Method for preparing fiber particle board

A technology of fiber particleboard and shavings, applied in the direction of flat products, manufacturing tools, pretreatment of molding materials, etc., to achieve the effects of not easy warping and deformation, high utilization rate, and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, the preparation method of this example comprises the following steps:

[0020] (1) Milling of small-diameter wood: cut small-diameter wood into short pieces of 400mm, and then use the milling machine to radially mill into large pieces of shavings. The size of the shavings is: length 20mm, width 7mm, thickness 0.2 mm;

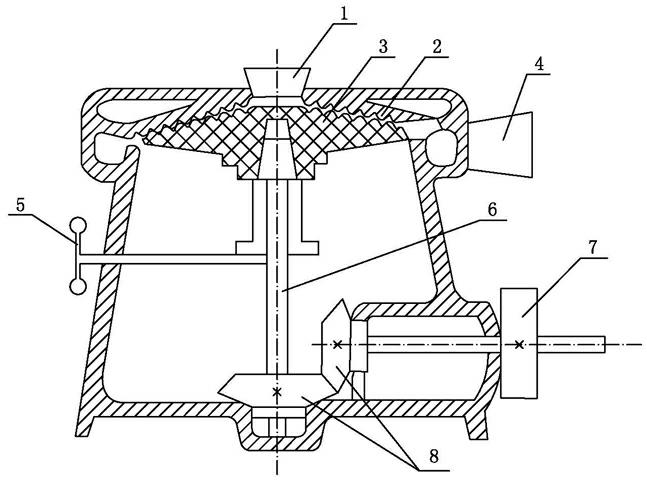

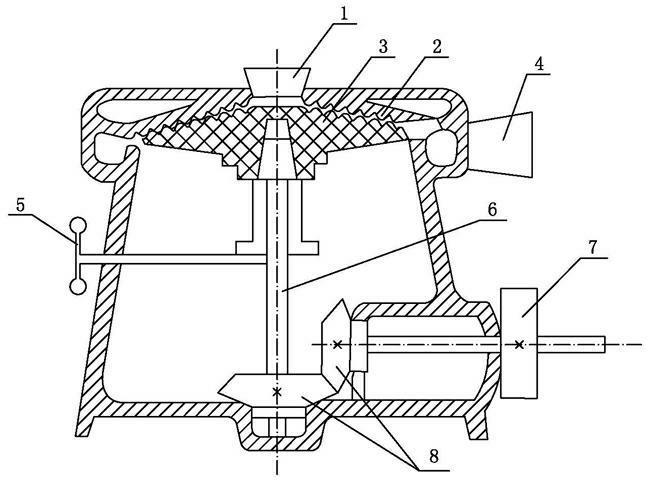

[0021] (2) Grinding large pieces of shavings: put large pieces of shavings into the toothed disc grinder (such as figure 1 As shown) ground into fibrous fine shavings, the size of the shavings is: length 20mm, width and thickness close to each other, about 0.1 mm;

[0022] (3) Pipeline sizing: Pipeline sizing is used for sizing. The adhesive used is urea-formaldehyde resin adhesive. The concentration of the adhesive is controlled at 40% (conventional formula). 8% of the amount of fine shavings, while adding ammonium chloride of 0.5% of its solid adhesive weight as a curing agent in the adhesive;

[0023] (4) Drying of fibrous fine shavings...

Embodiment 2

[0028] Embodiment two, the preparation method of this example comprises the following steps:

[0029] (1) Milling of small-diameter wood: cut small-diameter wood into short wood sections of 1000mm, and then radially mill them into large pieces of shavings on a milling machine. The size of the shavings is: length 50mm, width 12mm, thickness 0.4 mm;

[0030] (2) Grinding large pieces of shavings: put large pieces of shavings into the toothed disc grinder (such as figure 1 As shown) ground into fibrous fine shavings, the size of the shavings is: length 50mm, width and thickness close to each other, about 0.15 mm;

[0031] (3) Pipeline sizing: use the pipeline sizing method for sizing, the adhesive used is a modified urea-formaldehyde resin adhesive, the concentration of the adhesive is controlled at 45% (conventional formula), and the amount of sizing is the solid weight in the liquid glue. 12% of the amount of dry fibrous fine shavings, while adding 1.0% ammonium chloride of it...

Embodiment 3

[0037] Embodiment three, the preparation method of this example comprises the following steps:

[0038] (1) Milling of small-diameter wood: cut the small-diameter wood into short pieces of 700mm, and then use the milling machine to radially mill them into large pieces of shavings. The size of the shavings is: length 35mm, width 10mm, thickness 0.3 mm;

[0039] (2) Grinding large pieces of shavings: put large pieces of shavings into the toothed disc grinder (such as figure 1 As shown) ground into fibrous fine shavings, the size of the shavings is: length 35mm, width and thickness close to each other, about 0.12 mm;

[0040] (3) Pipeline sizing: Pipeline sizing is used for sizing, the adhesive used is modified urea-formaldehyde resin adhesive, the concentration of the adhesive is controlled at 43% (conventional formula), and the amount of sizing is the solid weight of liquid glue. 10% of the amount of dry fibrous fine shavings, while adding 0.8% ammonium chloride of its solid a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com