Laser cutting machine

A laser cutting machine, laser cutting head technology, applied in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of low precision and yield, and the size of the tool diameter cannot be realized, and achieve high cutting quality, High flexibility, smooth incision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

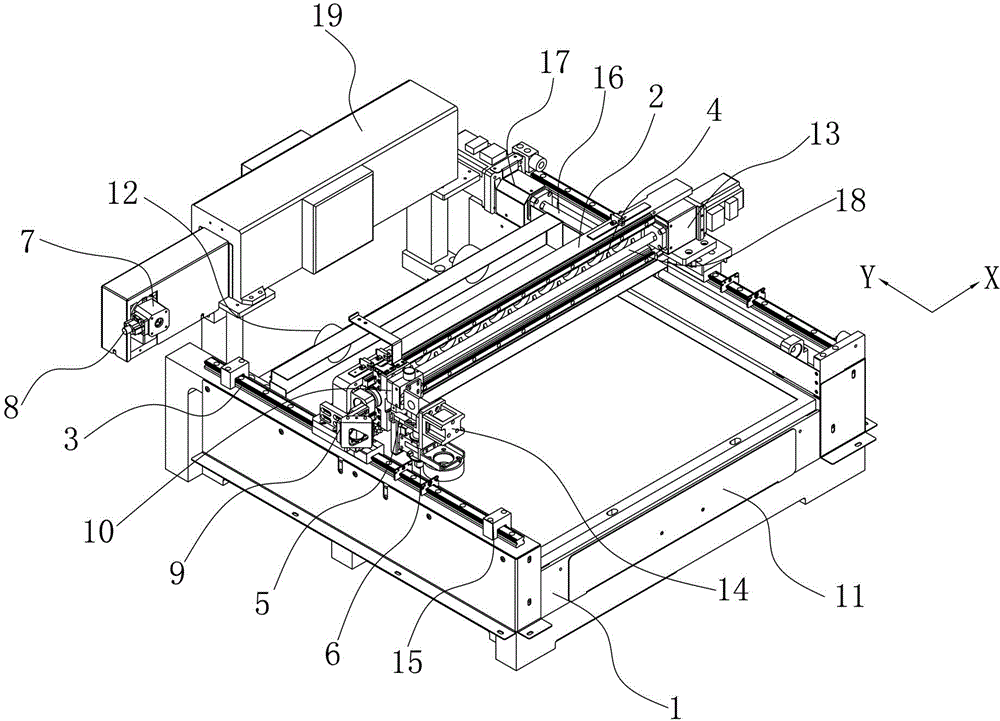

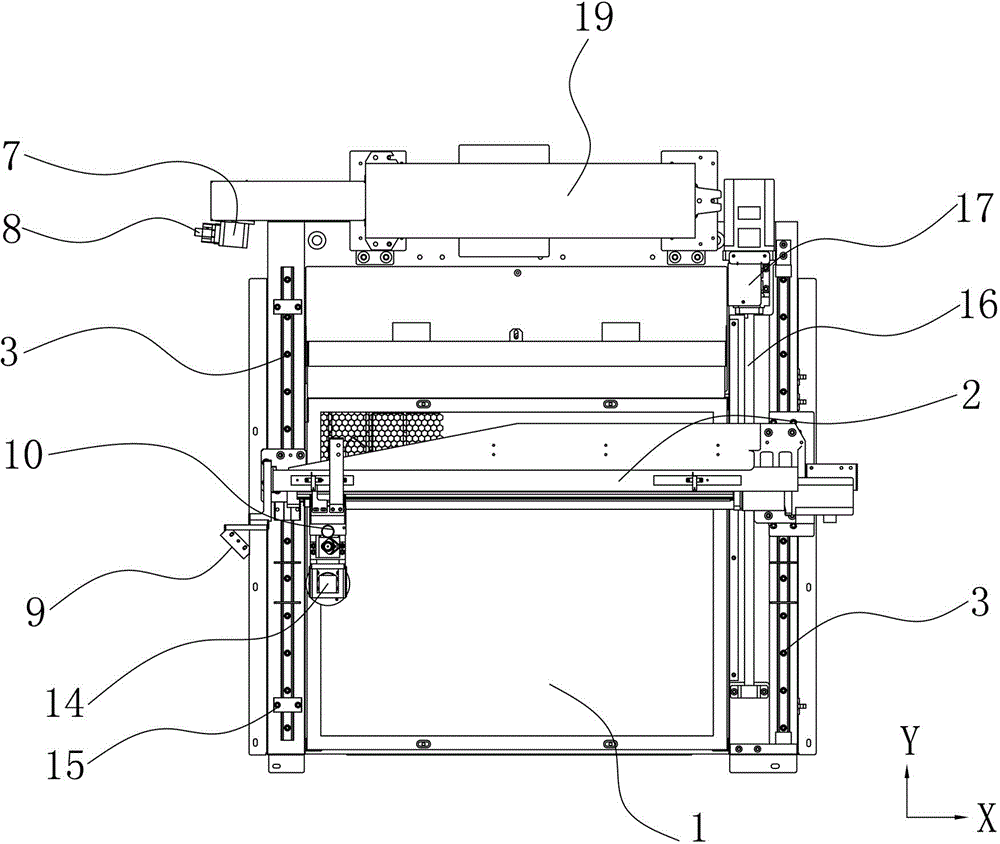

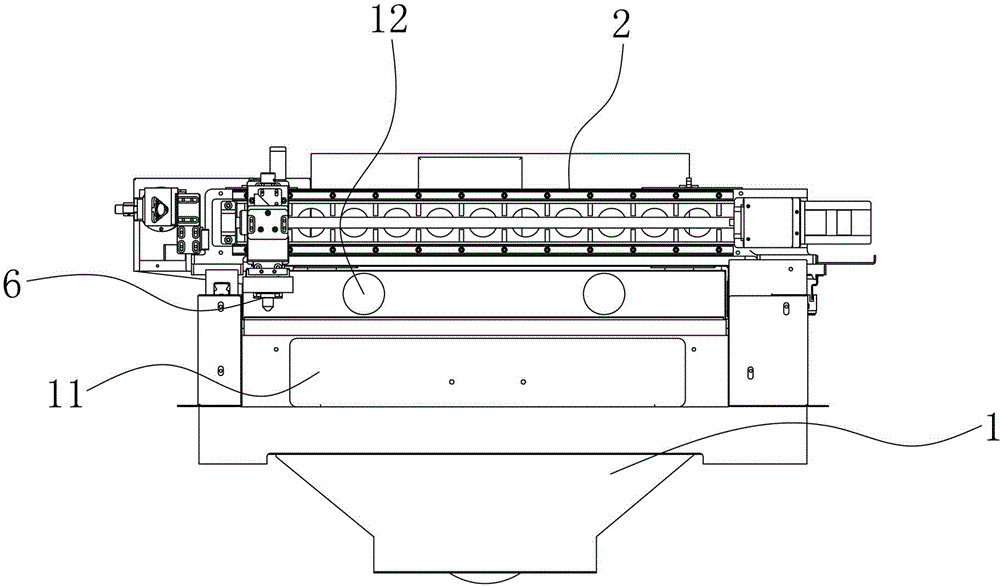

[0018] like figure 1 , figure 2 , image 3 As shown, the embodiment of the present invention provides a laser cutting machine, including a base 1 and an X-axis beam 2. The base 1 is provided with two Y-axis linear guide rails 3 arranged along the Y-axis direction of the base 1, and the X-axis beam 2 The two ends of the two Y-axis linear guide rails 3 are respectively slidably connected, and the base 1 is provided with a first driving device for driving the X-axis beam 2 to move along the length direction of the Y-axis linear guide rail 3; the X-axis beam 2 moves along the length direction of the Y-axis An X-axis linear guide rail 4 is provided, and a tool seat 5 is slidably connected to the X-axis linear guide rail 4. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com