Fire-proof door

A fireproof door and fireproof material technology, applied in the field of fireproof doors, can solve the problems of fireproof door fireproof performance decline, door frame not fireproof, easy warping and deformation, etc., achieve reasonable thickness and position configuration, improve fireproof performance, and not easy to warp deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

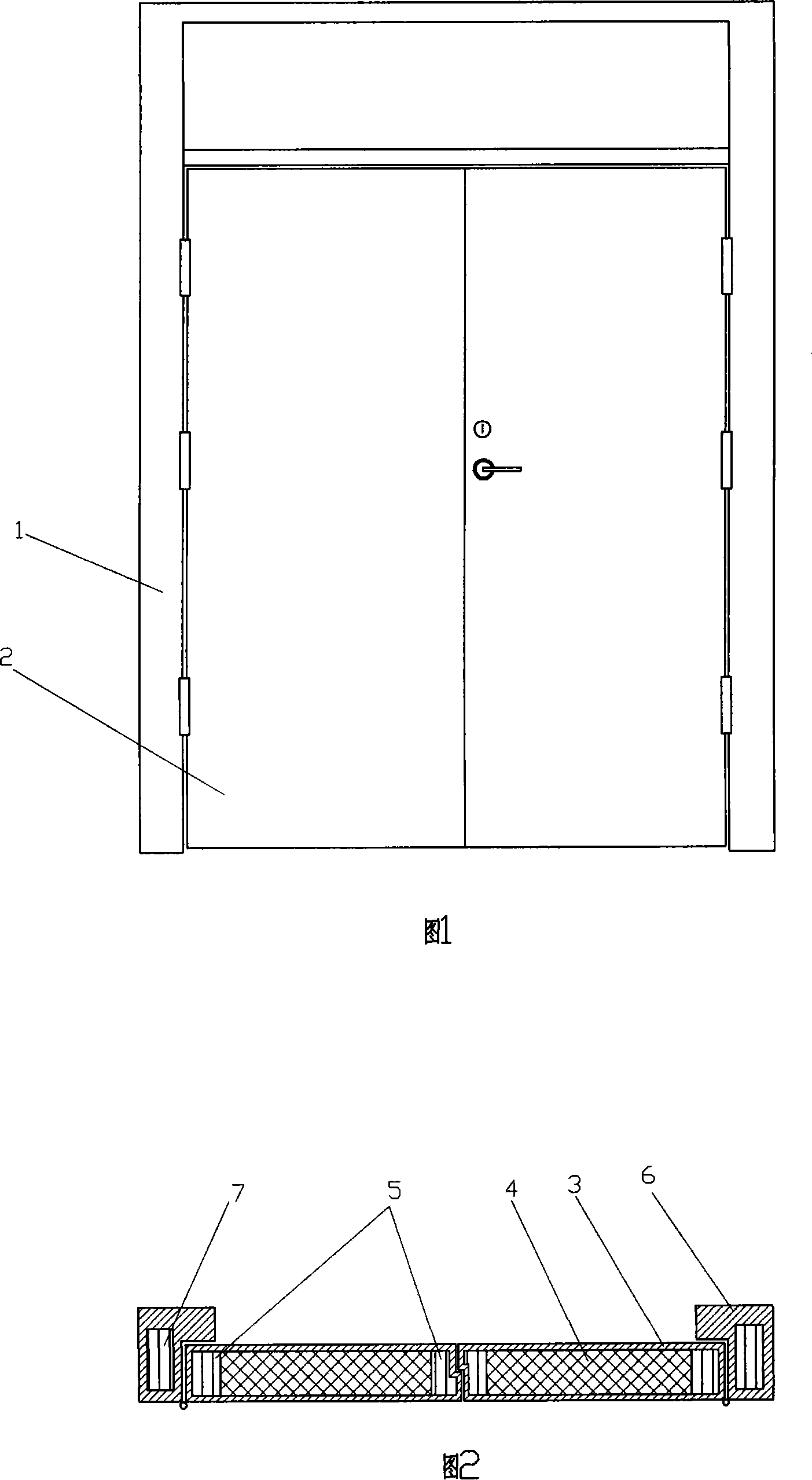

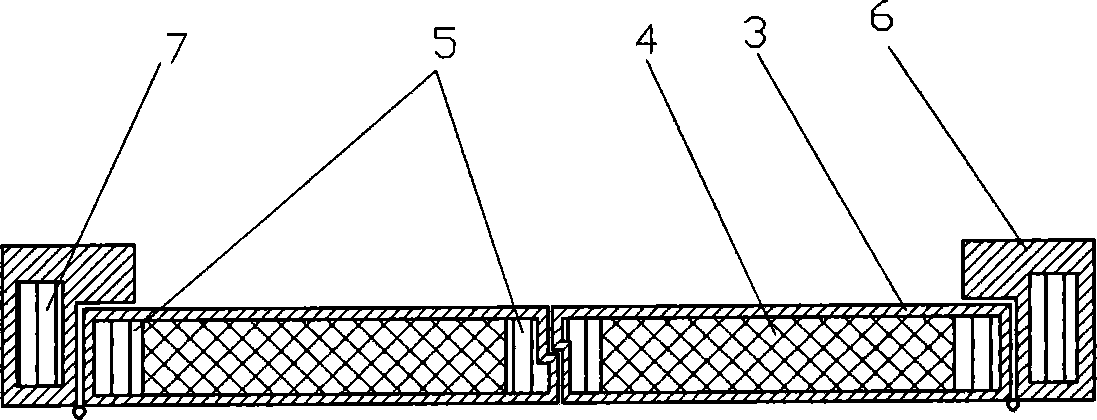

[0024] Such as figure 1 , 2 As shown, the fire door of this embodiment includes a door frame 1 and a door leaf 2, and the door leaf 2 includes a door leaf outer cladding 3, a door leaf inner core layer 4 and a door leaf skeleton 5, and the door leaf inner core layer 4 is arranged between the door leaf skeletons 5, The door leaf outer cladding 3 completely covers the door leaf frame 5 and the door leaf inner core layer 4, and the door leaf outer cladding layer 3, the door leaf inner core layer 4 and the door leaf frame 5 are formed by integral composite casting; the door frame 1 includes The door frame outer cladding 6 and the door frame skeleton 7, the door frame outer cladding 6 completely covers the door frame skeleton 7, and the door frame outer cladding 6 and the door frame skeleton 7 are formed by integral composite casting; the door leaf outer cladding 3 and the door frame outer cladding 6 adopt Made of inorganic fireproof materials; the thickness of the door leaf 2 is ...

Embodiment 2

[0029] Such as figure 1 , 2As shown, the fire door of this embodiment includes a door frame 1 and a door leaf 2, and the door leaf 2 includes a door leaf outer cladding 3, a door leaf inner core layer 4 and a door leaf skeleton 5, and the door leaf inner core layer 4 is arranged between the door leaf skeletons 5, The door leaf outer cladding 3 completely covers the door leaf frame 5 and the door leaf inner core layer 4, and the door leaf outer cladding layer 3, the door leaf inner core layer 4 and the door leaf frame 5 are formed by integral composite casting; the door frame 1 includes The door frame outer cladding 6 and the door frame skeleton 7, the door frame outer cladding 6 completely covers the door frame skeleton 7, and the door frame outer cladding 6 and the door frame skeleton 7 are formed by integral composite casting; the door leaf outer cladding 3 and the door frame outer cladding 6 adopt Made of inorganic fireproof materials; the thickness of the door leaf 2 is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com