Intelligent novel water groove cutting machine

A water tank cutting machine, a new type of technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve unsolved problems, improve product quality and work efficiency, reduce manual labor intensity, and achieve high automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

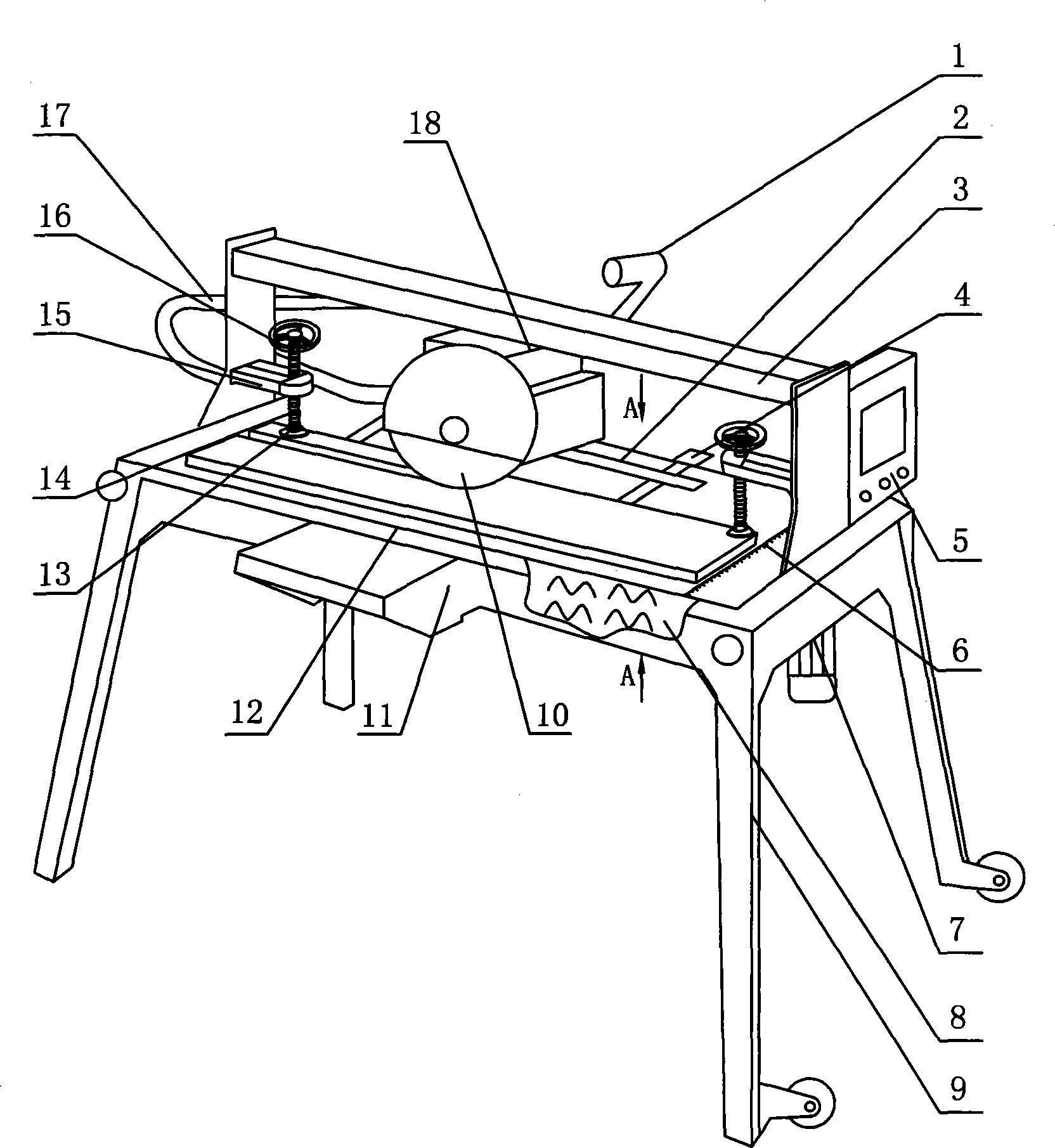

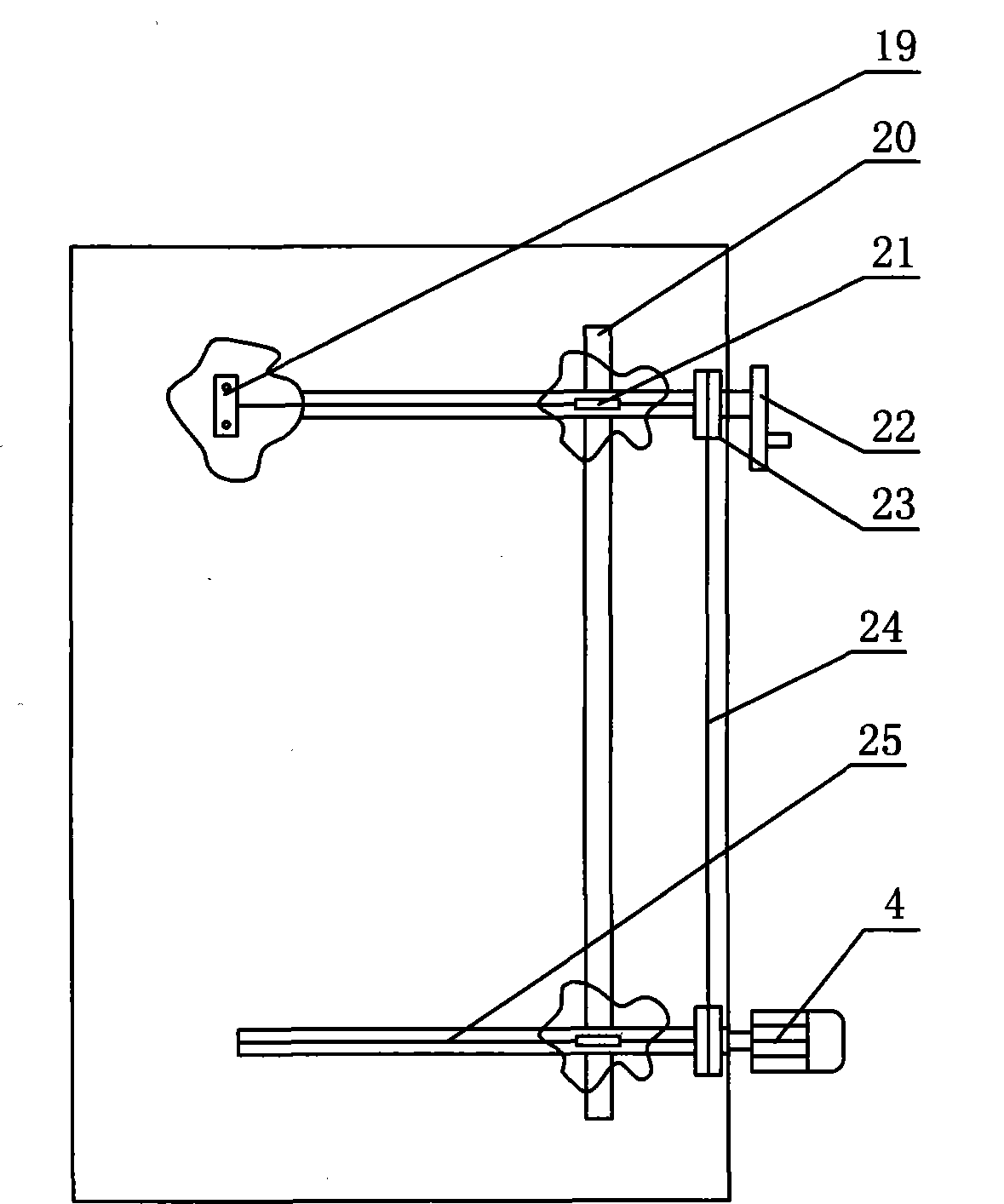

[0015] exist figure 1 , figure 2 Middle: The main body support frame 11 is a rectangular shape welded with steel plates. There are four support feet 9 below the main body support frame 11, of which two support legs 9 are provided with universal wheels, and the top of the main body support frame 11 is provided with The work surface 12 is provided with a guide ruler 6 at the top of the work surface 12, a water tank 8 is arranged in the work surface 12, and a water pump 7 is arranged at the bottom of the water tank 8, and the outlet pipe of the water pump 7 is aligned with the cutting piece 10; the main body support frame 11 There is an I-shaped bracket at the center of the upper end of the frame, the top of the I-shaped bracket is provided with a guide rail groove 3, and two guide rail light circles are arranged in the guide rail groove 3, and four davits are arranged on the top of the moving box 18, and the davits There is a radial bearing at the upper end of the radial beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com