Radiographic testing method for welding beams under radioactive environment of nuclear power station

A technology of radiation detection and radioactivity, which is applied in the field of radiation detection, can solve the problems that the classical method of detection and positioning accuracy cannot meet the requirements of nuclear power, and the film positioning accuracy cannot meet the requirements of nuclear power, so as to reduce time, facilitate continuous work, and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

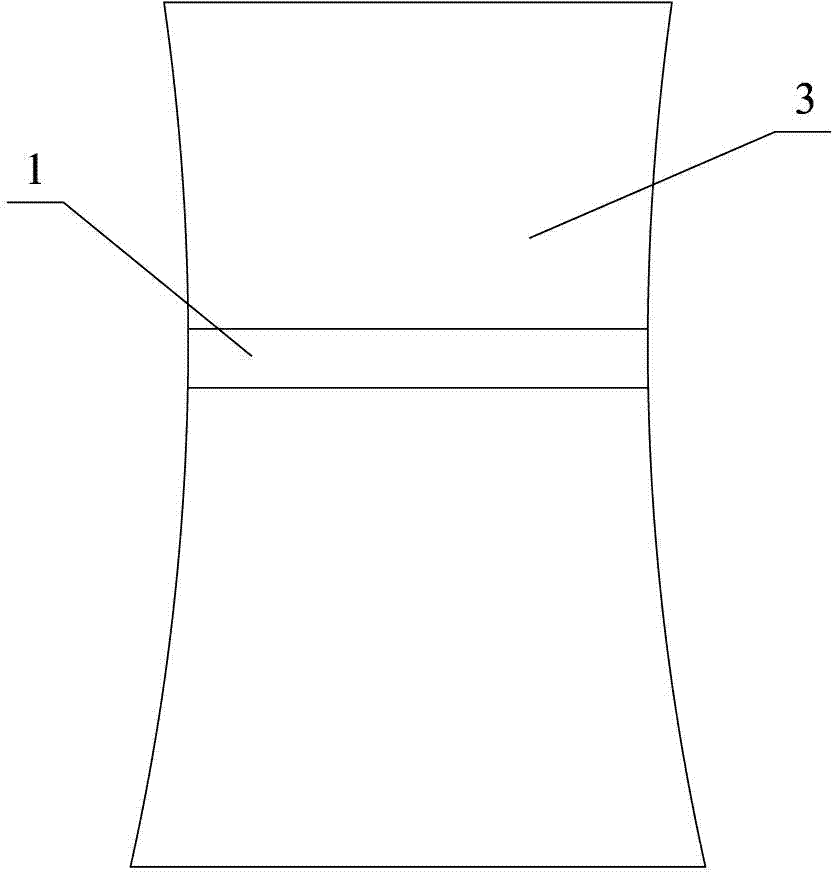

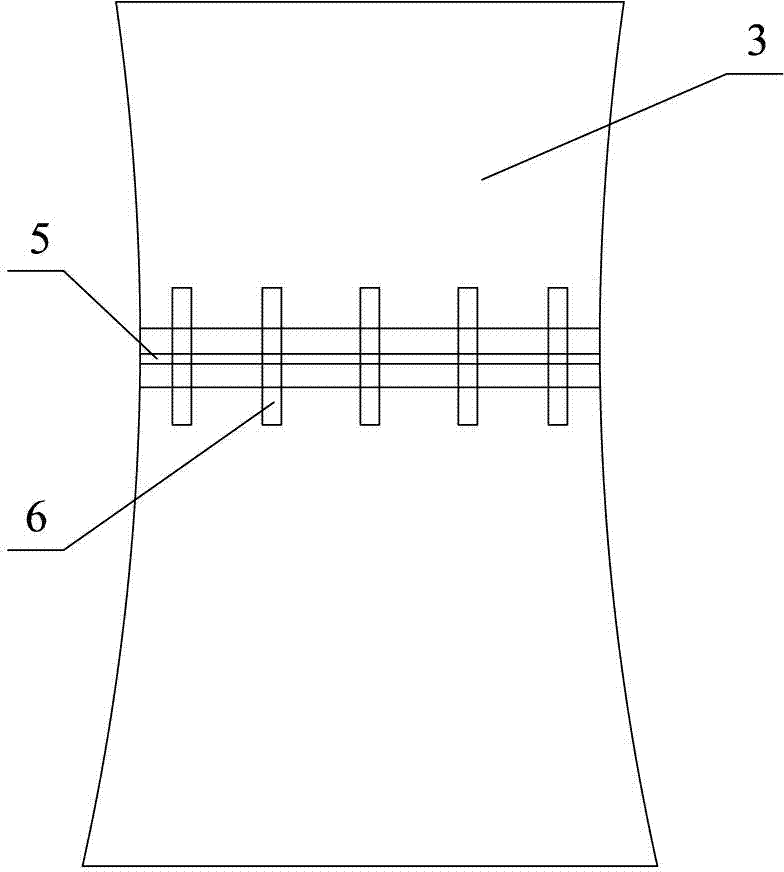

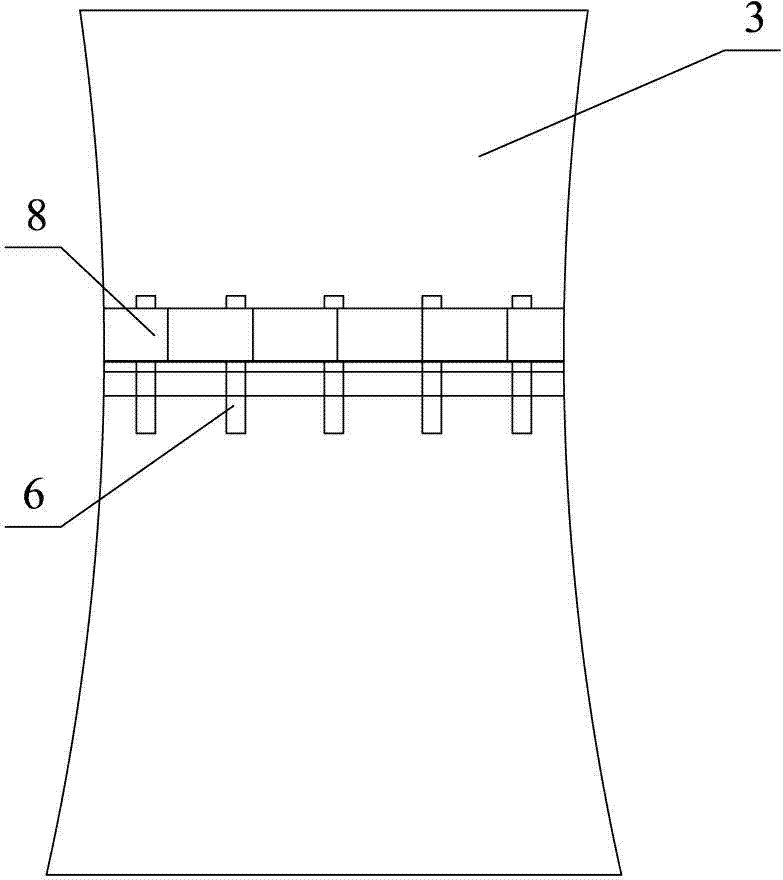

[0058] Embodiment 1: A radiation detection method for welds in a radioactive environment, used to detect such as attached figure 1 Weld 1 of large diameter pipe 3 is shown. Representative welds are the evaporator and reactor main pipe welds and all pipe welds that can be center exposed.

[0059] The radiographic detection method includes three stages of preparation, operation and post-processing. In the preparation stage, it includes preparation marking system, dark bag system, exposure system, auxiliary accessory system and data calculation system.

[0060] The marking system includes a lead ruler 5 for positioning the weld seam 1, and the lead ruler 5 includes lead characters for circumferentially positioning the weld seam 1 and lead strips for axial positioning, wherein the lead characters are lead numbers and the lead characters are evenly arranged in the length direction , wherein the lead strips are arranged between adjacent lead characters, and the image quality meter...

Embodiment 2

[0068] Embodiment 2: A radiation detection method for welds in a radioactive environment, used to detect such as attached by radiation detection methods in a radioactive environment Figure 5 The weld seam 1 of the pipe socket of the pressure vessel 2 is shown. The pressure vessel 2 is spherical, and the welding seam 1 is annular on the spherical surface. The representative welds are the welds of the tube sockets of various parts of the voltage stabilizer equipment.

[0069] The radiographic detection method includes three stages of preparation, operation and post-processing. In the preparation stage, it includes preparation marking system, dark bag system, exposure system, auxiliary accessory system and data calculation system.

[0070] The marking system includes marking stickers 6. The marking stickers 6 include lead characters for circumferential positioning of 1, lead strips for radial positioning of 1, hidden bag alignment lines and markings for overlapping steel stamp...

Embodiment 3

[0078] Embodiment 3: A radiographic detection method for welds in a radioactive environment, which is used to detect the weld 1 of a small-diameter pipeline 4 by means of a radioactive detection method in a radioactive environment. The representative welds are the welds of the nozzle of the voltage stabilizer and the upper head, the welds of the secondary and tertiary components and the double-wall transilluminated pipes of the auxiliary pipeline.

[0079] The radiographic detection method includes three stages of preparation, operation and post-processing. In the preparation stage, it includes preparation marking system, dark bag system, exposure system, auxiliary accessory system and data calculation system.

[0080] Similar to the detection of the large-diameter pipeline 3 , the marking system includes a marking tape 9 for circumferentially positioning the weld 1 , a lead strip for axially positioning the weld 1 , and an image quality meter. Lead type is marked on the mark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com