Pottery flying disk target and method for producing same

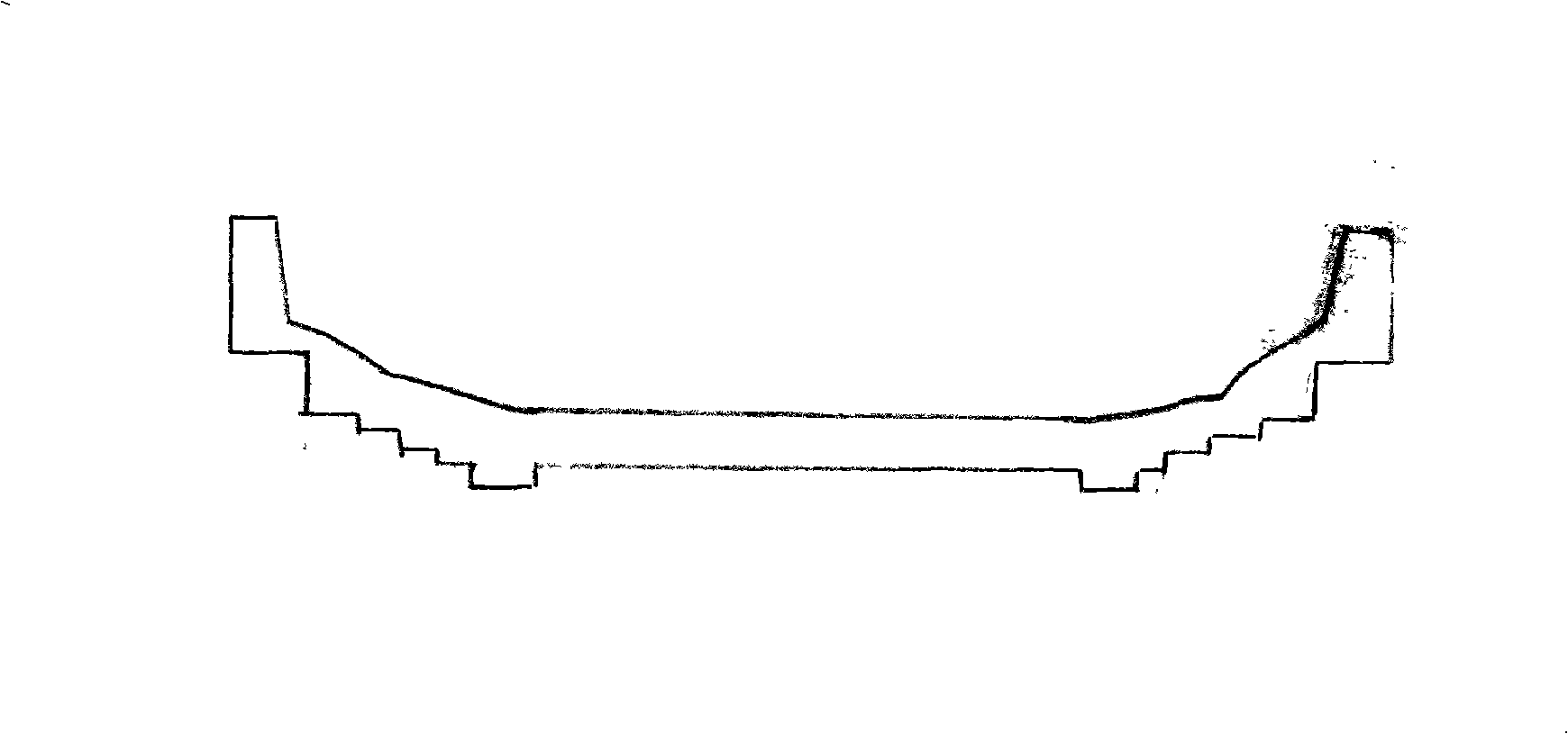

A technology made of flying saucers and pottery, which is applied to decomposable ceramic flying saucer targets and their preparation, in the field of environmental protection and pollution-free. It can solve the problems of difficult control of production weight consistency, residual flying saucer target debris environment, troublesome collection of debris, etc., and achieve product weight. Good consistency, easy weight control, conducive to the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: mineral material composition (wt%): kaolin 60%, quartz 20%, feldspar 20%. Crush each raw material into a normal fine powder, mix and stir well, add 3-5wt% water and a small amount (for example 5‰) of ceramic universal binder by weight of the material, fully mix (for example wheel mill mixing), and vibrate granulate to make 20- 60-mesh fine particles, piled up and stale for 10 hours, volume-measured, put into a mold, and stamped on a 60-100-ton press. After drying and dehydration, put it into an electric furnace for firing at 400°C for 1 hour. Then use lead-free ceramic paint to spray into design colors (such as orange red, black, green, yellow), and dry. Obtain an outer diameter of 110mm, a disc shape of 25mm in height, a bottom surface of 3mm in thickness, a weight of 105g, and a specific gravity of 2.2g / cm 3 , the finished product is soaked in water for 1.5 hours, the water absorption rate is 12%, and it falls by itself from a height of 8-10cm, and it ...

Embodiment 2

[0033] Embodiment 2: mineral material composition (wt%): white mud 25wt%, red mud 20%, mixed mud 50%, quartz 5%. The production process is the same as Example 1, firing at 450°C. Obtain an outer diameter of 108mm, a height of 25mm, a disc-shaped body with a bottom thickness of 4mm, a weight of 107g, and a specific gravity of 2.4g / cm 3 , The finished product is soaked in water for 1.5 hours, the water absorption rate is 11%, it will fall by itself from a height of 8-10cm, and it will break into 2 pieces for 2-3 consecutive times.

Embodiment 3

[0034] Embodiment 3: Mineral material composition (wt%): Zisha mud 50wt%, diatomite 30%, horse trace mud 15%, quartz 5%. The manufacturing process is the same as Example 1, firing at 400°C. Obtain an outer diameter of 107mm, a disc shape of 25mm in height, a bottom surface thickness of 3mm, a weight of 102g, and a specific gravity of 1.9g / cm 3 , The finished product is soaked in water for 1.5 hours, the water absorption rate is 18%, it will fall by itself from a height of 8-10cm, and it will break into 3 pieces for 2-3 consecutive times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com