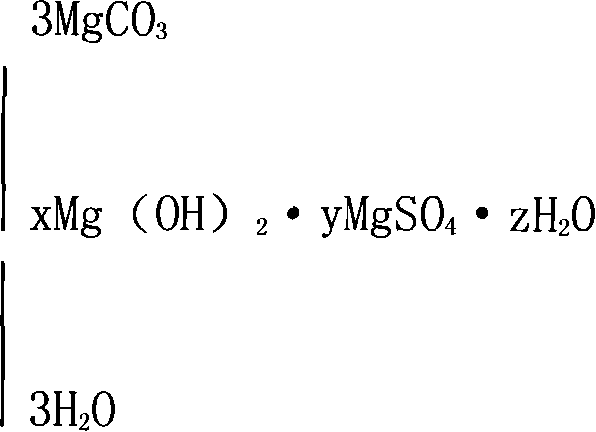

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: taking weight as a unit, pour 80 parts of magnesium sulfate and 1 part of tartaric acid into a blender, add quantitative water, stir, adjust the Pomi degree of magnesium sulfate and tartaric acid to be 26, add 85% light magnesium oxide 150 parts, 20 parts of perlite, 120 parts of heavy filler (heavy calcium carbonate), 22 parts of light filler (sawdust). Stir for 5 minutes, then discharge the material, and shape it on the fireproof board production line with double-layer 2-piece fiber mesh cloth. After it reaches a certain strength, it can be demoulded and cut.

Embodiment 2

[0025] Embodiment 2: taking weight as a unit, pour 80 parts of magnesium sulfate and 1 part of tartaric acid into a blender, add quantitative water, stir, adjust the Pomi degree of magnesium sulfate and tartaric acid to be 26, add 85% light magnesium oxide 150 parts, 12 parts perlite, 120 parts heavy calcium carbonate, 22 parts sawdust. Stir for 5 minutes, then discharge the material, and shape it on the fireproof board production line with double-layer 2 pieces of fiber mesh cloth. After it reaches a certain strength, it can be demolded and cut to produce magnesium cement fireproof board with excellent water resistance. plate. The product is detected by the test block, the flexural strength is >10mpa, the compressive strength is >25mpa, the softening coefficient is >0.9, the flame resistance is A grade, and there is no phenomenon of frosting and halogen return.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com