Method for manufacturing printed circuit board using base material of high thermal conductivity suitable for being inserted into non-surface component

A printed circuit board, high thermal conductivity technology, applied in the direction of printed circuit, printed circuit manufacturing, printed circuit components, etc., can solve problems such as insulation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

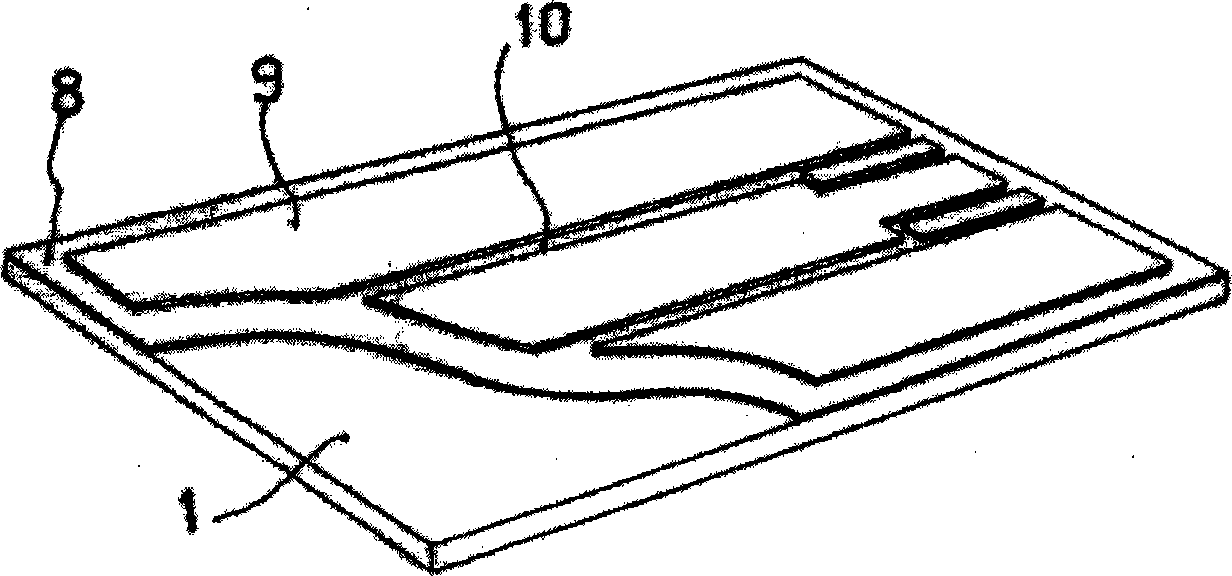

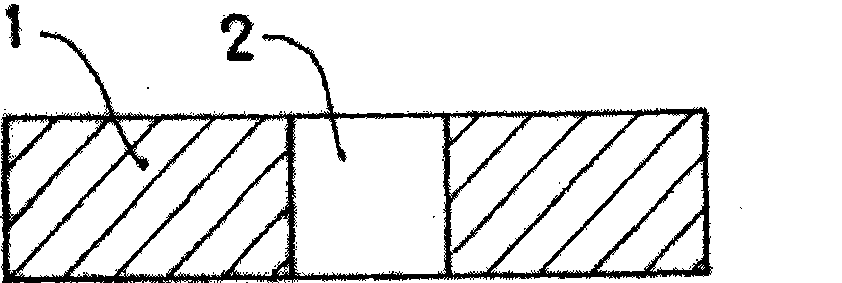

[0052] As can be seen in the figure, the procedure starts with the metal substrate (1) on which the embossing operation will be carried out, obtaining drilled holes (2) sufficient in number and position for the electronic components to be inserted later in the circuit. see figure 2 and 3 .

[0053] Next, the metal base plate (1) is deposited on a suction template (3) provided with appropriate suction holes (4) arranged correspondingly to the drilled holes (2). The injection head (5) of the printer with the injection hole (6) having the same diameter as the drilled hole (2) is located on the metal base (1). see Figure 4 .

[0054] The insulating resin (7) is then applied to the assembly under a certain pressure while evacuating air from the borehole (2) via the suction hole (4) until the borehole (2) is filled, as Figure 5 visible. Acrylate polymers obtained by exposure to ultraviolet light are advantageously used as insulating resins (7), more specifically Durashield ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com