Wood-plastic flooring structure convenient and quick to install

A wood-plastic floor, convenient technology, applied in the direction of building structure, floor, insulation layer, etc., can solve the problems of shortening the service life of wood-plastic floor, inconvenient installation and disassembly, easy moisture absorption and shrinkage, etc., to save labor costs , Easy installation, not easy to warp and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

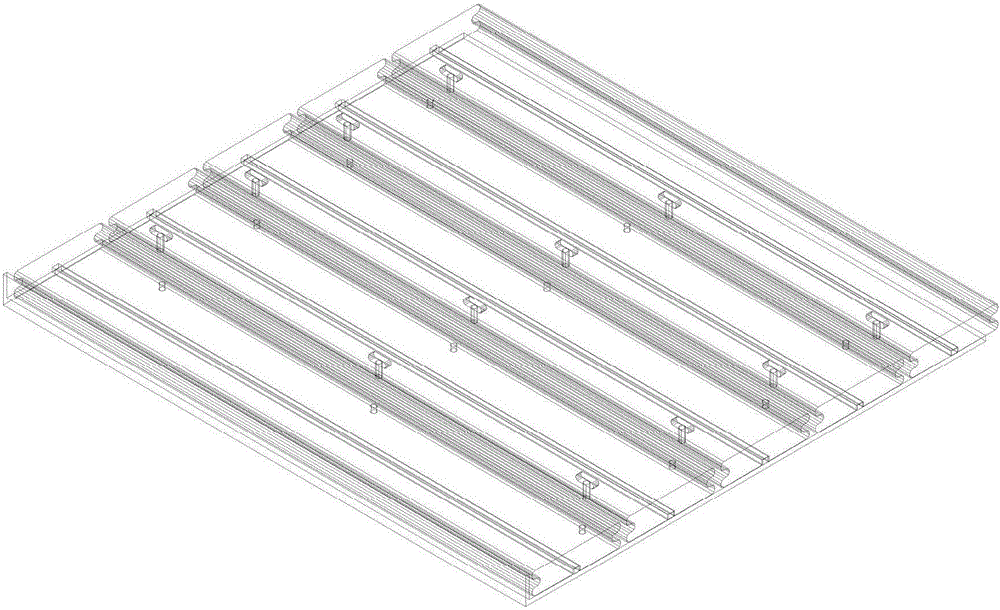

[0021] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

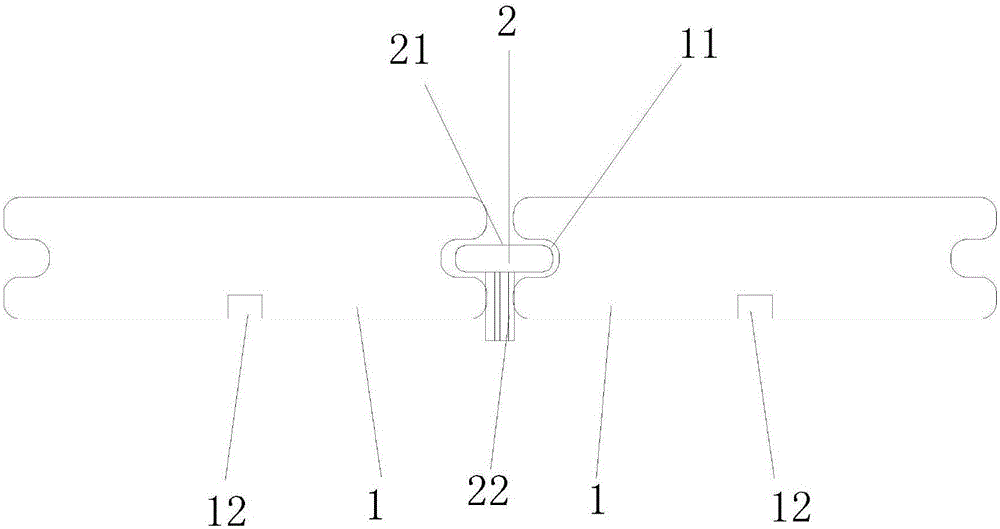

[0022] Referring to the accompanying drawings, an easy-to-install waterproof wood-plastic floor structure includes a support body 3, a wood-plastic floor unit body 1 and a rotatable buckle 2;

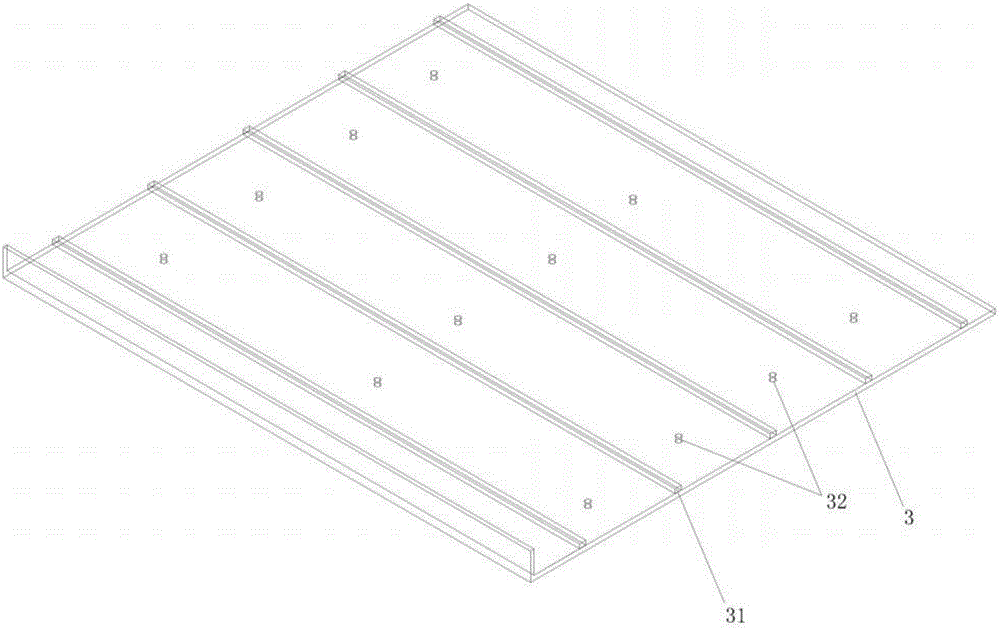

[0023] The support body 3 is provided with a plurality of parallel raised guide rails 31 along its length, and adjacent to the guide rails 31 are evenly arranged with a plurality of insertion slots 32 or insertion holes along the direction of the guide rails;

[0024] The bottom of the wood-plastic floor unit body 1 is provided with a guide groove 12 along its length, and the guide groove 12 cooperates with the guide rail 31 on the support body. The groove 11 in the long side direction of the plastic floor unit;

[0025] The rotatable buckle 4 is a "T" s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com