Modular box-type assembly-structure low-noise cabinet

A modular and noise machine technology, applied in pump devices, mechanical equipment, non-variable-capacity pumps, etc., can solve the problems of cumbersome assembly, large number of parts, and many connection positions of plate parts, etc. The effect of good structural strength and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

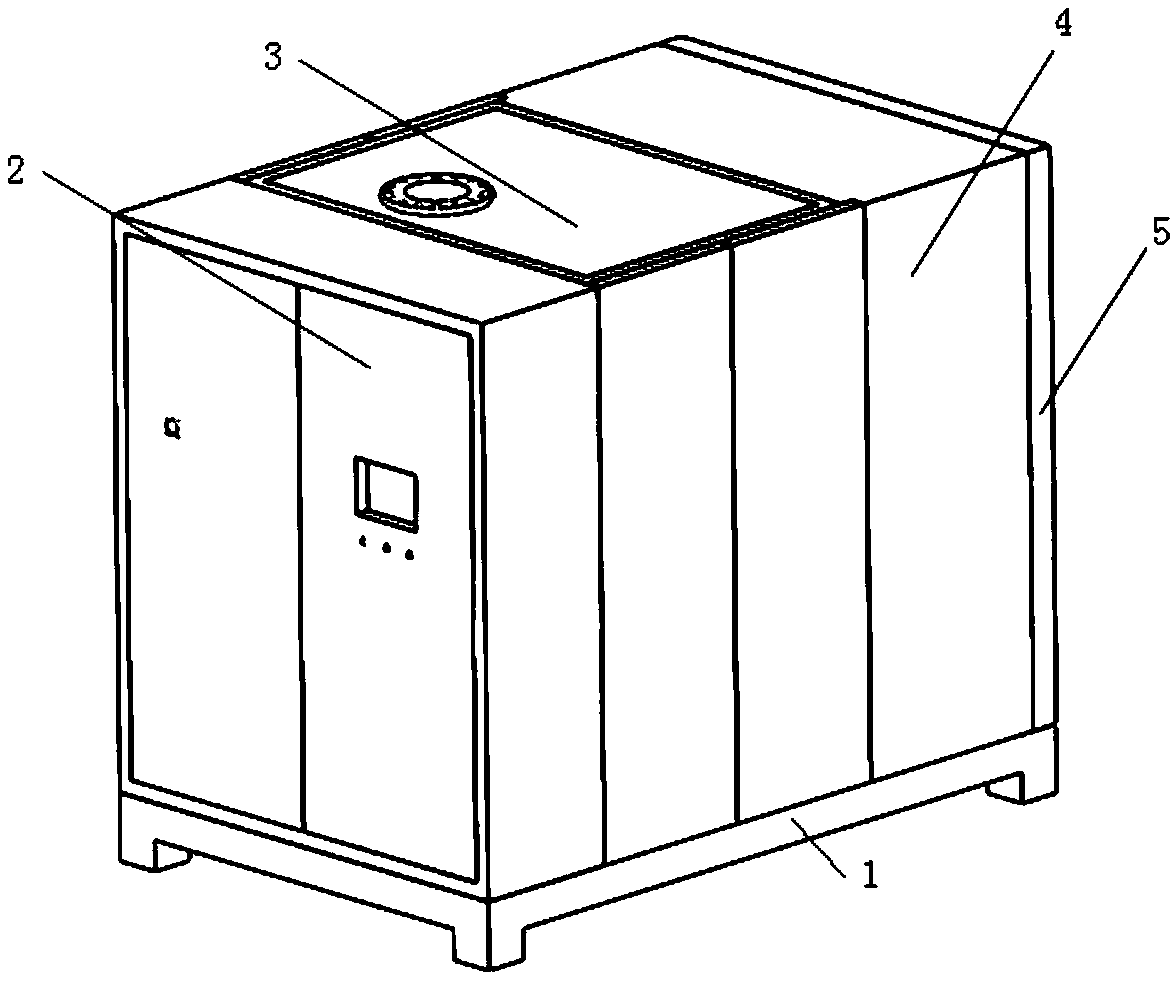

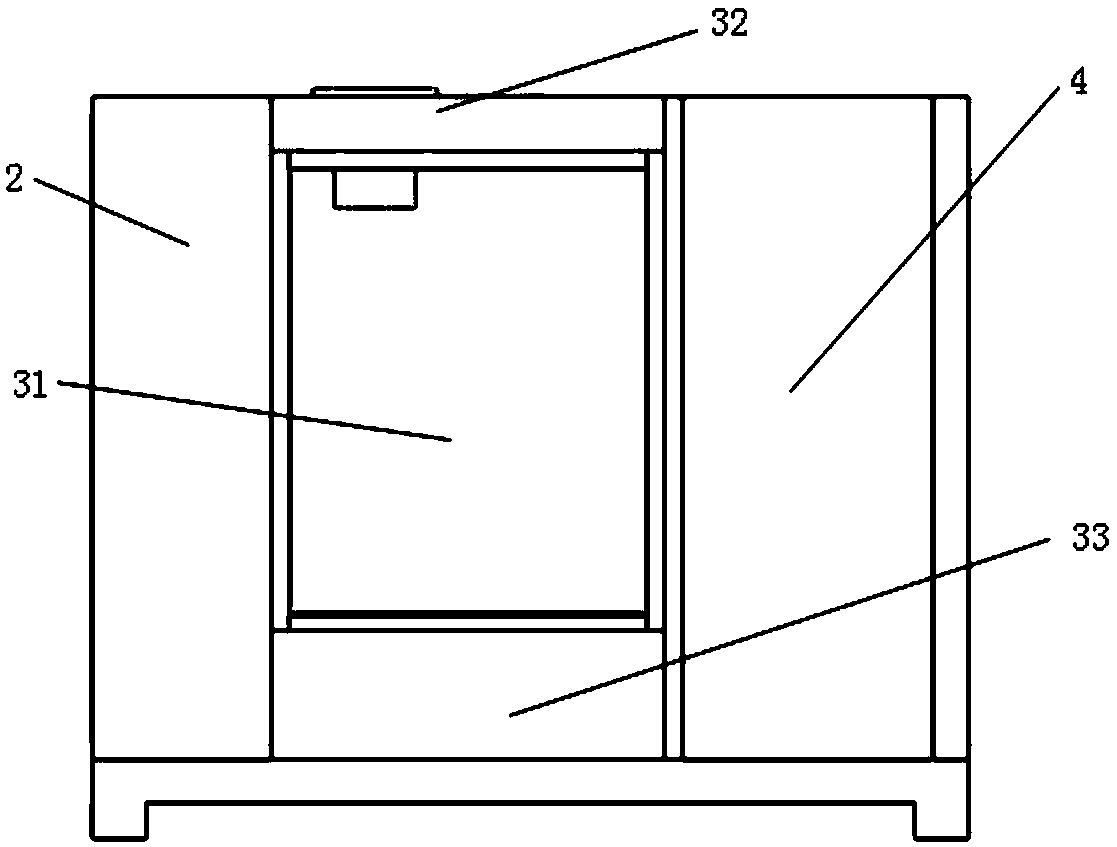

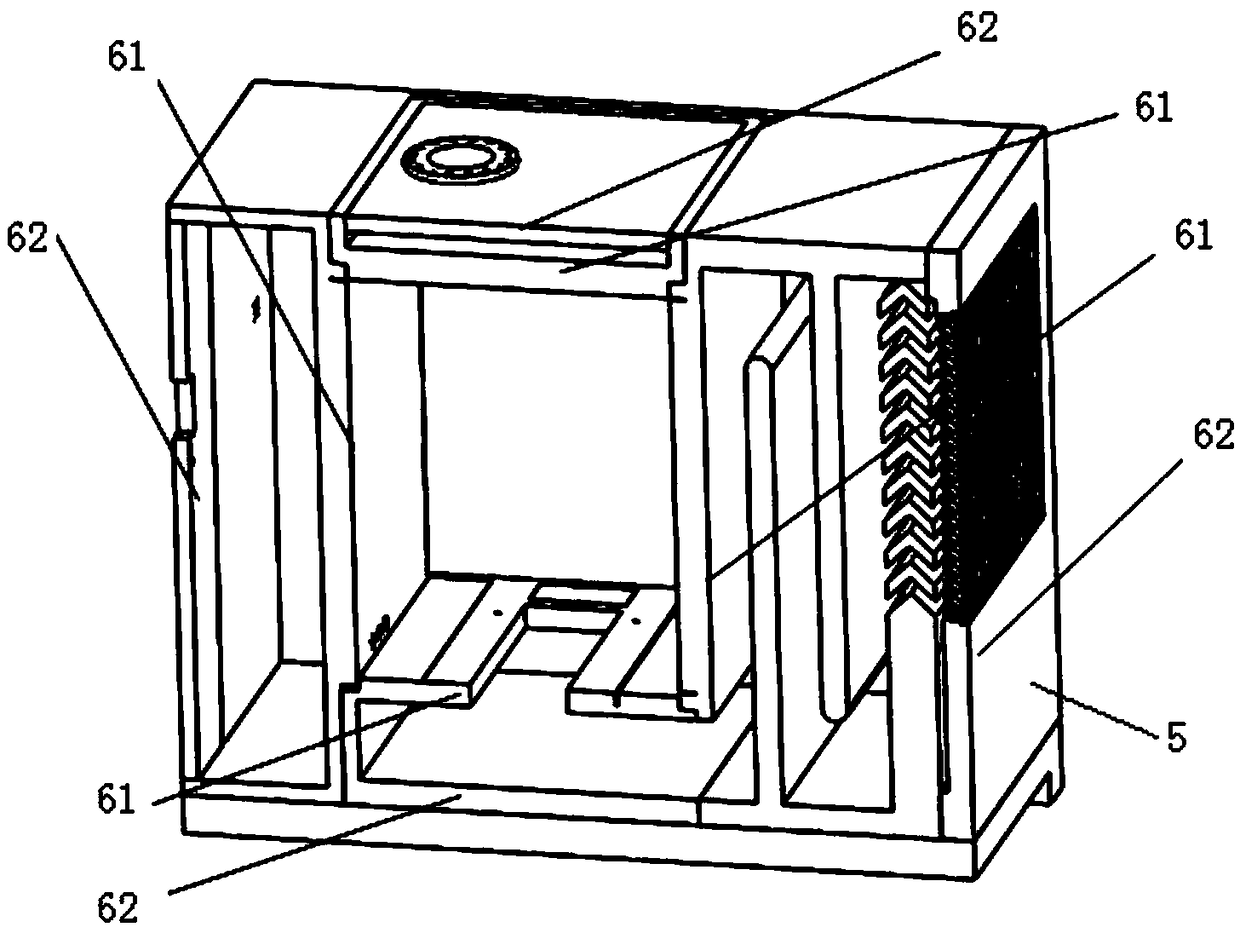

[0033] Such as figure 1 and figure 2 As shown, the present invention discloses a modular box-type assembly structure low-noise cabinet, including a chassis 1 and an electric control cabinet 2, a main cabinet 3, a main muffler cabinet 4 and a filter cabinet 5 installed on the chassis 1 in sequence from left to right .

[0034] The main cabinet 3 is a rectangular structure, including a main cabinet body 31, a main top cabinet 32 and a main bottom cabinet 33, and the main top cabinet 32 and the main bottom cabinet 33 are fixed on the upper and lower ends of the main cabinet body 31, and the main cabinet body The inner cavity of 31 corresponds to the inner cavity of the main top cabinet 32 and the inner cavity of the main bottom cabinet 33.

[0035] The main cabinet 3 is not an independent box, but a space surrounded by multiple boxes and panels. Different from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com