Sandwich material plate and preparation method thereof

A multi-layer structure and plate technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of low strength, high cost of hemp-plastic composite materials, easy warping and deformation, etc., and achieve low cost and difficult Effect of warpage deformation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

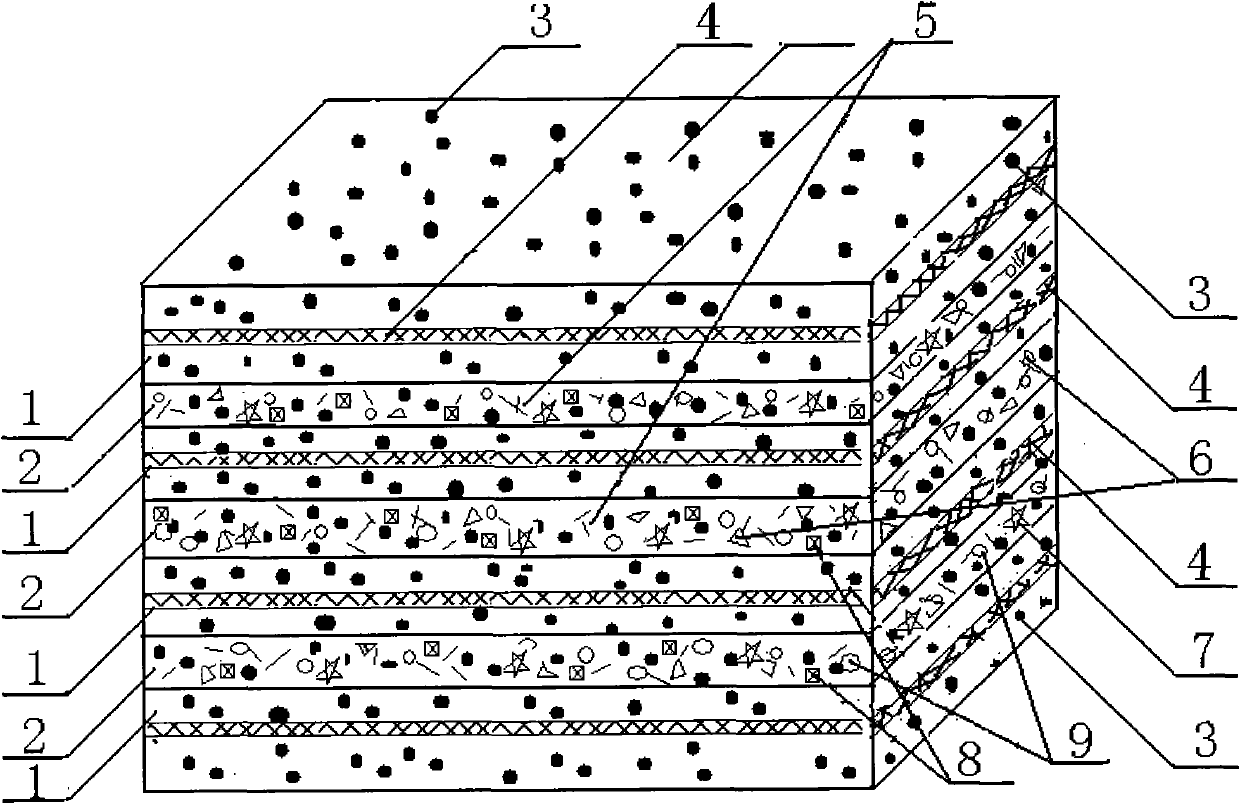

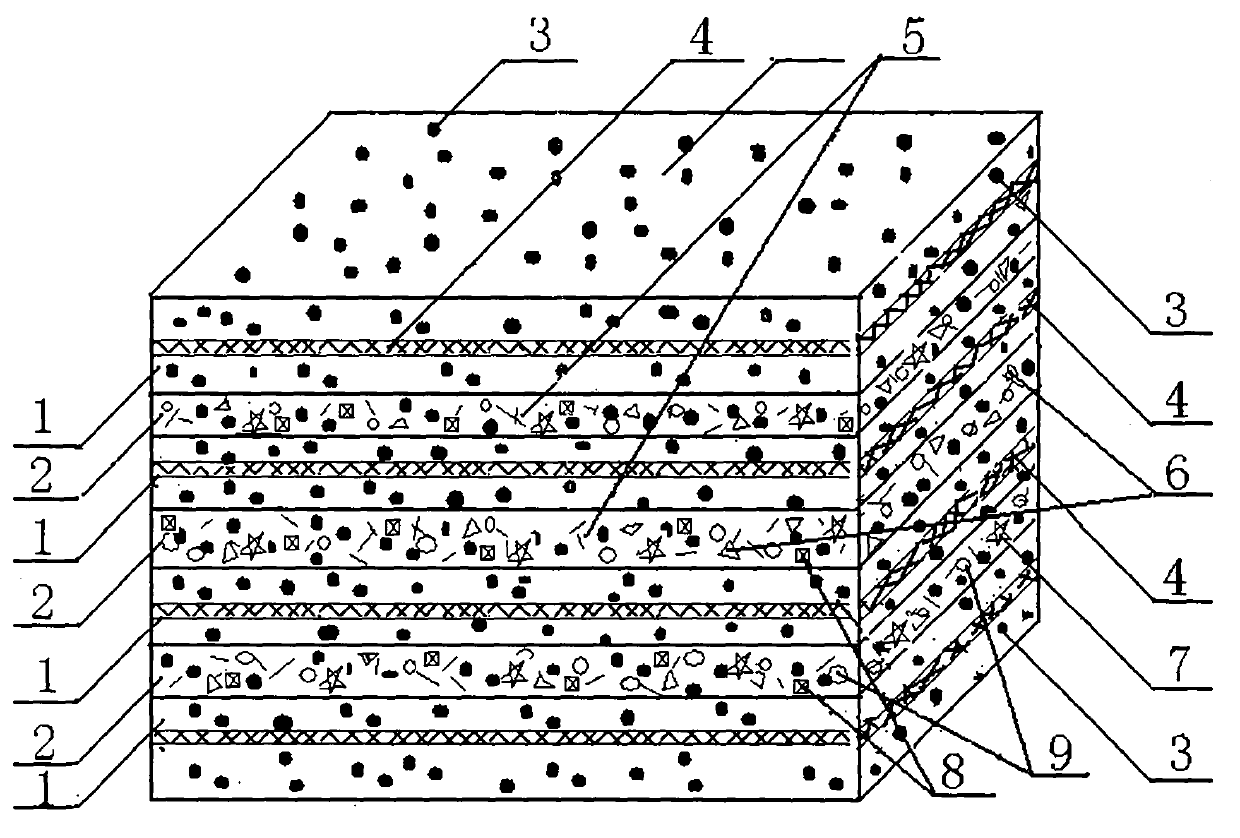

Image

Examples

Embodiment 1

[0039] Embodiment 1: a kind of preparation method of multilayer structure material plate, its preparation process is:

[0040] (1) According to the mass ratio of hemp fiber cloth and silane coupling agent 100:1, weigh 0.02kg of silane coupling agent, dilute the silane coupling agent with water, and the amount of water shall be based on the immersion of hemp fiber cloth; Soak 2kg in silane coupling agent diluted with water for 30min. After soaking, take out the hemp fiber cloth, drain it, put it in a vacuum oven, and dry it in vacuum for 3h at 40°C;

[0041] (2) Take wood powder, plastic particles, interface solubilizer, calcium carbonate, lubricant, and plasticizer in a mass ratio of 100:30:3:5:1:1, weigh 10kg of 60-mesh wood powder, and polyethylene plastic particles 3kg, maleic anhydride grafted polyethylene 0.3kg, calcium carbonate 0.5kg, calcium stearate 0.1kg, terpene resin 0.1kg, dry mixed and calendered to form a wood-plastic composite layer, the thickness of the wood-p...

Embodiment 2

[0048] Embodiment 2: a kind of preparation method of multi-layer structure material plate, its preparation process is:

[0049] (1) According to the mass ratio of hemp fiber cloth and silane coupling agent 100:5, weigh 0.15 kg of silane coupling agent, dilute the silane coupling agent with water, and the amount of water shall be based on immersing the hemp fiber cloth; Soak 3kg in silane coupling agent diluted with water for 120min. After soaking, take out the hemp fiber cloth, drain it, put it in a vacuum oven, and dry it in vacuum at 80°C for 6h;

[0050] (2) Take wood powder, plastic particles, interface solubilizer, calcium carbonate, lubricant, and plasticizer in a mass ratio of 100:50:5:10:2:2, and weigh 10 kg of 100-mesh wood powder, polystyrene plastic 5kg of particles, 0.5kg of maleic anhydride grafted polystyrene, 1kg of calcium carbonate, 0.2kg of zinc stearate, 0.2kg of terpene resin, dry mixed and calendered to form a wood-plastic composite material layer, the thi...

Embodiment 3

[0059] Embodiment 3: a kind of preparation method of multi-layer structure material plate, its preparation process is:

[0060] (1) According to the mass ratio of hemp fiber cloth and silane coupling agent 100:3, weigh 0.12 kg of silane coupling agent, dilute the silane coupling agent with water, and the amount of water shall be based on immersing the hemp fiber cloth; Soak 4kg in silane coupling agent diluted with water for 75min. After soaking, take out the hemp fiber cloth, drain it, put it in a vacuum oven, and dry it under vacuum for 4.5h at 60°C;

[0061] (2) Take wood powder, plastic particles, interface solubilizer, calcium carbonate, lubricant, and plasticizer in a mass ratio of 100:40:4:7.5:1.5:1.5, weigh 10kg of 80-mesh wood powder, and polypropylene plastic particles 4kg, maleic anhydride grafted polypropylene 0.4kg, calcium carbonate 0.75kg, zinc stearate 0.15kg, terpene resin 0.15kg, dry mixed and calendered to form wood-plastic composite material layer, wood-pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com