Construction method of pile body underwater cutting

A technology of underwater cutting and construction method, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve problems such as hidden danger, water leakage in dock, difficult to control the direction of dumping, etc., to achieve high safety and fast construction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

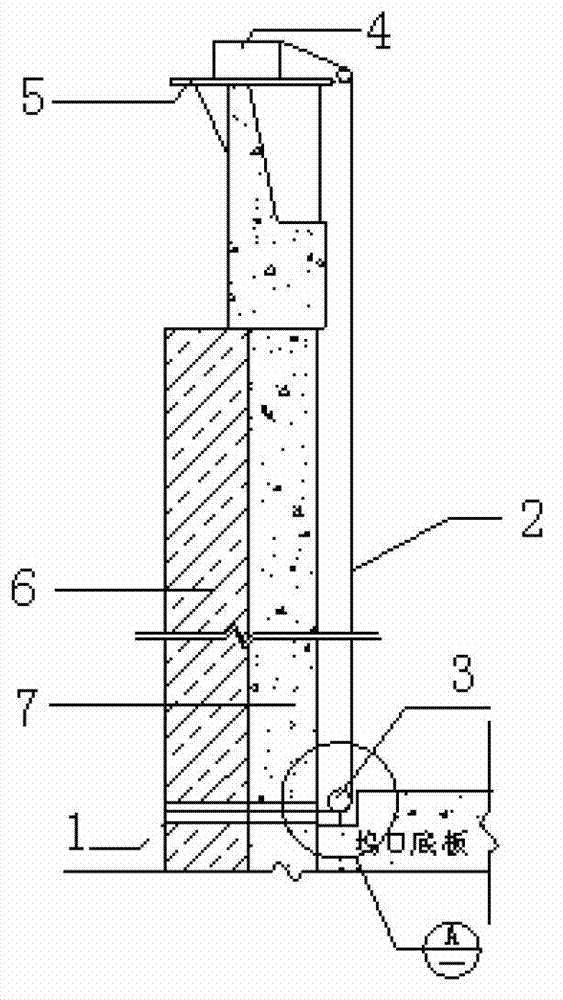

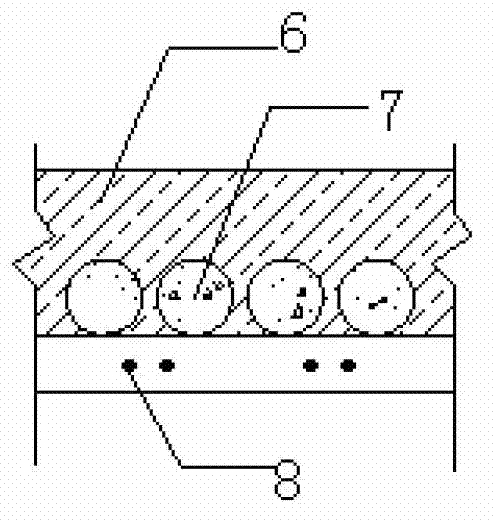

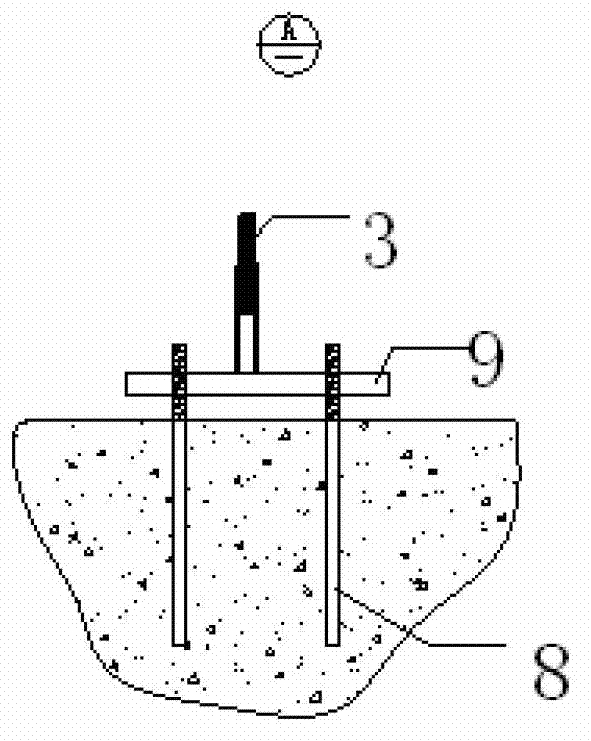

[0045] refer to figure 1 and Figure 4 As shown, the technological process is as follows:

[0046] Underwater cleaning→planting bolts on the bottom plate of the dock→perforating the retaining wall of the pile body→underwater cutting→cleaning outside the dock door

[0047] 1) Underwater cleaning

[0048] The +5.0m construction platform outside the enclosure system of the dock entrance and the soil below are excavated by dredgers. The underwater slope protection cleaning and underwater dredging are divided into two times. First, the surface rock slope protection is cleaned, and the mud surface is lowered to -4m, which meets the draft requirements of the large-scale watercraft used for demolition, and starts the second underwater dredging when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com