Patents

Literature

45results about How to "Smooth incision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

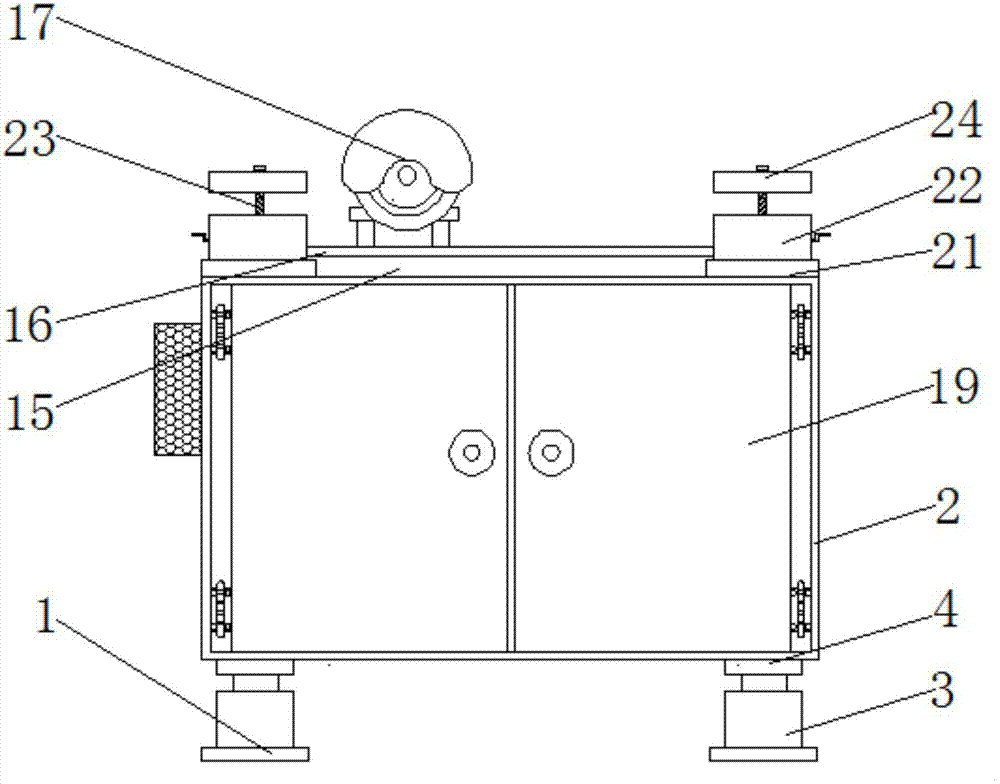

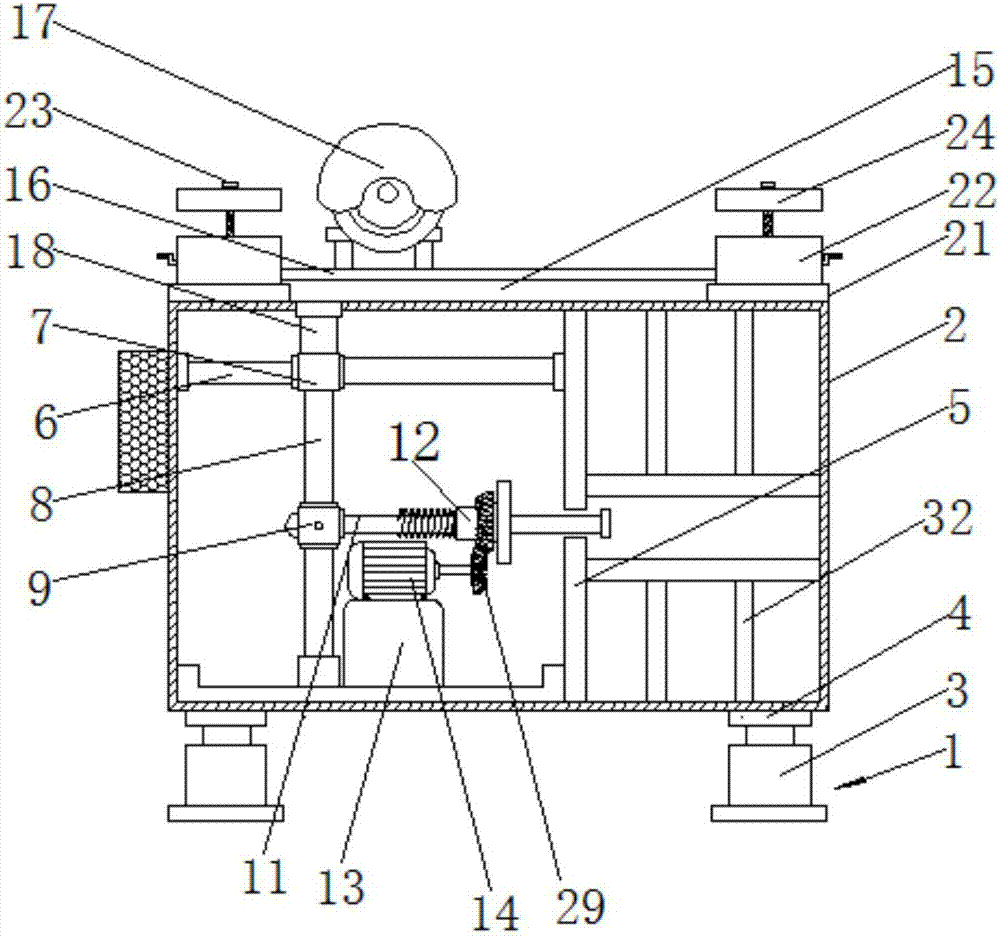

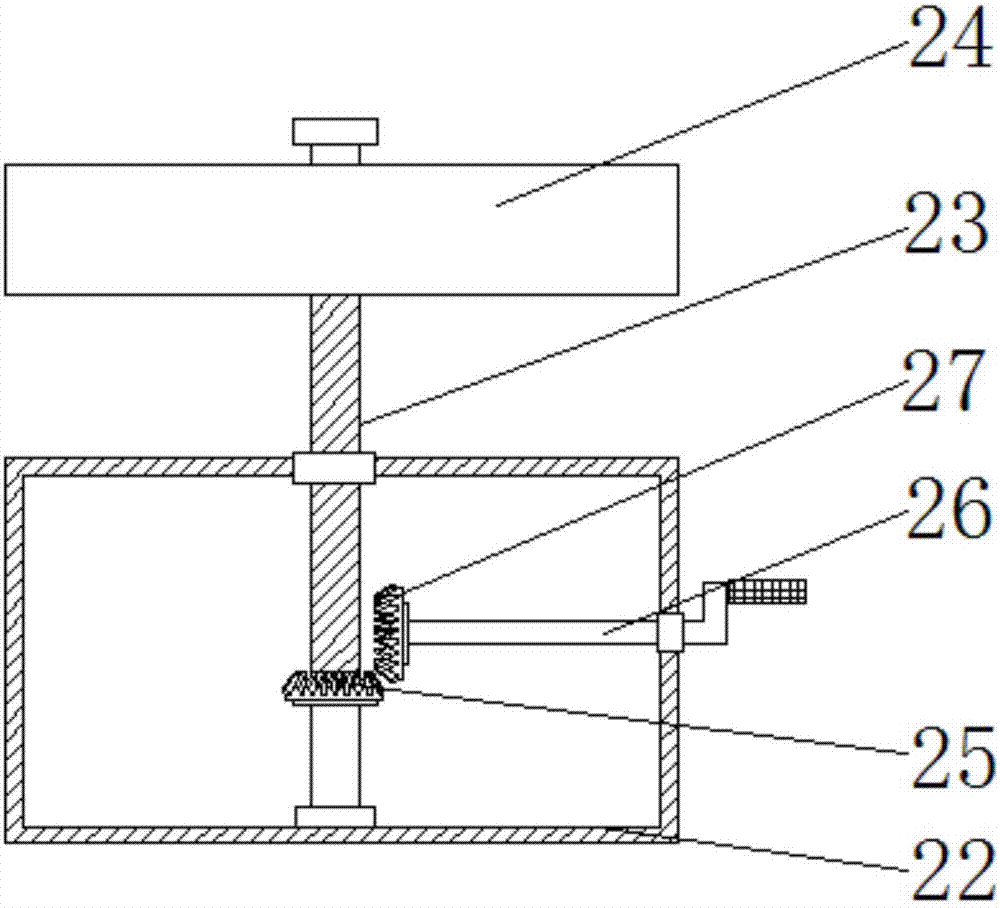

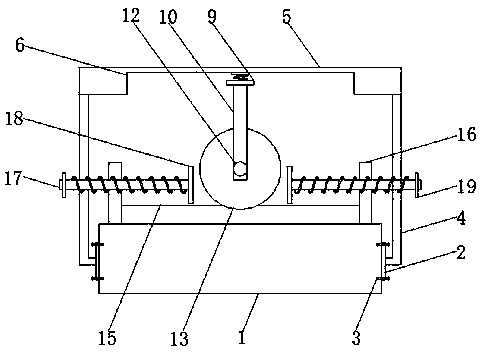

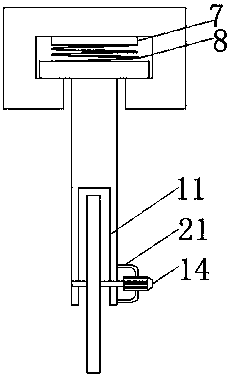

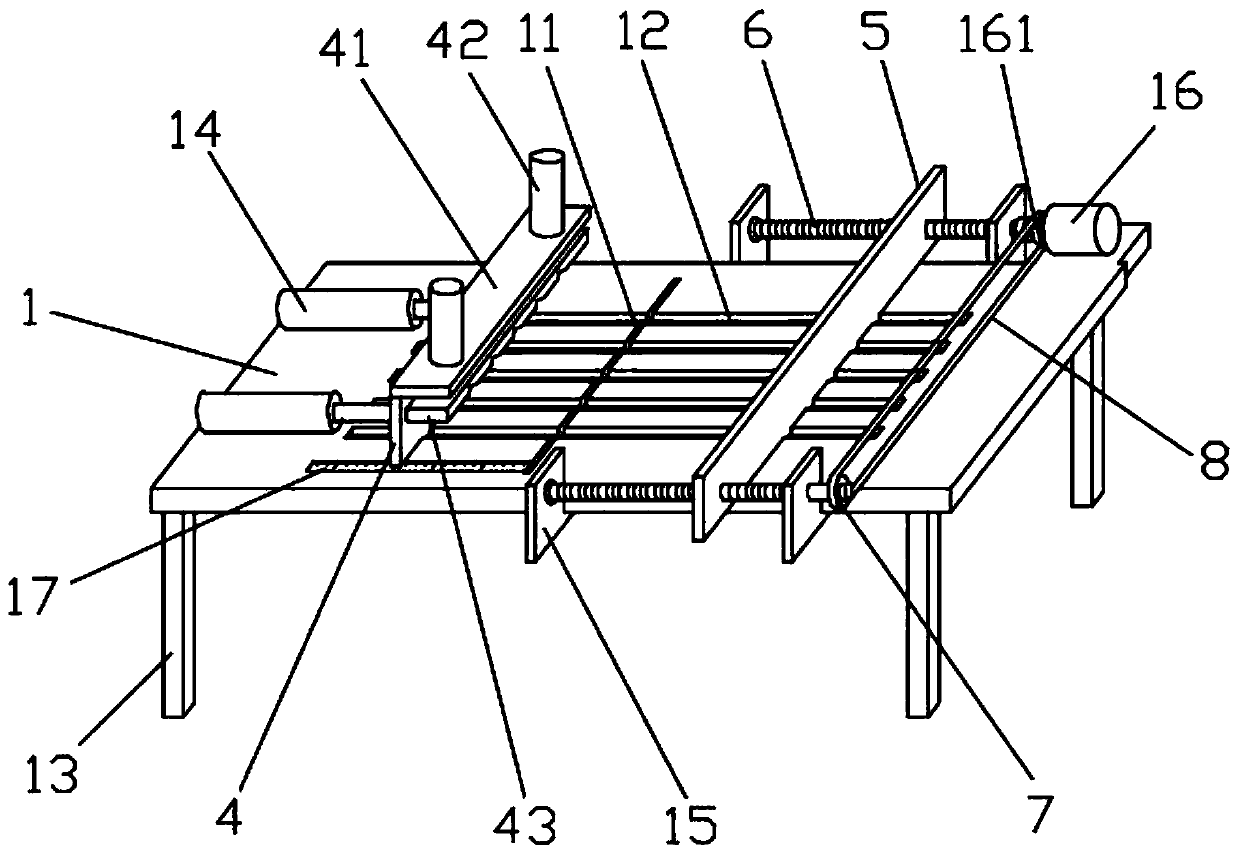

Building wood cutting mechanical device

The invention discloses a mechanical device for cutting construction timber, which comprises a box body, a slide plate is fixedly connected to the top of the box body, a slide block is slidably connected to the top of the slide plate, and a cutting machine is fixedly connected to the top of the slide block; The inside of the body is equipped with a power device that drives the slider to move back and forth in the skateboard; both sides of the top of the box and one side of the skateboard are fixedly connected with slide rails, and the top of the slide rails is slidably connected with a fixed box for fixing building timber. . The invention does not require manual adjustment, greatly increases the automaticity of the device, reduces the working intensity of the laborers, improves the working efficiency of the device, avoids the problem of irregular cuts in the process of cutting boards, and improves the safety of the device. The cutting quality makes the device have a good fixing function, increases the service life of the device, makes the device have a good shock absorption effect and a good storage function.

Owner:钟晓芳

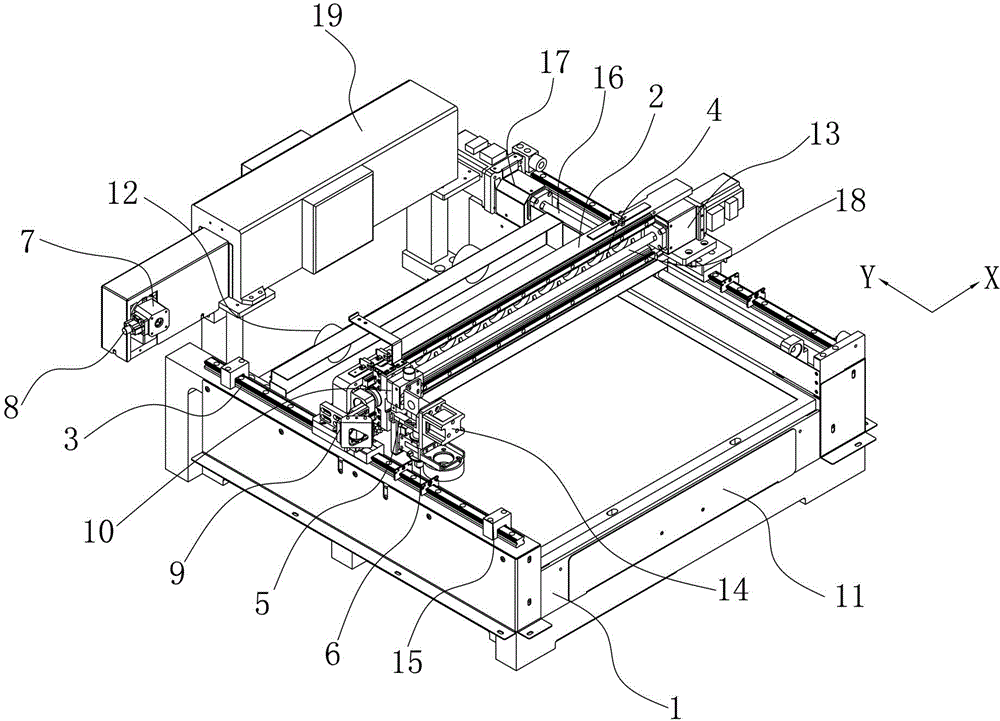

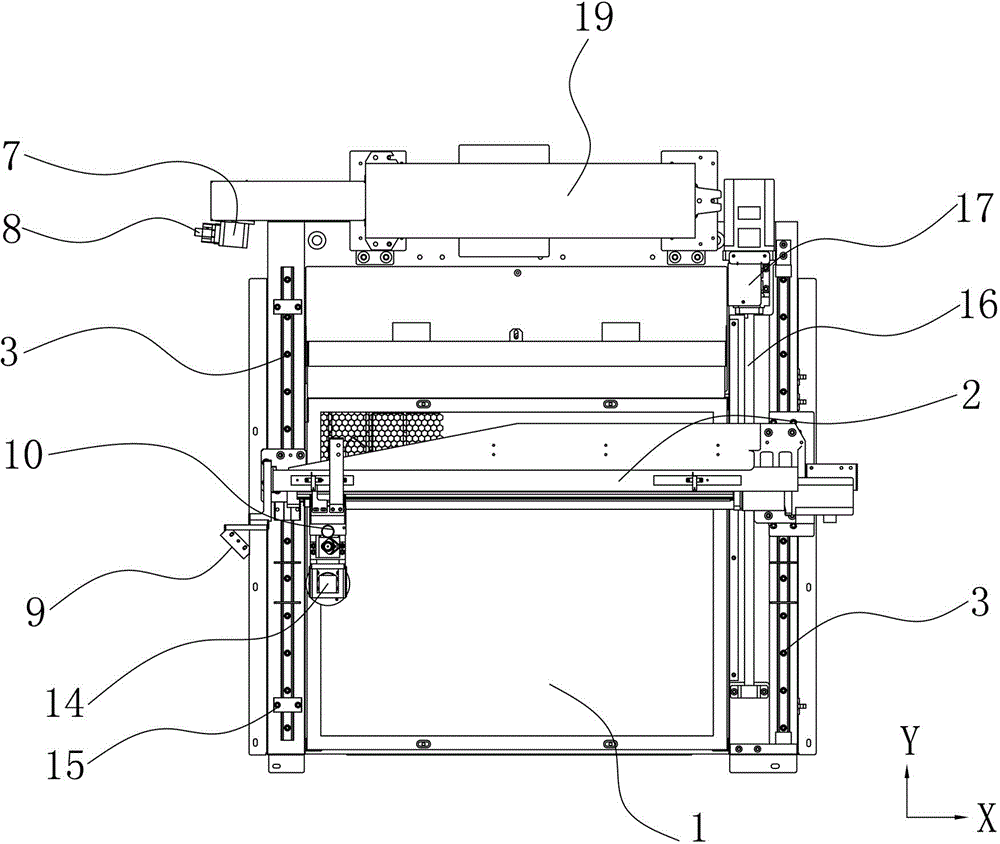

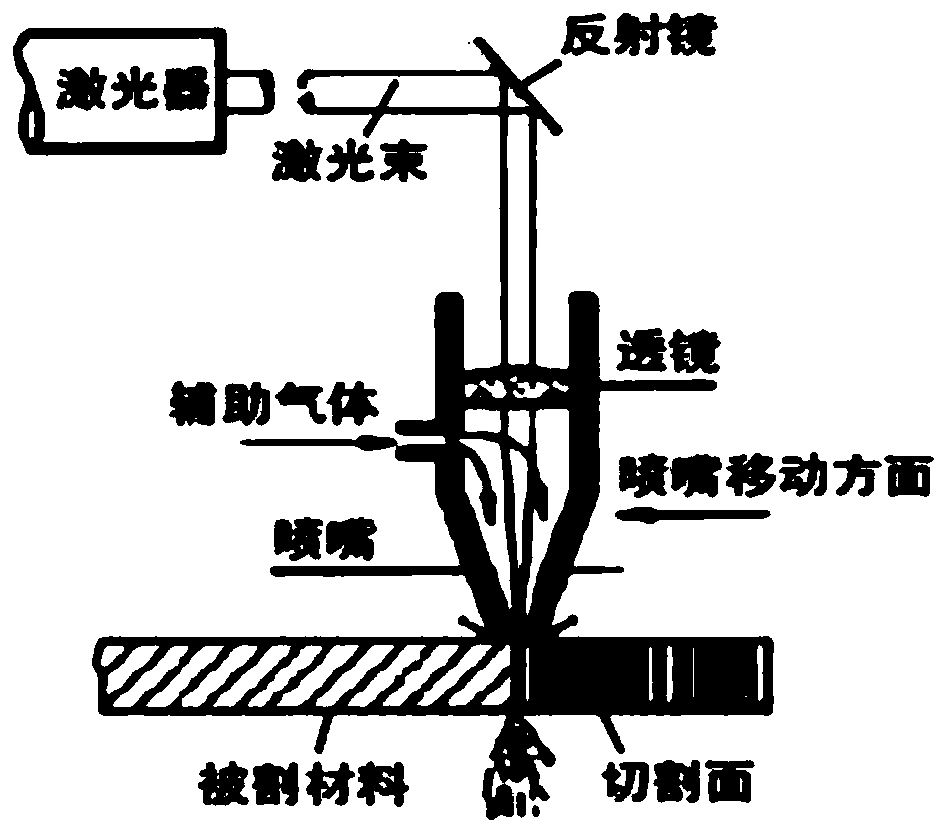

Laser cutting machine

ActiveCN104084698AImprove cut qualityFast cutting speedWelding/soldering/cutting articlesLaser beam welding apparatusLight beamLaser cutting

The invention provides a laser cutting machine. The laser cutting machine comprises a base and an X-axis beam, wherein a Y-axis linear guide rail is arranged on the base, the X-axis beam is connected to the Y-axis linear guide rail in a sliding mode, an X-axis linear guide rail is arranged on the X-axis beam, a tool base is connected to the X-axis linear guide rail in a sliding mode, and a laser cutting head is arranged on the tool base. The cutting machine comprises a laser arranged on the base, a first light path reflection adjuster, a red light indicting lamp and a red light adjuster, the first light path reflection adjuster is used for combining laser beams and red light and transmitting the combined laser beams and red light to a second light path reflection adjuster, the second light path reflection adjuster is used for reflecting the combined laser beams and red light to a third light path reflection adjuster, the third light path reflection adjuster is used for reflecting the combined laser beams and red light to a focusing lens of the laser cutting head so as to irradiate workpieces to be machined. The laser cutting machine has the advantages of being high in cutting accuracy and solves the technical problem that the cutting accuracy of an existing cutting machine is low.

Owner:SHENZHEN HANYO LASER TECH

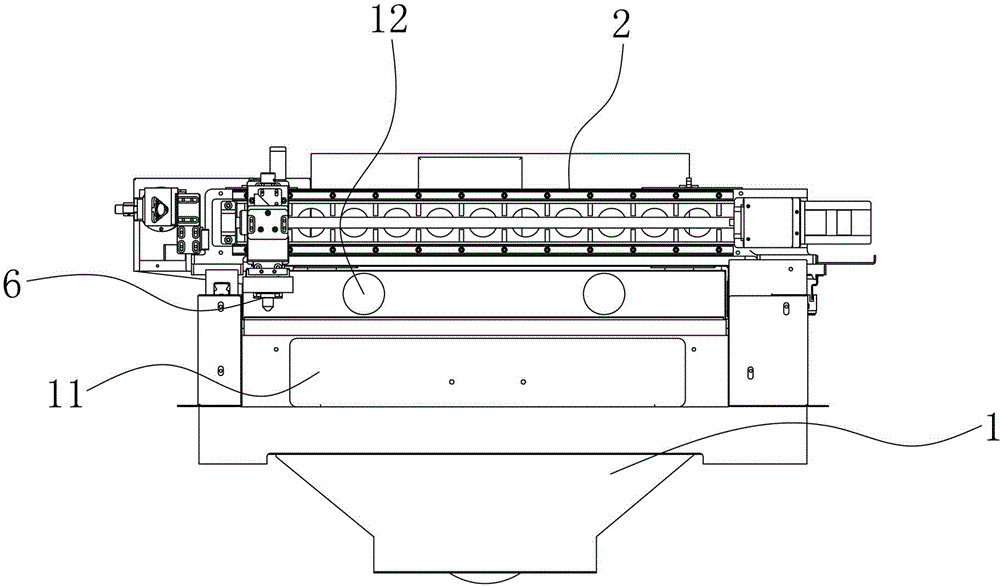

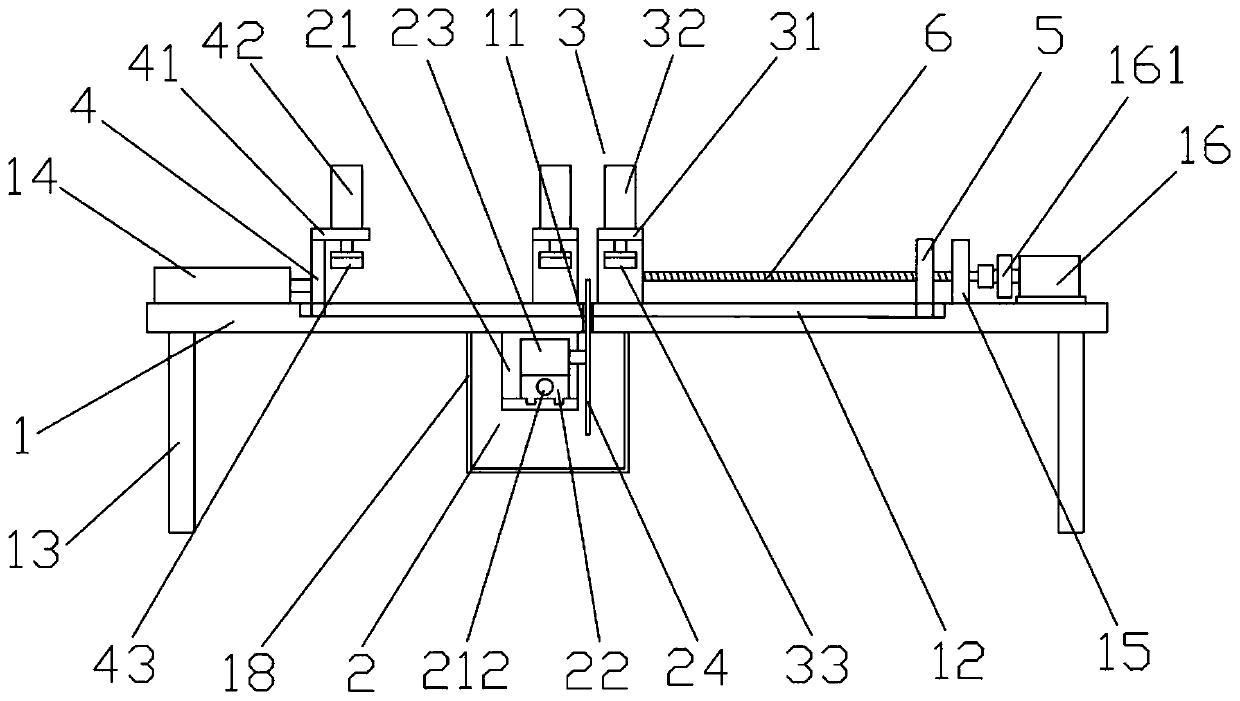

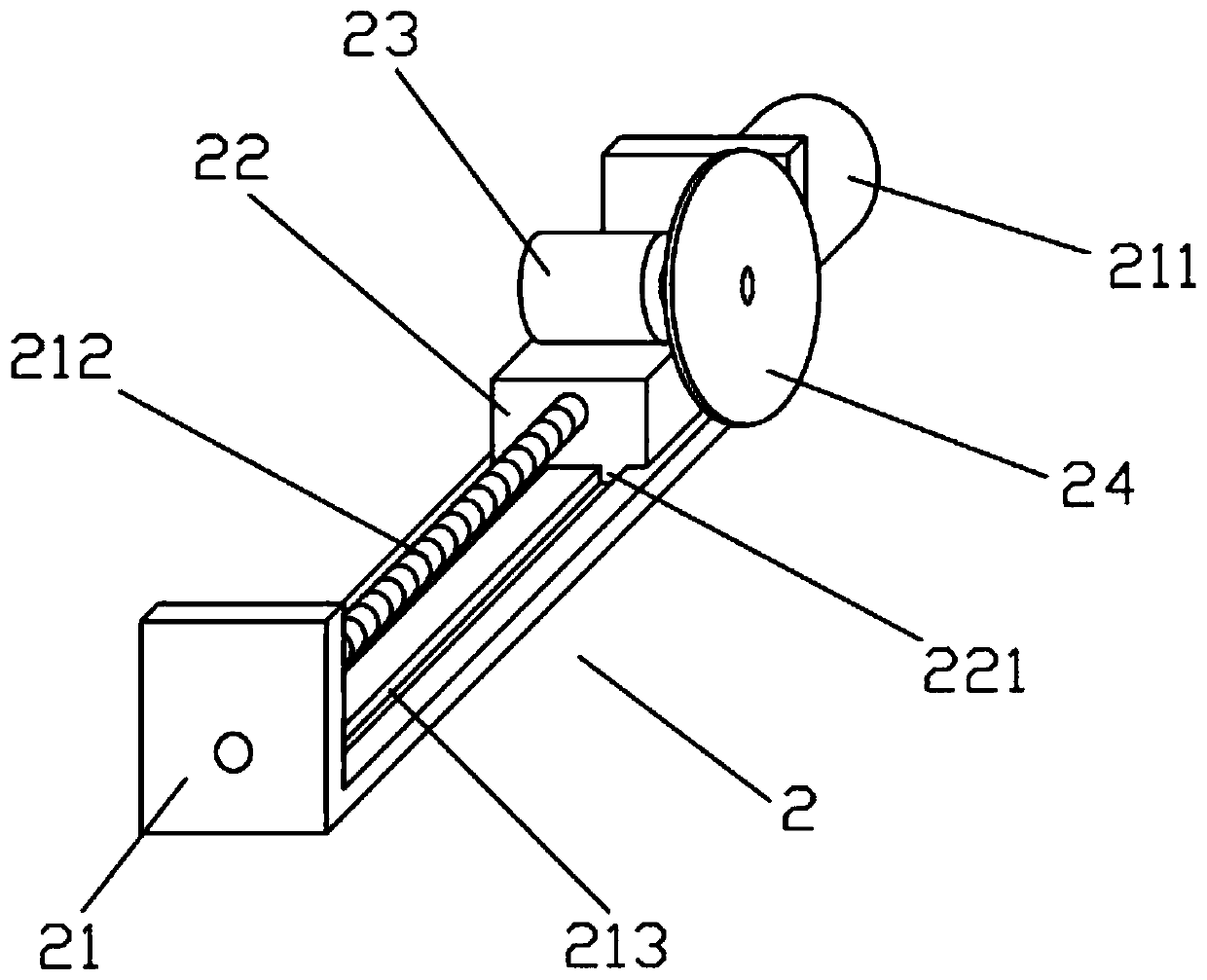

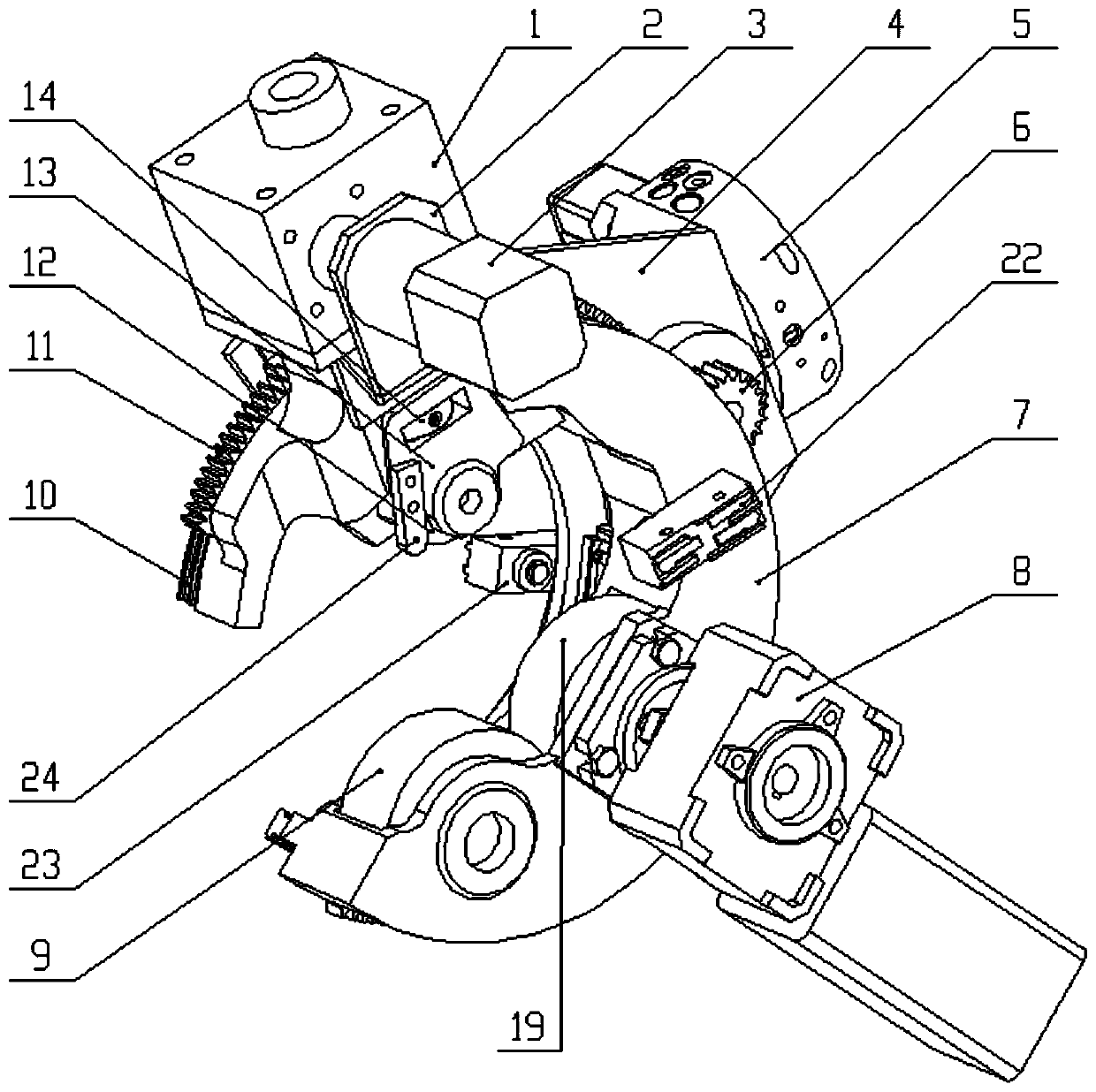

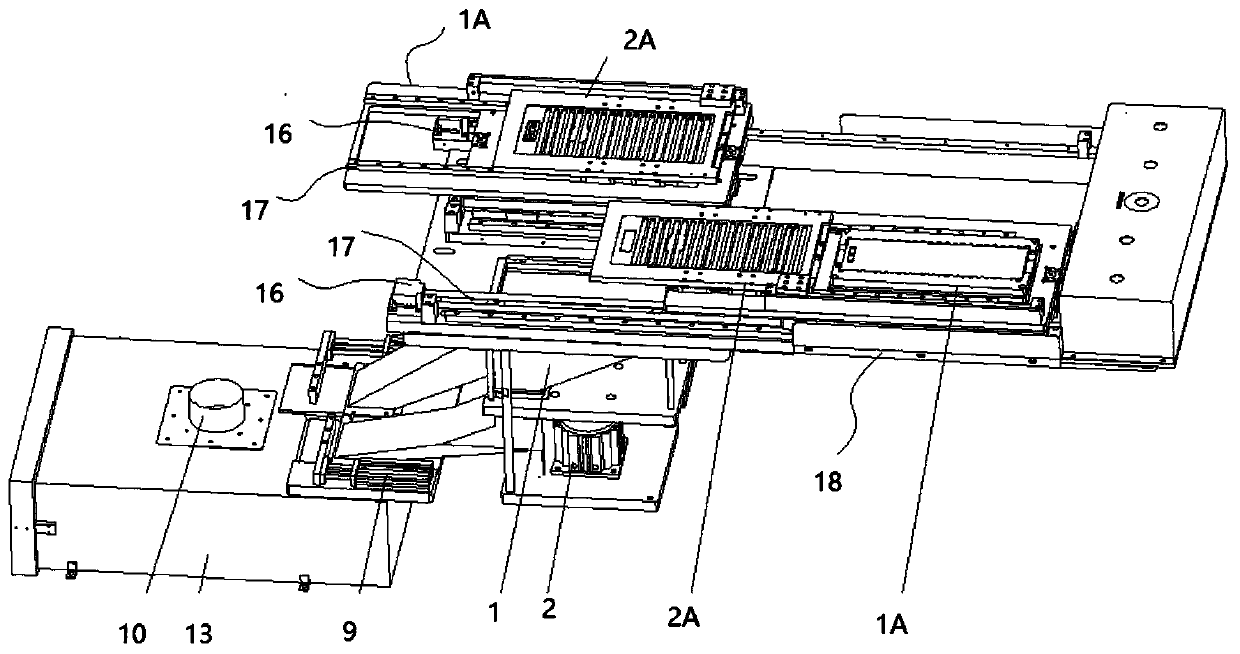

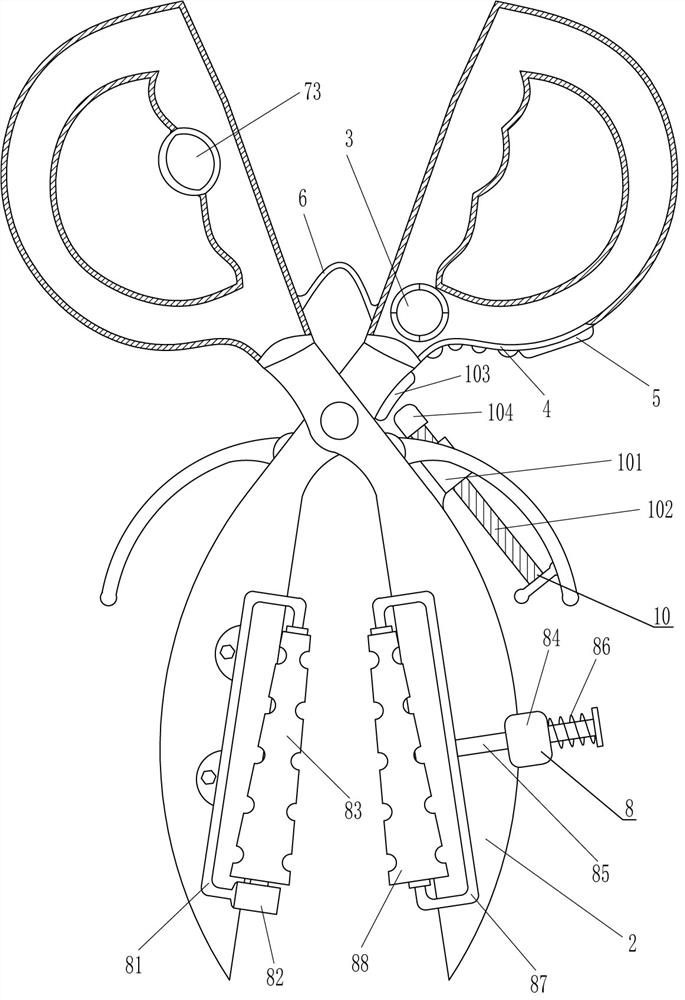

Pipe cutting device for self-positioning pipeline

InactiveCN109590758AHigh precisionReduce vibrationOther manufacturing equipments/toolsEngineeringSelf positioning

The invention discloses a pipe cutting device for a self-positioning pipeline. The device comprises a rack, and further comprises multiple straightening devices, a cutting machine and a positioning device which are sequentially arranged on the top of the rack in the machining direction; the cutting machine comprises a cutting table, two clamping tables and a cutting disc; the cutting table is fixed to the rack, the two clamping tables are symmetrically mounted on the two ends of the cutting table, the cutting disc is arranged on the cutting table through a supporting frame, the positioning device comprises a support, a screw, a servo motor, a baffle and automatic clamping claws, the support is fixed to the rack, multiple air cylinders which are arranged in a hanging manner are arranged onthe support, the automatic clamping claws are arranged on piston rods of the air cylinders, and a material accumulating groove is formed in the position, below the support, of the rack. The cutting machine and the positioning device are arranged, the long pipeline can be precisely positioned and cut, machining efficiency is improved, the process of cutting the pipeline again on the later is removed, and raw material waste is reduced.

Owner:自贡东光汽车配件有限公司

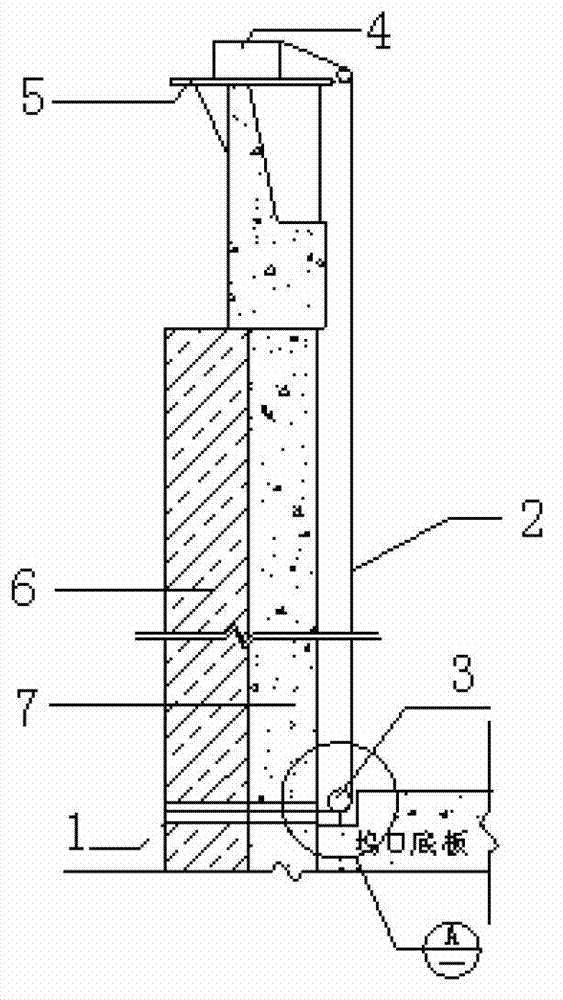

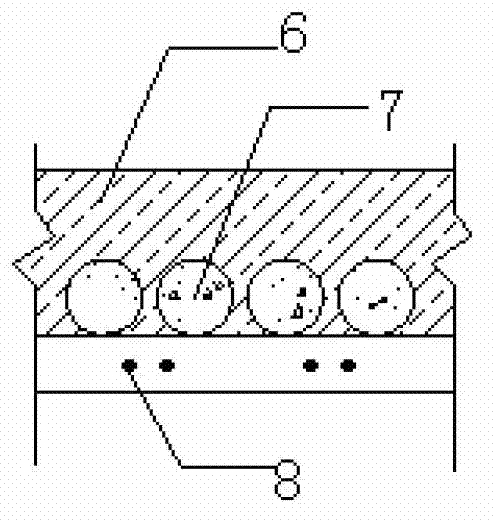

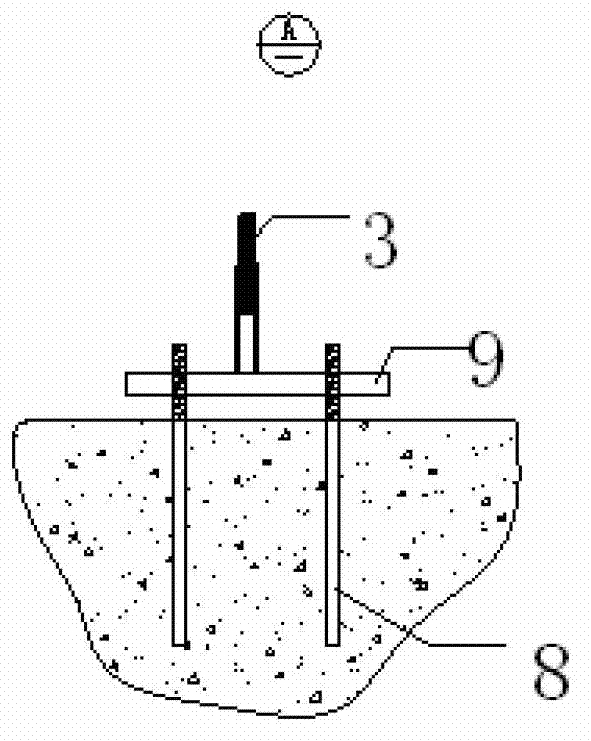

Construction method of pile body underwater cutting

The invention discloses a construction method of pile body underwater cutting, wherein the method comprises the following steps: underwater cleaning, embedding bolt on a base plate of a dock port, drilling enclosure wall of the pile body, underwater cutting, and cleaning out dock gate; a chain saw cutting machine is used to act on a cast-in-place pile and a three-shaft stirring body which are to be disassembled to directly destroy the combination among molecules when the materials (metal, concrete and the like) are located at a solid state so as to form a cut, and then the cut-off materials are lifted away. The construction method has the beneficial effects of possible mechanization, easy operation, smooth cut, being suitable for the underwater cutting of materials in irregular shape and materials in large area and large volume, high security, high construction speed, environment protecting, no vibration, no noise, no dust and no pollution to water area.

Owner:CCCC THIRD HARBOR ENG +1

Cutting machine achieving accurate locating

The invention discloses a cutting machine achieving accurate locating. The cutting machine comprises a base, a stand column is fixedly connected to the side, far away from the base, of each connectingplate, and a cross beam is fixedly connected to the tops of the stand columns; a cutter bar is fixedly connected to the bottom of a clamping block, a cutter is connected to the outer side of a rotating shaft in a sleeving manner, and a cutting table is fixedly connected to the top of the base; and baffles are fixedly connected to the two sides of the top of the base, a locating bar is connected to the side, far away from the cutting table, of each baffle in a penetrating manner, an extruding plate is fixedly connected to the side, close to the cutter, of each locating bar, and a connecting bar is connected to the side, far away from the corresponding extruding plate, of the top of each locating bar in a penetrating manner. According to the cutting machine achieving accurate locating, thebase, the cutting table, the baffles, the locating bars and the extruding plates are matched for use, so that the problem that a cutting notch is uneven due to inaccurate locating of the cutting machine is solved; and the cross beam, a sliding slot, a buffering block, a spring, the clamping block and the cutter bar are matched for use, so that the problem that the cutting machine is prone to be damaged by a to-be-cut object is solved.

Owner:无锡宝威焊割设备有限公司

Cutting device for automobile air conditioner aluminum pipe

InactiveCN111266648AImprove cutting efficiencyAvoid accidental injuryTube shearing machinesShearing machine accessoriesElectric machineryMachining

The invention discloses a cutting device for an automobile air conditioner aluminum pipe. The cutting device comprises a cutting table, a cutting mechanism, pressing mechanisms, a limiting plate and afeeding push plate. The cutting mechanism is mounted at the bottom end of the cutting table. A cutting trough is longitudinally formed in the middle of the cutting table. The pressing mechanisms arelocated on the left side and the right side of the upper portion of the cutting trough. The limiting plate and the feeding push plate are mounted at the left end and the right end of the top of the cutting table in a sliding manner. Containing grooves are transversely formed in the top end of the cutting table at intervals. The cutting mechanism comprises a first U-shaped frame, a sliding seat, afirst motor and a cutting disc. Each pressing mechanism comprises a second U-shaped frame, a first air cylinder and a first pressing plate. The cutting device is improved according to the problems that in the prior art, the cutting efficiency and the safety coefficient of a cutting device are low, aluminum pipes are not clamped firmly enough, consequently, cut openings are not level, and the difficulty and time of subsequent machining are increased; and the cutting device has the advantages that the cutting efficiency of the automobile air conditioner aluminum pipe is improved, the safety coefficient is high, the aluminum pipe is clamped more firmly, and subsequent machining is convenient.

Owner:芜湖腾龙汽车零部件制造有限公司

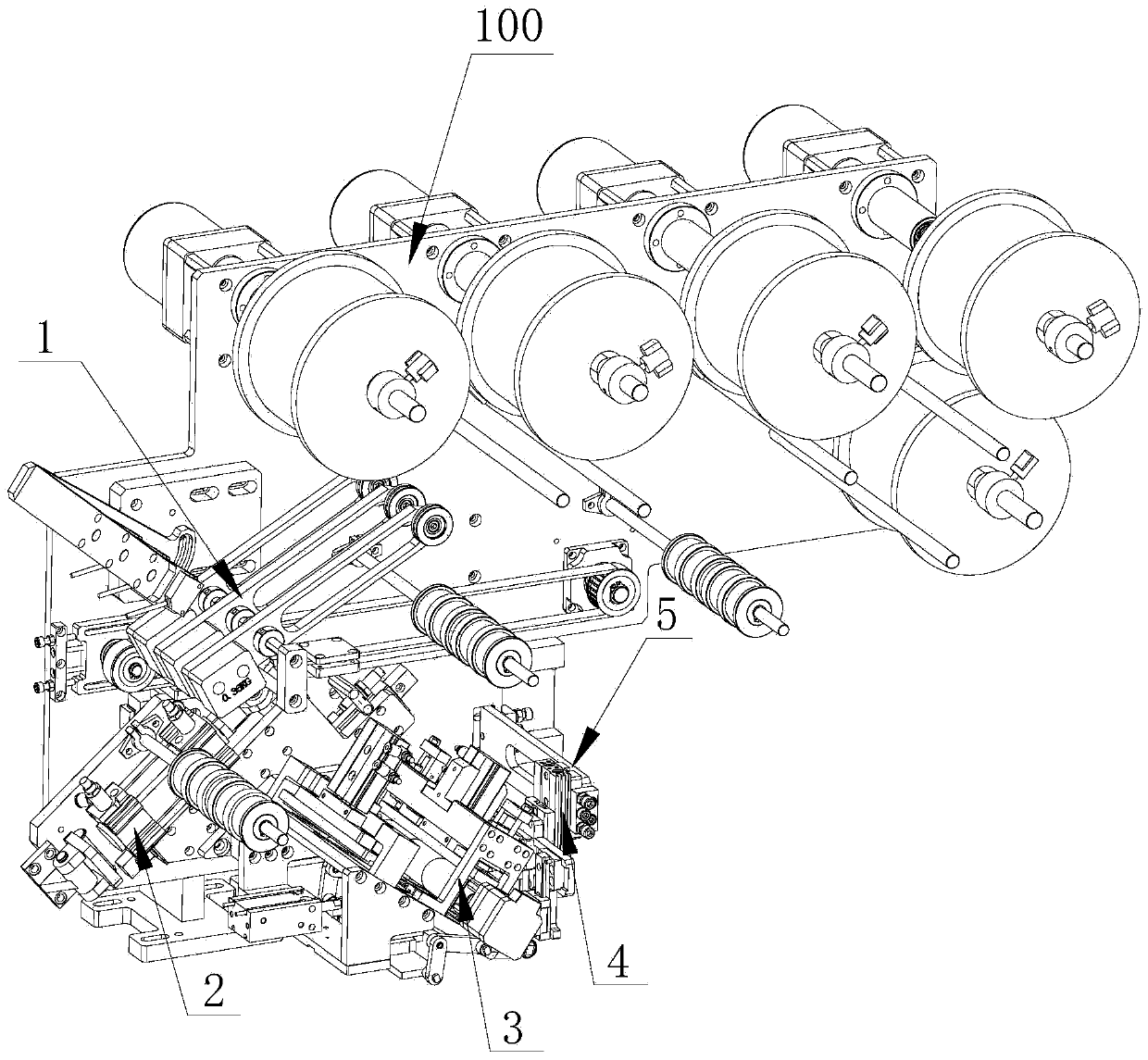

Full-automatic coiled tape pasting and covering equipment

ActiveCN105365334AAvoid tearingEnsure consistencyLamination ancillary operationsLaminationEngineeringMechanical engineering

The invention provides full-automatic coiled tape pasting and covering equipment which comprises a mounting plate, an unreeling buffering device, a driving device, a cutting device and a pasting and covering device. The unreeling buffering device is fixedly arranged on the mounting plate and pulls out a coiled tape from a reel by way of constant tension and buffers the coiled tape. The driving device is arranged on the mounting plate and comprises a first driving assembly which drives the cutting device and the pasting and covering device to reciprocate horizontally and a second driving assembly which drives the cutting device to move up and down. The cutting device is connected with the driving device and is arranged at one side of the unreeling buffering device along the conveying direction of the coiled tape, conveys the pulled-out coiled tape and cuts off the coiled tape by using a plurality of split cutting blades. The pasting and covering device is connected with the first driving assembly and is driven by the first driving assembly to paste and cover the coiled tape which is conveyed along the pasting and covering direction of the coiled tape.

Owner:HANGZHOU COMFIRMWARE TECH CO LTD

Cable cutting machine convenient to adjust

InactiveCN110625040AHeight adjustableSmooth rotationLine/current collector detailsEngineeringMechanical engineering

The invention discloses a cable cutting machine convenient to adjust. The cable cutting machine convenient to adjust comprises a base. A main tank is fixedly connected to the upper surface of the base. Two symmetric fixed blocks are fixedly connected to the upper portions of the inner sidewalls of the main tank. The side faces, close to each other, of the two fixed blocks are both provided with grooves. A sliding bar is fixedly connected to the interior of each groove. According to the cable cutting machine convenient to adjust, a motor can operate to drive a movable plate to ascend and descend so that the height of a cutting machine body can be adjusted, a threaded rod can be prevented from getting stagnated and swinging in the using process, the adjustability and safety performance to the cable cutting machine are improved, and the height of the cutting machine body can be adjusted better. A cable material can be pressed tightly while the cutting machine body conducts cutting on thecable material, and the problem that the cable material moves during moving and cuts are not tidy is avoided. Damage to the main tank by the cutting end of the cutting machine body in the using process can be prevented.

Owner:刘国庆

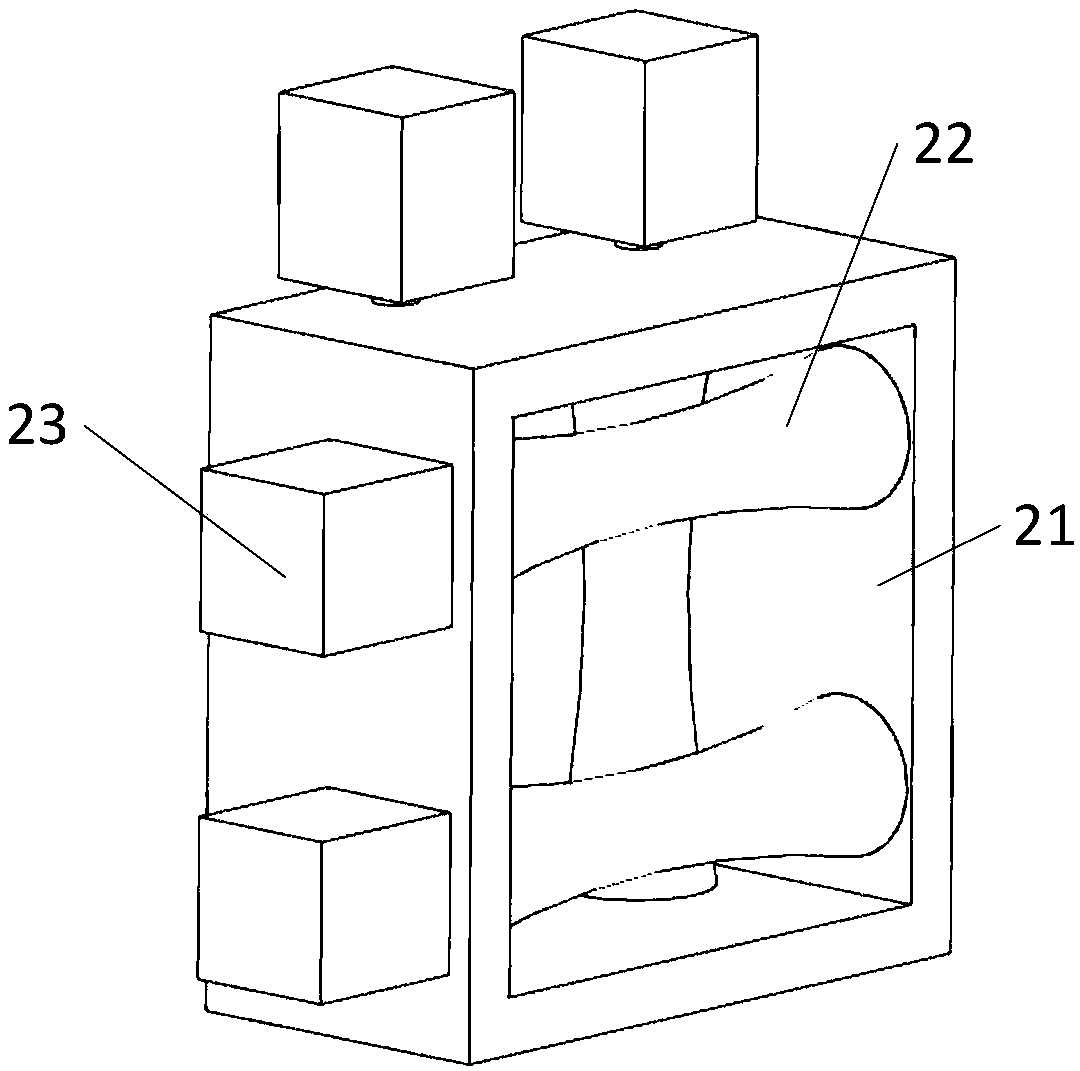

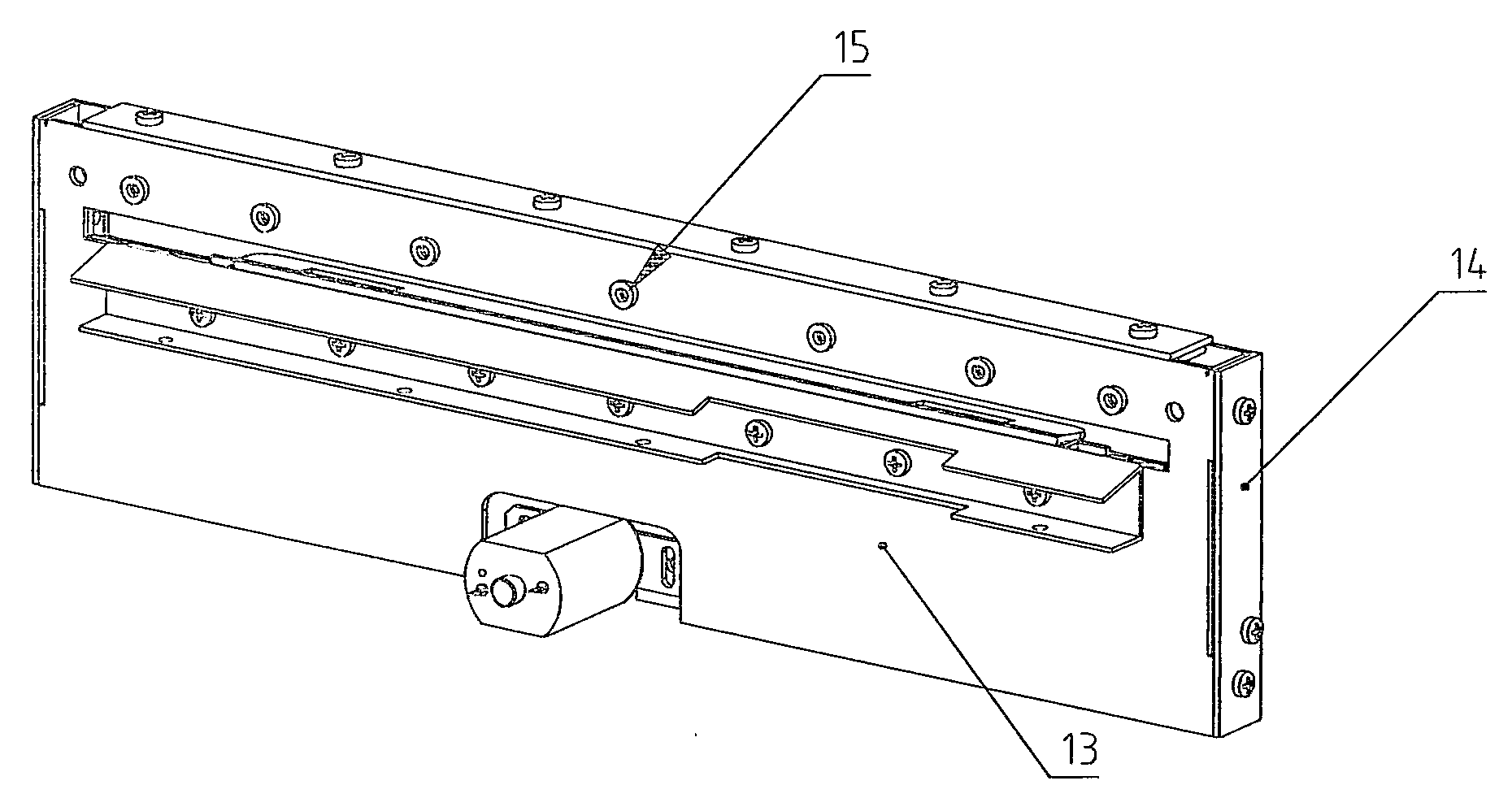

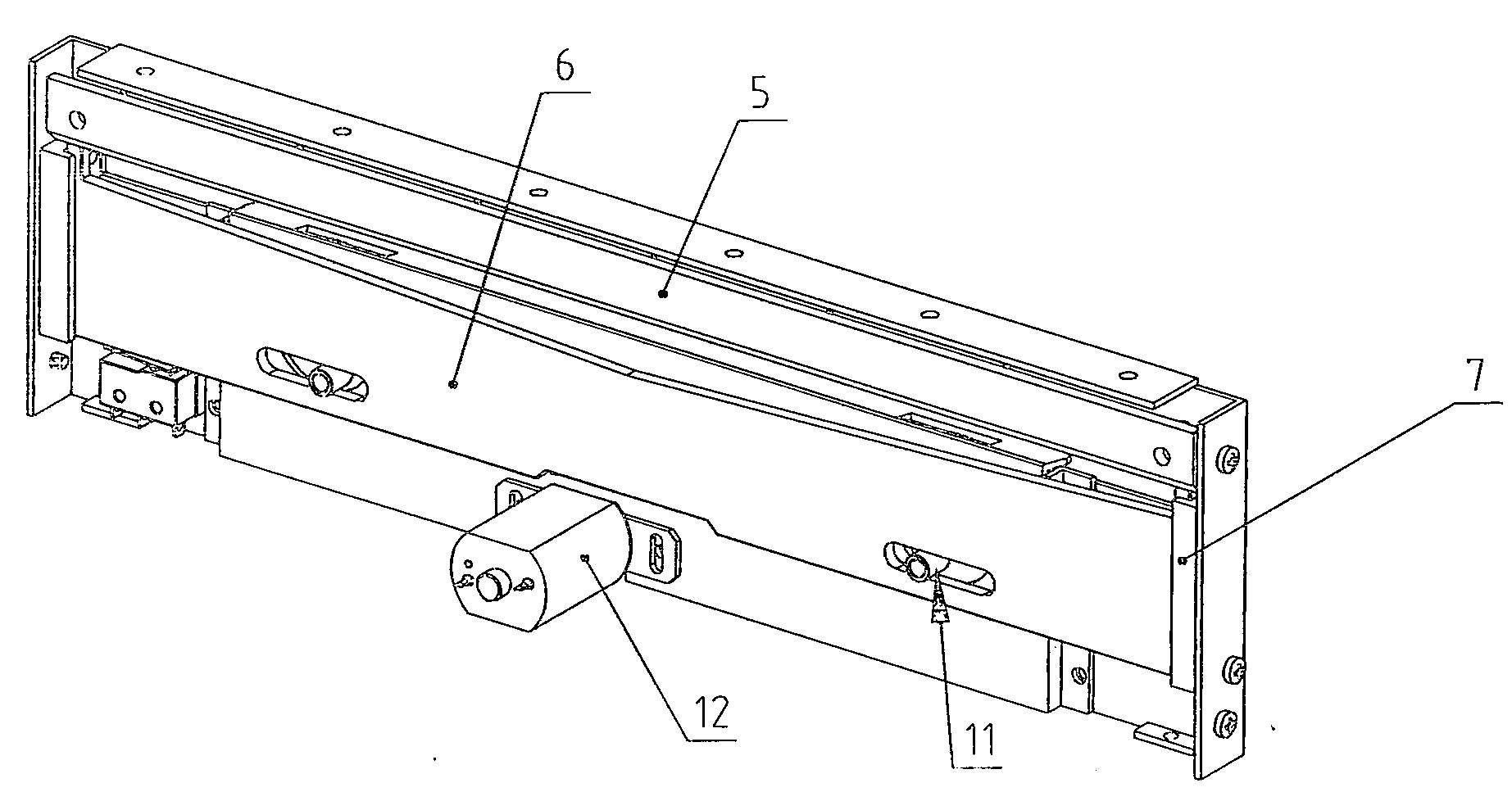

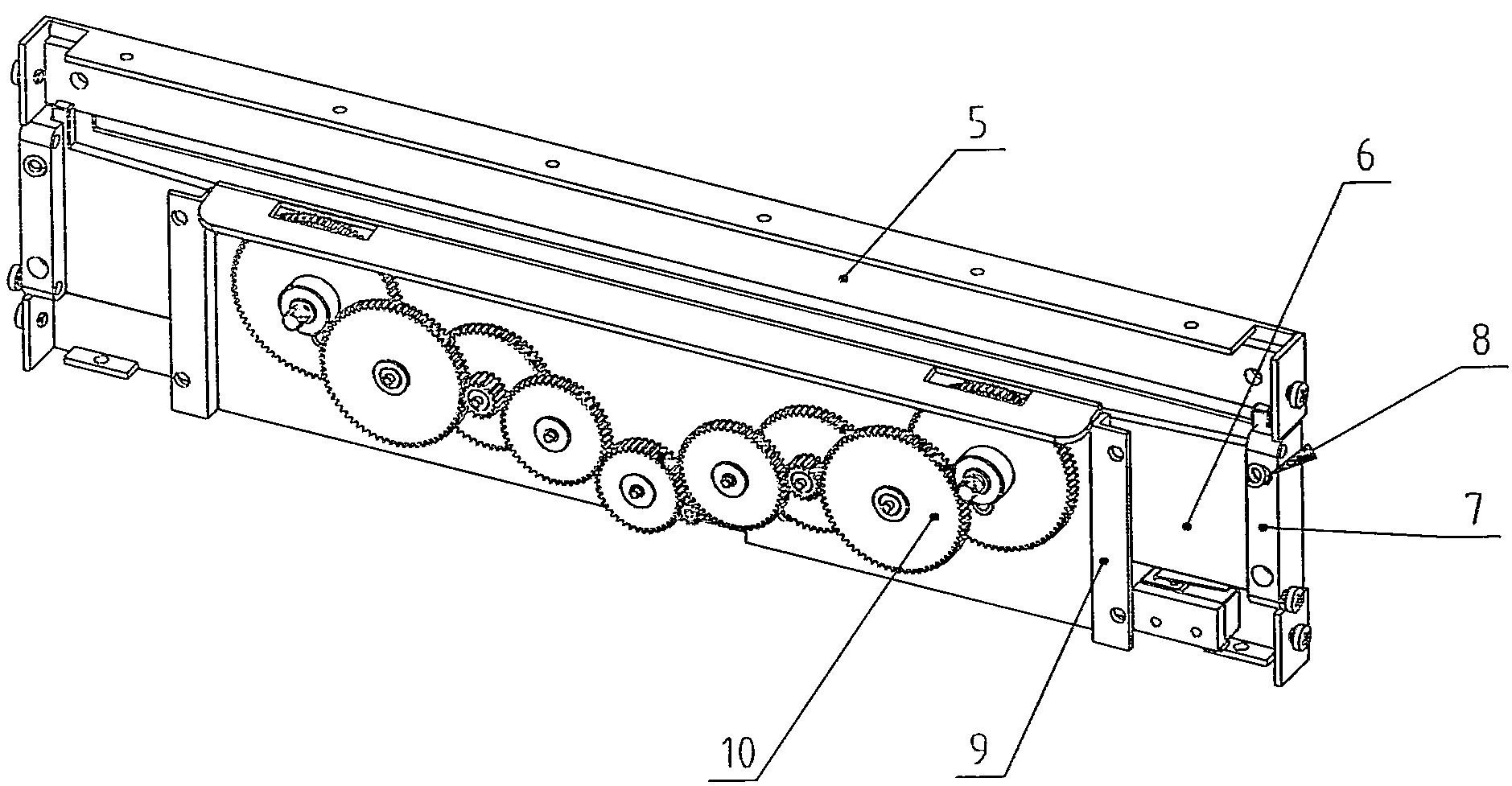

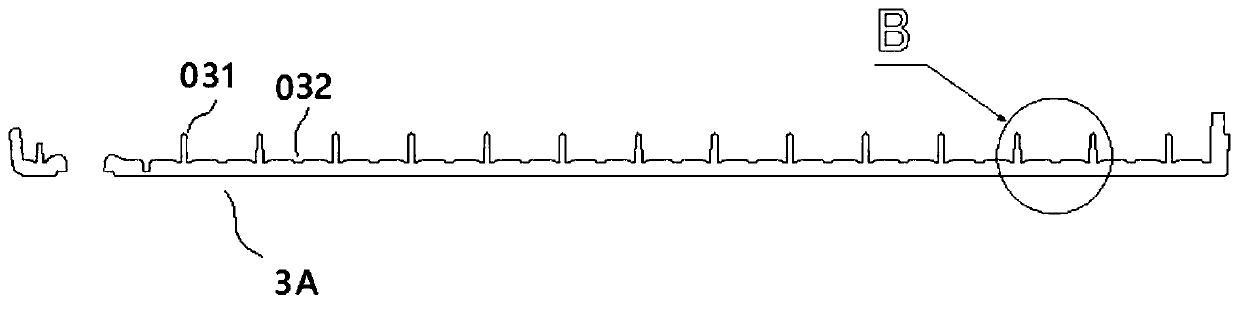

Automatic paper cutting device for multi-piece chain paper bill printer

InactiveCN103158374ASolution to short lifeAvoid burrsOther printing apparatusEdge surfacePulp and paper industry

The invention discloses an automatic paper cutting device for a multi-piece chain paper bill printer. The automatic paper cutting device comprises a fixed knife installation frame, a movable knife installation frame, a fixed knife, a movable knife matched with the fixed knife, a movable limit guide mechanism and a drive transmission mechanism which drives the movable knife to slide on the movable knife installation frame up and down and is matched with the fixed knife to cut paper; the fixed knife installation frame is arranged on the top of the movable knife installation frame; the fixed knife is arranged on the fixed knife installation frame; the movable knife is arranged on the movable knife installation frame; the fixed knife installation frame is provided with a jacking and bending structure which can ensure that the fixed knife has certain curvature and gradually bends toward one side of the movable knife from two sides of the fixed knife to the middle part of the fixed knife; and the movable knife is provided with a knife edge surface of which the middle part is lower than two sides. The automatic paper cutting device avoids phenomena that burrs are easily produced, and paper is wound and jammed during paper cutting, a cut of cut paper is smooth and clean, the paper is cut reliably, and multiple layers of paper can be cut.

Owner:颜炳辉

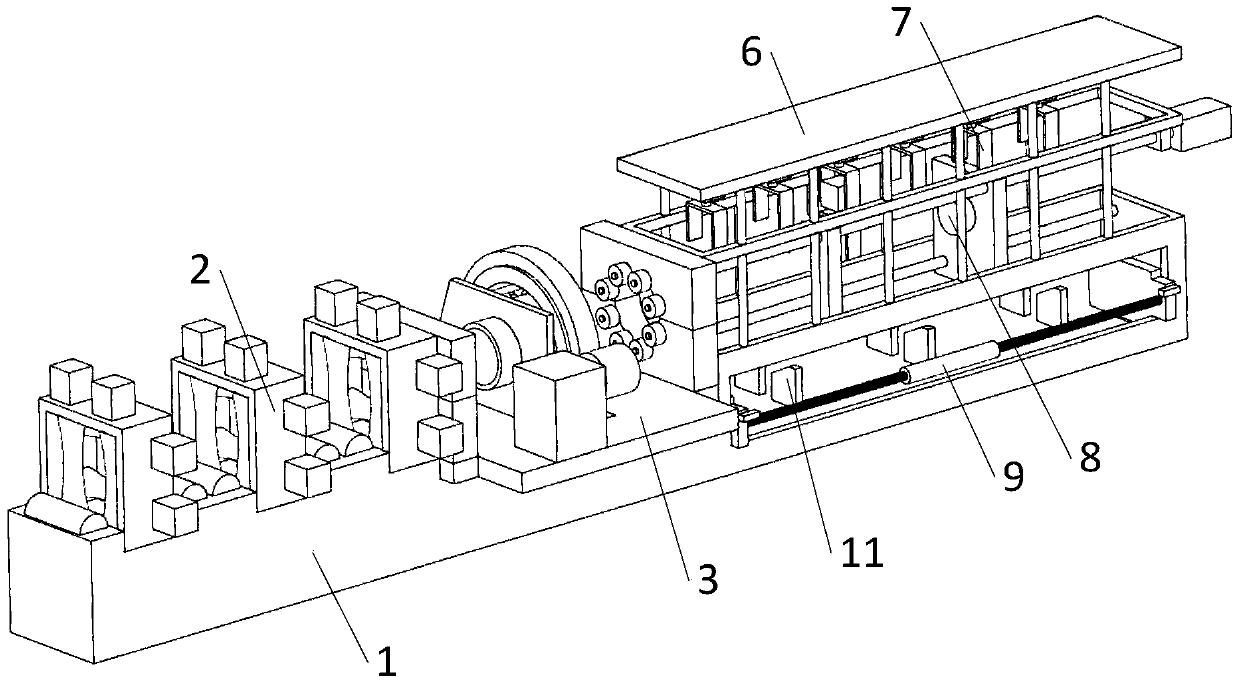

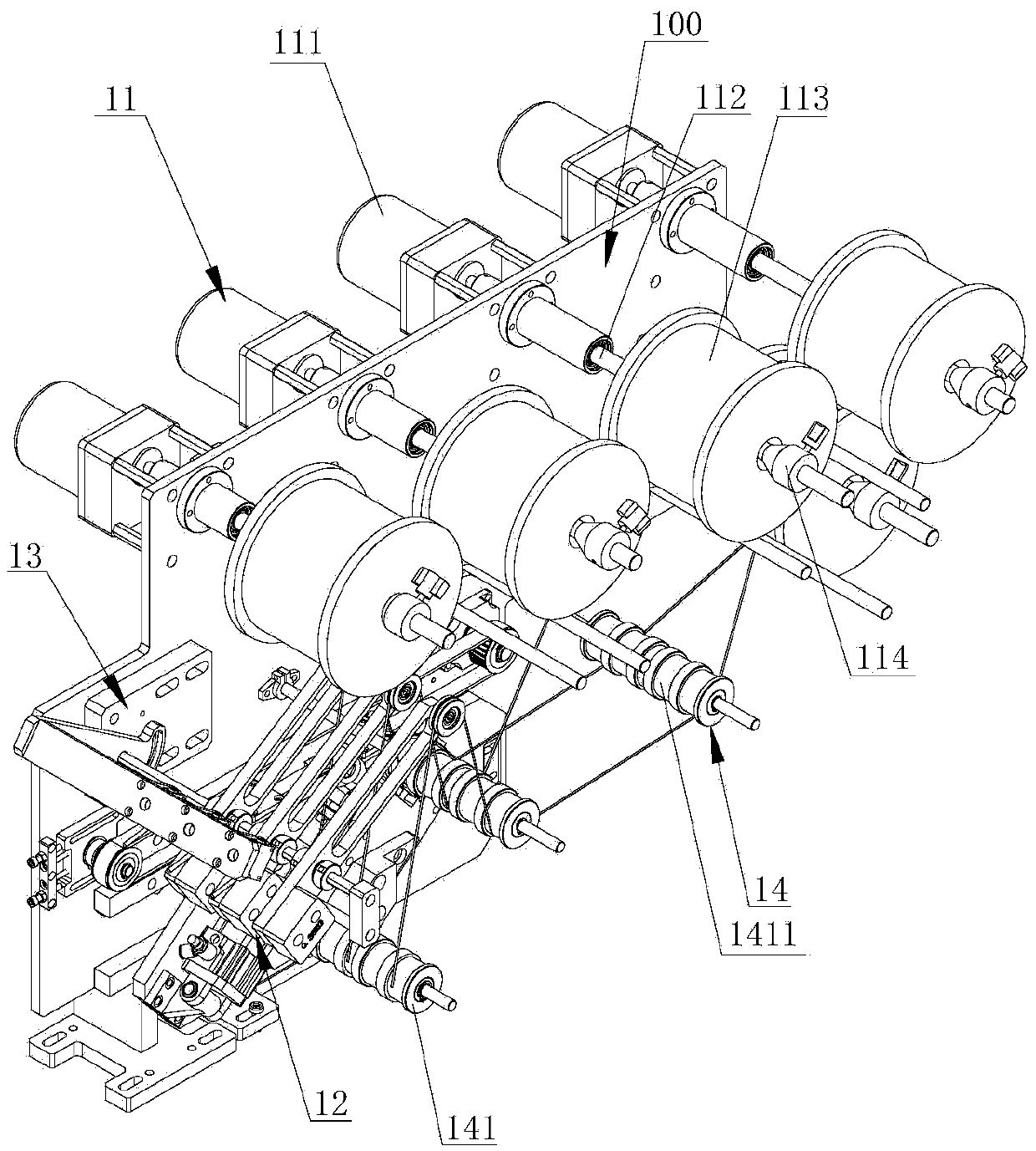

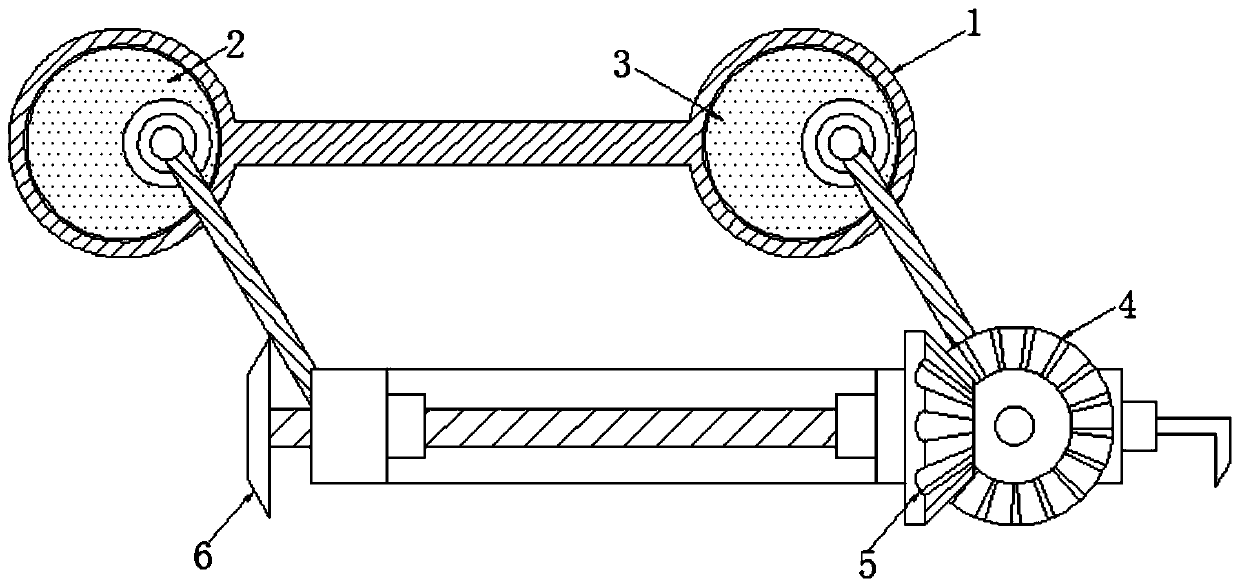

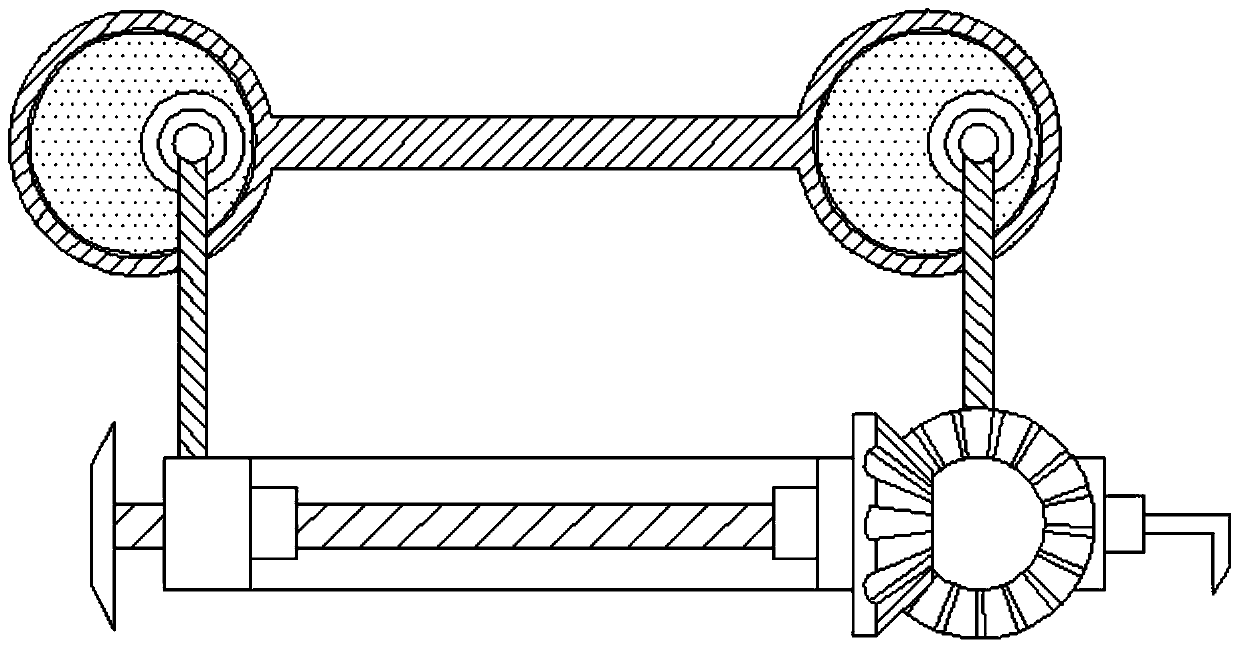

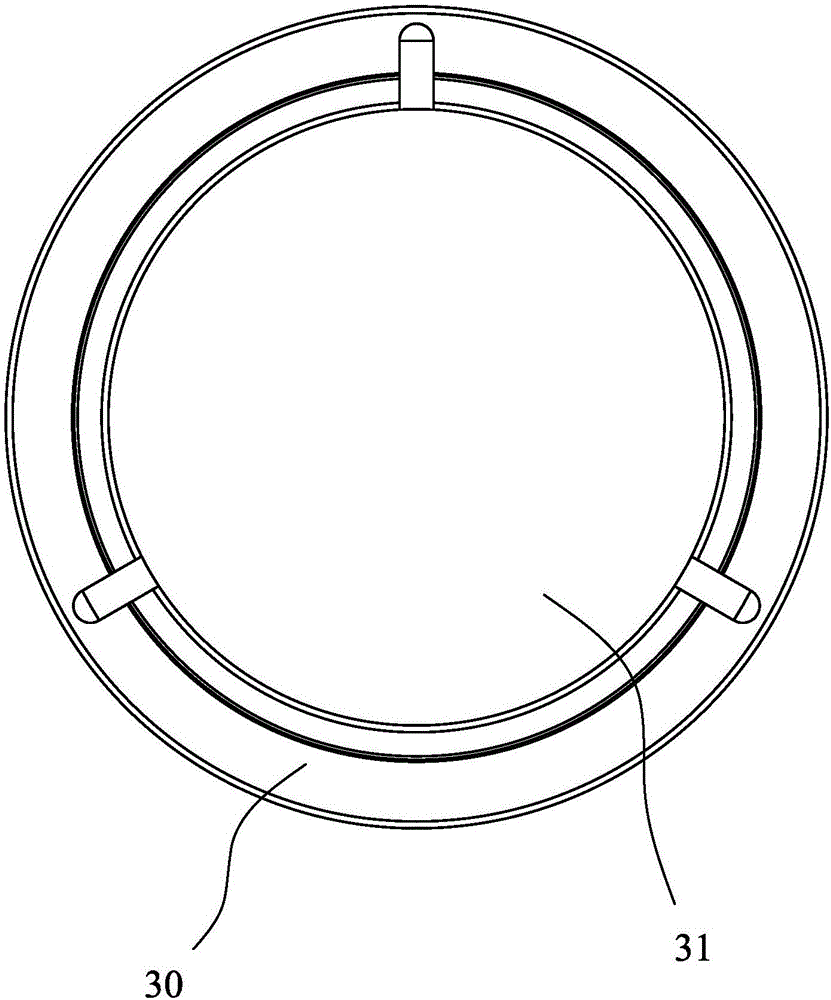

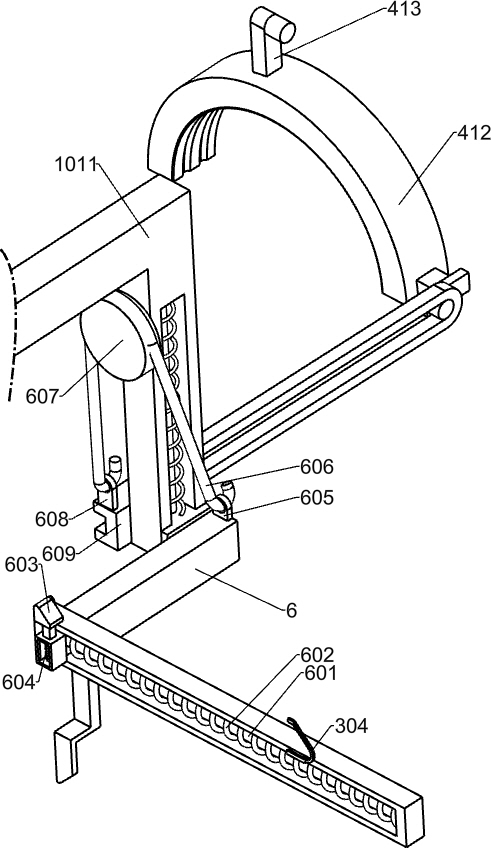

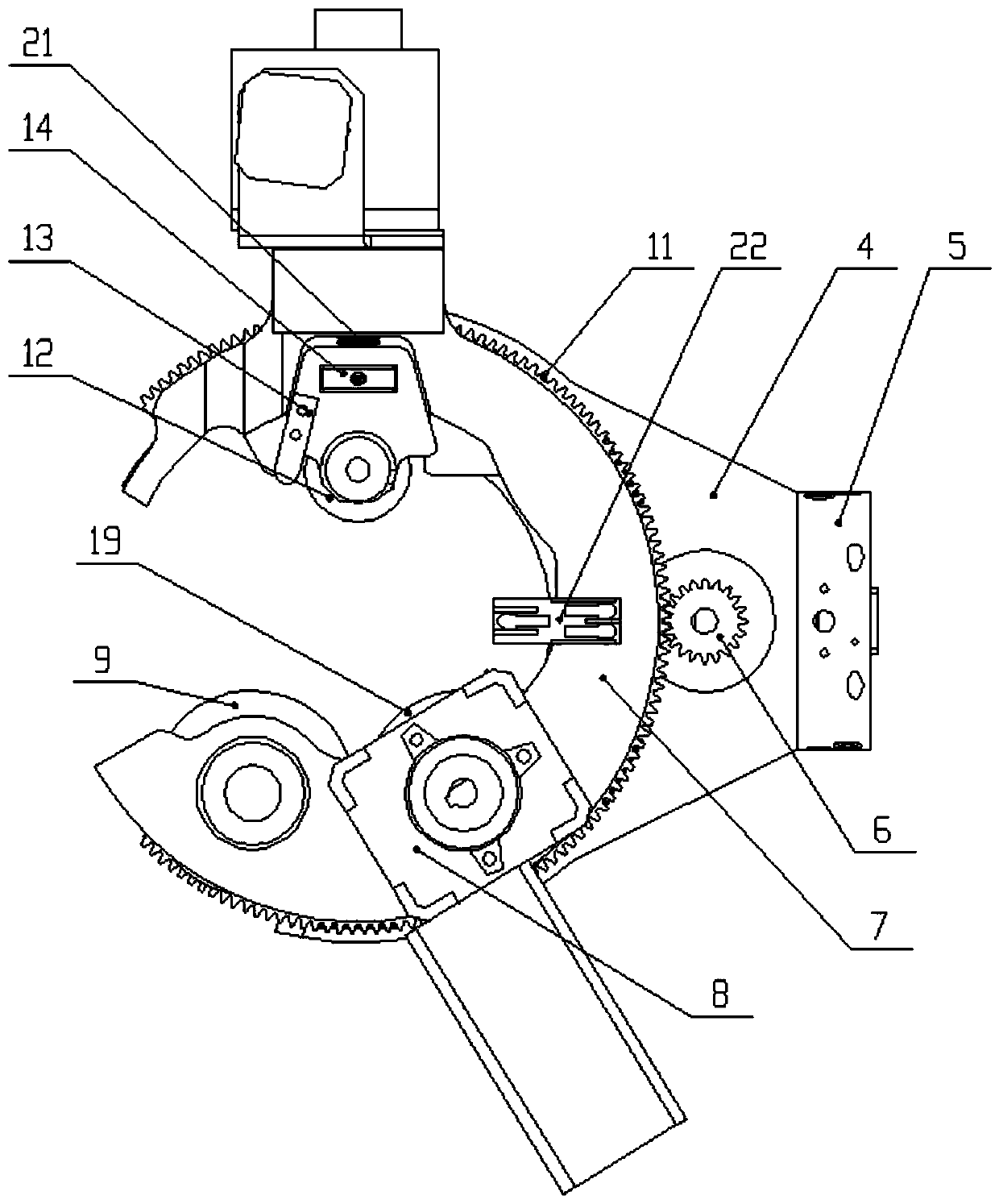

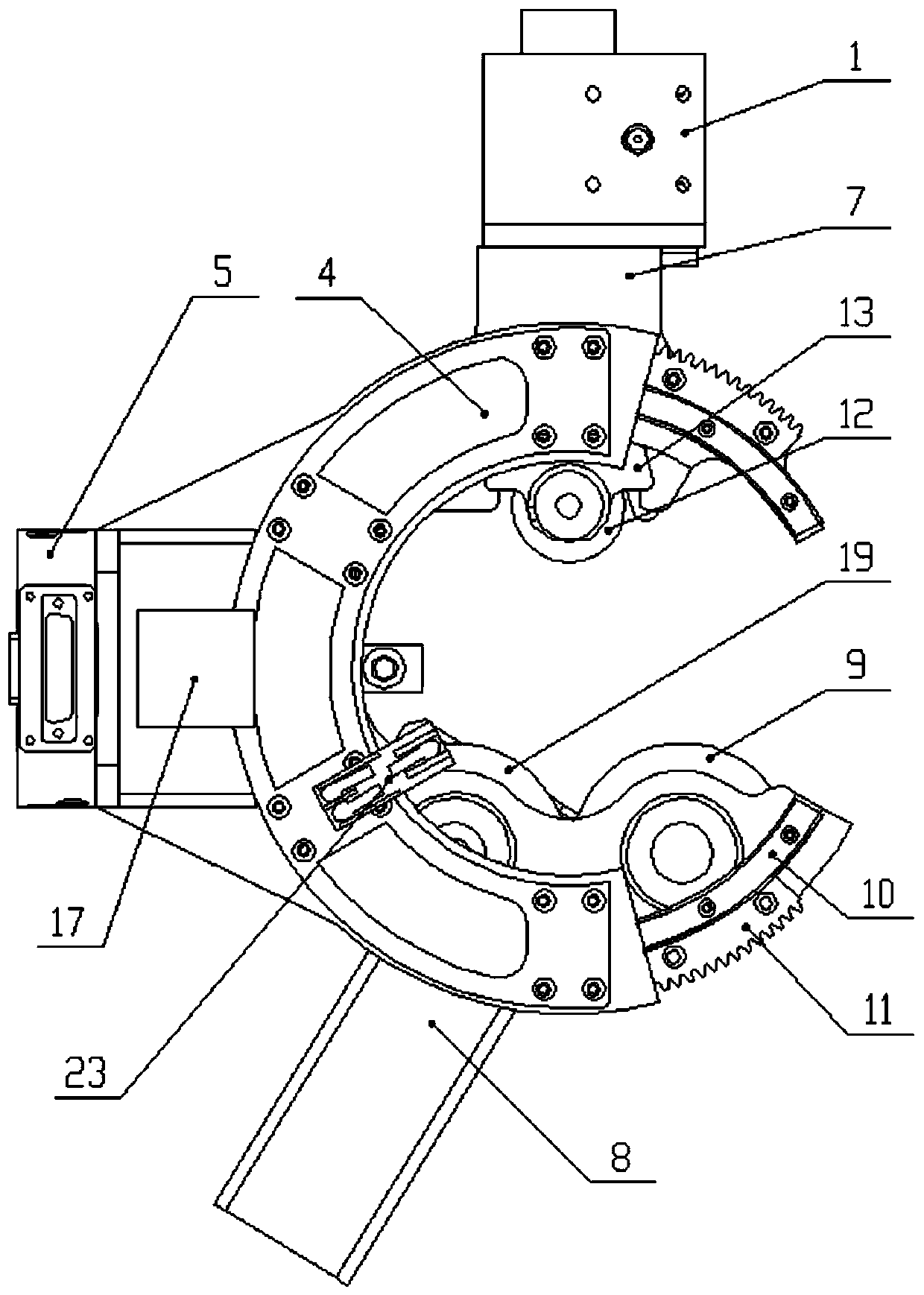

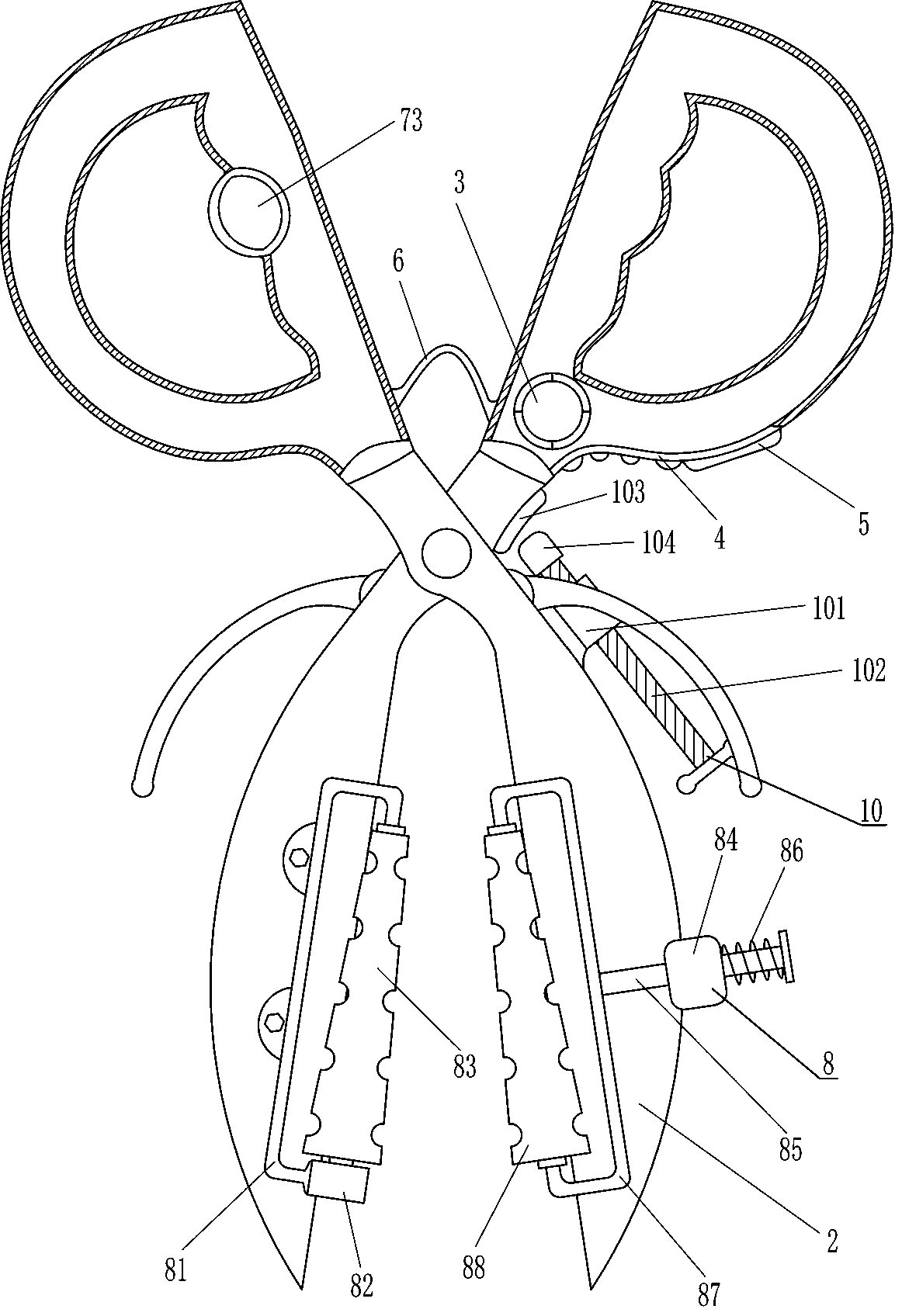

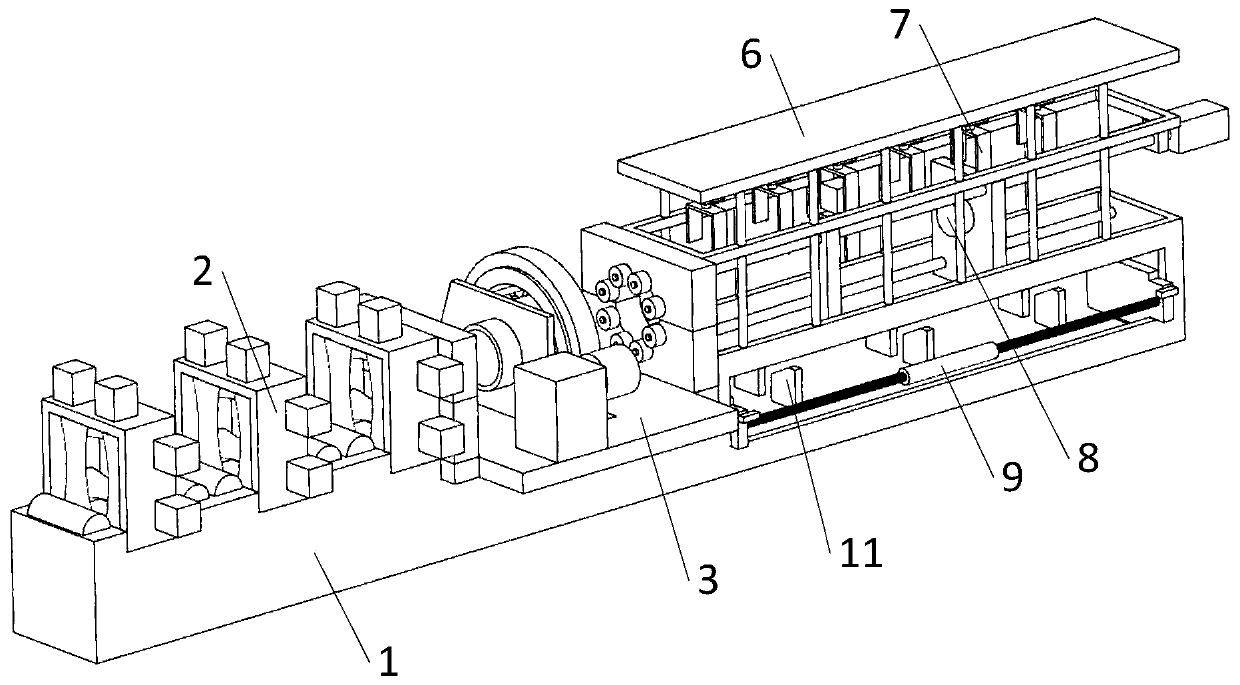

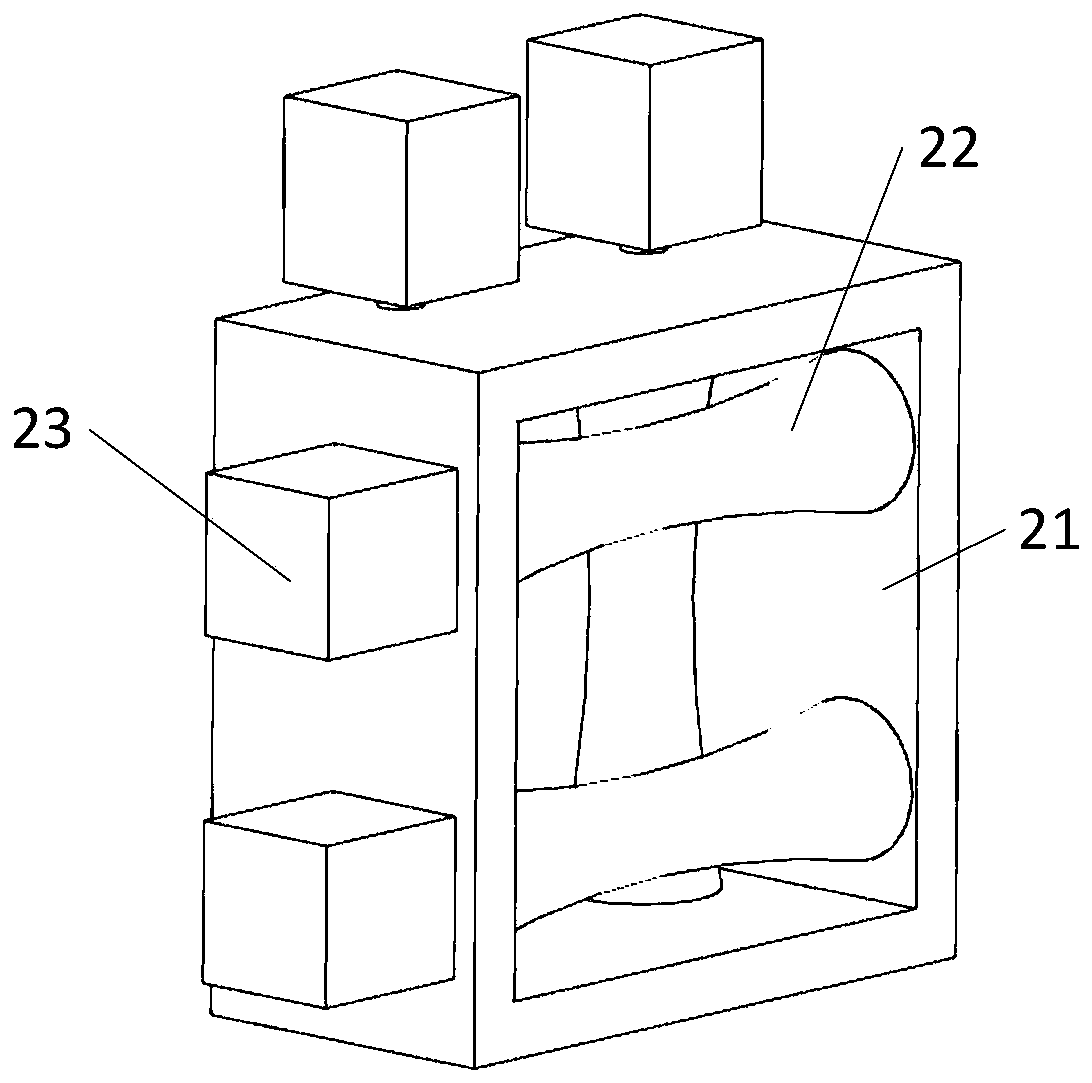

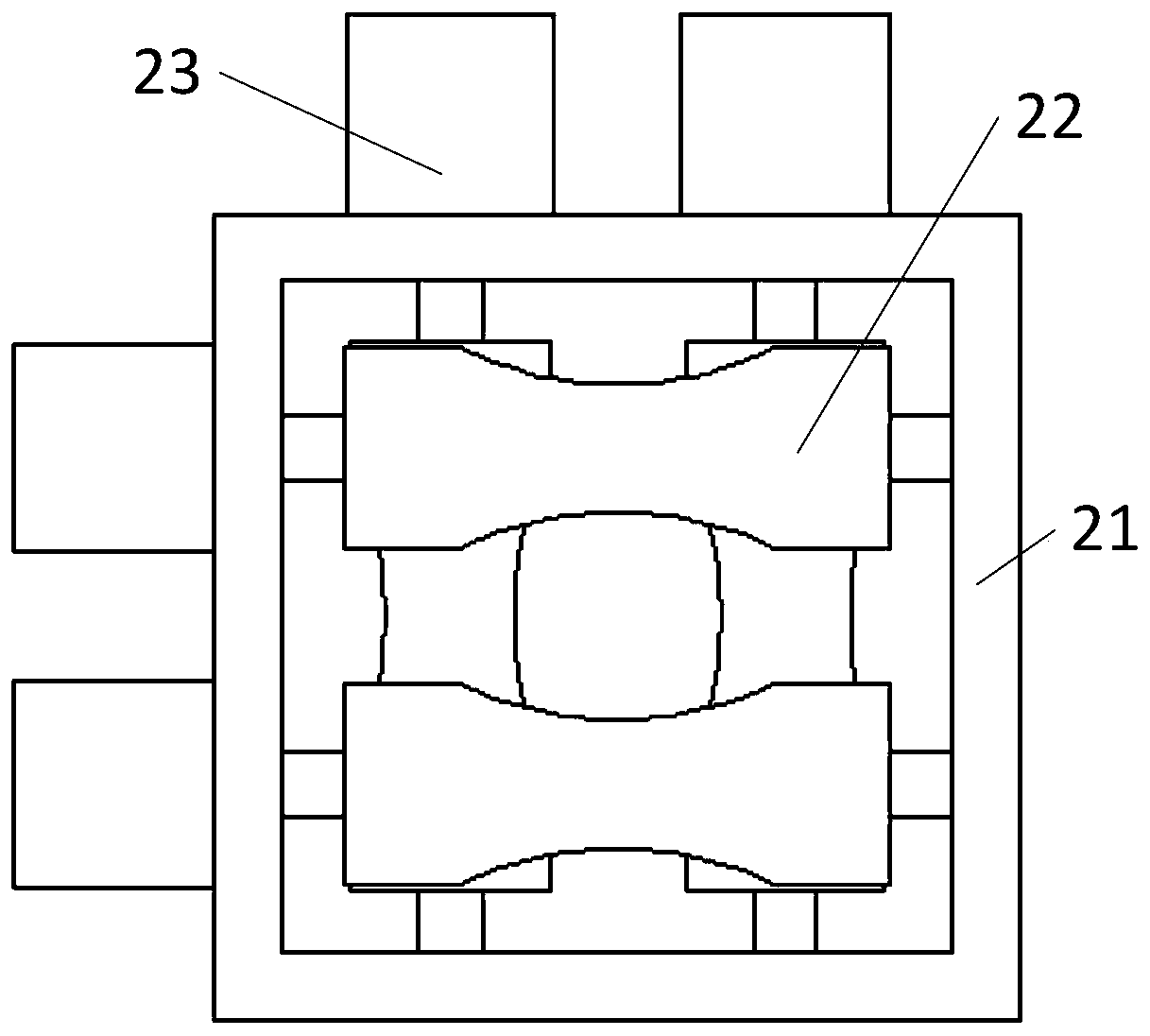

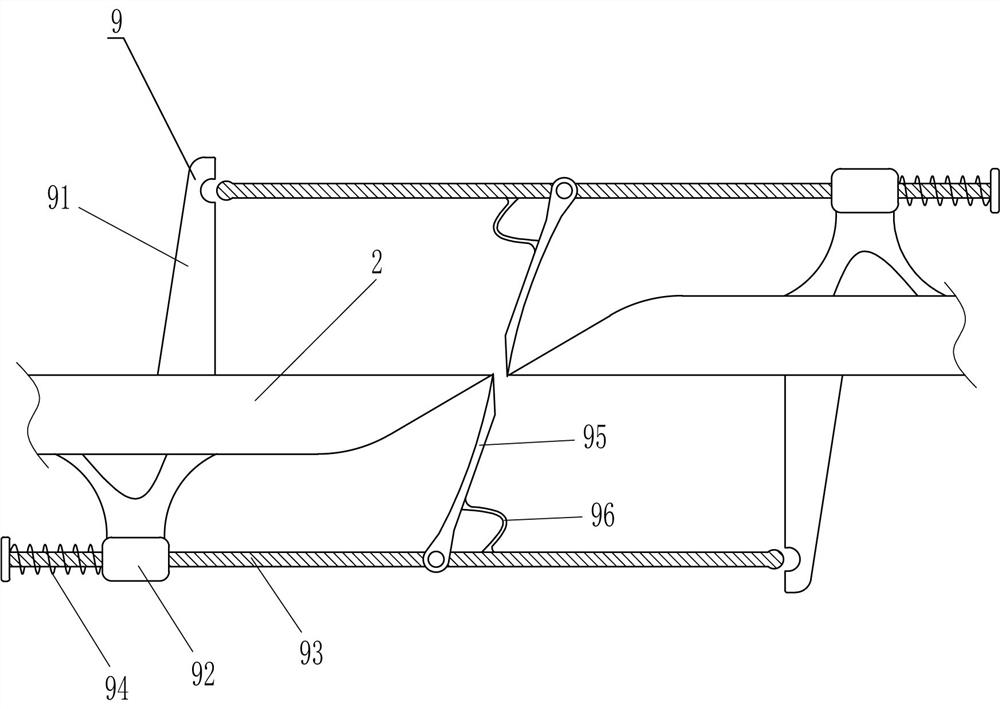

Pipe cutting equipment capable of realizing automatic fixing and equal-interval material pushing

ActiveCN110977010ARealize intermittent cuttingEasy to operateTube shearing machinesShearing machine accessoriesStructural engineeringPipe

The invention relates to the technical field of novel machinery, and discloses pipe cutting equipment capable of realizing automatic fixing and equal-interval material pushing. The pipe cutting equipment comprises a ring disc set, and a first rotating disc is movably connected to the interior of the ring disc set; a second rotary disc eccentrically rotates to enable a cutter to synchronously rotate to cut the pipe, so that intermittent cutting is realized, and operation is more convenient; a hook rod on the outer side of a fixation plate drives a pull rod to move leftwards, and a pressing plate is tightly attached to the surface of the pipe to fix the pipe, so that the stability of the pipe during cutting is ensured, and the case that irregular cuts are caused due to shaking of the pipe during cutting is avoided; when a protruding disc rotates, a protruding block on the outer side of the protruding disc gets close to the push rod to push the push rod to move leftwards, and a clamping rod synchronously moves to enable a toothed rod to be clamped in the groove; and due to the fact that the size of the protruding block is increased in a stepped mode, the push rod gradually pushes thepipe, the position after pushing is fixed to make the pushing distance same, and thus the consistency of the cutting length is guaranteed.

Owner:泰州远大体育用品有限公司

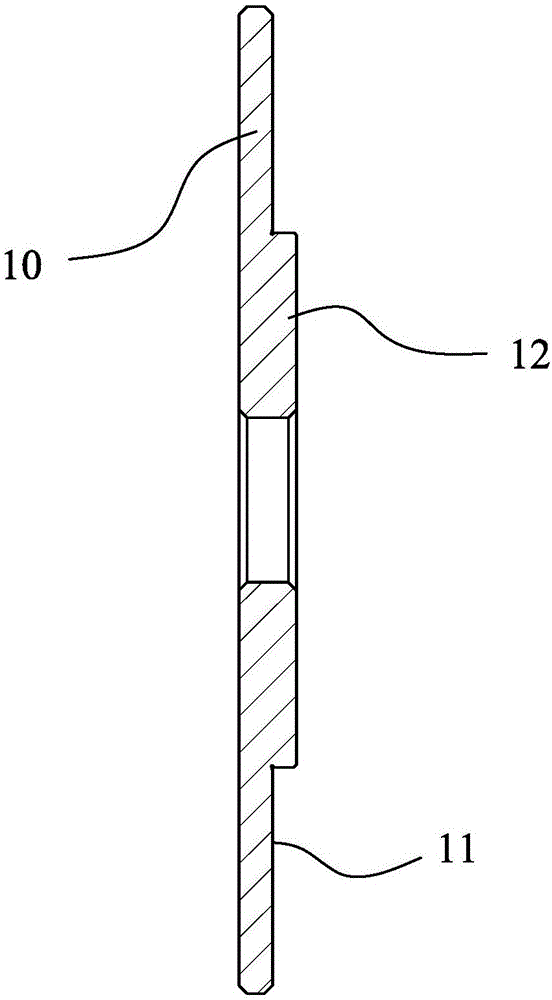

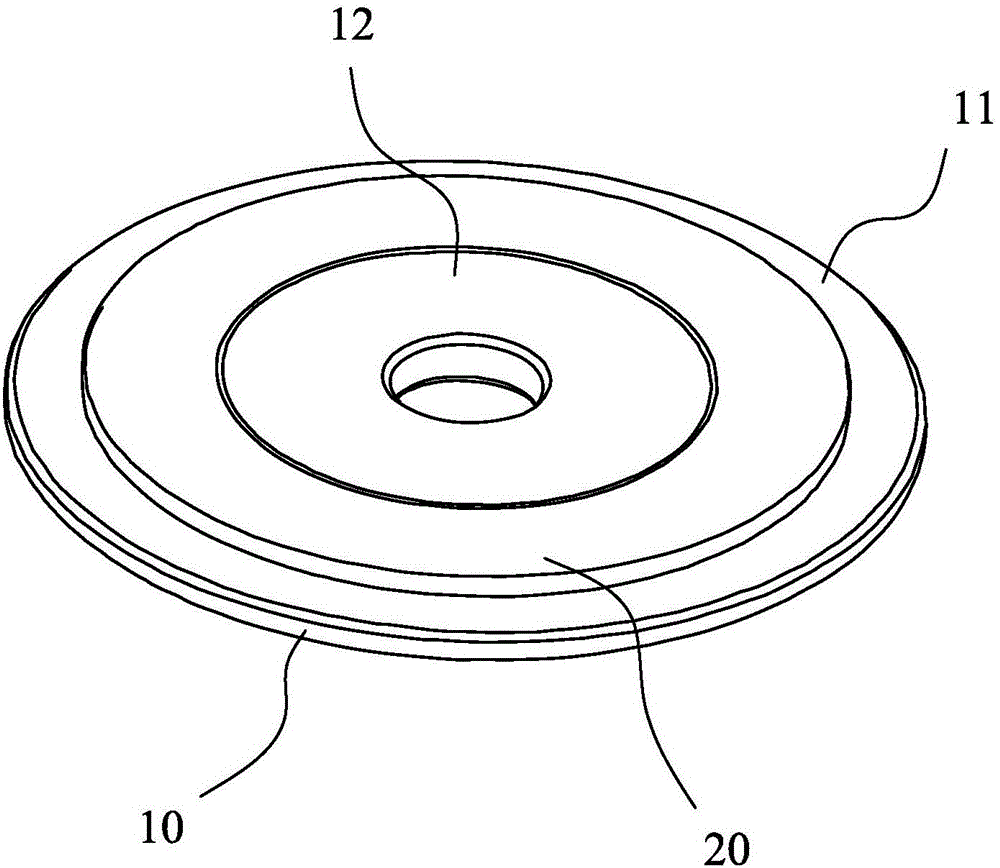

Machining process for ceramic ring cutter used for slitting of lithium battery materials

ActiveCN106392778AAvoid breakageImprove sharpnessCeramic shaping apparatusOther manufacturing equipments/toolsResonanceGrinding wheel

The invention provides a machining process for a ceramic ring cutter used for slitting of lithium battery materials. The machining process comprises the following steps that (1) ceramic materials are mold-pressed into a ring-shaped blank provided with a central hole in a magnetic resonance mode; (2) the blank is subjected to continuous electric heating sintering and then cooled, and a ceramic cutter blank is obtained; (3) the face A is flatly ground for the first time with the allowance of 0.5-0.6 mm reserved; (4) an inner hole of the face B of the ceramic cutter blank is subjected to rough grinding and accurate grinding with the allowance of 0.1-0.2 mm reserved; (5) the face B of the central hole is subjected to accurate grinding and polishing; (6) the face A is subjected to flat grinding for the second time; (7) the face A is polished; (8) the outer circle of the ceramic cutter blank is ground; and (9) the ceramic cutter blank is fastened to an external grinding tool, a diamond molding grinding wheel is fed from top to bottom, the cutter blade is ground from the single side of the ceramic cutter blank, and the ceramic ring cutter used for slitting of lithium battery materials is obtained. According to the machining process for the ceramic ring cutter used for slitting of lithium battery materials, the materials are directly pressed into the ring-shaped blank which is then sintered into the ceramic cutter blank, and the machining efficiency of the ring cutter is improved; and the machining precision is improved through rough grinding with the allowance reserved and appropriate accurate grinding, and the sharpness of the blade of the cutter is guaranteed.

Owner:DONGGUAN HONBRO LI BATTERY EQUIP TECH

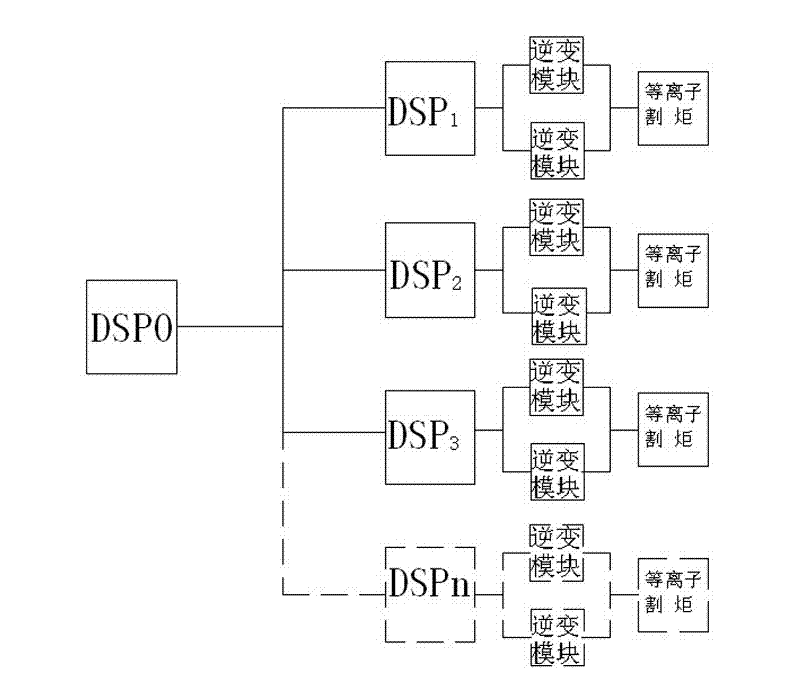

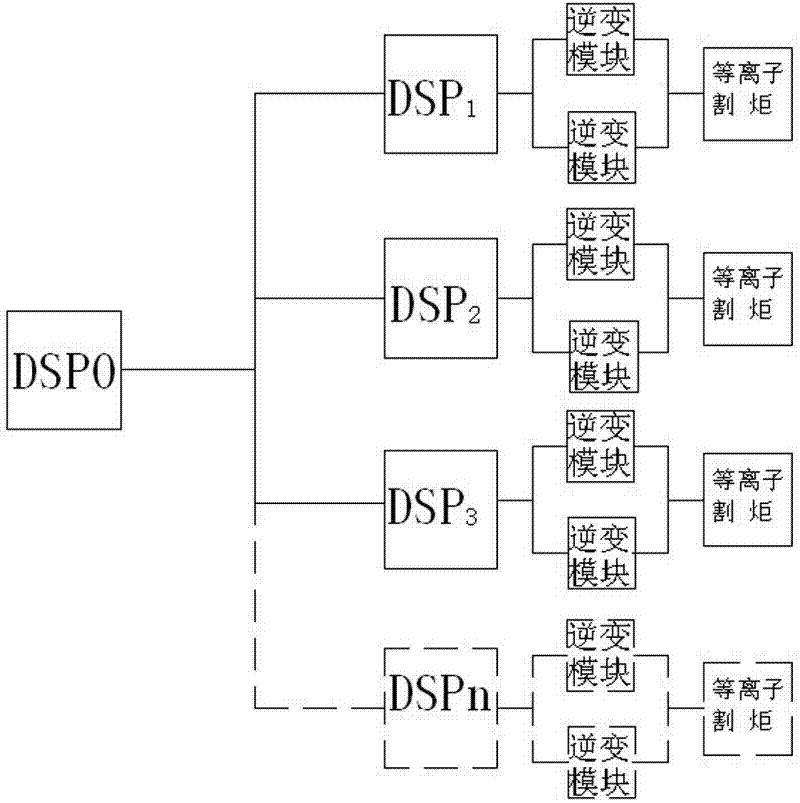

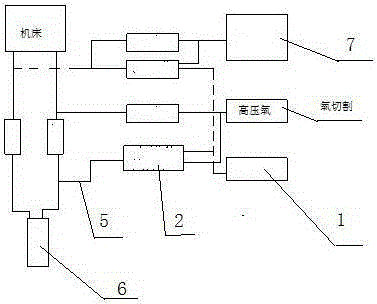

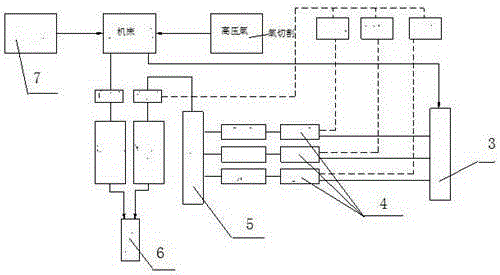

Numerical-control plasma power source with multiple plasma cutting torches

InactiveCN102380698AOutput for easy controlSave resourcesPlasma welding apparatusNumerical controlArea network

The invention discloses a numerical-control plasma power source with multiple plasma cutting torches. The plasma power source is connected with a main DSP (digital signal processor) digital signal controller, the main DSP digital signal controller is further connected with input ends of multiple sub DSP signal controllers through control lines, each sub DSP digital signal controller is connected with one plasma cutting torch through at least two inverter modules, and each inverter module is connected with a CAN (controller area network) bus. According to the technical scheme, the numerical-control plasma power source adopts simple principles, one plasma power source can be distributed to multiple plasma cutting torches so as to facilitate constant-current power output control, and accordingly, the multiple plasma cutting torches can be subjected to completely synchronous arc striking and complicated cutting of grooves can be completed at one step. In addition, the numerical-control plasma power source with the multiple plasma cutting torches has the advantages of high cutting precision and capability of improving operation efficiency and saving resources.

Owner:安徽西锐重工科技有限公司

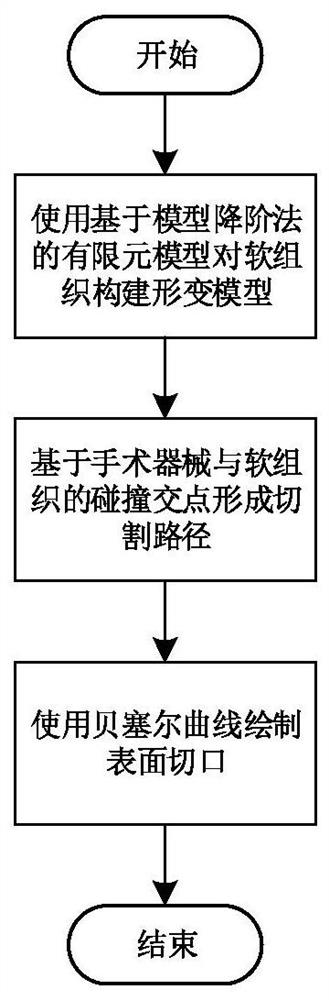

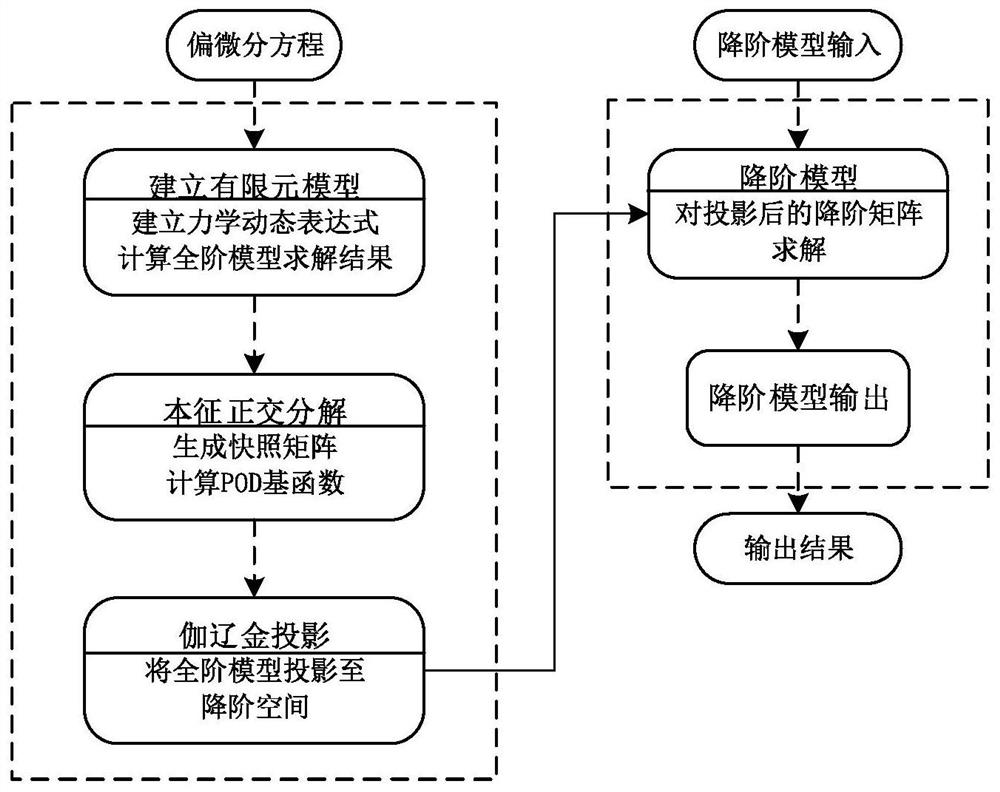

Method and device for simulating soft tissue deformation and path cutting

ActiveCN113343513AReduce space complexityReduce the amount of deformation calculationDesign optimisation/simulationComplex mathematical operationsElement modelSoft tissue deformation

The invention discloses a method and device for simulating soft tissue deformation and path cutting, and the method is used for simulating the troubleshooting and excision process of a stomach lesion area in a virtual operation, and comprises the steps: firstly, simulating the deformation process of stomach soft tissue by using a finite element model; realizing model order reduction by applying a model order reduction method combining intrinsic orthogonal decomposition and Galerkin projection in a deformation process, then forming a cutting path according to an intersection point position formed by collision detection of a surgical machine and the soft tissue, and finally drawing a surface incision generated after the soft tissue is cut by adopting a Bezier curve. Calculation speed and real-time performance of soft tissue deformation simulation by utilizing the finite element model are improved, and a smoother and more natural cutting path and incision effect can be created in the processing of a virtual operation cutting problem.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

PVC corrugated pipe cutting equipment

ActiveCN114454238APrevent free fallReduce free fallMetal working apparatusIndustrial engineeringSupport plane

The invention relates to PVC corrugated pipe cutting equipment which comprises a first supporting frame, a second supporting frame, a third supporting frame, a sliding rail, a cutting mechanism and the like. The first supporting frame is located at the forefront of the equipment, two sliding rails are fixed to the bottom of the rear wall of the first supporting frame, a third supporting frame is fixed to the rear portions of the top walls of the two sliding rails, a second supporting frame is fixed to the front position of the middle of the right wall of the sliding rail on the right side, and the cutting mechanism is installed in the third supporting frame. According to the corrugated pipe cutting device, a corrugated pipe can be cut from the inside, the corrugated pipe is clamped from the outside during cutting, and the pipe wall near the cutting point is fixedly clamped, so that the situation that notches are uneven due to shaking of the corrugated pipe during cutting can be avoided, and the cutting quality is improved; the automatic feeding mechanism can automatically pull the corrugated pipe into the equipment, so that the manpower consumption is reduced, and the production efficiency is improved; and the length of the cut corrugated pipe can be adjusted by adjusting the position of the limiting block, and a plurality of length gears are arranged and can be adjusted according to requirements.

Owner:湖南中源管业有限公司

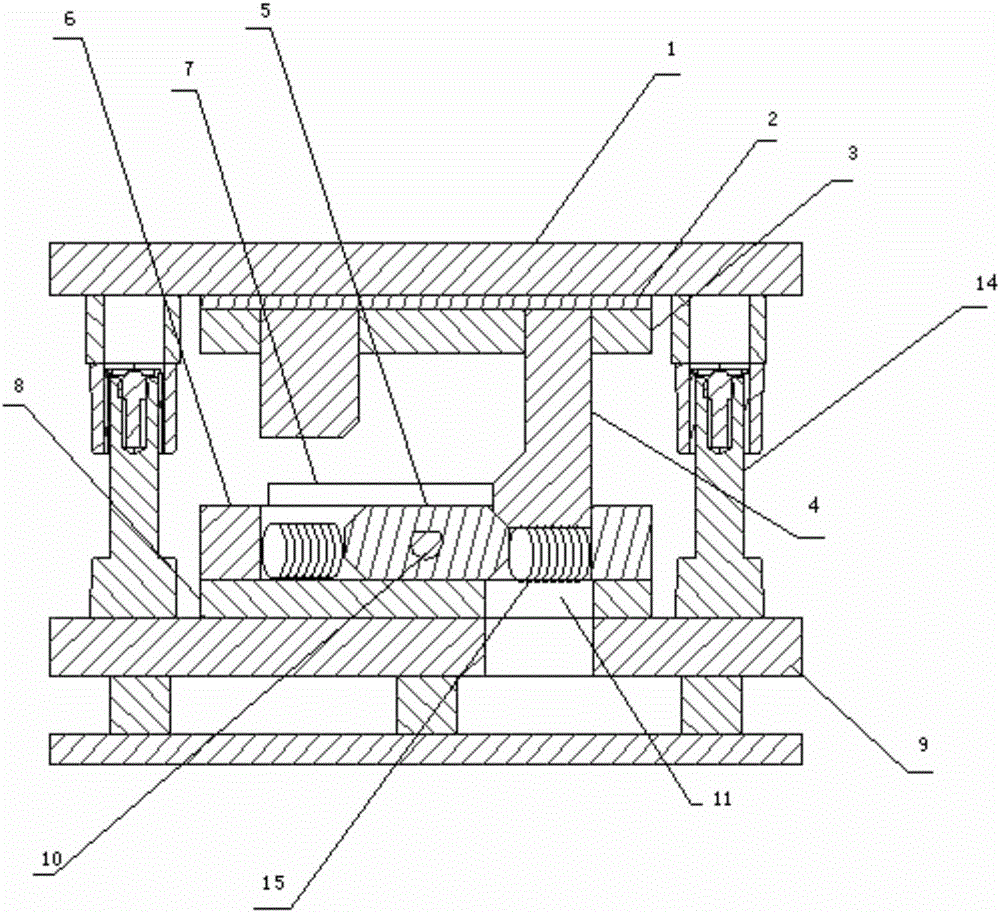

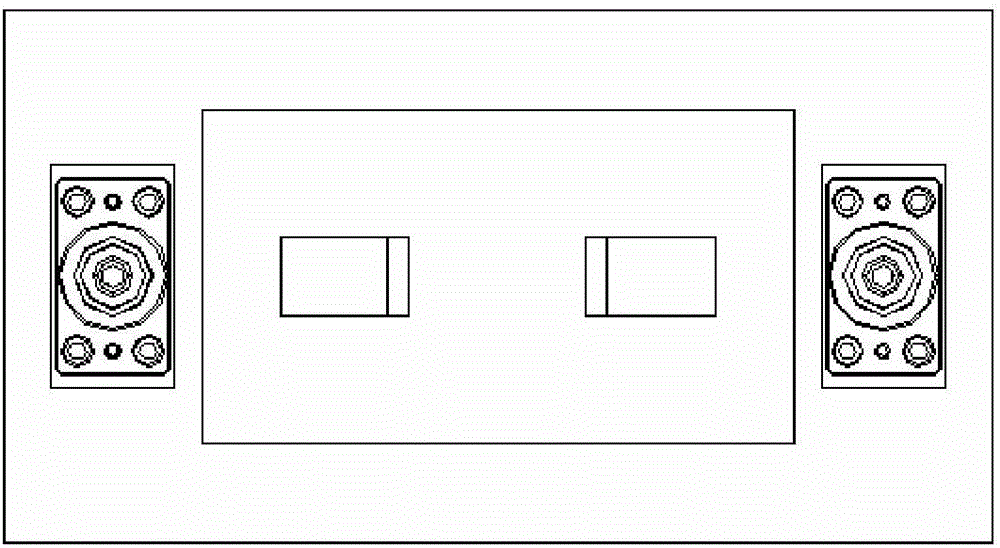

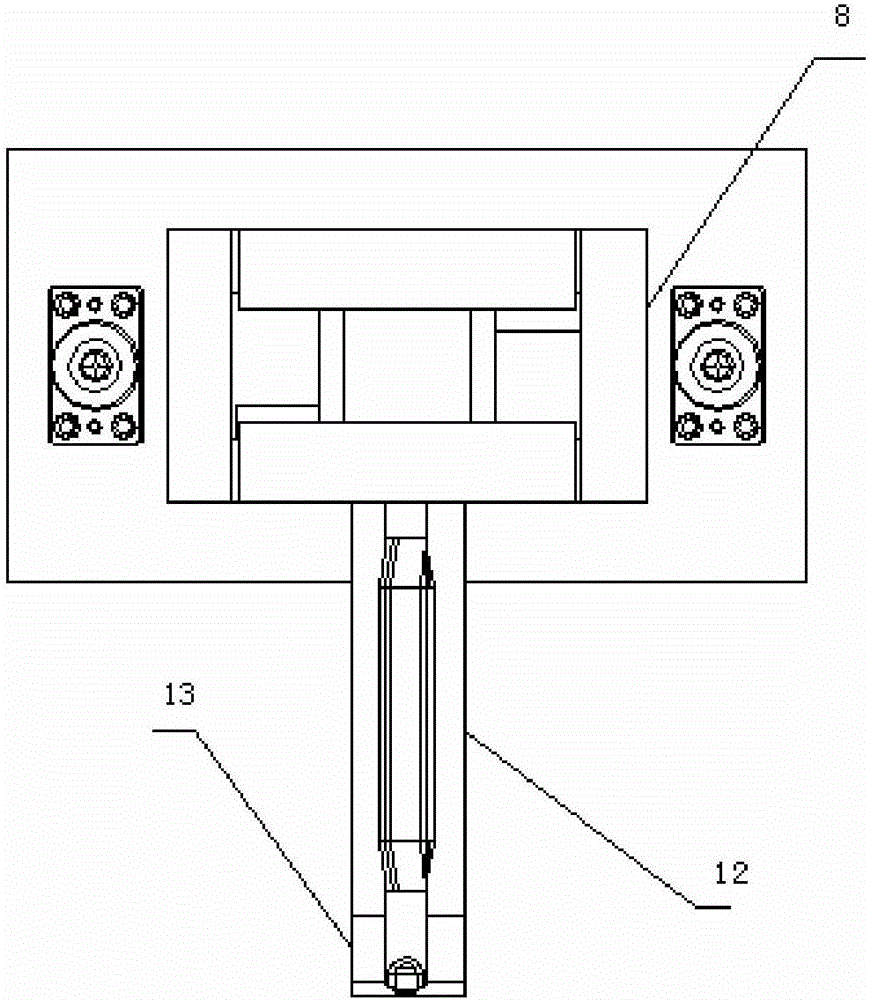

Rotary cutting die for pipe fittings

The invention discloses a rotary cutting die for pipe fittings. The rotary cutting die comprises a punch set, a bolster, a punch holder, an inclined block drive block, a lower slide block, return springs, side stop blocks, a product locking block and a die set, wherein the bolster is fixedly connected at the bottom end of the punch set, the punch holder is fixedly connected at the bottom of the bolster, the inclined block drive block is fixed at two bottom ends of the punch holder and abuts against the side stop blocks and the lower slide block, the two ends of each return spring abut against the corresponding side stop block and the lower slide block, a cutter slot is formed in the middle of the lower slide block, the side stop blocks and the lower slide block are fixed on a die holder, the product locking block is fixed on the die holder through a locking plate, and the die holder is fixed on the die holder. The rotary cutting die for the pipe fittings has the advantages of high strength, high tenacity, operational simplicity and stability, high working efficiency and long service life.

Owner:NANJING HUIDE MACHINERY

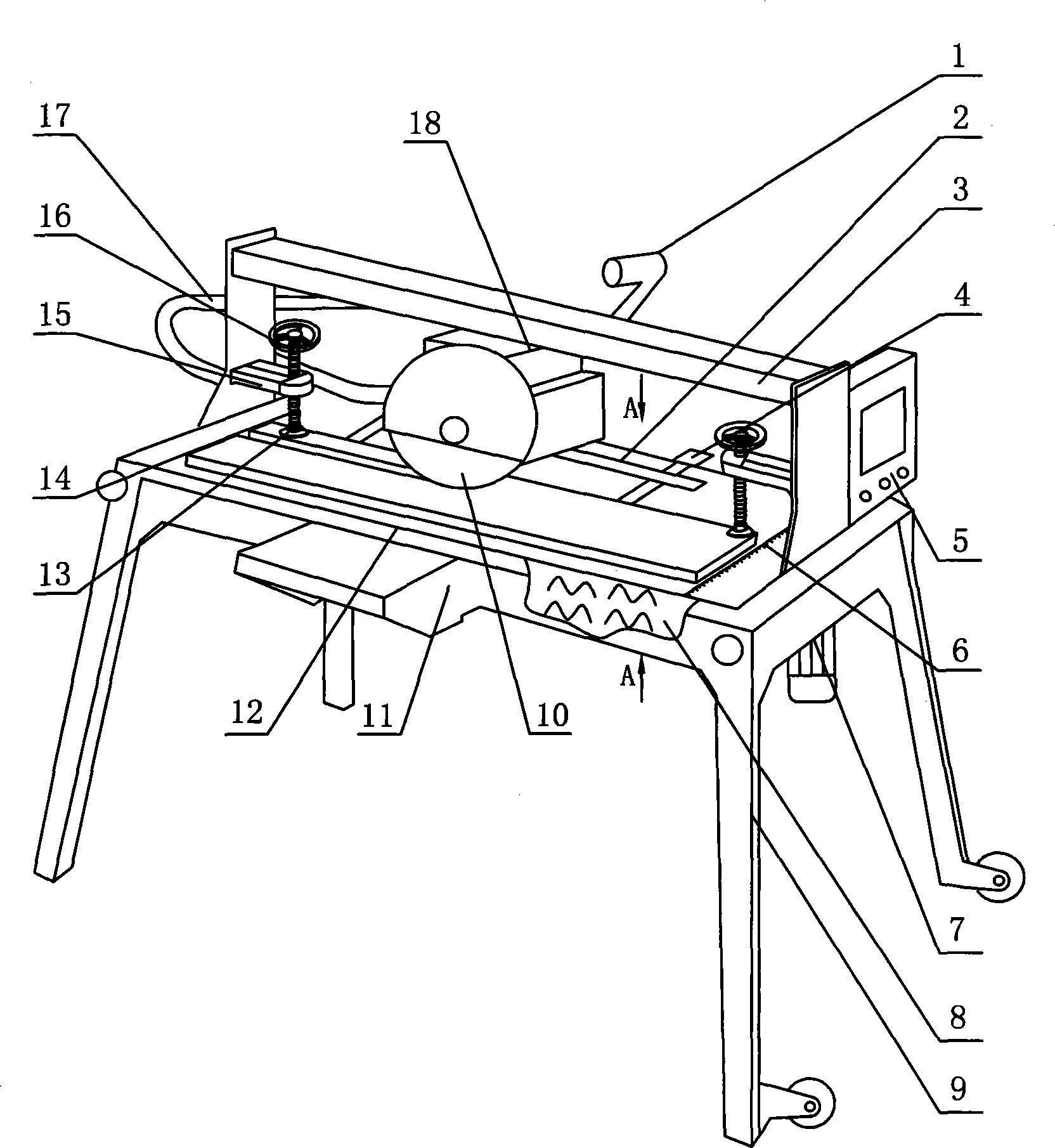

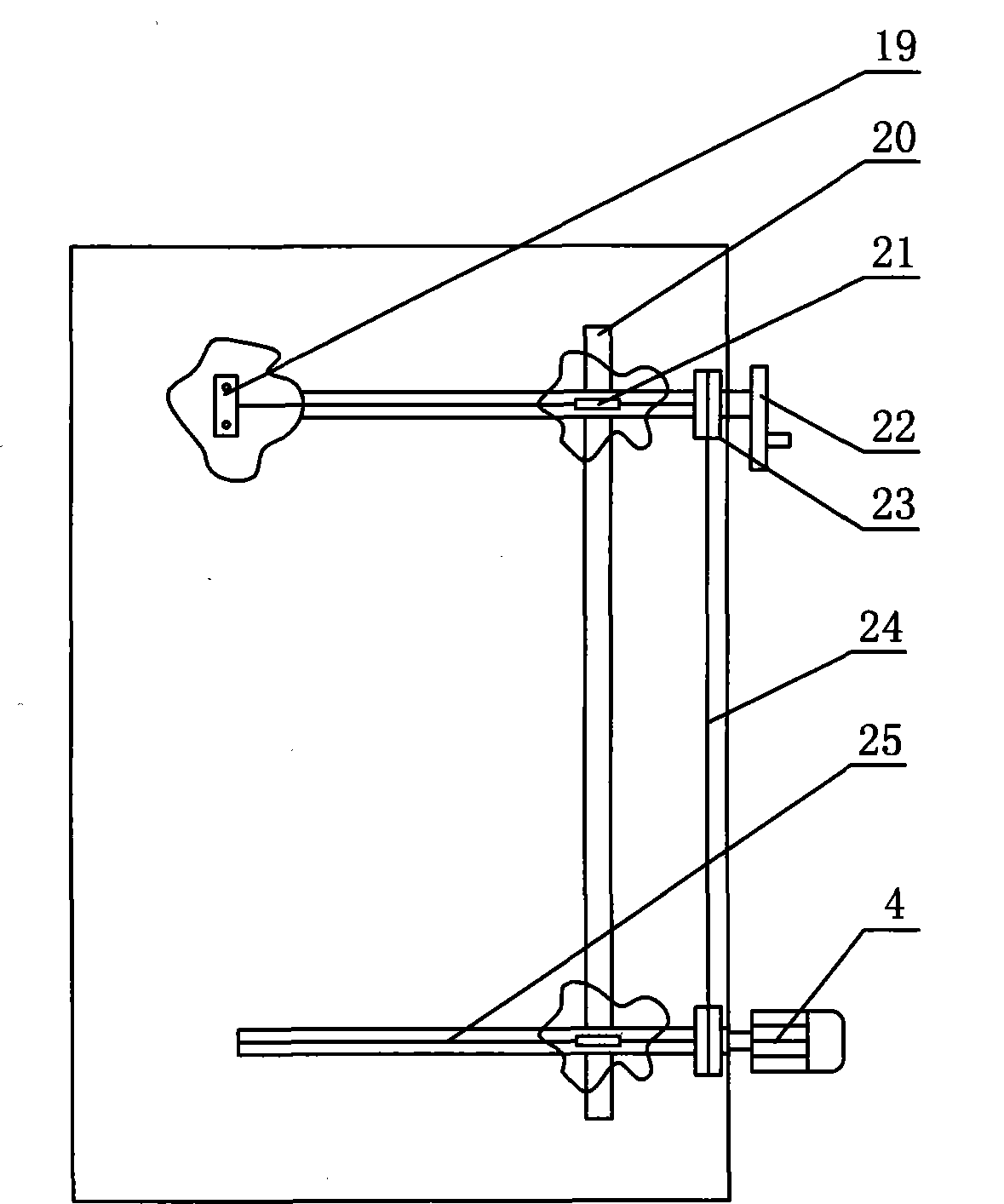

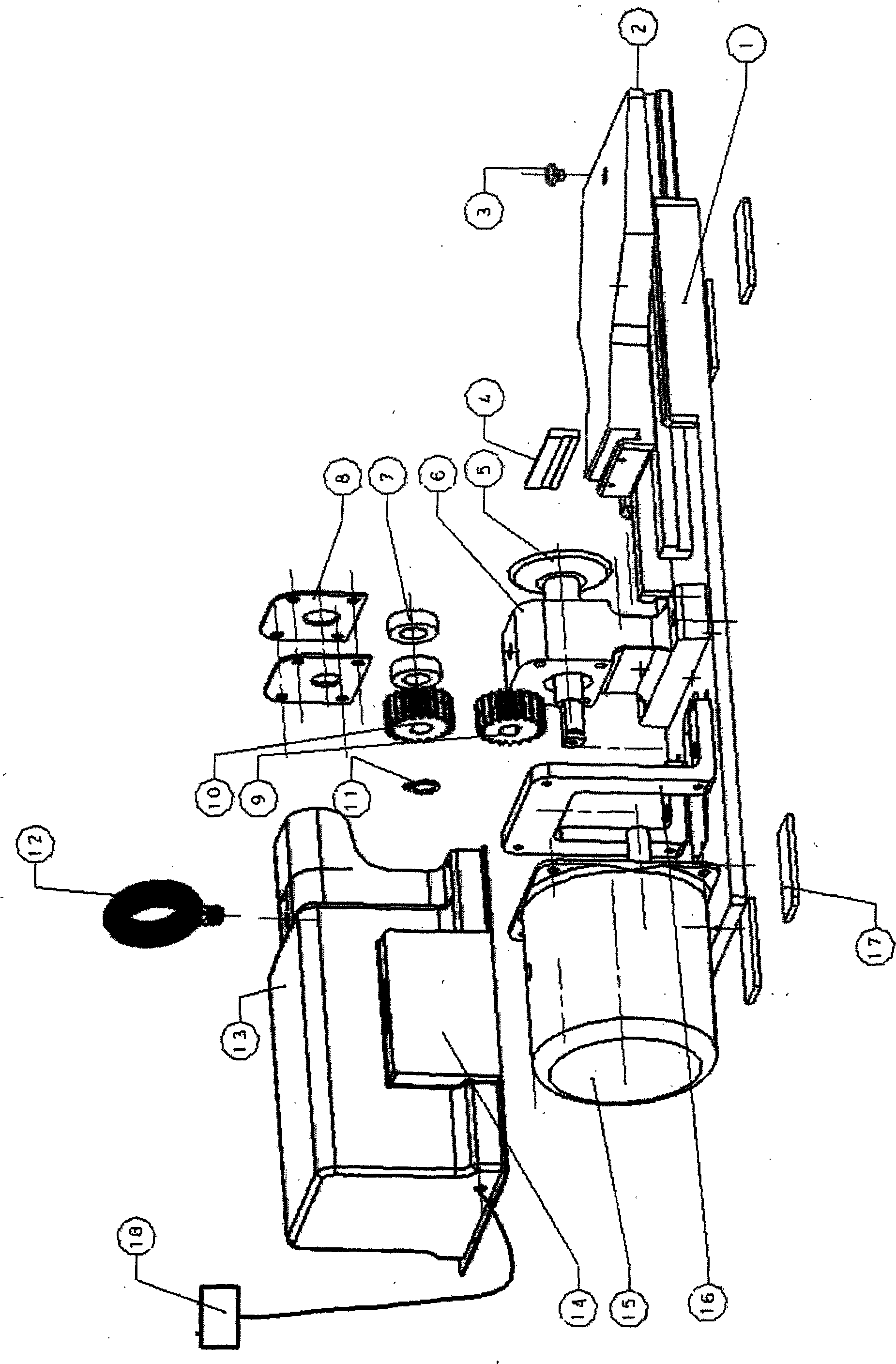

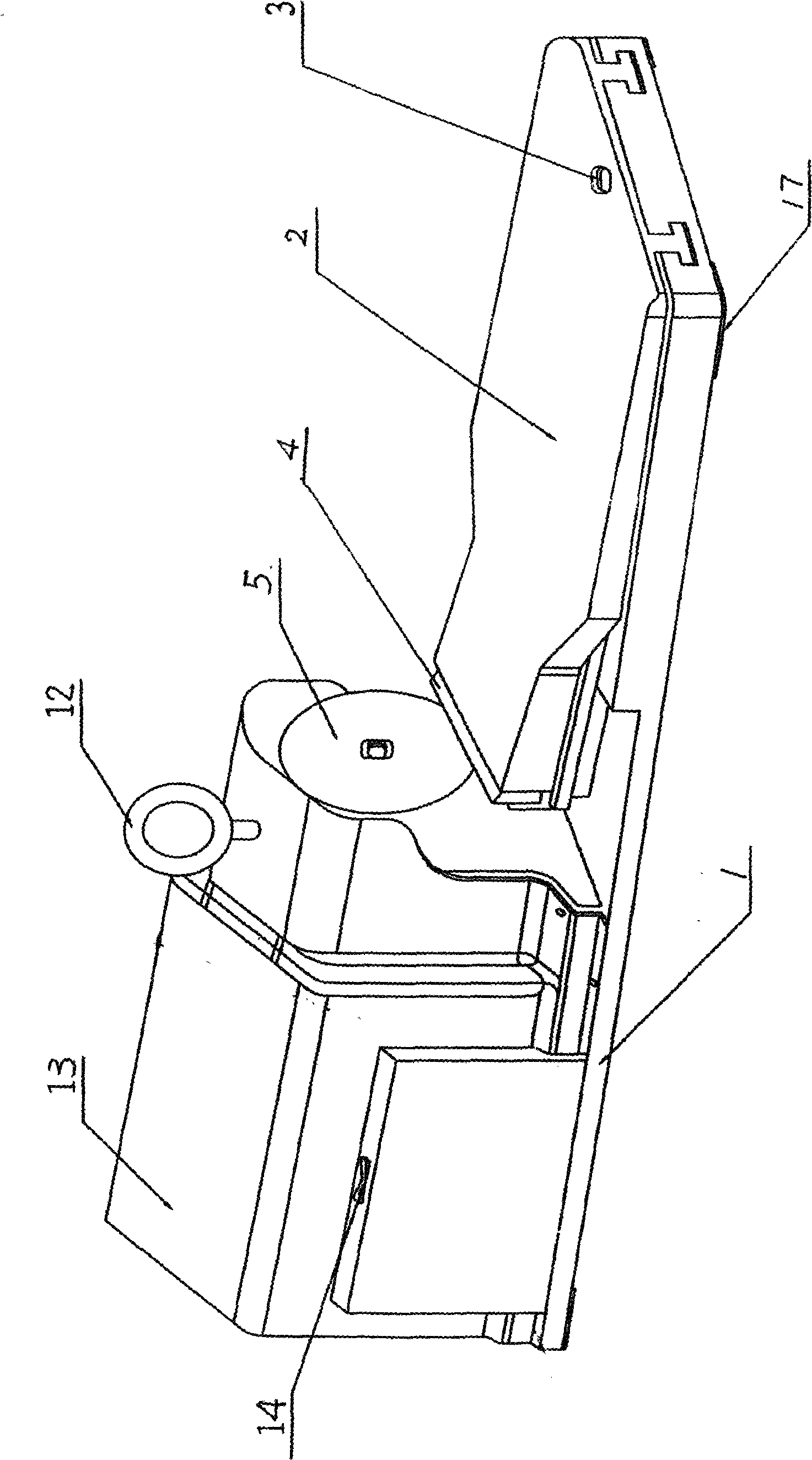

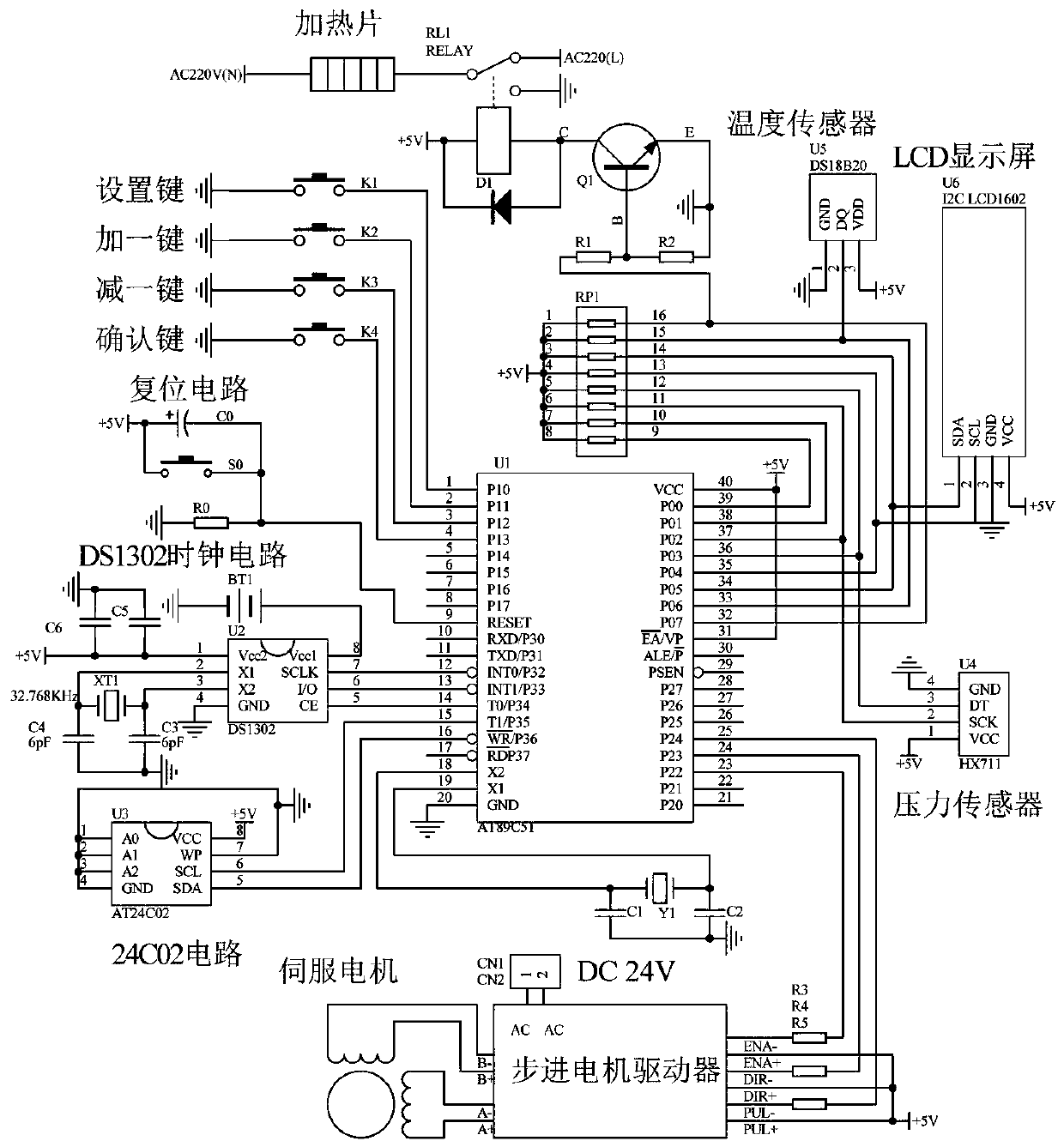

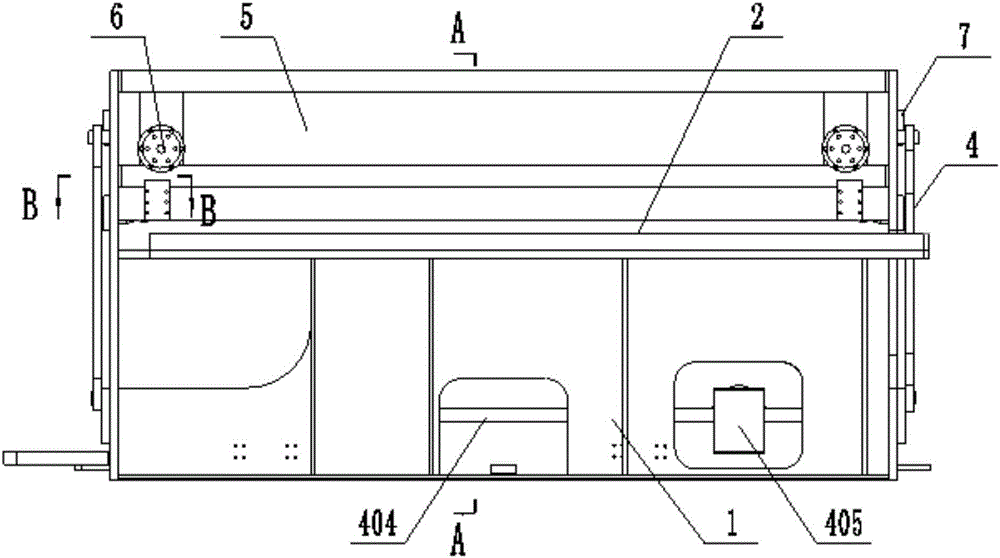

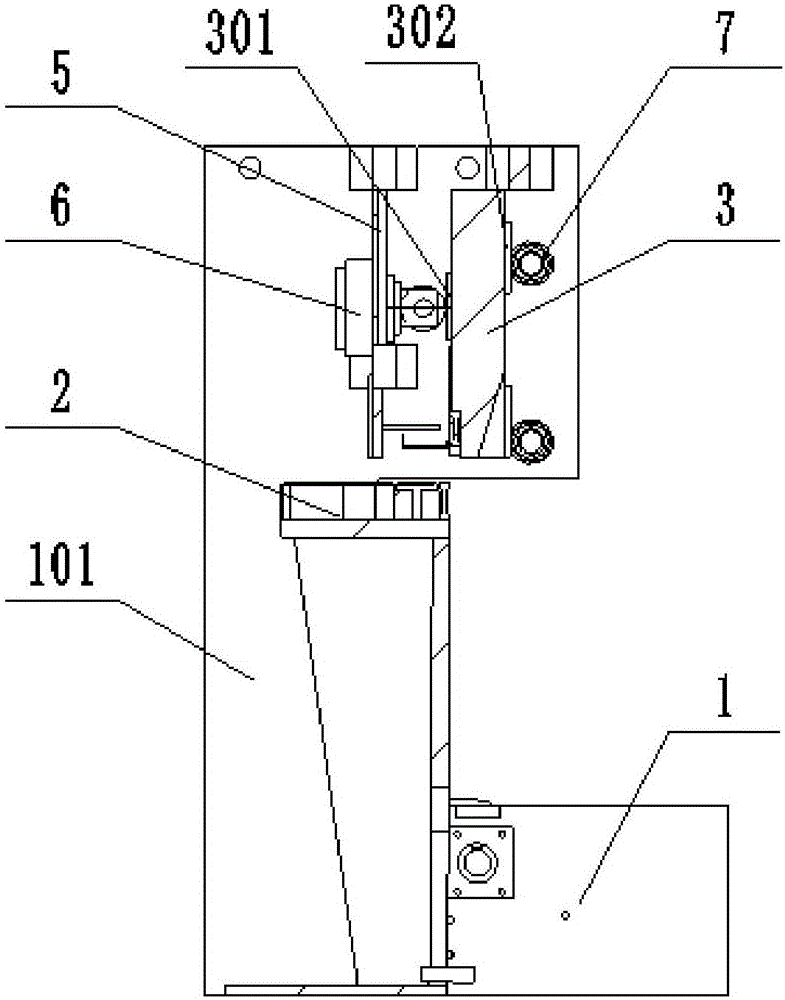

Intelligent novel water groove cutting machine

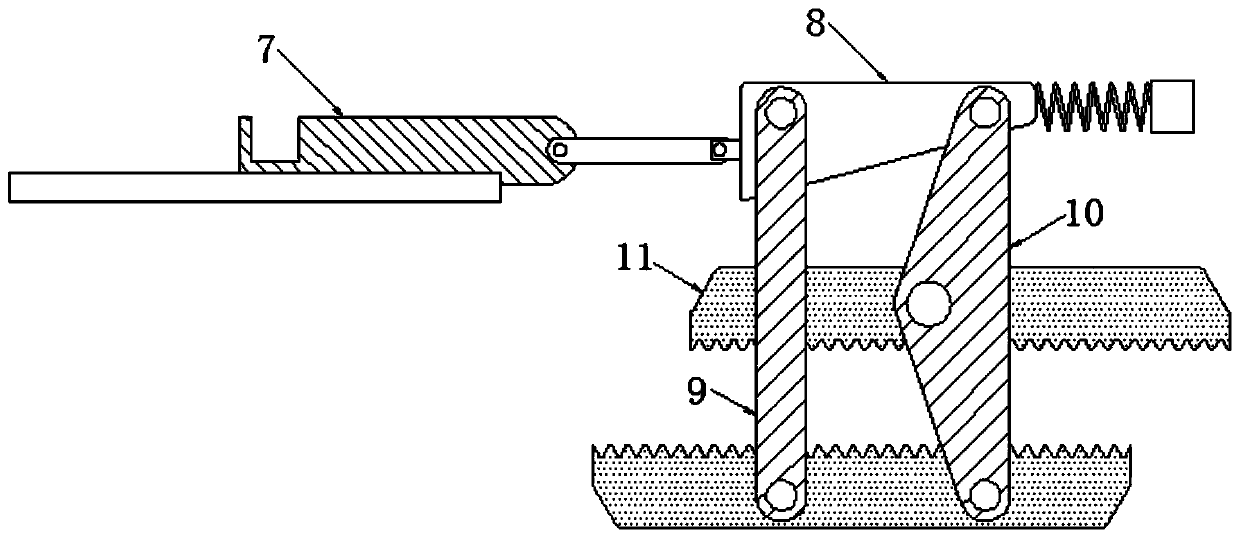

ActiveCN104275748AEffectively fixedSmooth incisionWorking accessoriesStone-like material working toolsAutomatic controlProgrammable logic controller

The invention provides an intelligent novel water groove cutting machine and relates to the field of electric tools. The cutting machine is reasonable in structure; a PLC (Programmable Logic Controller) program is used for controlling a movable box, an automatic feeding device and a water pump, so that digital automatic cutting and automatic cooling procedures are realized; the automation degree is high and the performance is safe and reliable. According to the cutting machine, hold-down mechanisms are arranged at the two ends of an I-shaped bracket; a working tabletop is provided with the automatic feeding device and manual control and automatic control can be realized. Each hold-down mechanism is composed of a small supporting frame, a hold-down hand wheel, a screw rod and a rubber compression disc; all types of workpieces can be effectively held down and the workpieces are not damaged. The automatic feeding device can be used for automatically adjusting cutting positions of the workpieces, so that the labor intensity of workers is alleviated, the working errors are reduced, and the product quality and the working efficiency are improved.

Owner:YANCHENG BAODING POWER TOOLS

Table tennis bat rubber cutting machine

The present invention discloses a cutter for table tennis bat rubber. The cutter comprises a driver installed on baseboard, a cutting component and a platform. The cutting component is a shearing pair which is composed of a rotating blade and a fixed blade. The rotating blade is provided with a rotating shaft which is supported on the bearing base. The shaft end of rotating shaft is connected with the driver. The fixed blade is installed on the platform which is a moving platform. The moving platform and the baseboard are a longitudinal rail-groove sliding fit structure. The cutter of the invention has the advantages of good cutting quality, continuous and smooth kerf opening, high speed, high efficiency, small volume, light weight, convenient carrying and low cost. The cutter of the invention is especially suitable for cutting the adhered table tennis bat rubber before the competition of professional table tennis athletes.

Owner:兰成伟

C-shaped pipeline cutting knife

The invention discloses a C-shaped pipeline cutting knife. The cutting knife comprises a support, wherein a cutting tool is connected with one end of the support, the cutting tool comprises a tool rest with a C-shaped section, a gear ring is fixedly arranged on a surface of the knife rest along the circumferential direction, a gear motor is fixedly installed on a side wall of the support through screws, a pinion is mounted on a motor shaft of the gear motor, the pinion is meshed with the gear ring, a lifting assembly is installed at upper end of the knife rest, a cutting knife wheel is installed at a bottom end of the lifting assembly, a transmission assembly is installed at a lower end of the knife rest, a to-be-cut pipe is placed between the knife wheel and the transmission assembly, anarc-shaped guide rail is fixedly installed on a side wall of the knife rest in the circumferential direction of the knife rest, and four sliding blocks are fixed to a side face of the support throughscrews. The cutting knife is advantaged in that a pipe opening of a cut pipeline is not deformed, a notch is flat and smooth, follow-up maintenance and welding are facilitated, no cuttings or cuttingmedium exists after cutting, no secondary pollution is caused to the pipeline, and mounting and dismounting are convenient.

Owner:四川东方龙源动力设备有限公司 +1

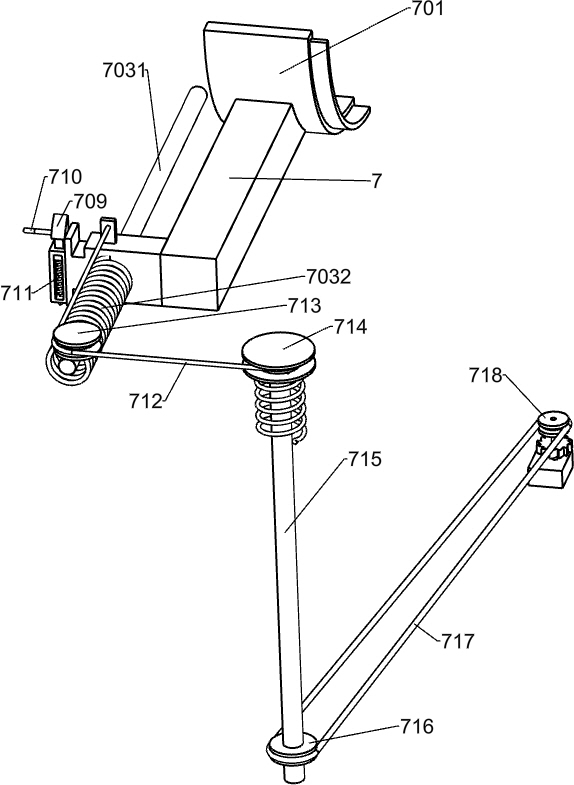

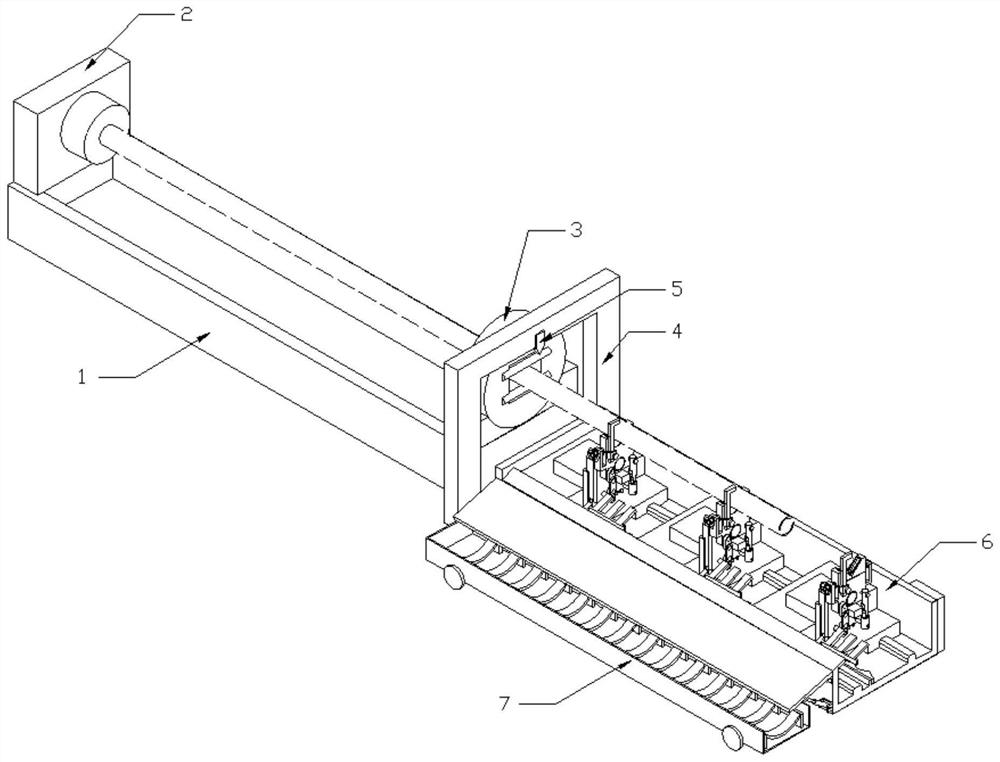

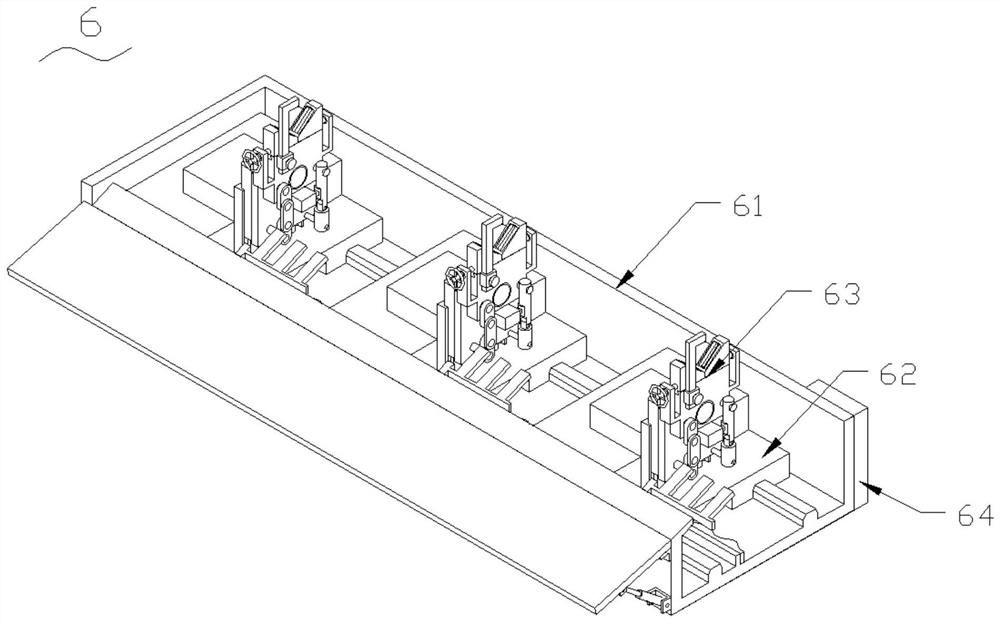

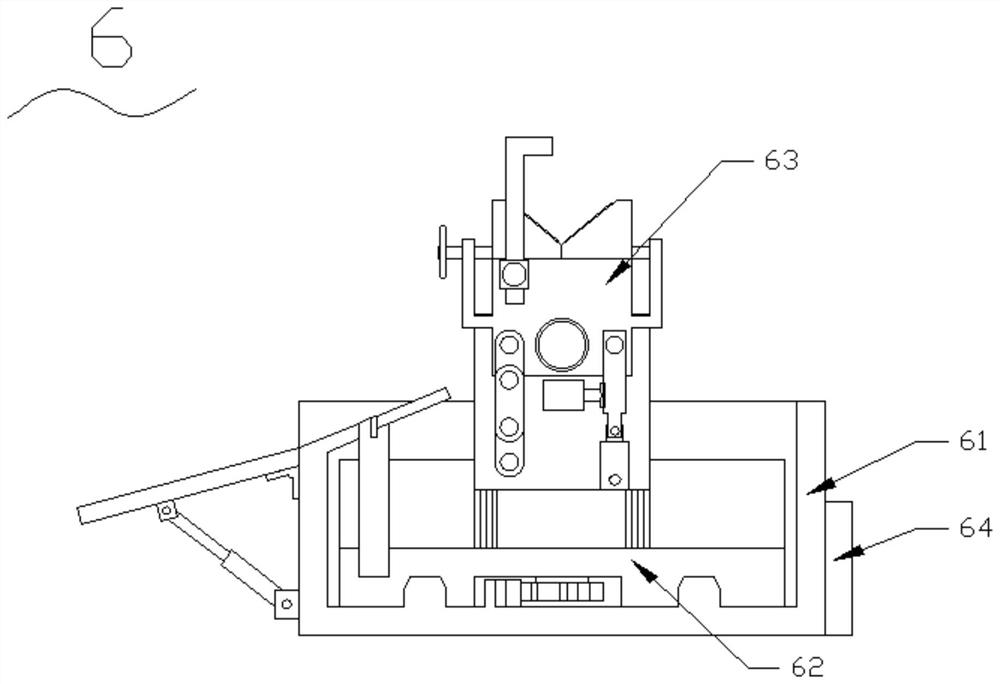

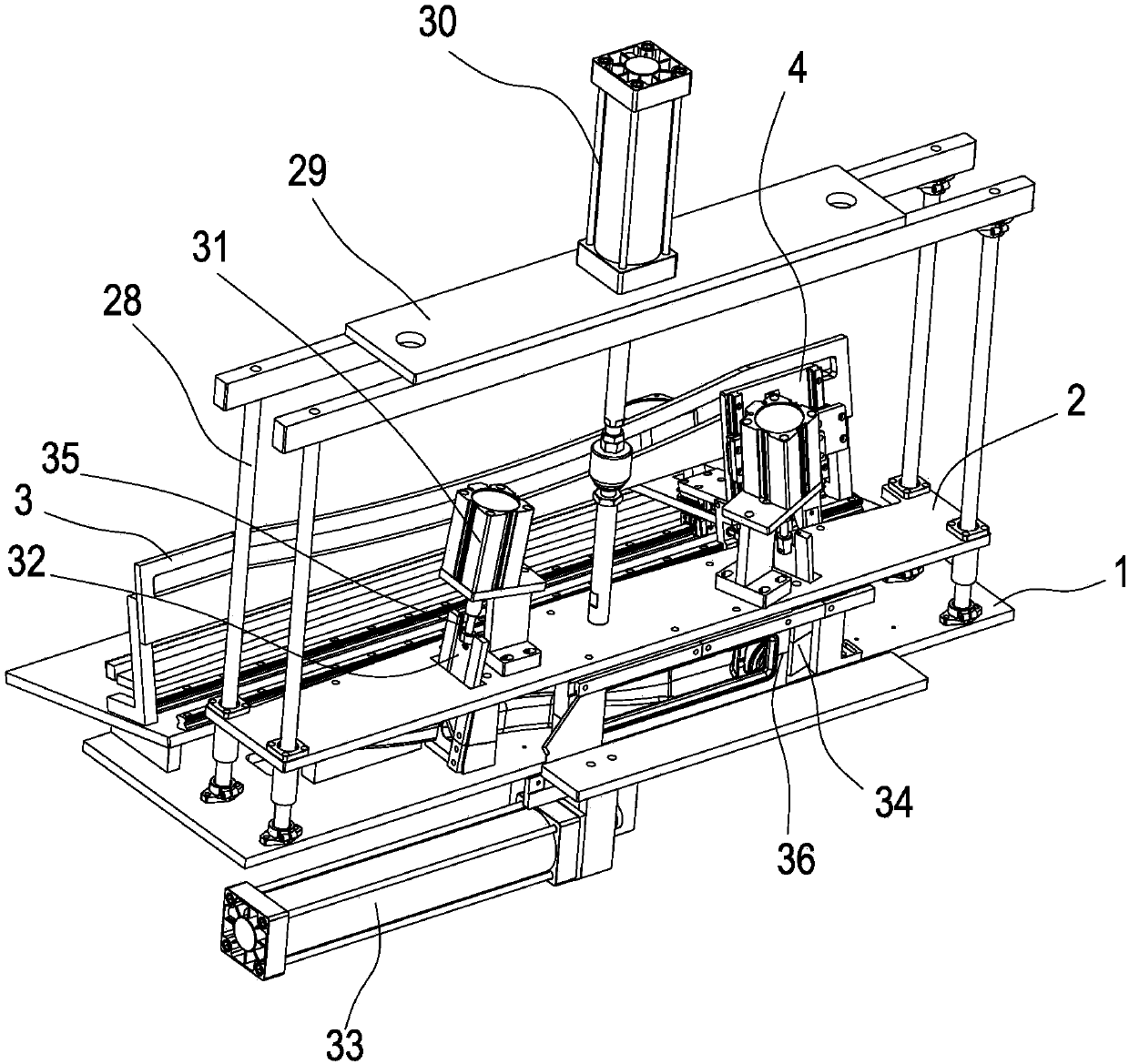

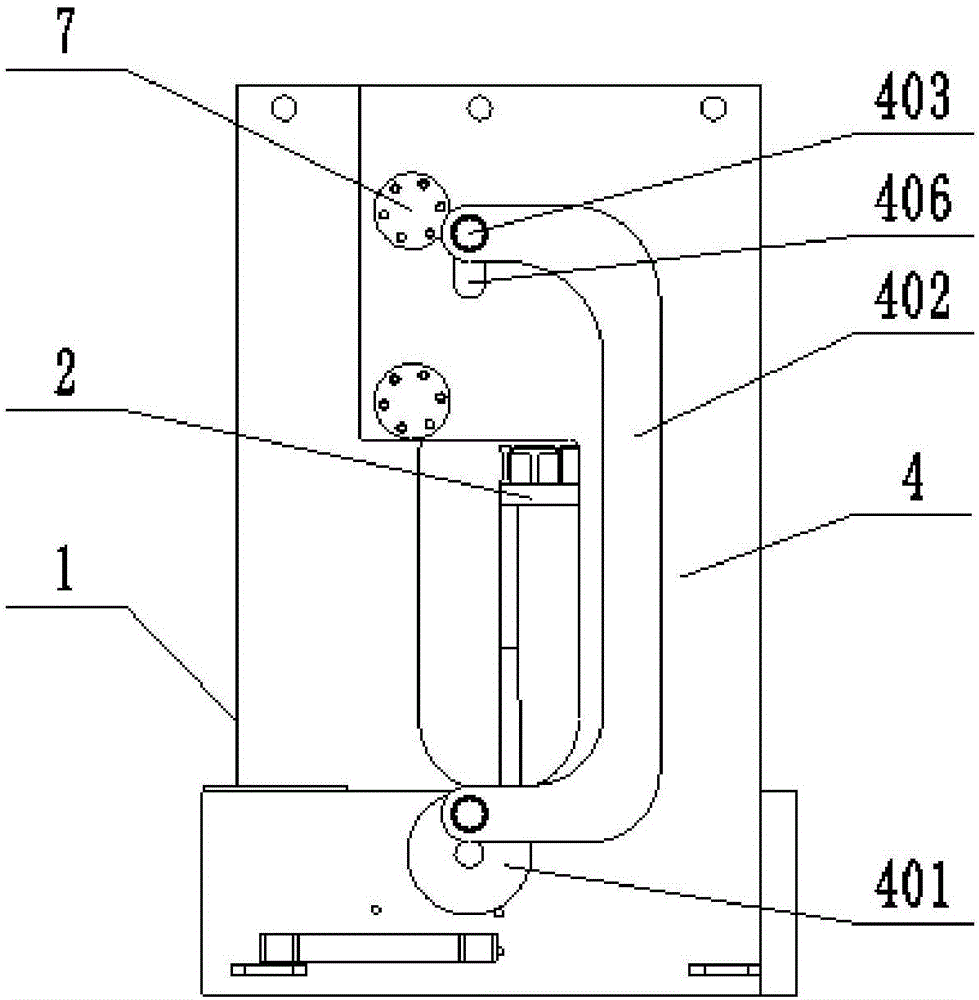

Split type auxiliary supporting and discharging device for laser pipe cutting machine

ActiveCN113857688ATo achieve the role of multi-point supportSmooth incisionLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a split type auxiliary supporting and discharging device for a laser pipe cutting machine. The split type auxiliary supporting and discharging device comprises a laser pipe cutting machine base, a movable chuck is arranged at one end of the upper surface of the laser pipe cutting machine base, a fixed chuck is arranged at the other end of the upper surface of the laser pipe cutting machine base, a portal frame is arranged on one side of the fixed chuck, a laser cutting head is arranged on one side face of the portal frame, a supporting and discharging device is arranged at one end of the laser pipe cutting machine base, a material collecting trolley is arranged on one side of the supporting and discharging device, the supporting and discharging device comprises a bottom frame, a plurality of moving devices are arranged inside the bottom frame, supporting and adjusting devices are arranged on the upper surfaces of the moving devices, and a control module is arranged on the outer surface of one side of the bottom frame. According to the split type auxiliary supporting and discharging device, the supporting effect can be achieved when a finished pipe is cut, the situation that a notch is irregular is avoided, the cutting quality is improved, and the situation that the finished pipe is damaged or falls off due to the fact that impact force is too large in the discharging process of the finished pipe can be effectively prevented.

Owner:江苏卡米特激光智能科技有限公司

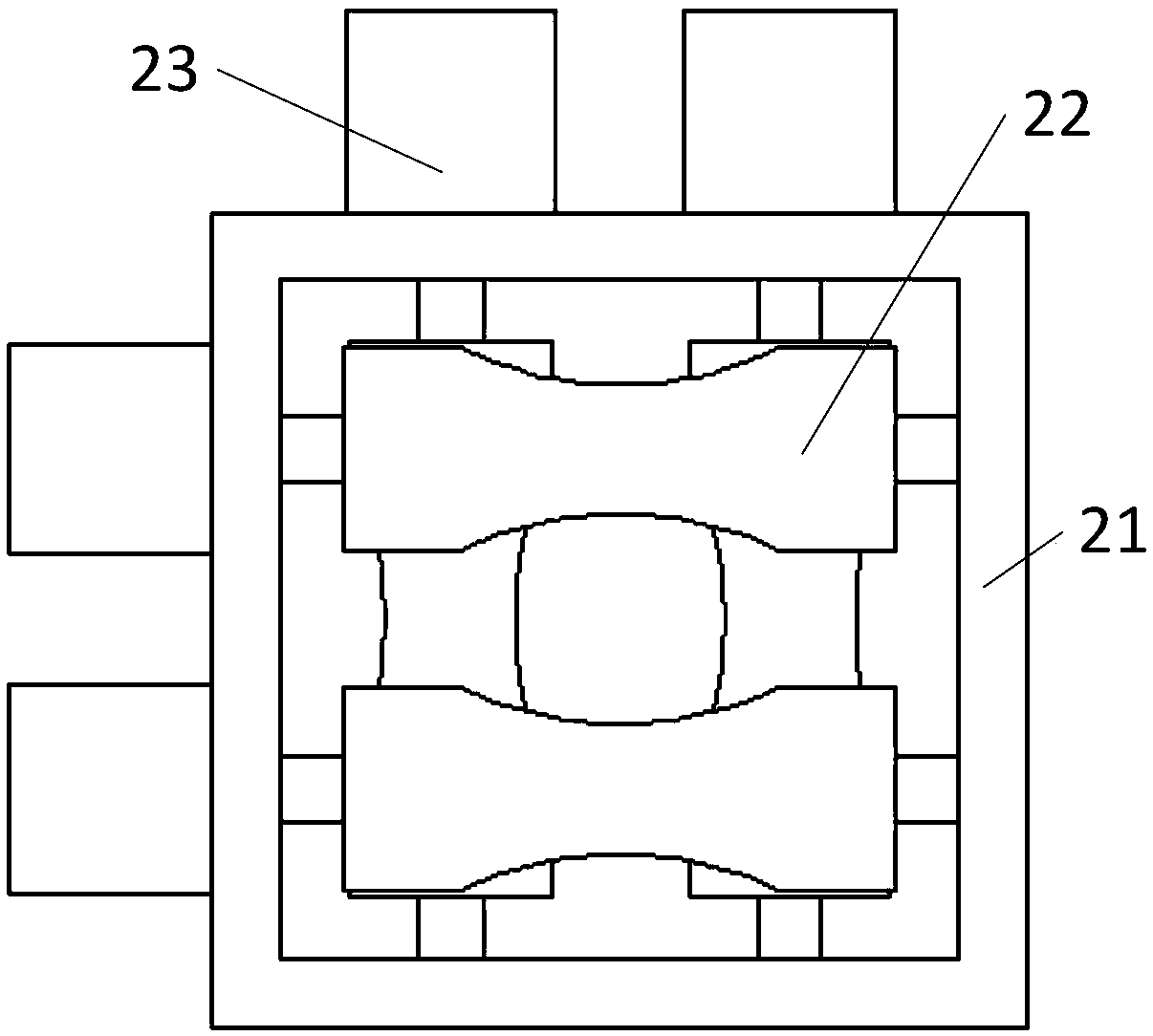

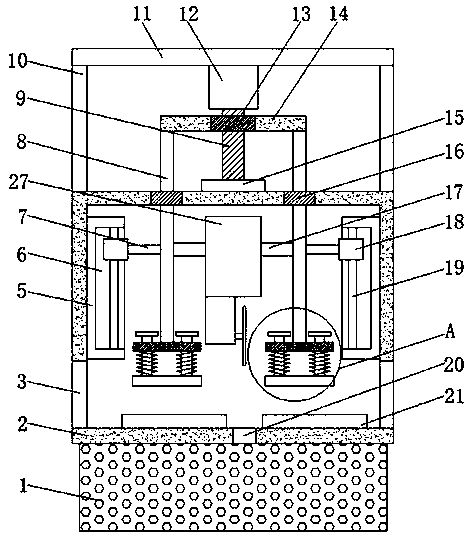

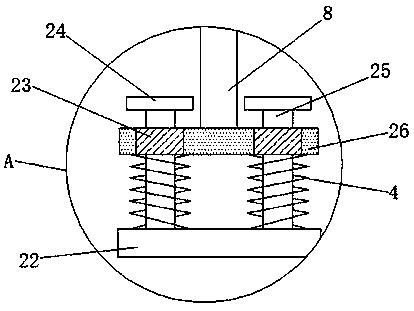

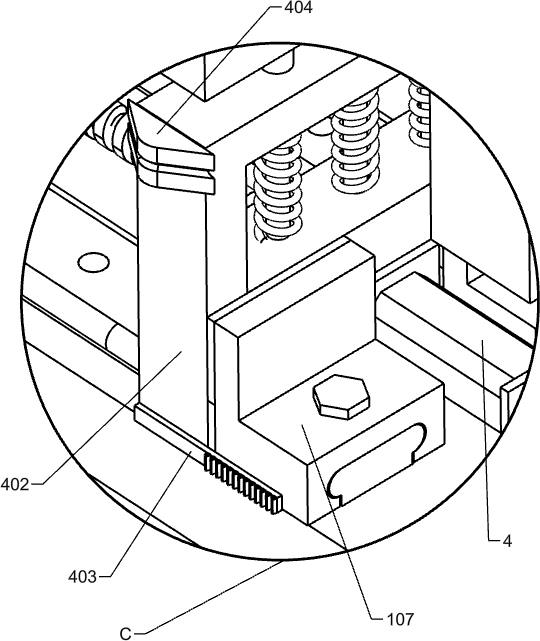

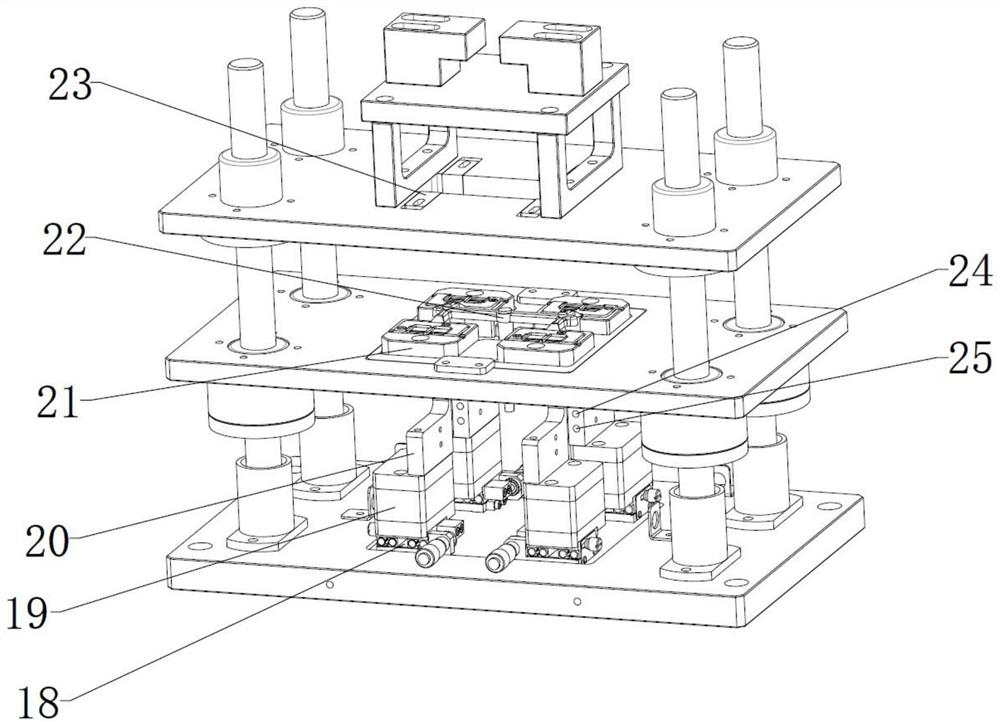

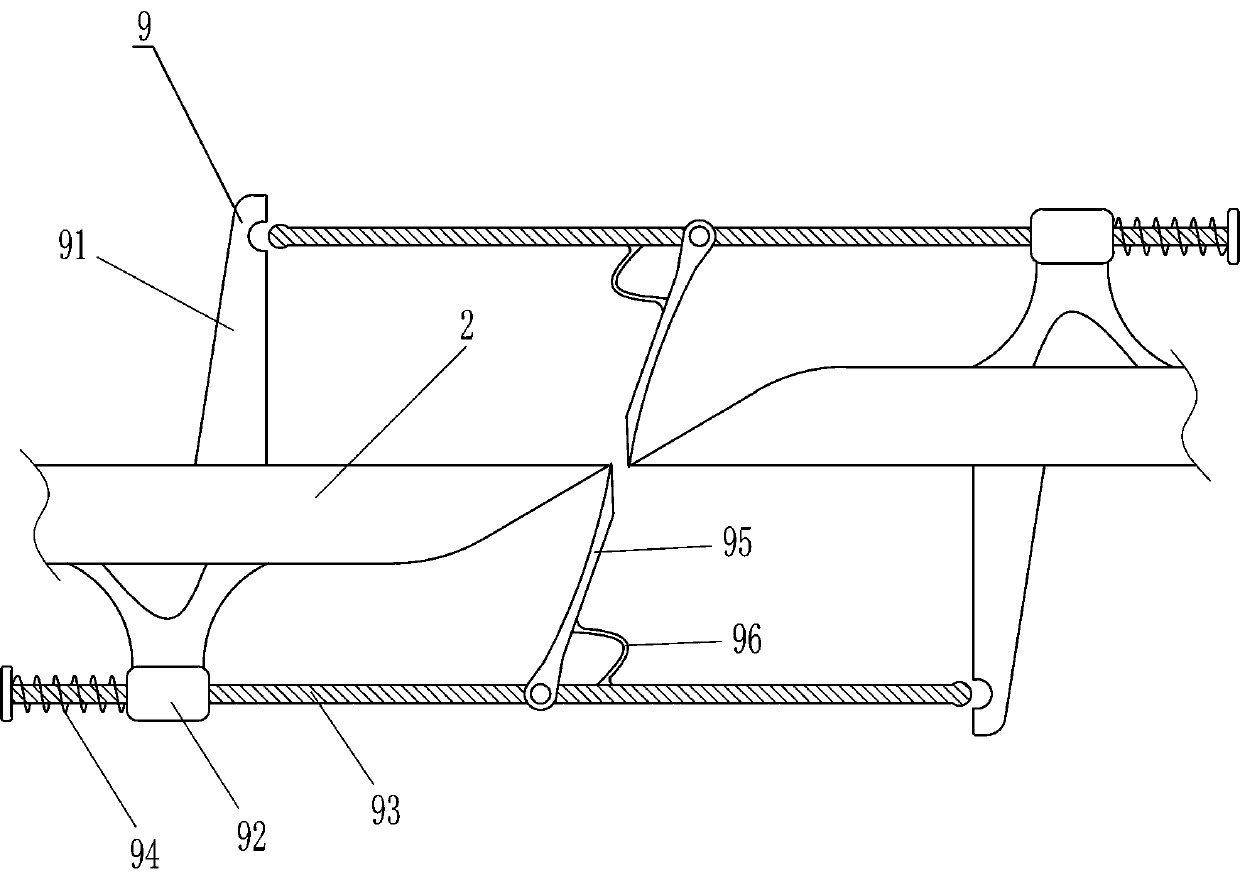

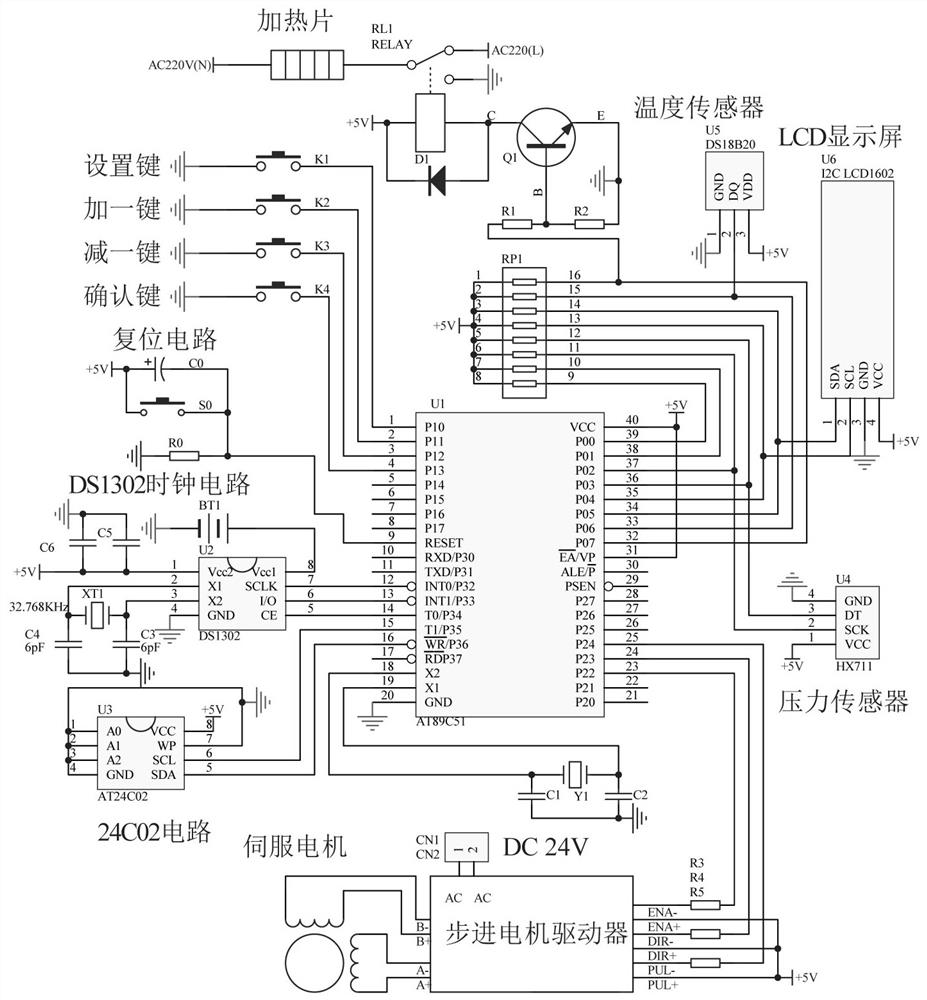

Hot punching device for runner of MIM (Metal Injection Molding) part

The invention relates to a hot punching device for a runner of an MIM (Metal Injection Molding) part. The hot punching device for the runner of the MIM part comprises a device table and is characterized in that a main body structure and an electric control system are arranged on the device table, wherein the main body structure comprises a bottom layer plate; the bottom layer plate is provided with a cutter used for punching a pouring gate of the injection molding part; a cutter body is internally provided with at least one heating rod and one thermocouple and is connected with a temperature control meter of the electric control system; guide columns and elastic reset mechanisms are arranged at the four corners of the bottom layer plate so as to be connected with a middle layer plate; a jig used for positioning the injection molding part is arranged on the middle layer plate; an upper layer pressing block capable of being controlled by a lifting mechanism to ascend and descend is arranged on the upper part of the middle layer plate, and is pressed downwards to make contact with the injection molding part; and the middle layer plate is pushed to overcome the elastic force of an elastic reset mechanism and move downwards until the injection molding part is in contact with the cutting edge of the cutter to cut off the runner. According to the hot punching device for the runner of the MIM part provided by the invention, the quality of a notch of the injection molding part is improved, and the yield of product production is improved.

Owner:杭州铭赫科技有限公司

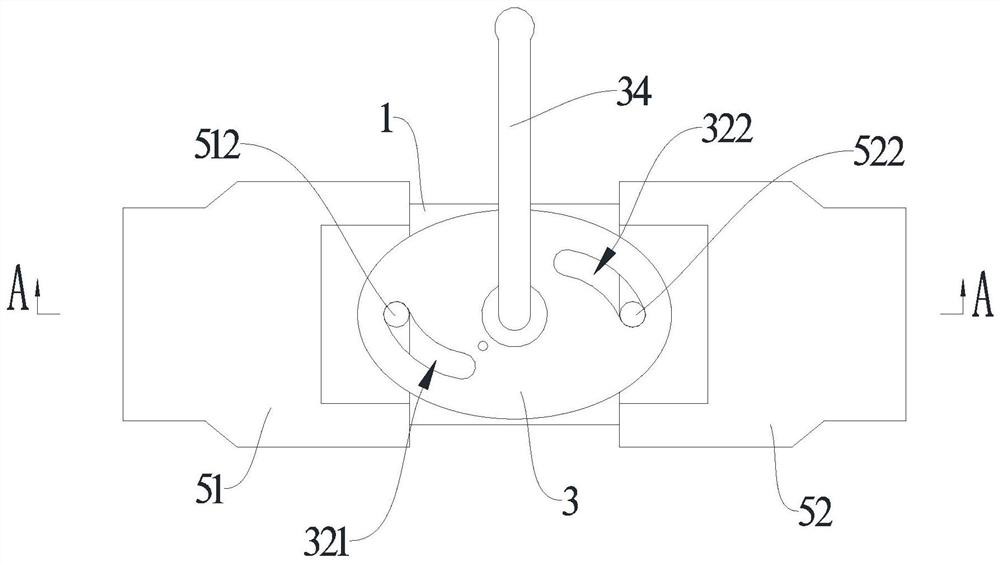

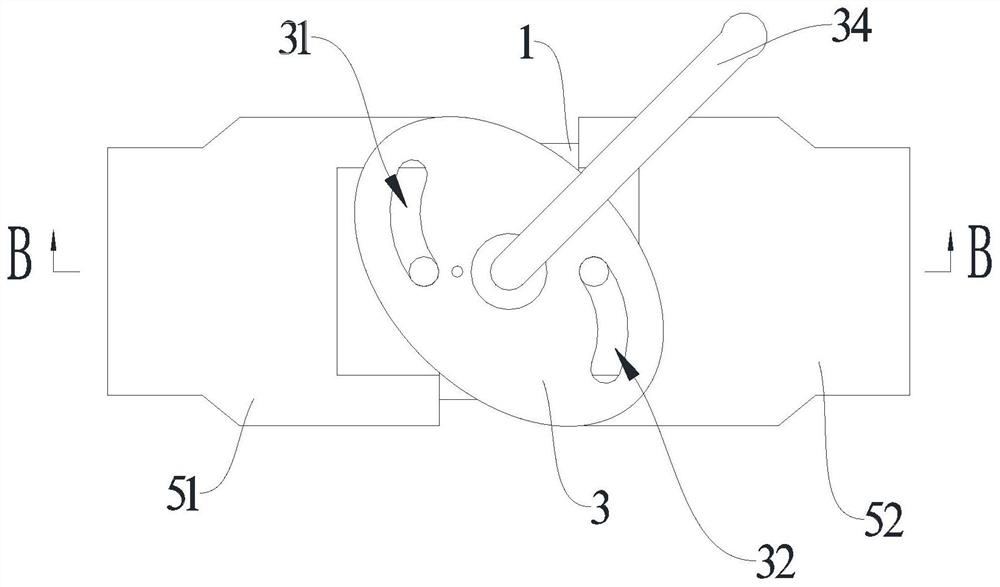

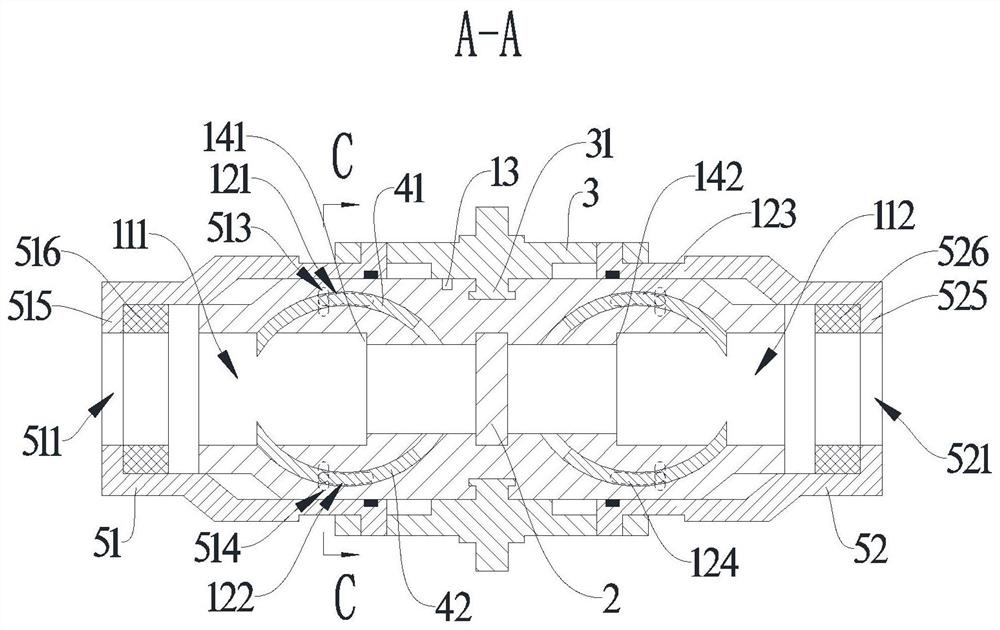

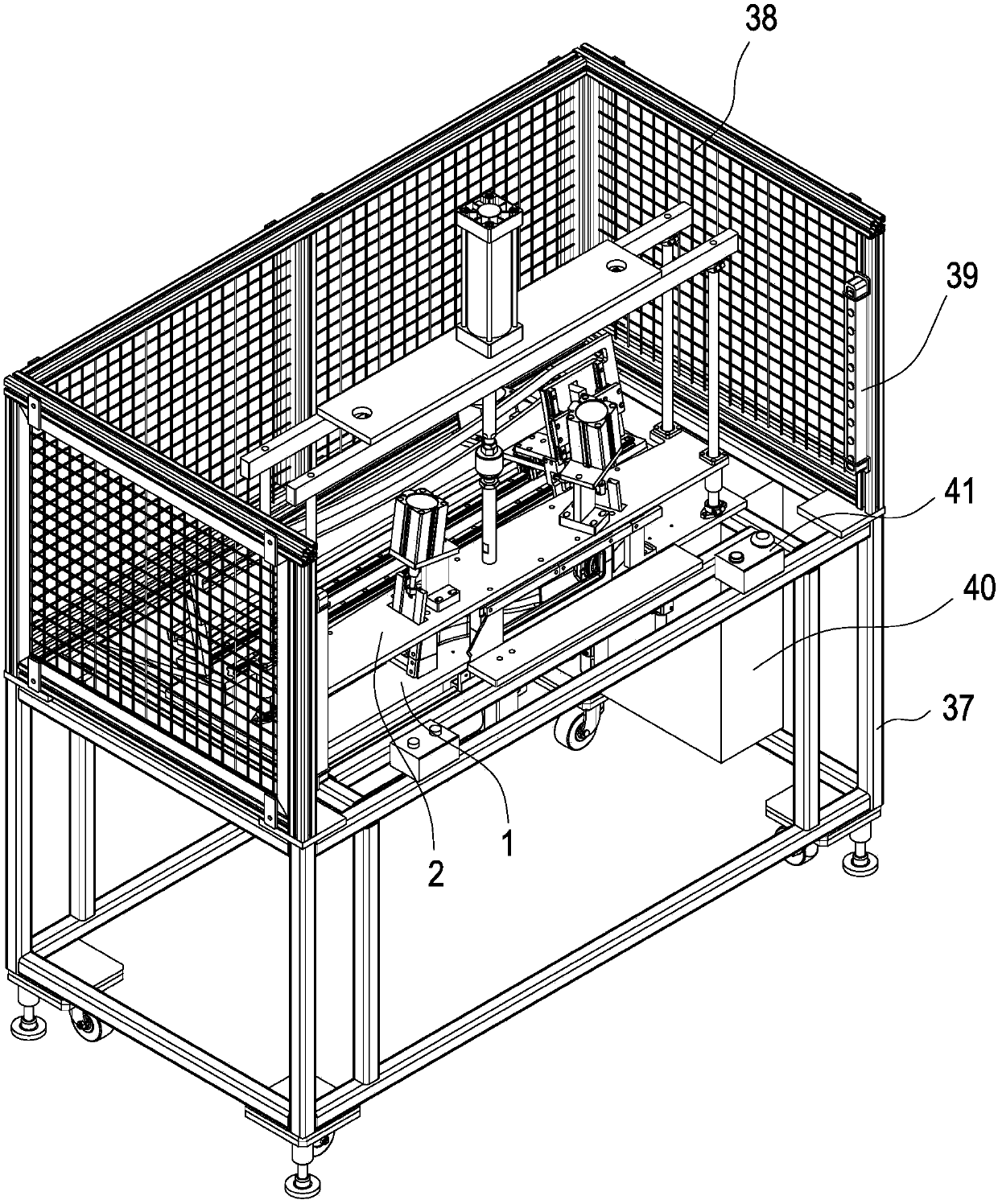

Cable connector

ActiveCN113594760APrevent leakageSmooth incisionElectrically conductive connectionsCouplings bases/casesElectric cablesRotating disc

The invention relates to a cable connector which is used for connecting a first cable and a second cable, and the cable connector comprises a shell, wherein the middle part of which is provided with a first connecting hole; a rotating shaft which is arranged in the middle of the rotating disc, wherein the rotating shaft is rotationally connected to the side wall of the shell, and a first arc-shaped groove is formed in the rotating disc; a first sleeve; a first arc-shaped clamping jaw; and a second arc-shaped clamping jaw. By controlling the rotating disc to rotate forwards, the arc-shaped clamping jaw can clamp the cable, and by controlling the rotating disc to rotate reversely, the arc-shaped clamping jaw can cut an insulating layer of the cable. The cable connector has the advantages that a vertical groove is formed in the sleeve, the arc-shaped through groove is formed in the shell and matched with the connecting shaft on the arc-shaped clamping jaw, the arc-shaped clamping jaw can be controlled by rotating the rotating disc to clamp the cable, connection is completed, and the cable connector is convenient and fast to use.

Owner:东莞市格瑞斯科技有限公司

Automobile air flue arc-shaped cutting tool

PendingCN107813366AReduce processing costsSmooth incisionMetal working apparatusProcessing costProduct processing

The invention provides an automobile air flue arc-shaped cutting tool, and belongs to the technical field of automobile spare part production. The automobile air flue arc-shaped cutting tool comprisesa material containing plate used for containing to-be-cut workpieces, a movable clamping plate capable of doing reciprocating motion towards the material containing plate so as to get close to or befar away from the material containing plate is movably connected to the material containing plate, and an arc-shaped guide plate assembly is arranged on the material containing plate; and a self-adaption arc-shaped cutting assembly which is movably connected with the arc-shaped guide plate assembly and can walk along the arc-shaped guide plate assembly is further arranged on the movable clamping plate. According to the automobile air flue arc-shaped cutting tool, cutting of plastic pieces with arc-shaped notches is achieved, and the product machining cost is reduced.

Owner:TAIZHOU RIXING AUTOMOTIVE EQUIP

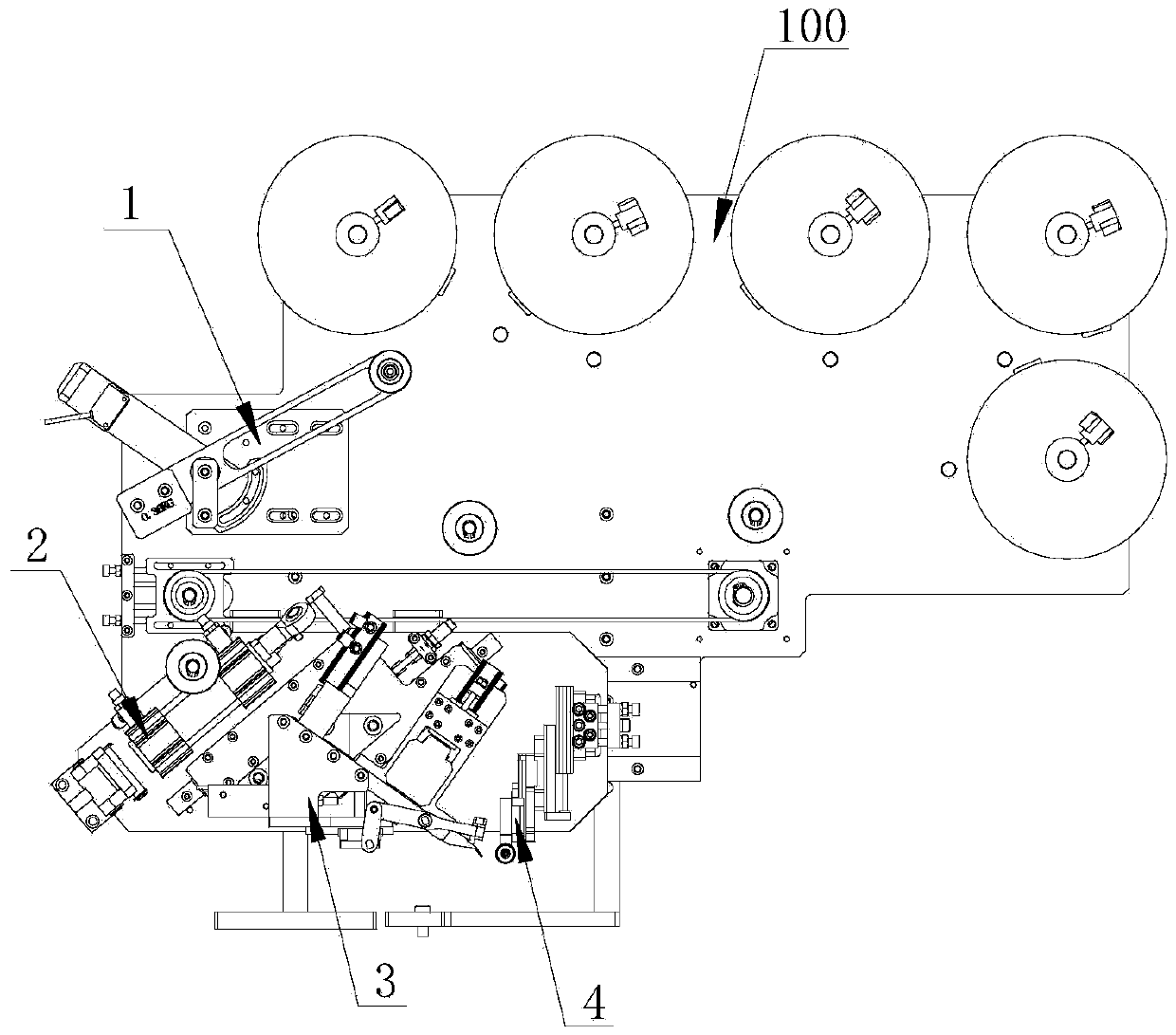

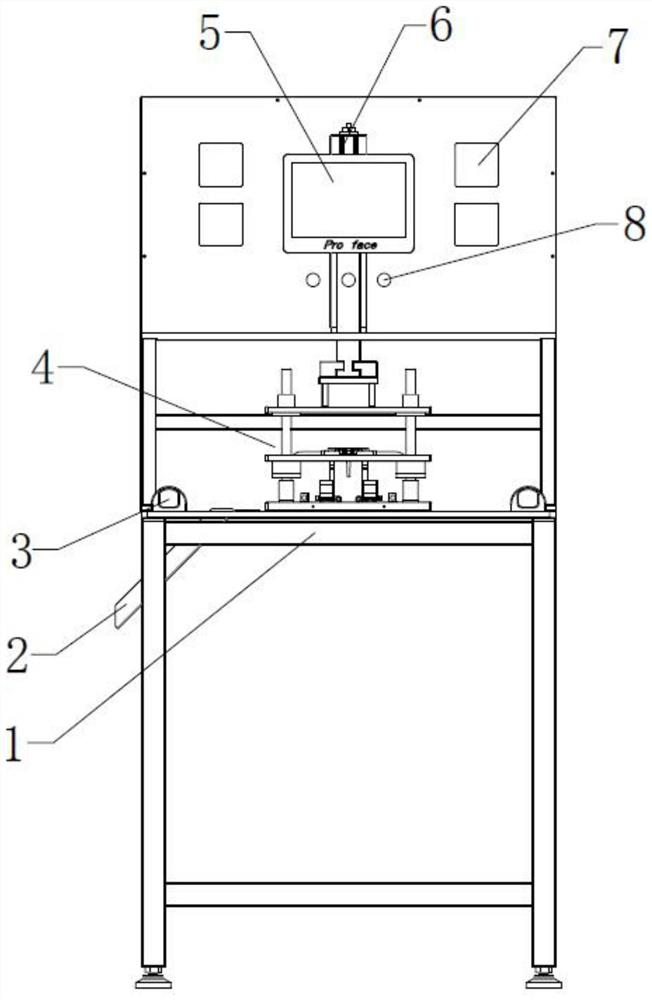

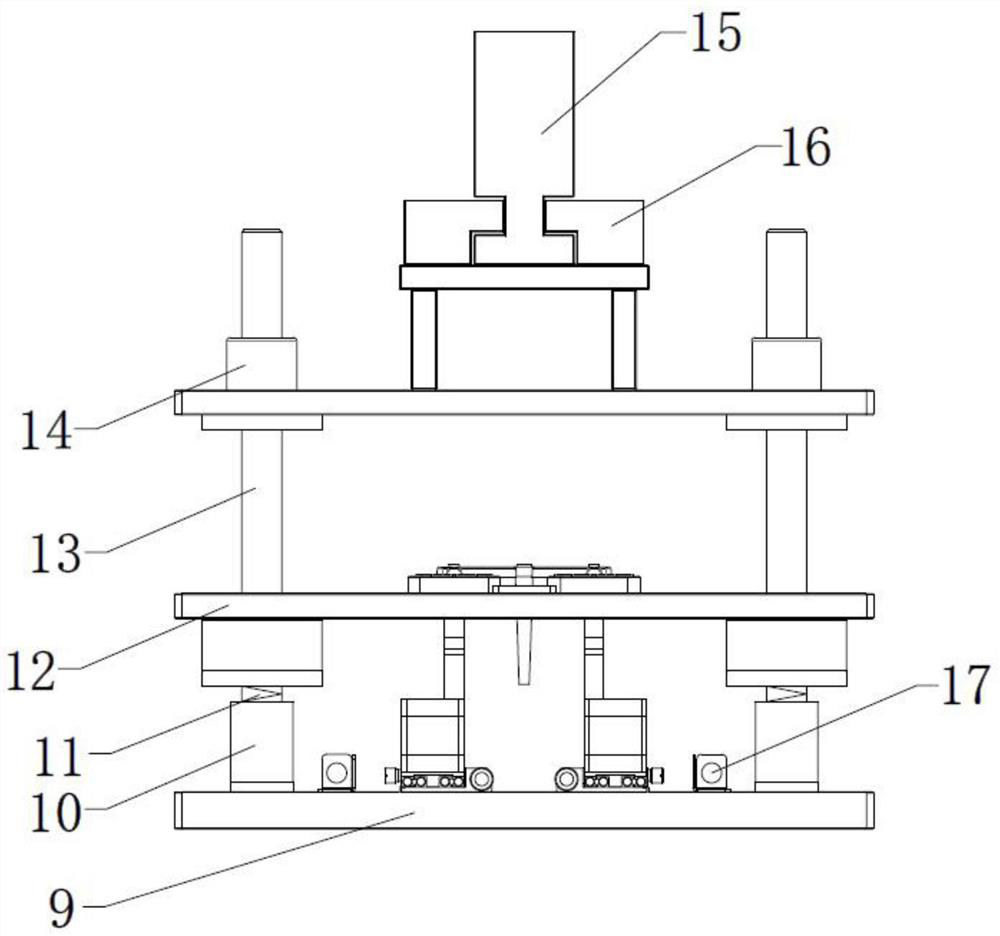

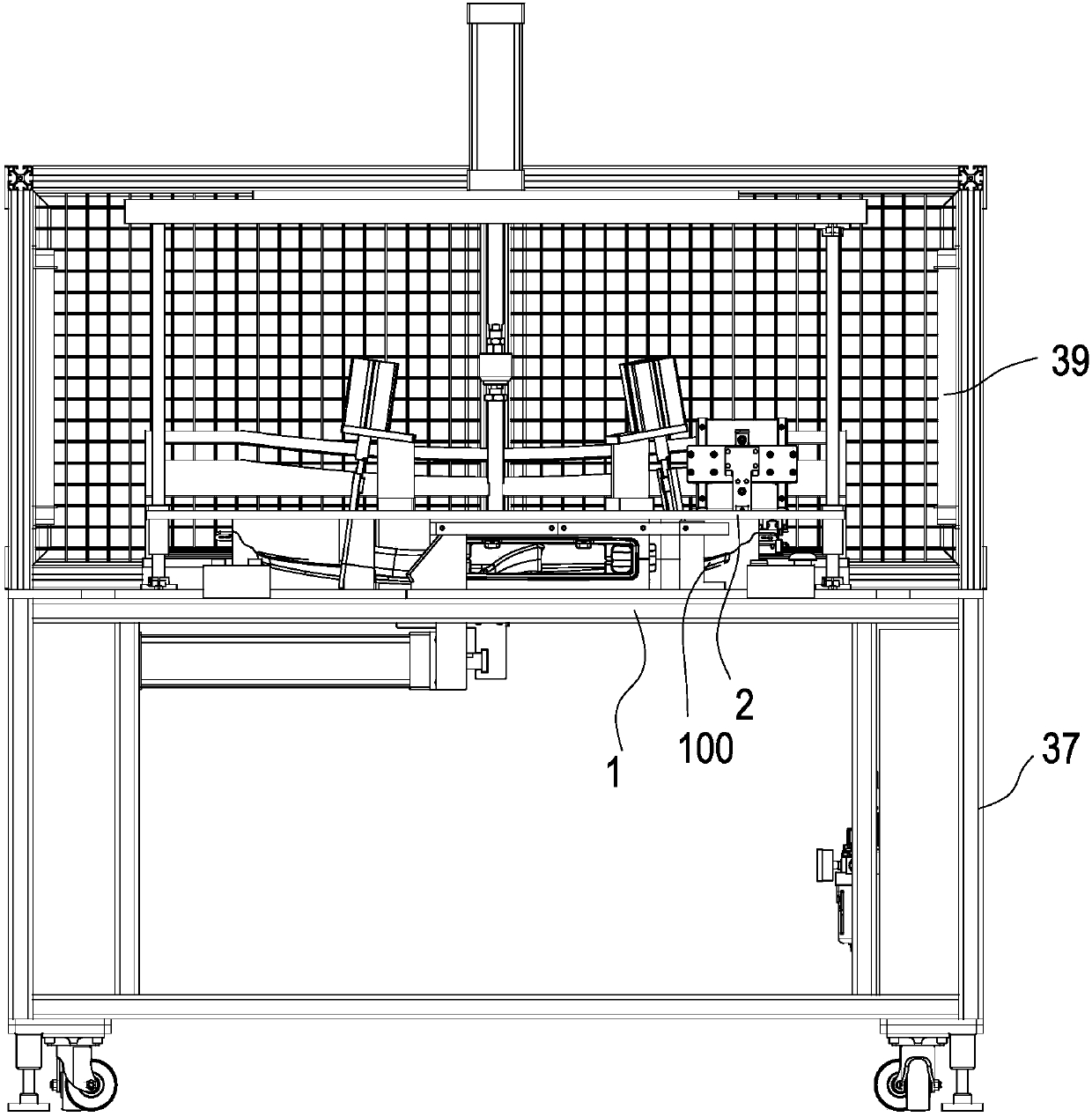

Collecting mechanism for automotive interior laser cutting and cutting method thereof

ActiveCN110977192APrevent overflowAvoid separationLaser beam welding apparatusElectric machineryLaser cutting

The invention discloses a collecting mechanism for automotive interior laser cutting. The collecting mechanism comprises a laser device, cutting jigs, a special material taking device and a waste gascollecting device connected with the cutting jigs; the collecting mechanism comprises the two cutting jigs of the left cutting jig and the right cutting jig, namely the left station and the right station, and the cutting jigs are arranged on jig bases 18 through sliding rails 17; and sliding rail motors 16 are arranged on the sliding rails 17, so that the cutting jigs slide on the rails to realizeseamless connection between the jigs and a waste material collecting hopper 1. According to the collecting mechanism for the automotive interior laser cutting, the application of laser cutting in PCand ABS plastic product cutting is achieved, the problem that a plastic product is difficult to cut by laser is solved, and after the process is adopted, a product notch is bright and clean, the slagadhering amount at the bottom is extremely small, and no smoke and dust exist on the surface of the product; a laser hot melting area is obviously reduced, and the amount of cutting smoke and dust isobviously reduced; and the developed jigs are convenient for fixing the product, and improving the precision, so that good product machining precision is obtained, and the error of the product is + / -0.03 mm.

Owner:南京上美冠丰塑胶有限公司

Hot melting type shearer

The invention relates to a pair of shearer, in particular to a pair of hot melting type shearer. With the hot melting type shearer, it can be avoided that a cut of a nylon rope does not have burrs, and the length of the nylon rope can be guaranteed. The hot melting type shearer comprises heat-insulating handles, blades and the like. The blades are fixedly connected with the ends of the two heat-insulating handles respectively, and the two blades are connected in a hinged manner. According to the hot melting type shearer, the blades can be heated through heater bands, the nylon rope can be cutin a melted manner by the blades, burrs at the cut of the nylon rope are melted by the high temperature, and then the cut of the nylon rope can be smoother; a conveying mechanism can convey the nylonrope for four seconds, and because the distance of the nylon rope conveyed each time is accurately controlled according to time, and then it can be guaranteed that all the segments of the nylon rope are the same in length; and scraps on the blades can be removed by a cleaning mechanism, and it is avoided that the scraps stick to the nylon rope.

Owner:南京梵鼎信息技术有限公司

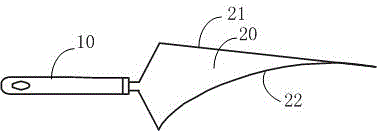

Pastry knife

InactiveCN104416589AMeet a variety of cutting needsSmooth cutMetal working apparatusMetal-working hand toolsEngineering

An embodiment of the invention discloses a pastry knife which comprises a knife body and a handle. The handle is connected with the knife body, the tail ends of two knife edges of the knife body intersect with each other, and one of the knife edges is concavely arranged. The pastry knife has the advantages that the pastry knife is simply structurally improved, so that various cutting requirements can be met, and nicks are neat and smooth.

Owner:彭楚铭

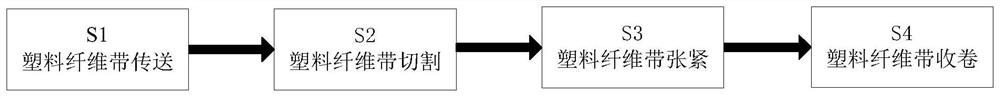

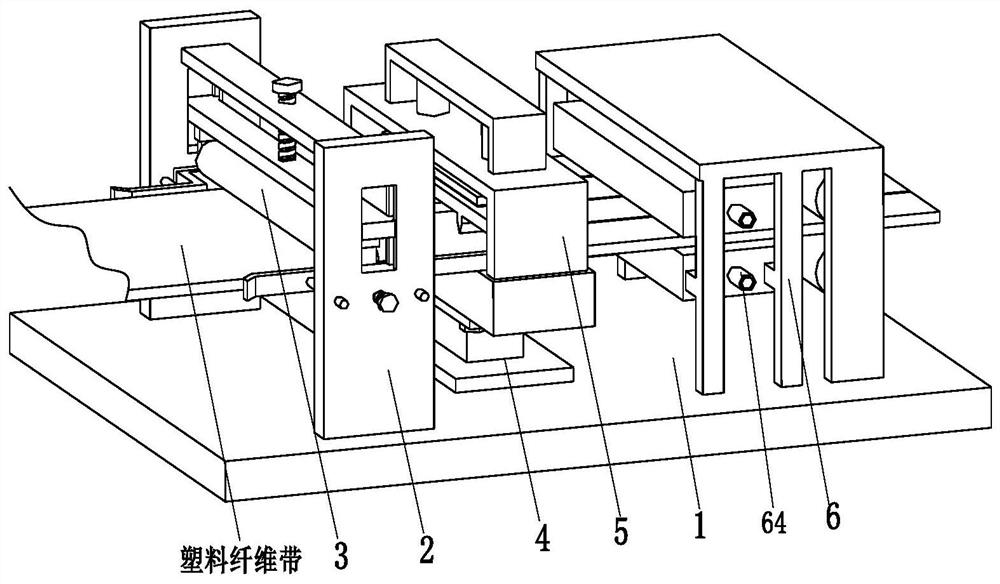

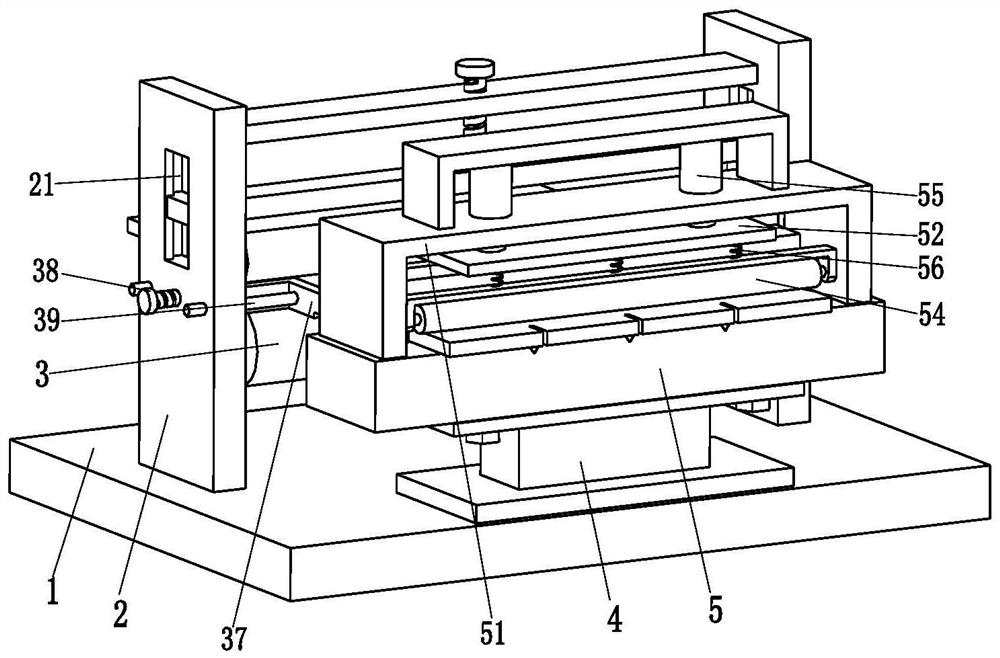

A kind of preparation method of plastic fiber braided yarn

ActiveCN112323155BImprove cutting effectImprove the winding effectFilament/thread formingYarnPlastic fiber

The invention relates to a preparation method of plastic fiber braided yarn. The plastic fiber braided yarn preparation method adopts the following plastic fiber braided yarn preparation device. The plastic fiber braided yarn preparation device includes a bottom plate, a clamping support plate, a clamping mechanism, a cutting base, a cutting A frame and a conduction mechanism; a method for preparing a plastic fiber braided wire using the above-mentioned plastic fiber braided wire preparation device, comprising the following steps: S1, plastic fiber belt transmission; S2, plastic fiber belt cutting; S3, plastic fiber belt tensioning; S4, plastic fiber belt Fiber tape is reeled. The invention can solve the existing problems when cutting plastic fiber filaments: the phenomenon that the plastic fiber tape will be cut off when it is cold-cut, the plastic fiber tape has no support when it is cut, so that the plastic fiber tape is cut unevenly; When thermal cutting is used, the excessive tension of the plastic fiber belt will cause the plastic fiber belt to stretch, and the cooling temperature of the plastic fiber belt cannot be adjusted.

Owner:贵州安顺开发区光大塑业有限公司

A pipe cutting device for self-positioning pipes

InactiveCN109590758BHigh precisionReduce vibrationOther manufacturing equipments/toolsMachinePiston rod

The invention discloses a pipe cutting device for a self-positioning pipeline. The device comprises a rack, and further comprises multiple straightening devices, a cutting machine and a positioning device which are sequentially arranged on the top of the rack in the machining direction; the cutting machine comprises a cutting table, two clamping tables and a cutting disc; the cutting table is fixed to the rack, the two clamping tables are symmetrically mounted on the two ends of the cutting table, the cutting disc is arranged on the cutting table through a supporting frame, the positioning device comprises a support, a screw, a servo motor, a baffle and automatic clamping claws, the support is fixed to the rack, multiple air cylinders which are arranged in a hanging manner are arranged onthe support, the automatic clamping claws are arranged on piston rods of the air cylinders, and a material accumulating groove is formed in the position, below the support, of the rack. The cutting machine and the positioning device are arranged, the long pipeline can be precisely positioned and cut, machining efficiency is improved, the process of cutting the pipeline again on the later is removed, and raw material waste is reduced.

Owner:自贡东光汽车配件有限公司

A hot melt shear

The invention relates to a shear, in particular to a hot-melt shear. The technical problem to be solved is how to provide a hot-melt cutter that can avoid leaving burrs at the incision of the nylon rope and can ensure the length of the nylon rope. The utility model relates to a hot-melt shear, which includes heat-insulating handles, blades, etc.; the ends of the two heat-insulating handles are fixedly connected with blades, and the two blades are hingedly connected. The invention can heat the blade through the heating plate, the blade can fuse the nylon rope, and the high temperature can melt the burr at the incision of the nylon rope, making the incision of the nylon rope more smooth, and the transmission mechanism can transmit the nylon rope for 4 seconds, and the passing time Accurately control the distance of the nylon ropes each time, so as to ensure that the length of each nylon rope is equal; the debris on the blade can be cleaned by the cleaning mechanism to prevent the debris from sticking to the nylon rope.

Owner:南京梵鼎信息技术有限公司

Nonmetal thin material shearing machine

InactiveCN106584541AIncrease cutting speedSmooth incisionMetal working apparatusElectric machineryWall plate

The invention discloses a nonmetal thin material shearing machine, and belongs to the field of soft thin material machining equipment. The nonmetal thin material shearing machine comprises a frame, a worktable provided with a lower blade, an upper cutter frame provided with an upper blade, and cutter frame driving mechanisms; the cutter frame driving mechanisms include driving wheels, connecting rods and motors; one ends of the connecting rods are eccentrically connected with the driving wheels, and the other ends are connected with the upper cutter frame through connecting shafts; the driving wheels are driven through the motors, and drive the connecting rods to drive the upper cutter frame to move up and down, so that the upper blade generates a shearing motion corresponding to the lower blade; two cutter frame driving mechanisms are provided, and are respectively arranged on the outer sides of two wall plates of the frame; two driving wheels are arranged on the wall plates through bearings, and are connected as a whole through driving shafts; and the motors are connected with the driving shafts through gear boxes. The nonmetal thin material shearing machine can finish shearing of such nonmetal thin materials as films, rubber and soft glass, is not easy to clamp cutters, is smooth in incision, high in quality of finished products and adjustable in edge gaps, can adapt to the cutting requirements of materials with different thicknesses, and is high in adaptability.

Owner:安徽汉邦重工机床制造有限公司

A kind of oxyhydrogen flame numerical control punching and cutting process

ActiveCN103203514BNo pollution in the processSafe to use at any timeGas flame welding apparatusNumerical controlPunching

The invention belongs to the technical field of metal flame cutting processing and provides an oxyhydrogen flame numerical control punching and cutting process. The oxyhydrogen flame numerical control punching and cutting process is characterized in that oxyhydrogen is adopted as cutting gas of a numerical control flame machine tool, the oxyhydrogen is delivered to a cutting torch (6) of the numerical control flame machine tool through a busbar (5), the pressure of the cutting gas is controlled to be in a range from 0.1MPa to 1.6MPa in a numerical control manner, and is gradually increased from low to high. The oxyhydrogen flame numerical control punching and cutting process adopts the oxyhydrogen and a gradually pressurizing mode to perform metal cutting, and solves the problem of serious pollution and potential safety hazards of the traditional process.

Owner:SHAANXI HUAQIN NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com