Rotary cutting die for pipe fittings

A technology for molds and pipe fittings, applied in the field of pipe rotary cutting molds, can solve problems such as low work efficiency, unstable positioning, and inability to meet production efficiency, and achieve the effects of improving efficiency, avoiding uneven incisions, and stable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

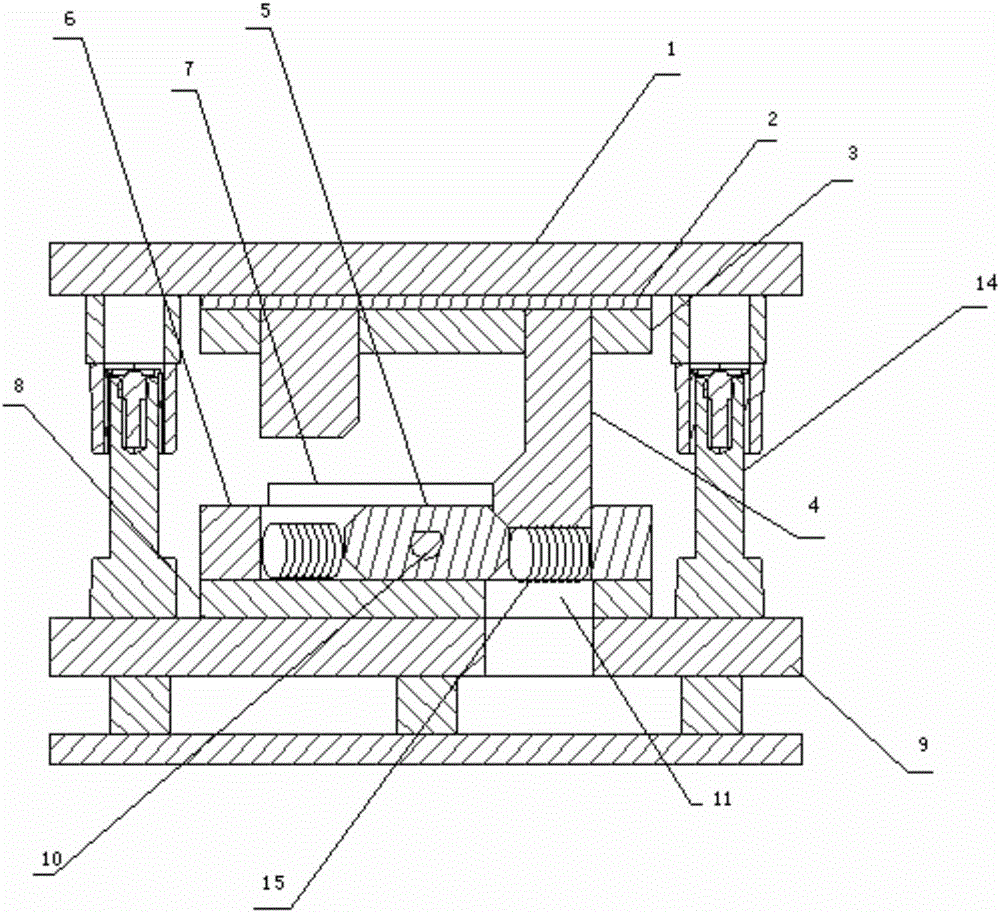

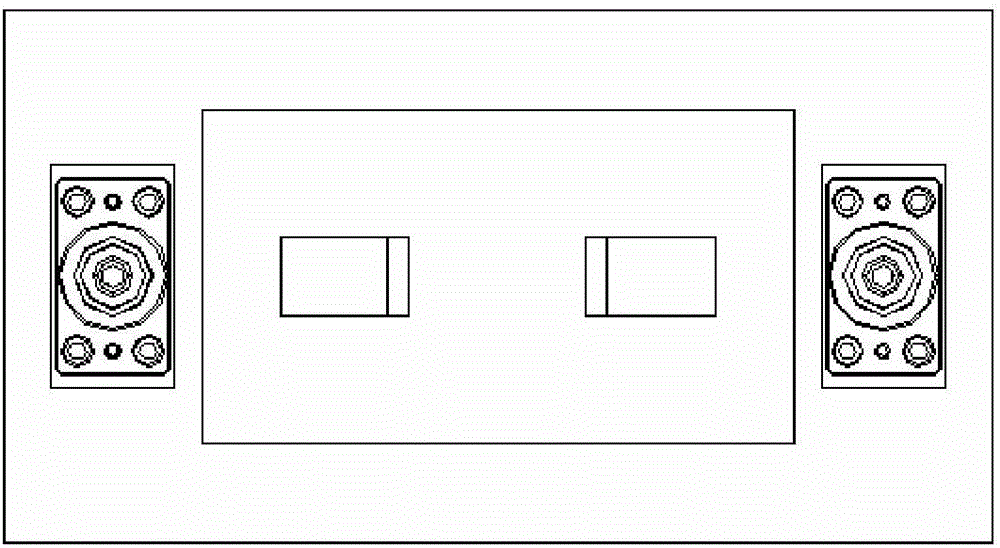

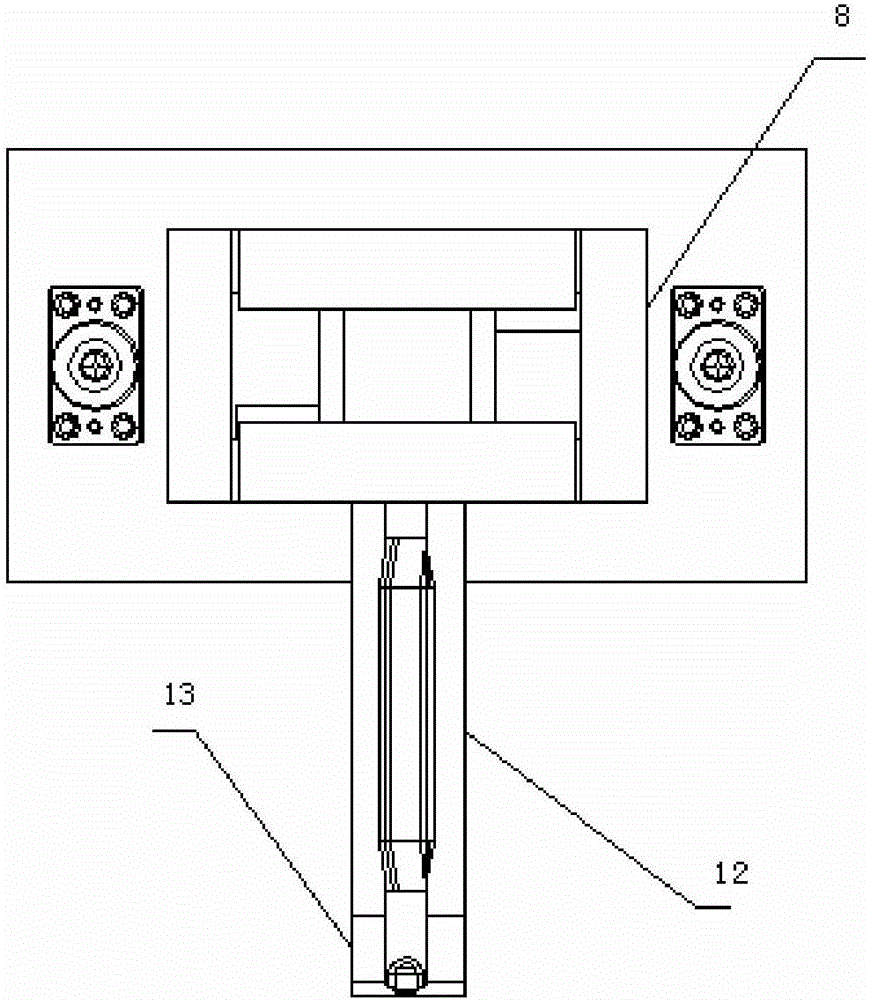

[0023] This embodiment provides a pipe fitting rotary cutting die, the structure is as follows Figure 1-3 As shown, it includes upper mold base 1, backing plate 2, upper clamping plate 3, bevel drive block 4, lower slider 5, return spring 15, side stopper 6, product positioning block, lower clamping plate 8 and lower mold base 9 , the backing plate 2 is affixed to the bottom of the upper mold base 1, the upper splint 3 is affixed to the bottom of the backing plate 2, and the bevel drive block 4 is fixed to the two ends of the bottom of the upper splint 3, and the height is different, the bevel drive block 4 Respectively against the side stopper 6 and the lower slider 5, the two ends of the return spring 15 are respectively against the side stopper 6 and the lower slider 5, and the middle part of the lower slider 5 is provided with a knife-edge groove 10, which is a sliding structure , and the knife-edge groove 10 is provided with a knife-edge mandrel, the side stopper 6 and t...

Embodiment 2

[0028] This embodiment provides a pipe fitting rotary cutting die, the structure is as follows Figure 1-3 As shown, it includes upper mold base 1, backing plate 2, upper clamping plate 3, bevel drive block 4, lower slider 5, return spring 15, side stopper 6, product positioning block, lower clamping plate 8 and lower mold base 9 , the backing plate 2 is affixed to the bottom of the upper mold base 1, the upper splint 3 is affixed to the bottom of the backing plate 2, and the bevel drive block 4 is fixed to the two ends of the bottom of the upper splint 3, and the height is different, the bevel drive block 4 Respectively against the side stopper 6 and the lower slider 5, the two ends of the return spring 15 are respectively against the side stopper 6 and the lower slider 5, and the middle part of the lower slider 5 is provided with a knife-edge groove 10, which is a sliding structure , and the knife-edge groove 10 is provided with a knife-edge mandrel, the side stopper 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com