Facing bamboo plastic heat conduction wallboard with negative ions and processing method thereof

A negative ion and bamboo-plastic technology, which is applied in the handover field of decorative bamboo-plastic thermally conductive wallboards, can solve the problems that cannot meet the increasing expansion of functional wallboards, have not found decorative bamboo-plastic thermally conductive wallboards, and do not have natural textures. It is not easy to achieve moisture resistance, dimensional stability, good market prospects, and the effect of enhancing interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

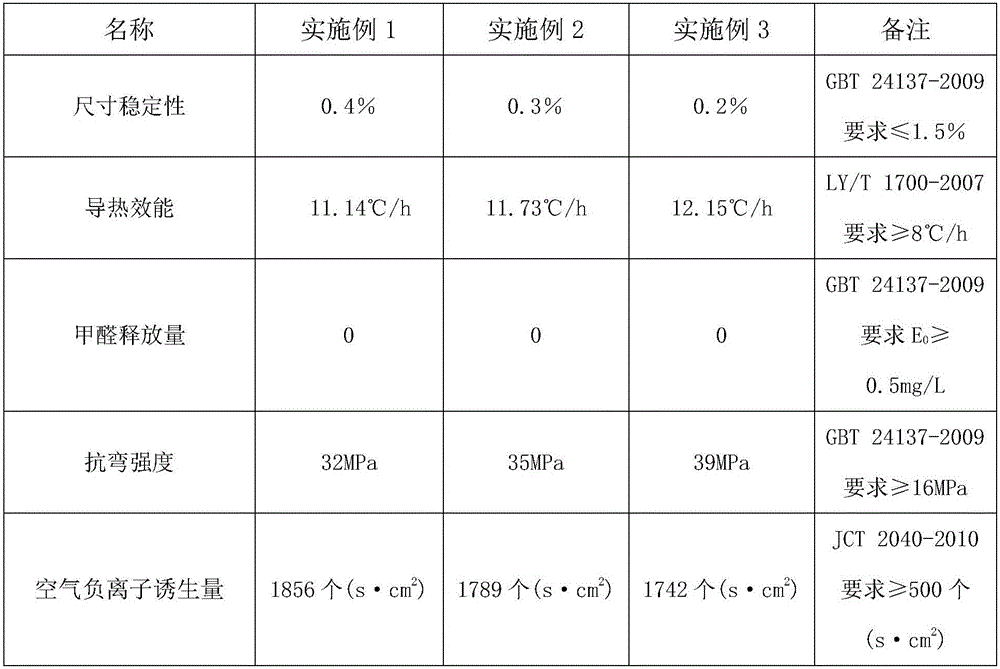

Embodiment 1

[0035] A decorative bamboo-plastic heat-conducting wallboard with negative ions is composed of the following components according to the mass ratio: bamboo powder 25%, PVC and polyether block amide blend 30%, nano-scale bamboo charcoal powder 8%, germanium stone powder 30% %, lubricant 2%, foaming agent 3%, coupling agent 2%.

[0036] Among them, PVC and polyether block amide blends are mixed in a mass ratio of 2:8; the lubricant is a mixture of zinc stearate and ethylene bisstearic acid amide, mixed in a mass ratio of 1:2 Formed; the coupling agent is titanate; the foaming agent is azodicarbonamide.

Embodiment 2

[0038] A negative-ion decorative bamboo-plastic heat-conducting wallboard is composed of the following components according to the mass ratio: bamboo powder 23%, PVC and polyether block amide blend 33%, nano-scale bamboo charcoal powder 9%, germanite powder 26% , lubricant 3%, foaming agent 3%, coupling agent 3%.

[0039] Among them, PVC and polyether block amide blends are mixed in a mass ratio of 1:1 and the lubricant is a mixture of zinc stearate and ethylene bisstearic acid amide, mixed in a mass ratio of 2:1. into; the coupling agent is titanate; the foaming agent is azodicarbonamide.

Embodiment 3

[0041] A negative-ion decorative bamboo-plastic heat-conducting wallboard is composed of the following components according to the mass ratio: bamboo powder 20%, PVC and polyether block amide blend 35%, nano-scale bamboo charcoal powder 10%, germanium stone powder 25% , lubricant 4%, foaming agent 3%, coupling agent 3%.

[0042]Among them, PVC and polyether block amide blends are mixed in a mass ratio of 8:2; the lubricant is a mixture of zinc stearate and ethylene bisstearic acid amide, mixed in a mass ratio of 1:2 Formed; the coupling agent is titanate; the foaming agent is azodicarbonamide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com