Paper-plastic adhesive tape, plastic composite woven bag and preparation method

A technology for woven bags and adhesive materials, which is applied in chemical instruments and methods, synthetic resin layered products, paper/cardboard layered products, etc., can solve the problems that industrial production cannot be realized, the durability of composite bags is not long, and the cost is high. , to reduce production costs, improve barriers, and save human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] 1. Schematic diagram of the structure of the plastic composite woven bag and the paper-plastic adhesive tape of the present invention:

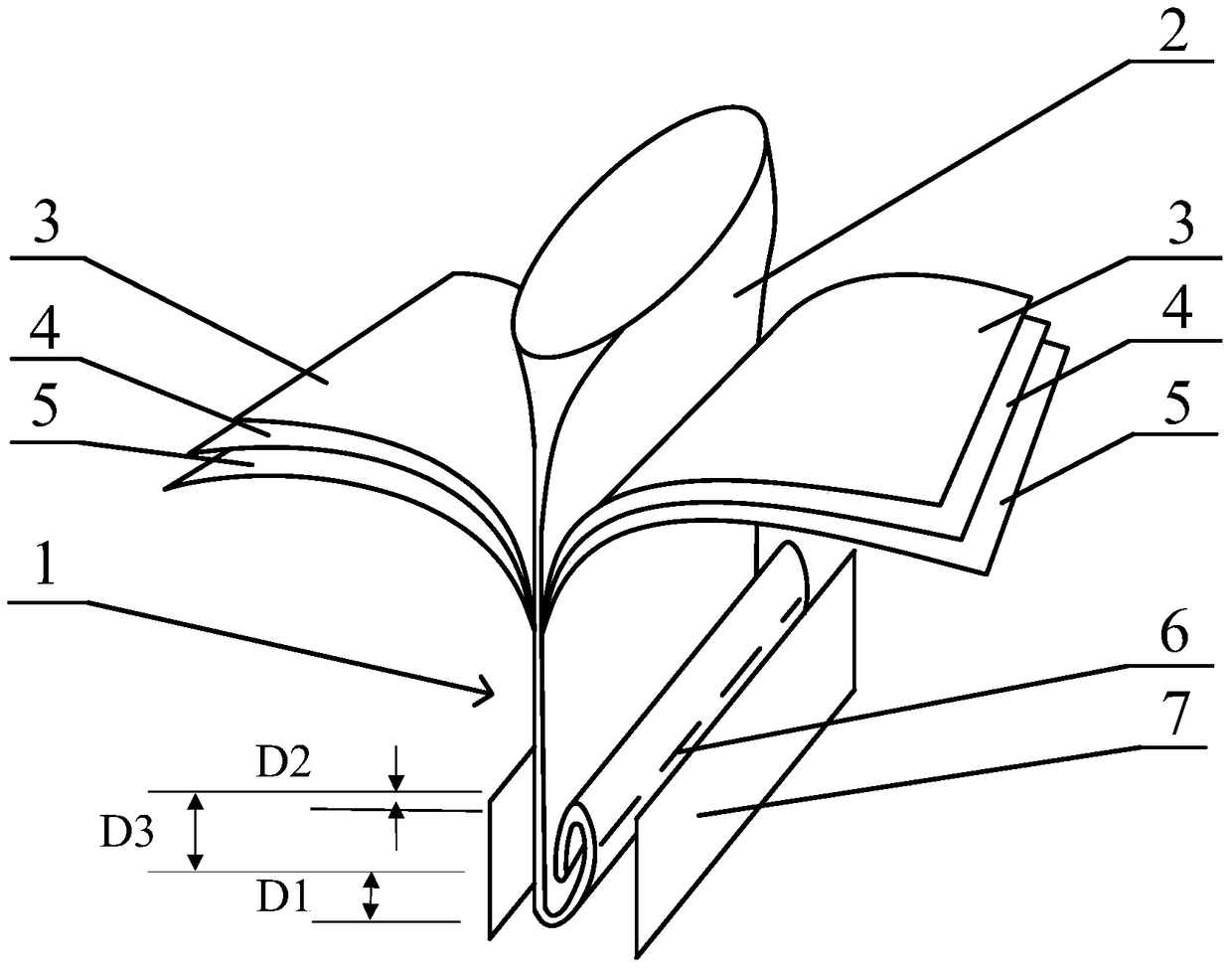

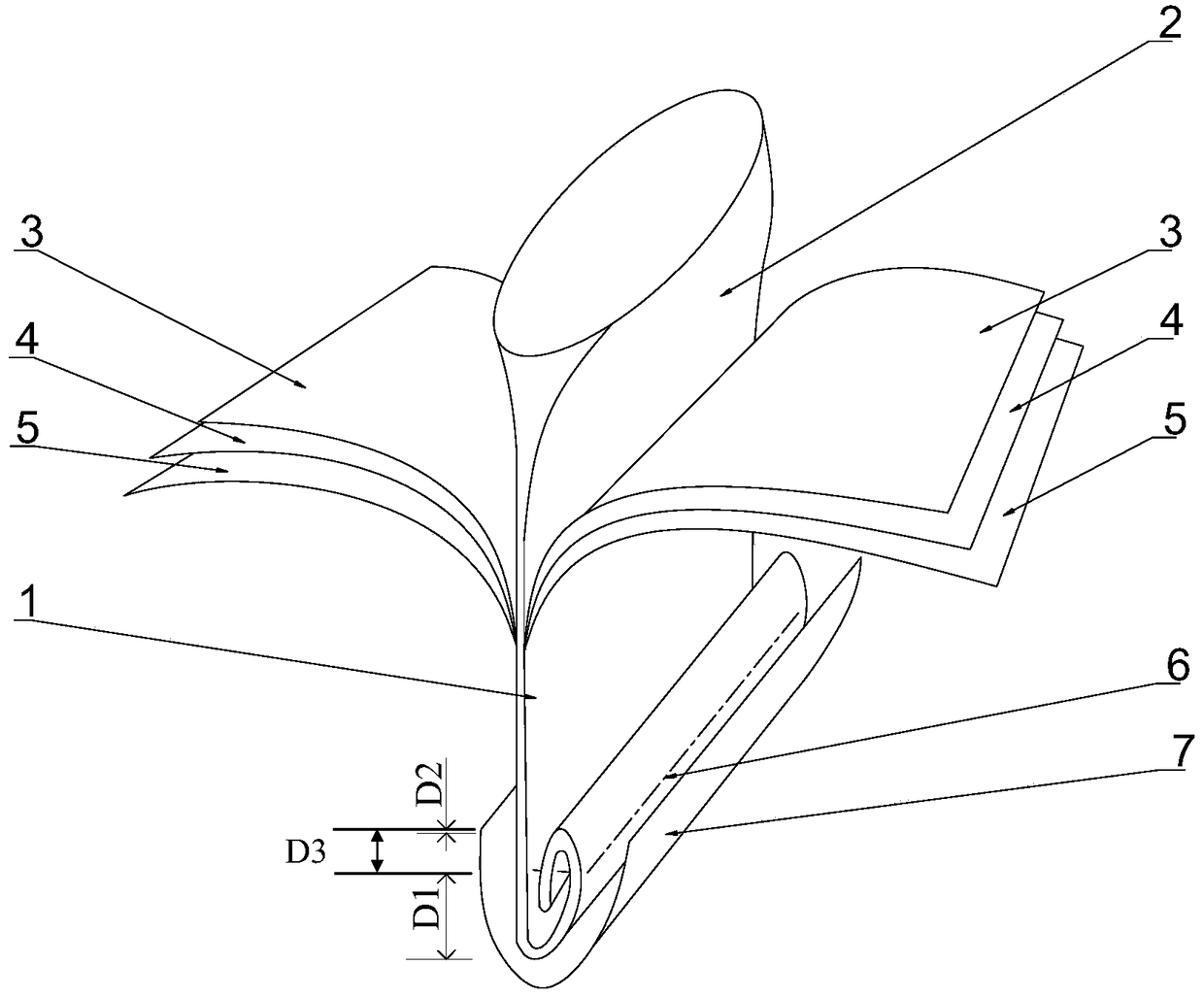

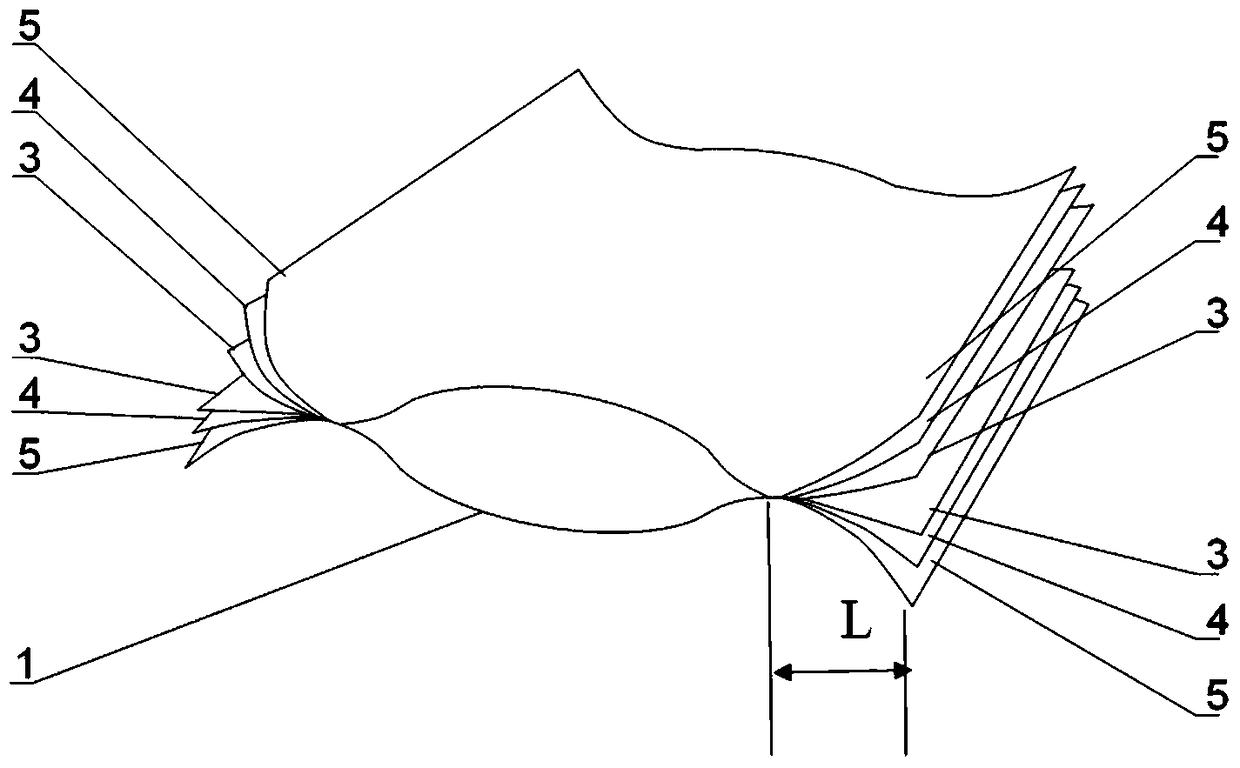

[0083] figure 1 It is the structural representation of the plastic composite woven bag of embodiment 1, image 3 It is a structural schematic view of another state of the plastic composite woven bag of Example 1. Please combine figure 1 , image 3 It should be understood that the composite woven bag 1 is a four-layer composite structure, and the composite woven bag 1 includes a woven bag body 2 , an adhesive material layer 3 , a high barrier material layer 4 and a film layer 5 . Wherein, the woven bag body 2 is used to hold articles; the adhesive material layer 3 is coated on the outer surface of the woven bag body 2; the high barrier material layer 4 is coated on the adhesive material layer 3 On the outer surface, the high barrier material layer 4 is used to prevent external moisture and oxygen from entering the woven bag body 2...

Embodiment 2

[0107] The structure of this embodiment is basically the same as that of Embodiment 1, except that the paper-plastic adhesive tape 7 is bonded to the seam in a V shape. figure 2 It is the structural representation of the plastic composite woven bag of embodiment 2.

[0108] In this embodiment, the paper-plastic adhesive tape 7 is a V-shaped adhesive tape, and the V-shaped adhesive tape is wrapped in the film layer 5 at the position where the seam cover line 6 is arranged. Compared with Example 1, the use of the V-shaped adhesive tape only requires adhesive connection at the corresponding two ends of the V-shaped adhesive tape, the operation is simpler, and the barrier and sealing properties are better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com