Cutting device for automobile air conditioner aluminum pipe

A technology of cutting device and automobile air conditioner, which is applied in the direction of pipe shearing device, shearing device, accessory device of shearing machine, etc., can solve the problems of increasing the difficulty and time of processing, insufficient clamping of aluminum tubes, and low safety factor. , to achieve the effect of improving cutting efficiency, facilitating processing and improving tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

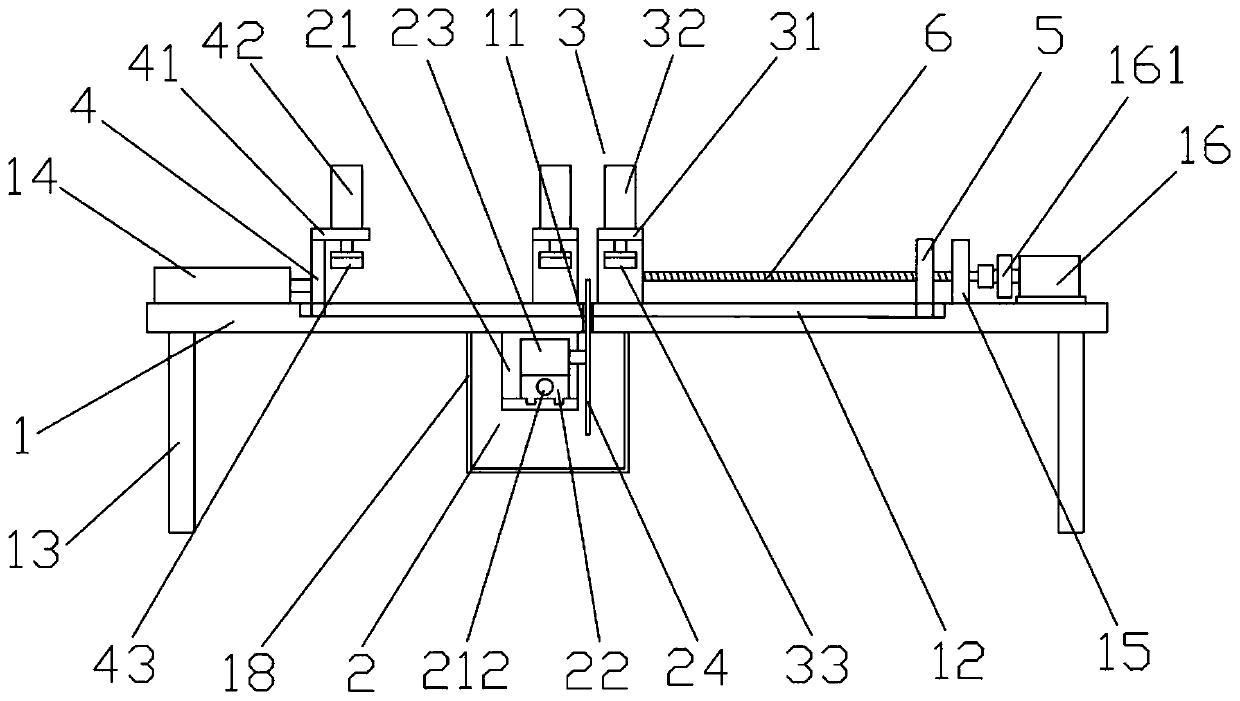

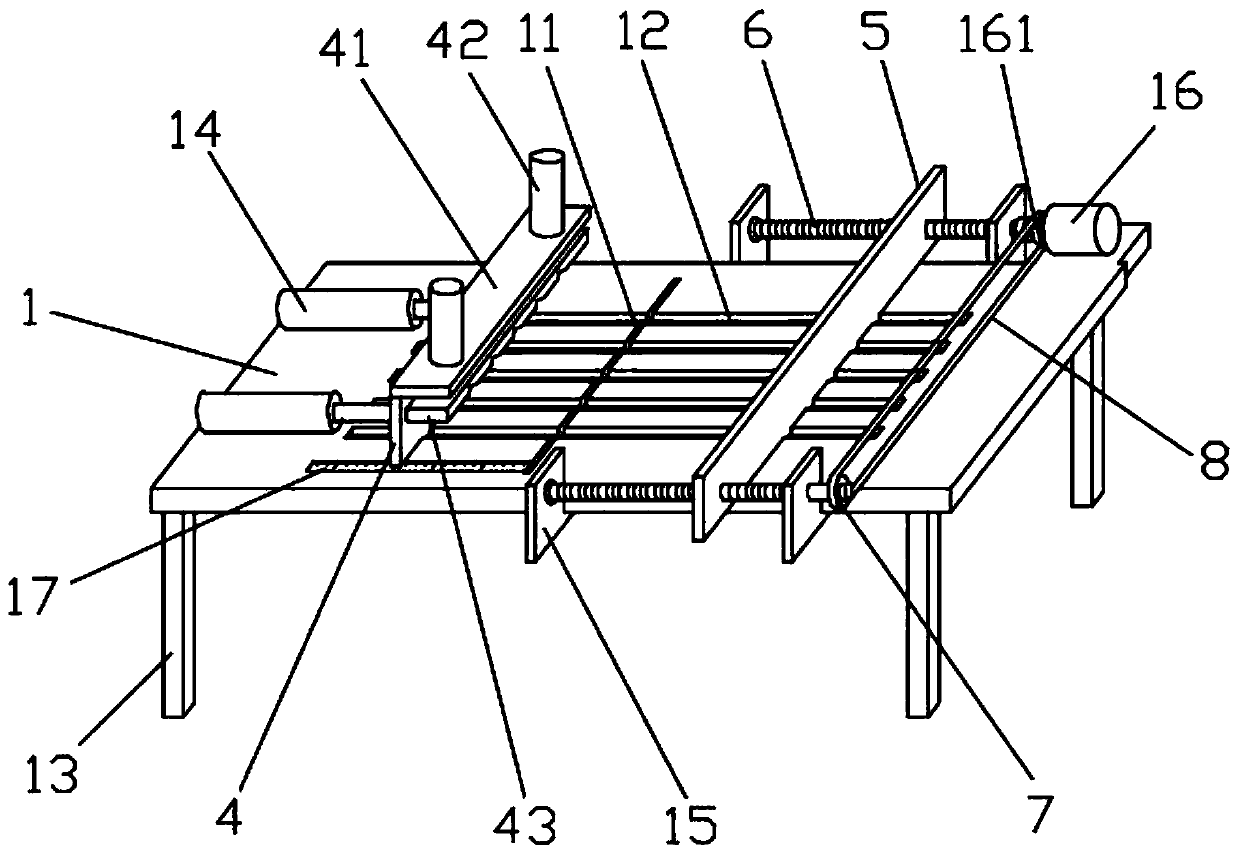

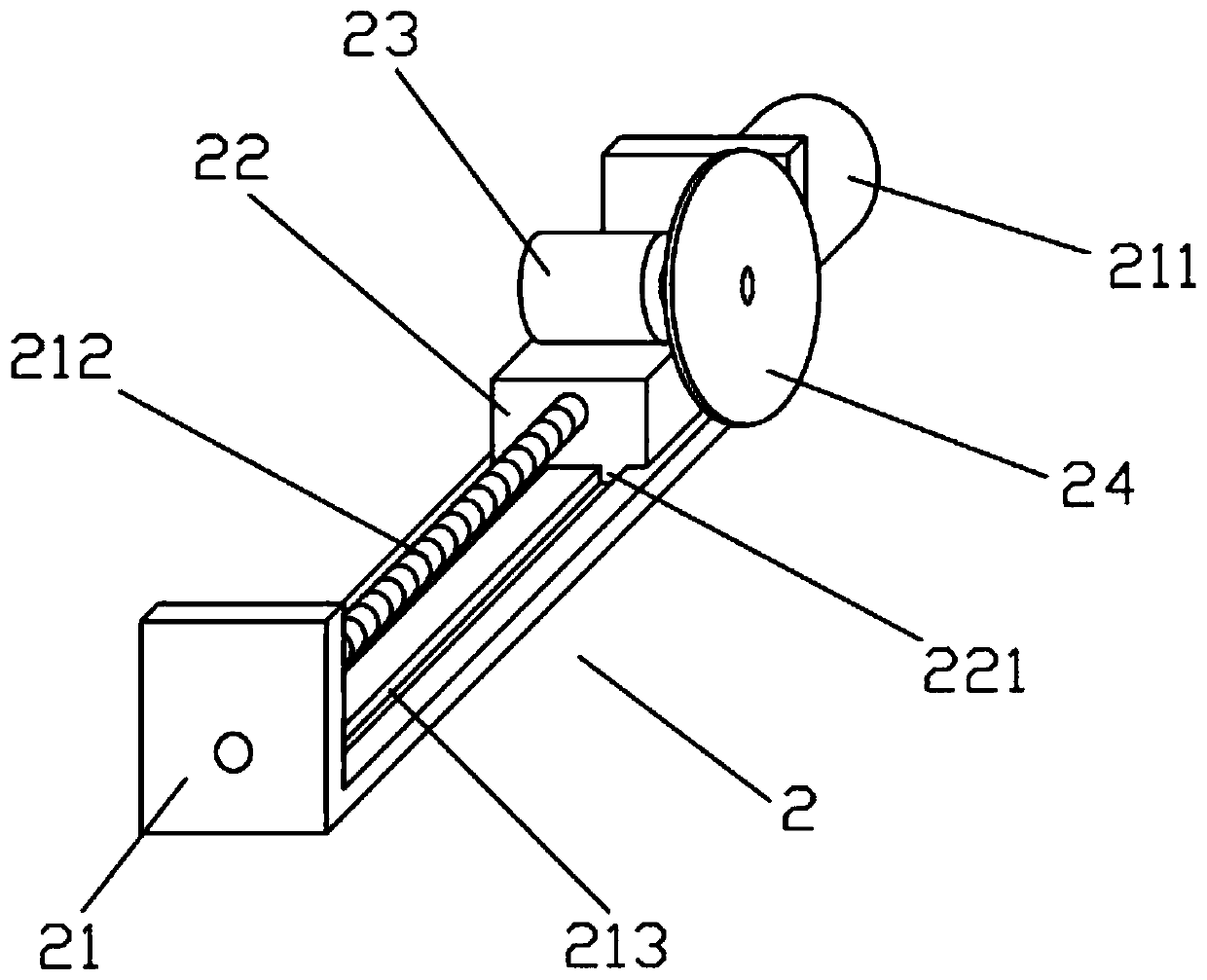

[0028] Embodiment 1 discloses a cutting device for automotive air-conditioning aluminum pipes, such as figure 1 and figure 2 As shown, it includes a cutting table 1, a cutting mechanism 2, a pressing mechanism 3, a limit plate 4 and a feeding push plate 5. The cutting mechanism 2 is installed at the bottom of the cutting table 1, and the middle part of the cutting table 1 is longitudinally provided with a cutting groove 11. , the pressing mechanism 3 is located on the left and right sides of the cutting groove 11 top, the limiting plate 4 and the feeding push plate 5 are respectively located at the left and right ends of the top of the cutting table 1; The four corners at the bottom of platform 1 are all fixedly equipped with columns 13; figure 1 and image 3 As shown, the cutting mechanism 2 includes a first U-shaped frame 21, a sliding seat 22, a first motor 23 and a cutting disc 24. The model of the first motor 23 is 6GU-12.5K, and the first U-shaped frame 21 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com