Machining process for ceramic ring cutter used for slitting of lithium battery materials

A processing technology, ceramic knife technology, applied in the field of lithium battery slitting ceramic ring knife processing technology, can solve the problems of increased production cost, broken blade, not sharp, etc., to improve the processing accuracy, neat and clean incision, good consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

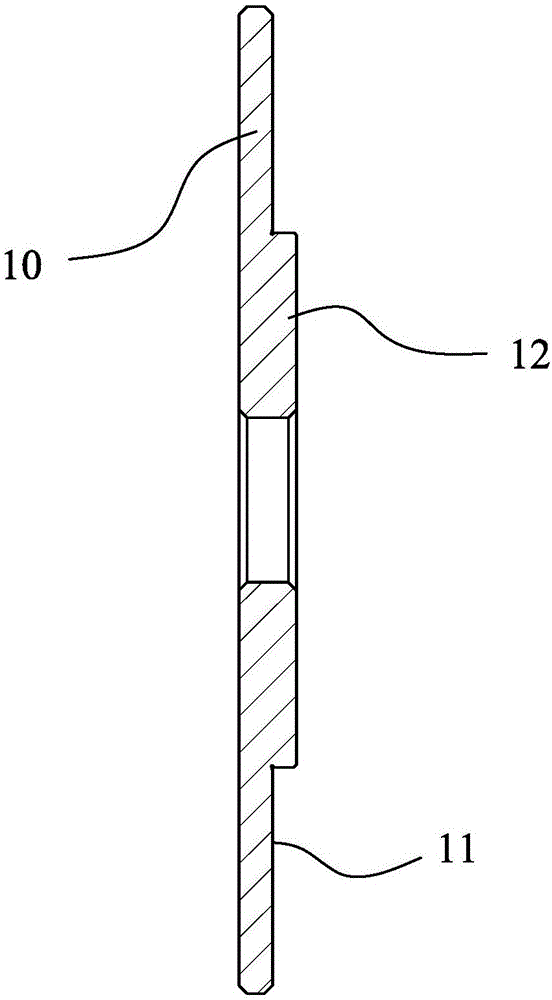

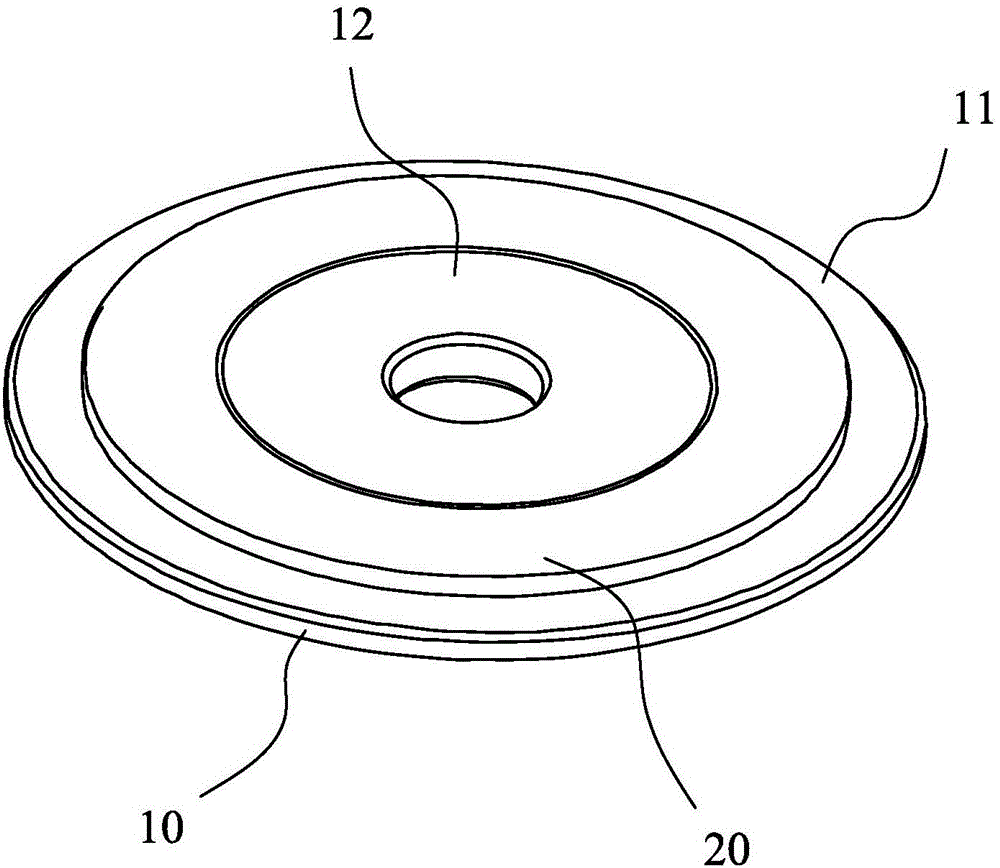

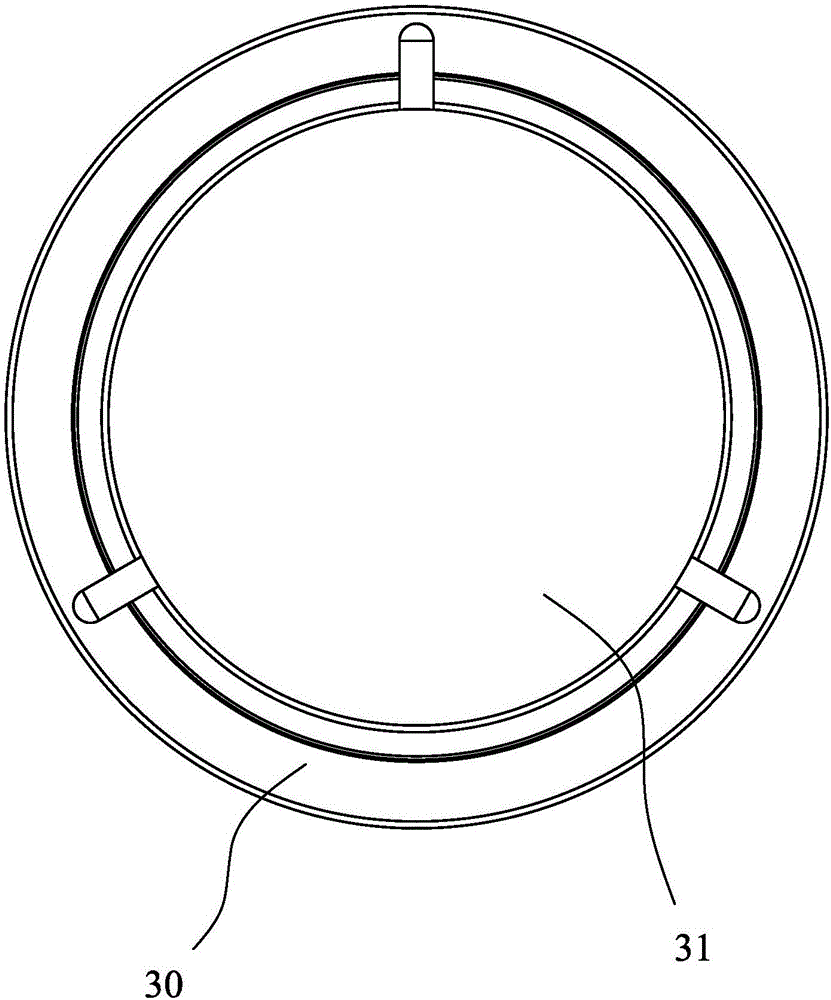

[0035] A processing technology of a lithium battery slitting ceramic ring cutter, comprising the following steps:

[0036] 1) Molding the ceramic material into an annular green body with a middle hole;

[0037] 2) Carry out continuous electrothermal sintering to the green body, and obtain a ceramic knife blank after cooling down; the continuous electrothermal sintering process includes the first stage of temperature-raising pre-sintering, the second stage of high-temperature sintering and the third stage of temperature-lowering sintering. The pre-sintering temperature rise rate is controlled at 0.3-0.5°C / Min, and when the temperature is increased to 900-980°C, the temperature is kept for 1.8-2.4 hours; the high-temperature sintering is carried out under the premise of temperature rise pre-sintering, and the temperature rise rate is controlled at 1.5-2.5°C / Min, when the temperature is increased to 1570-1650°C, heat preservation for 3.8-5.6 hours; the cooling sintering is carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com