Patents

Literature

79results about How to "Equal length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

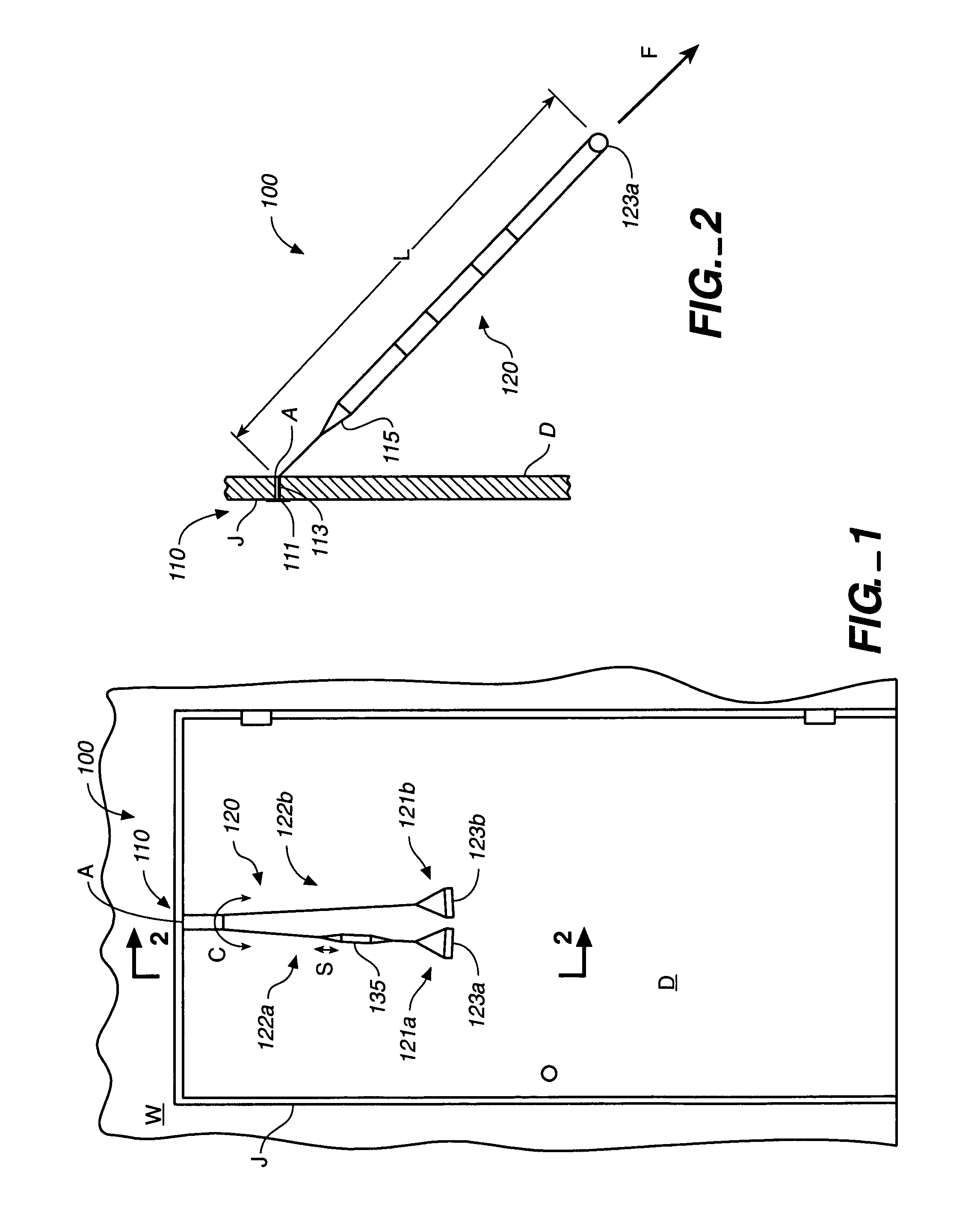

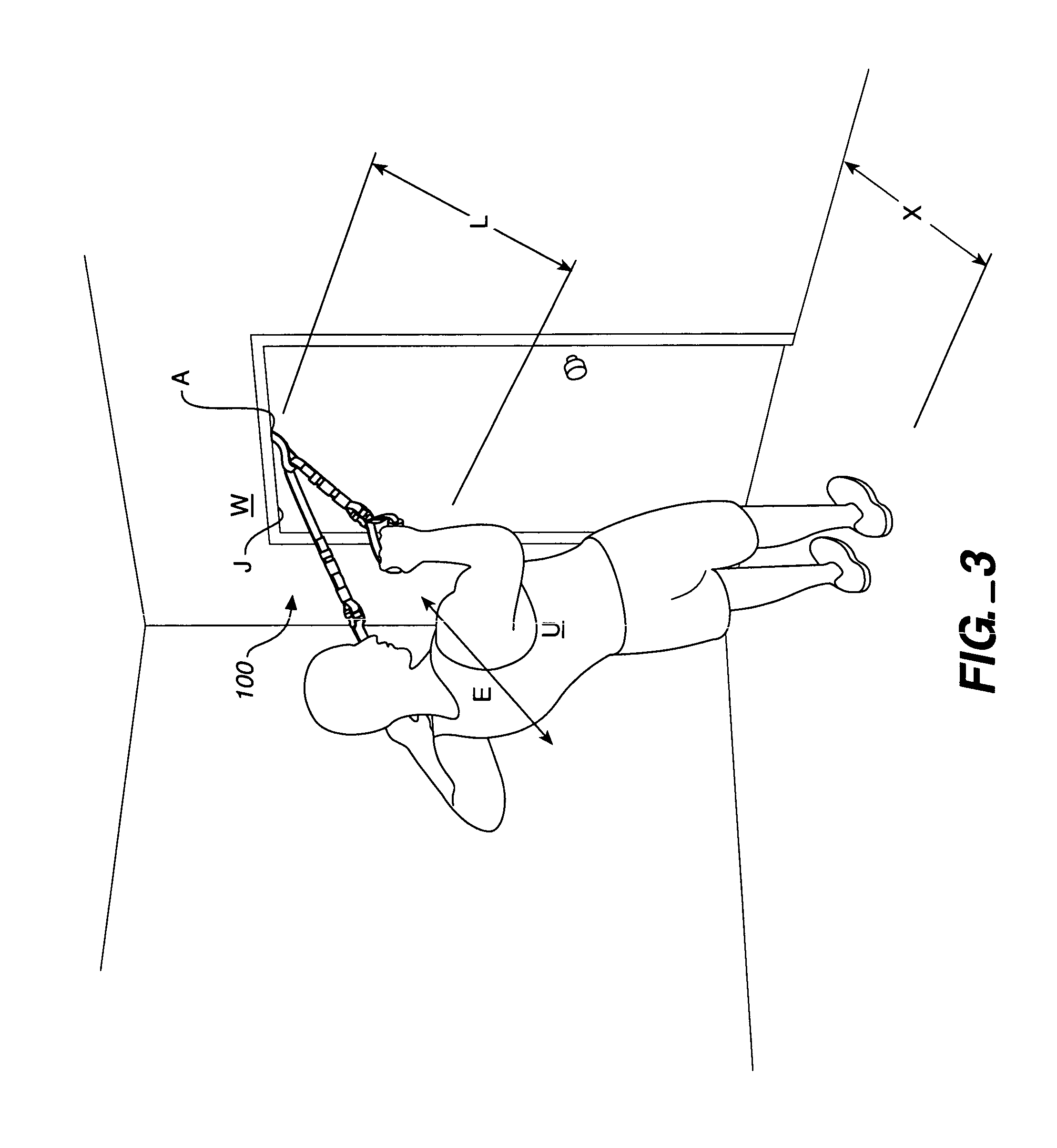

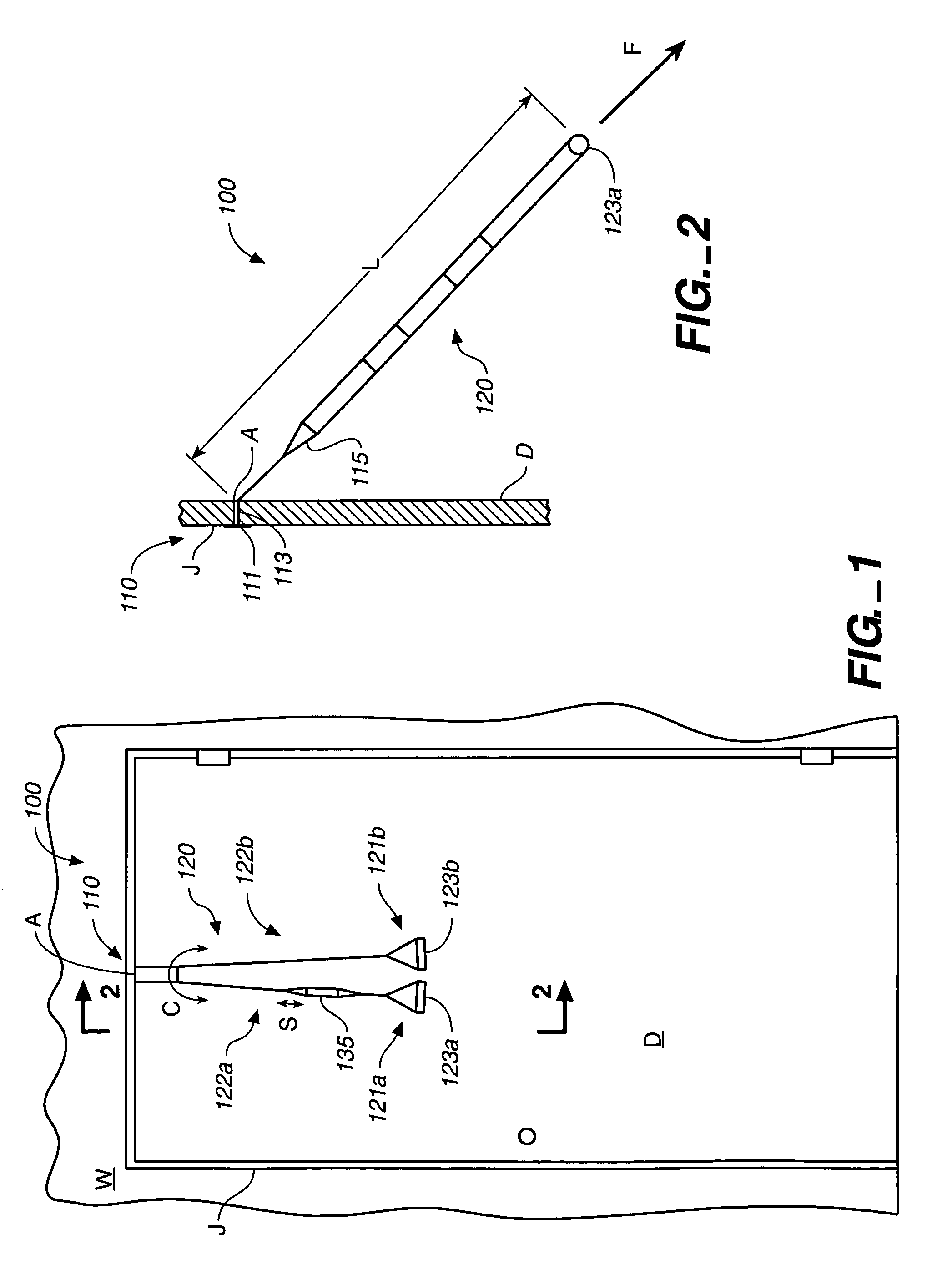

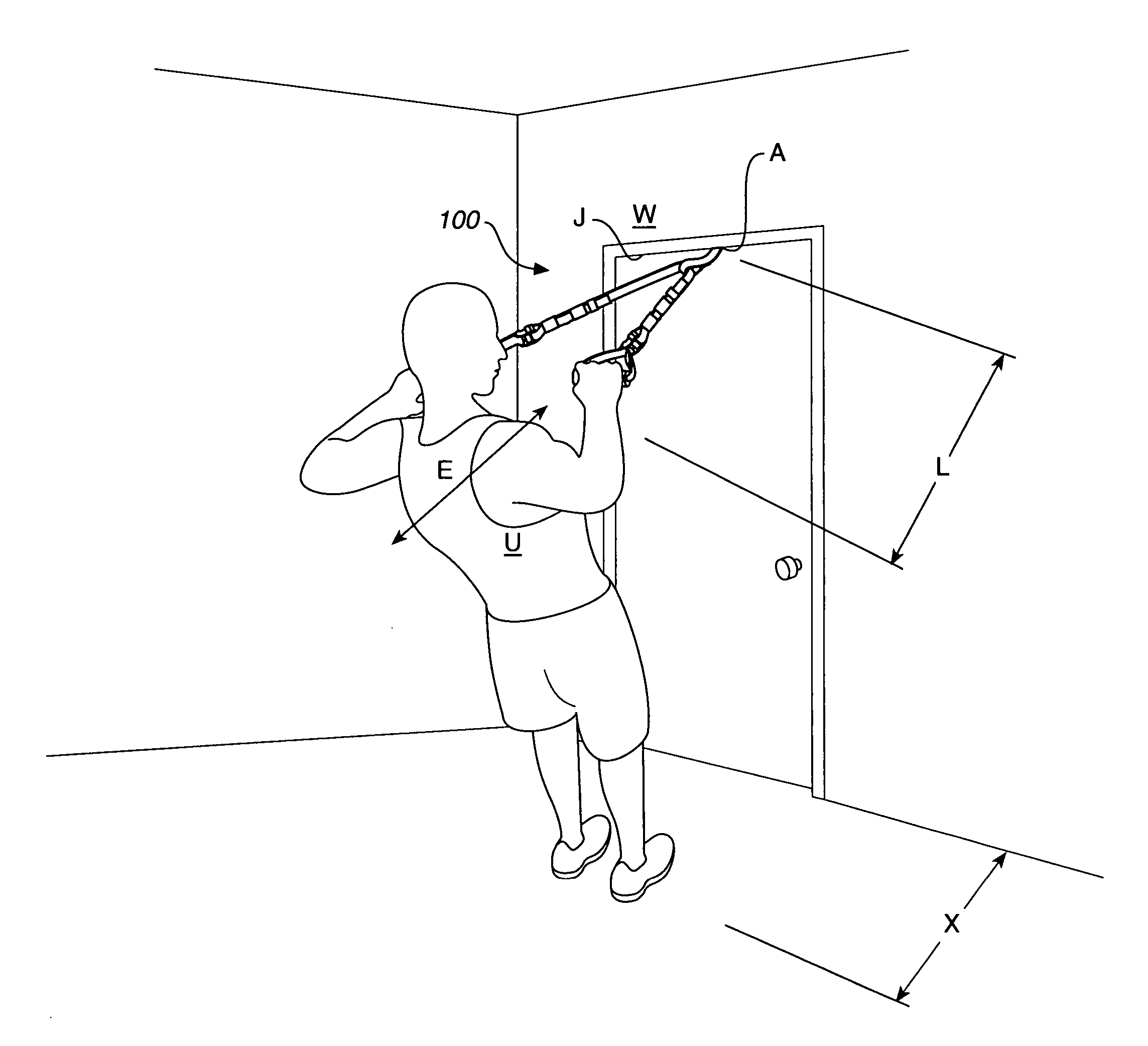

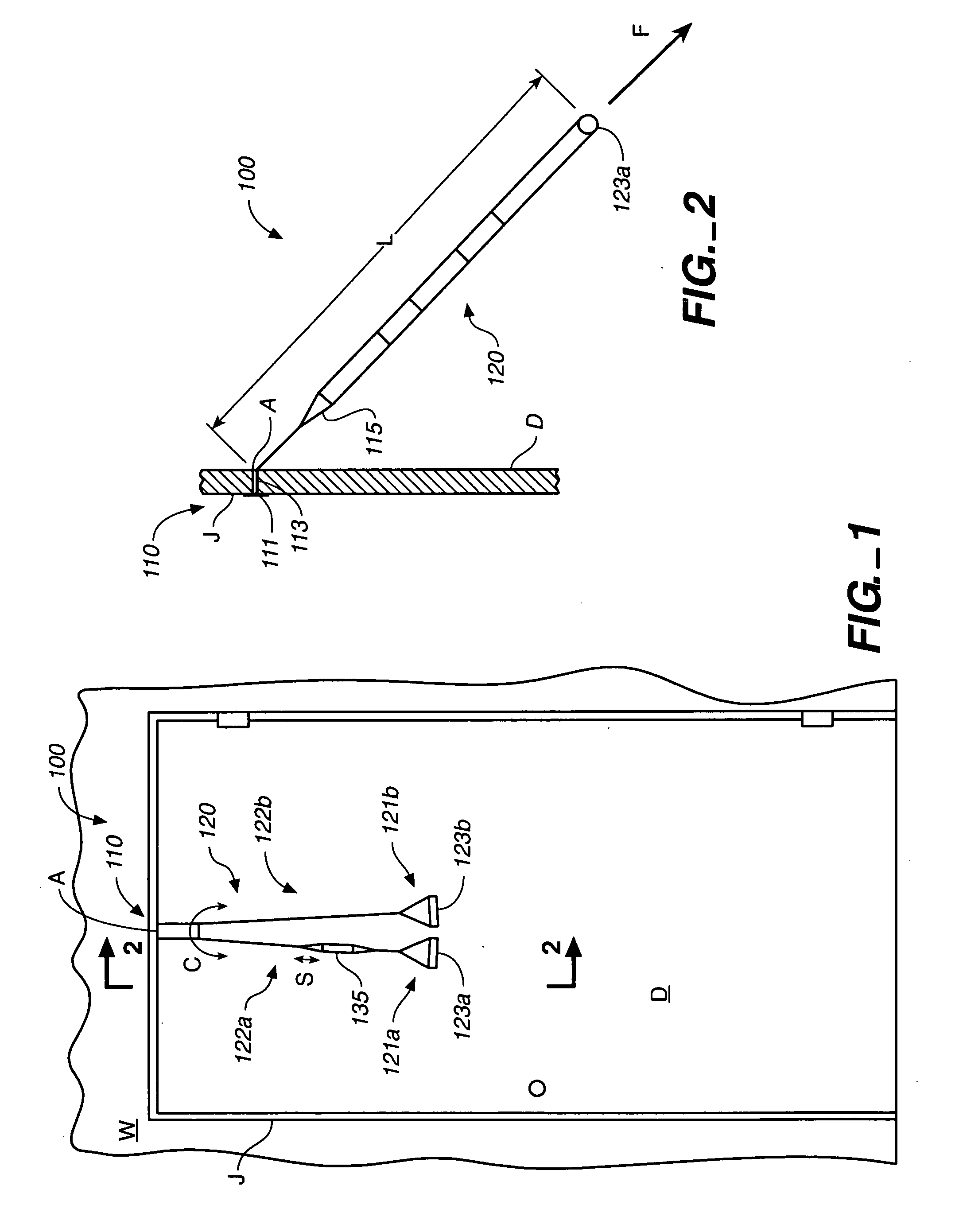

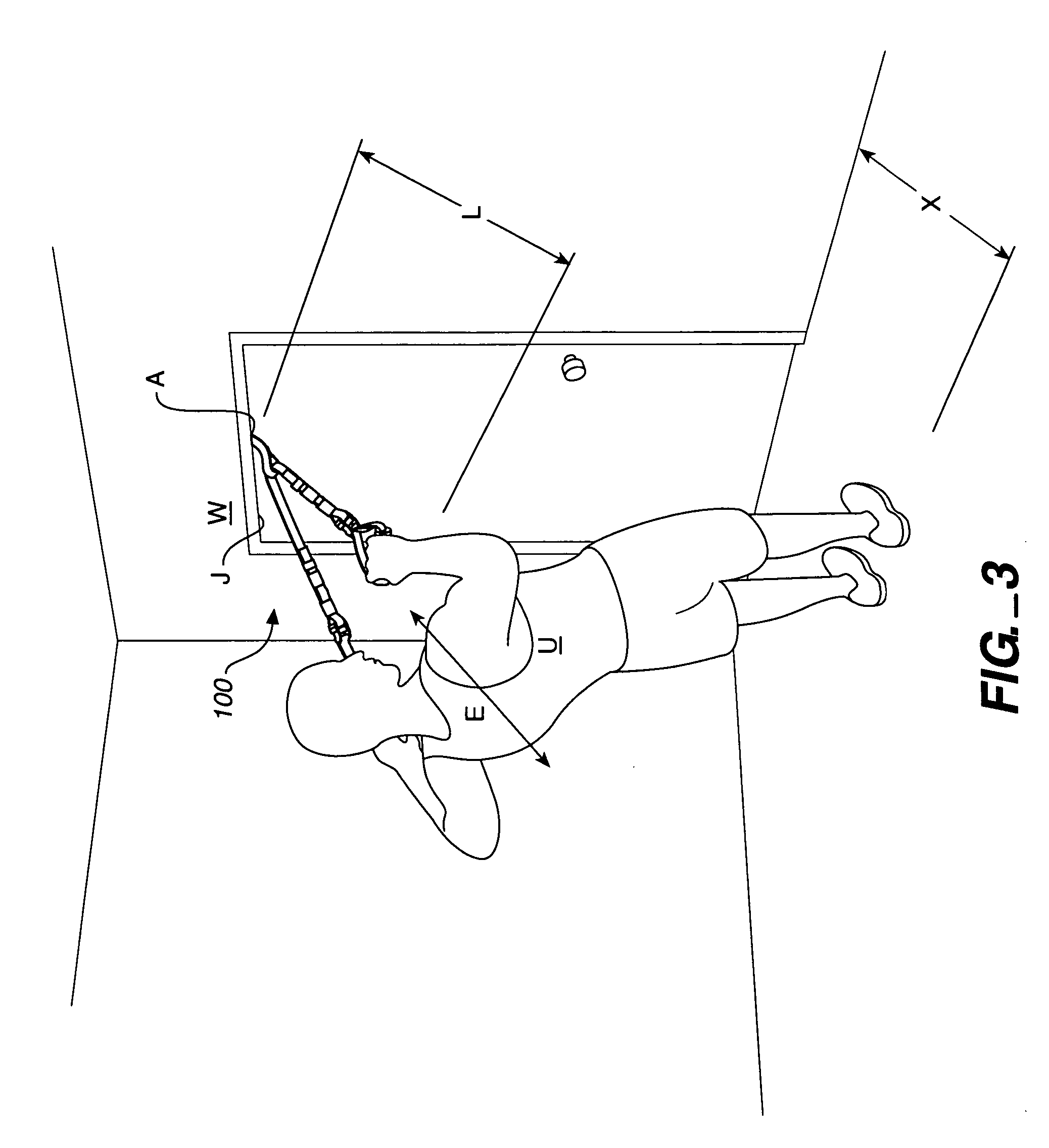

Exercise device including adjustable, inelastic straps

InactiveUS7044896B2Easy to adjustEffective centeringResilient force resistorsTherapy exerciseWhole bodyEngineering

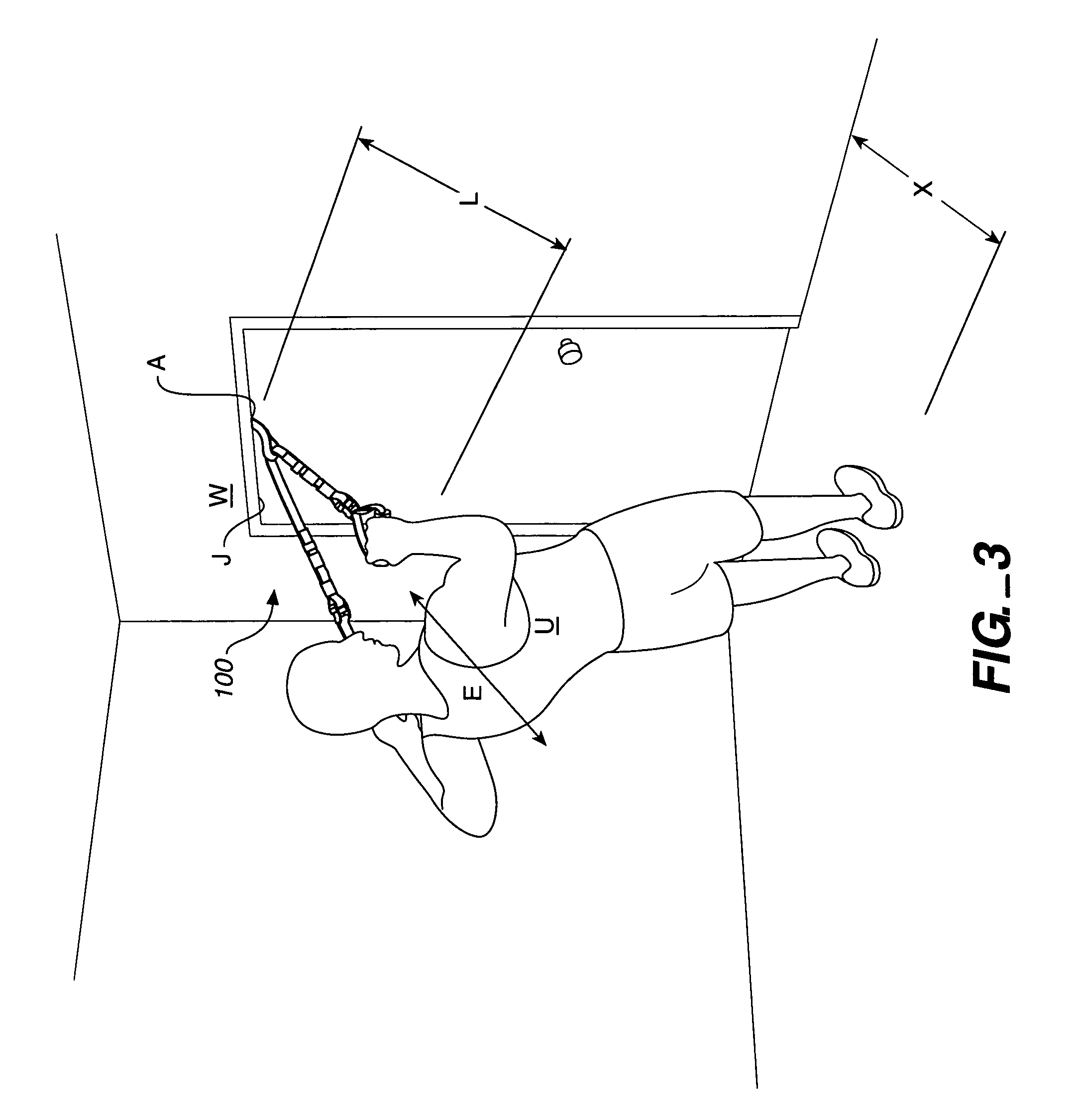

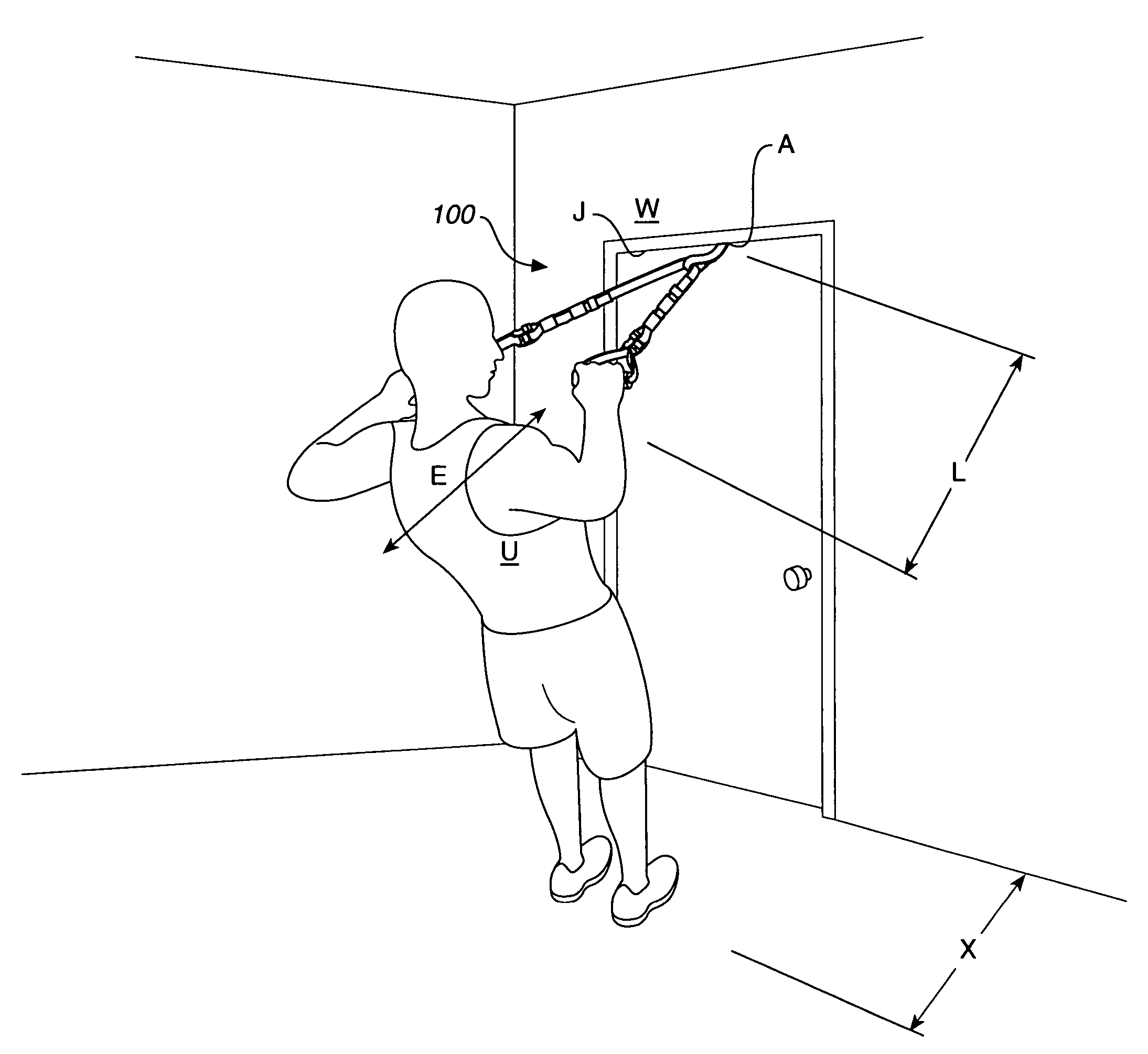

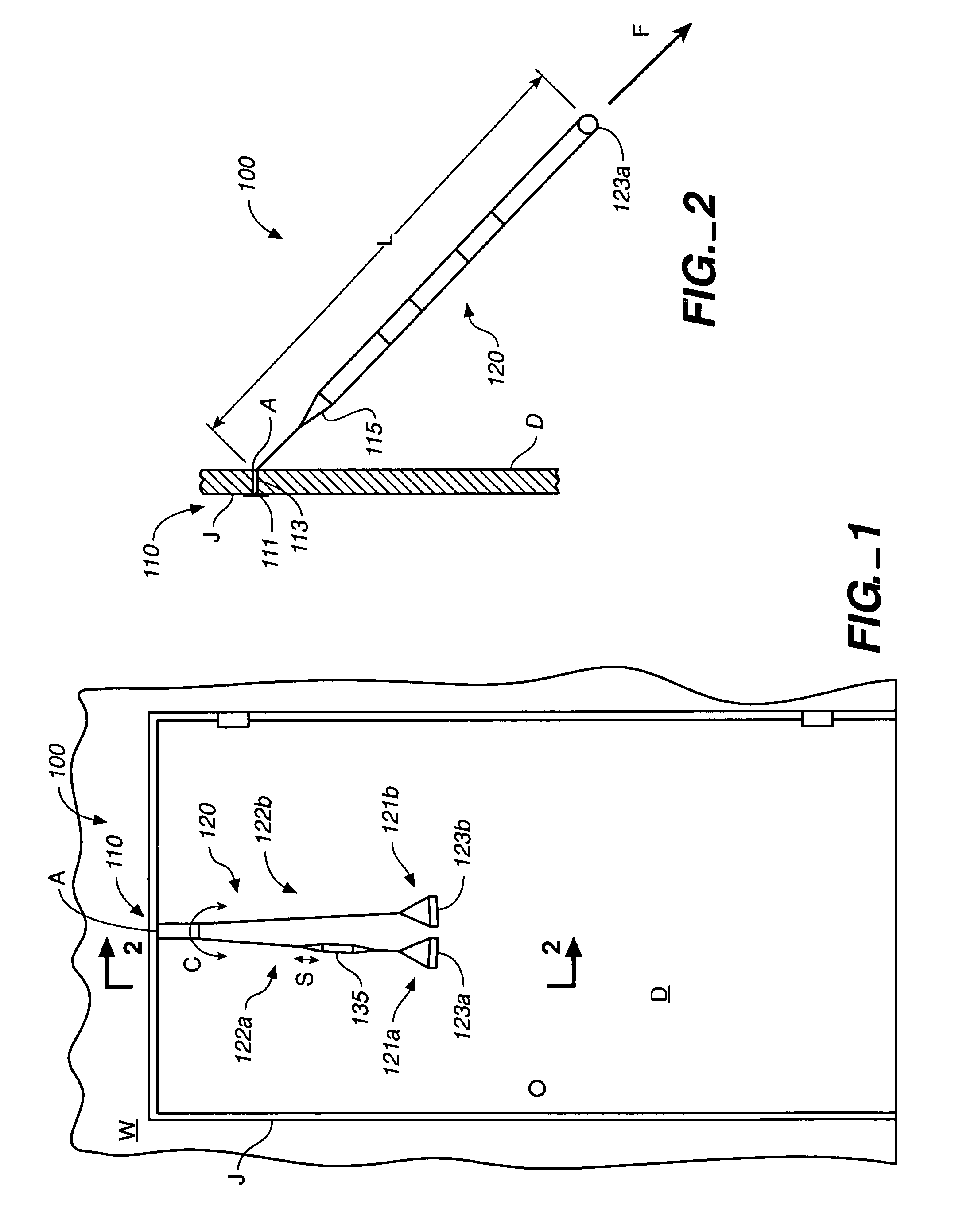

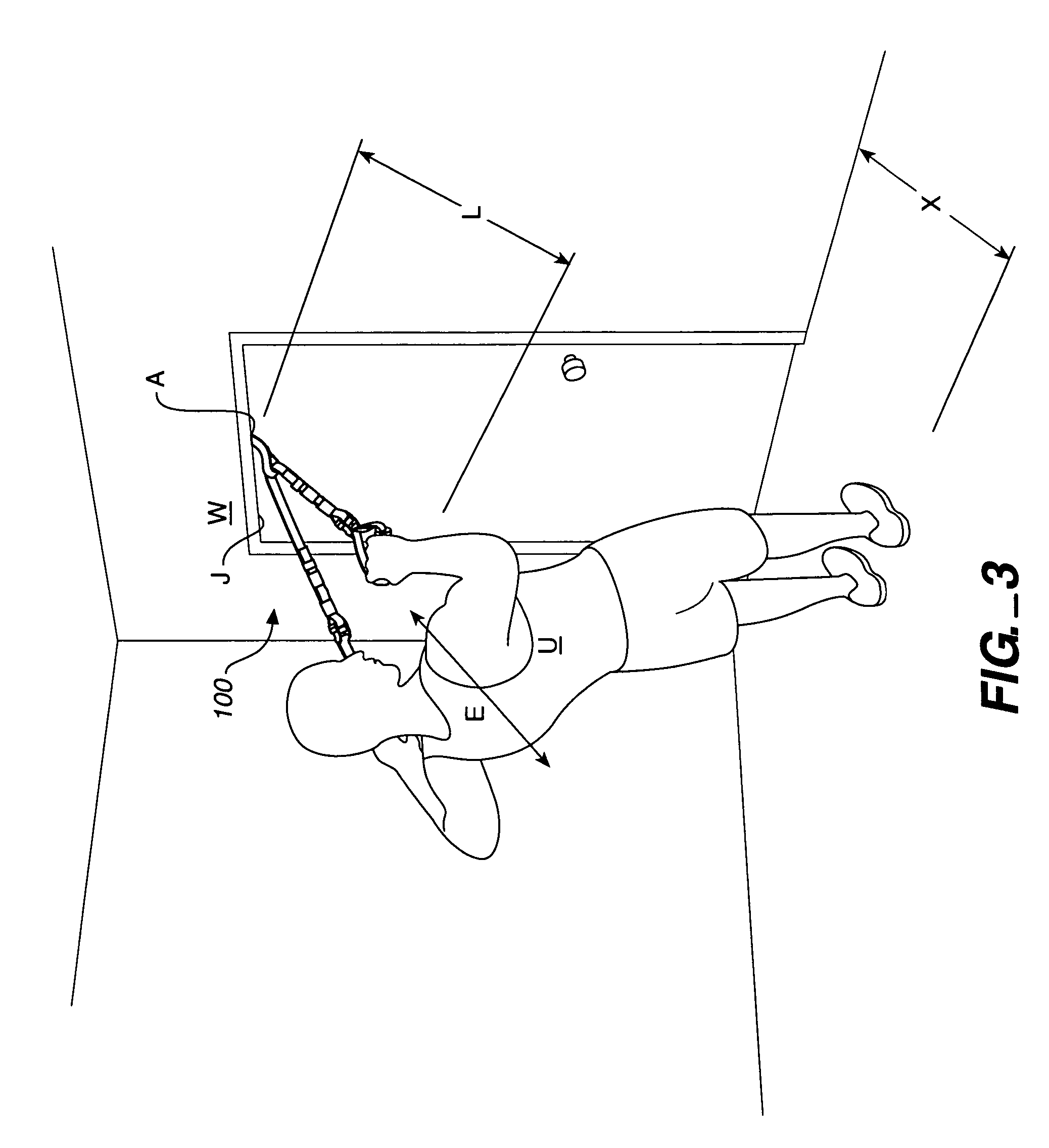

An exercise device having many advantageous features is described, including the ability to provide a user selected resistance from nearly zero resistance to the user's full body weight, the ability to easily adjust between exercises and between users, and the ability to balance the device between reconfigurations to provide for ease-of-use. The device includes an inelastic adjustable length member with two arms and a grip at both ends, and a centrally located anchor that provides for a distribution of the length between the arms. In one embodiment, the exercise device is compact and can be removably attached to a door frame. When grabbing each of the grips and uniformly pulling away from the anchor, the arms of the device center on the anchor.

Owner:JFXD TRX ACQ LLC

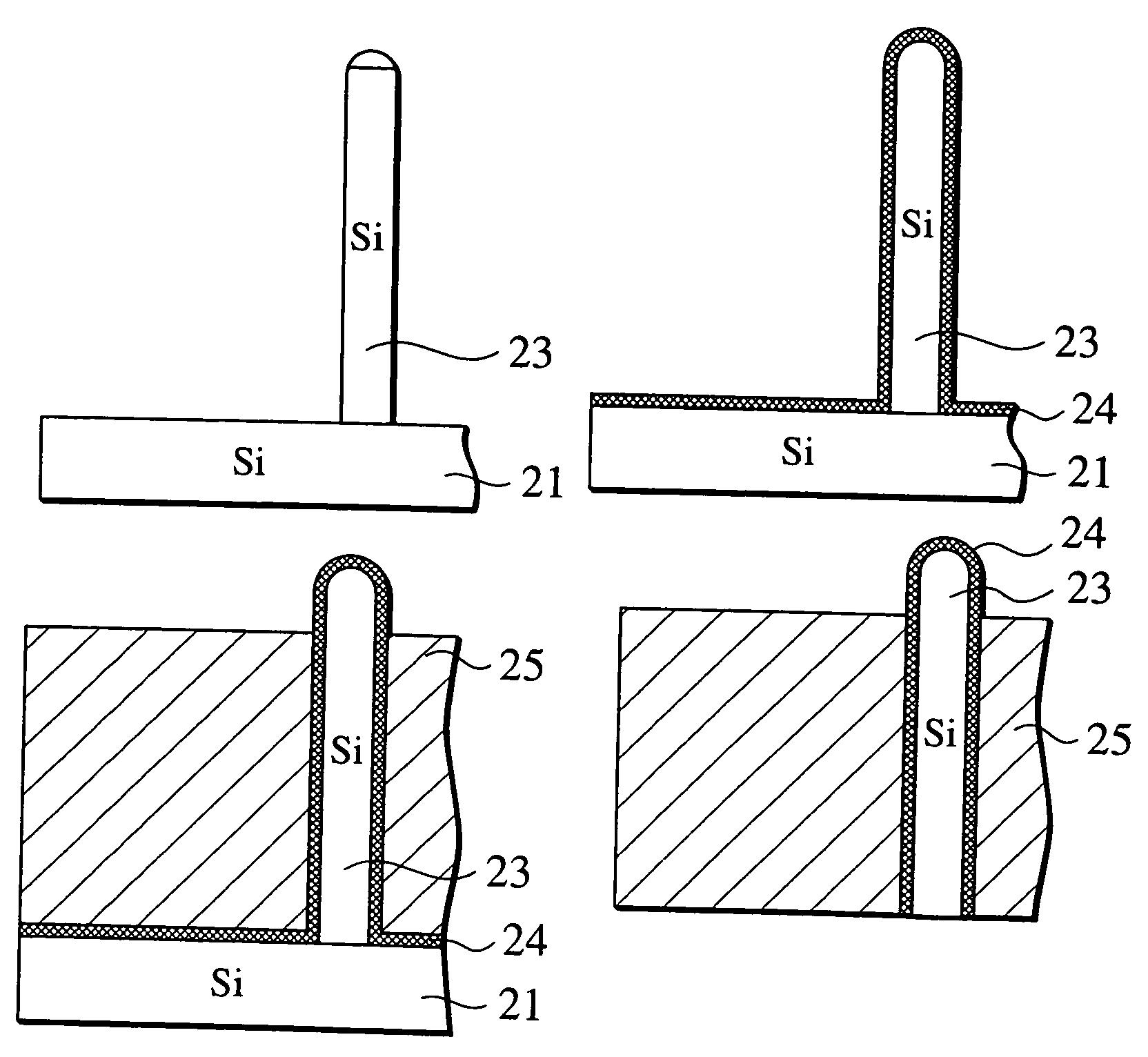

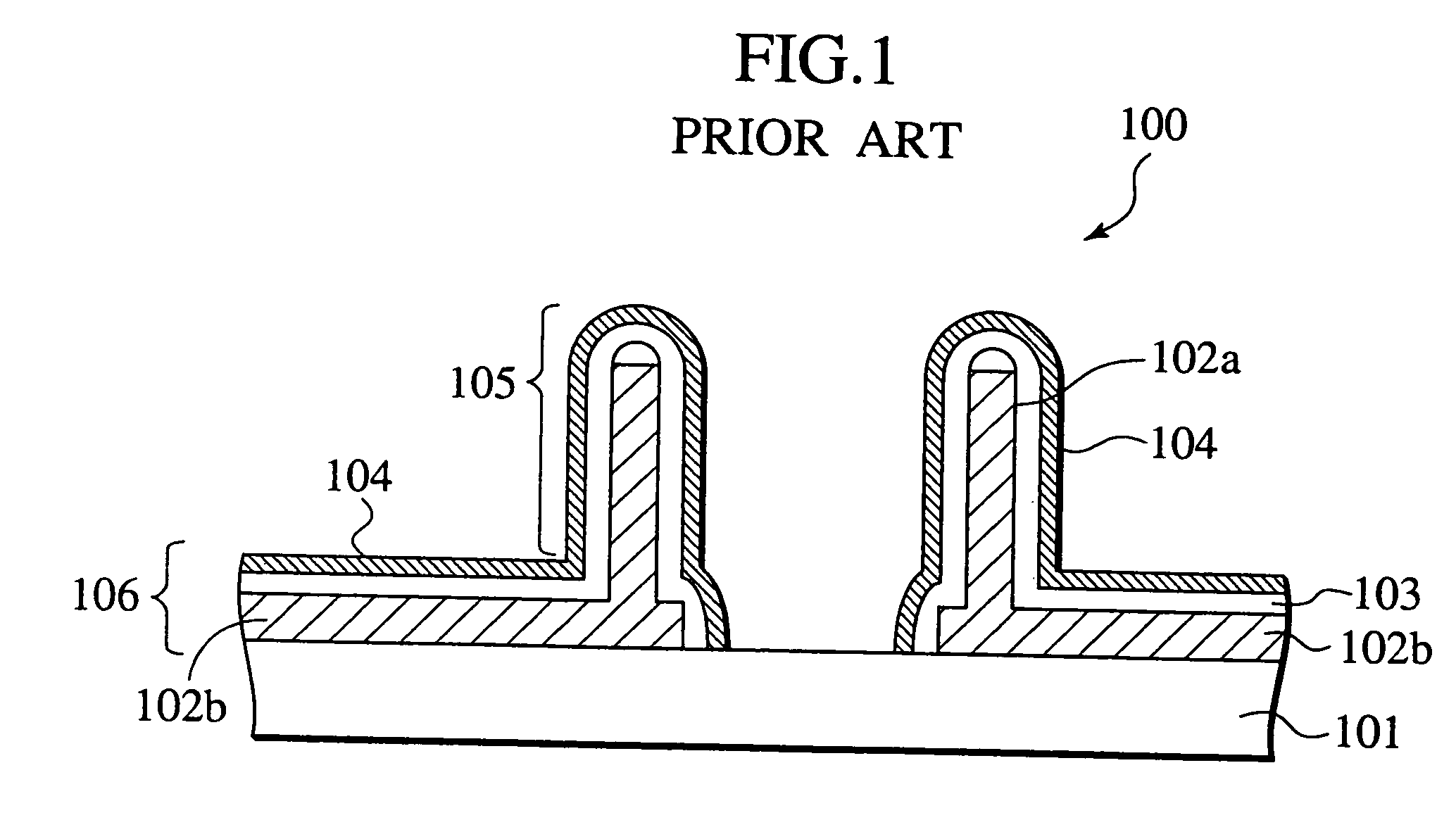

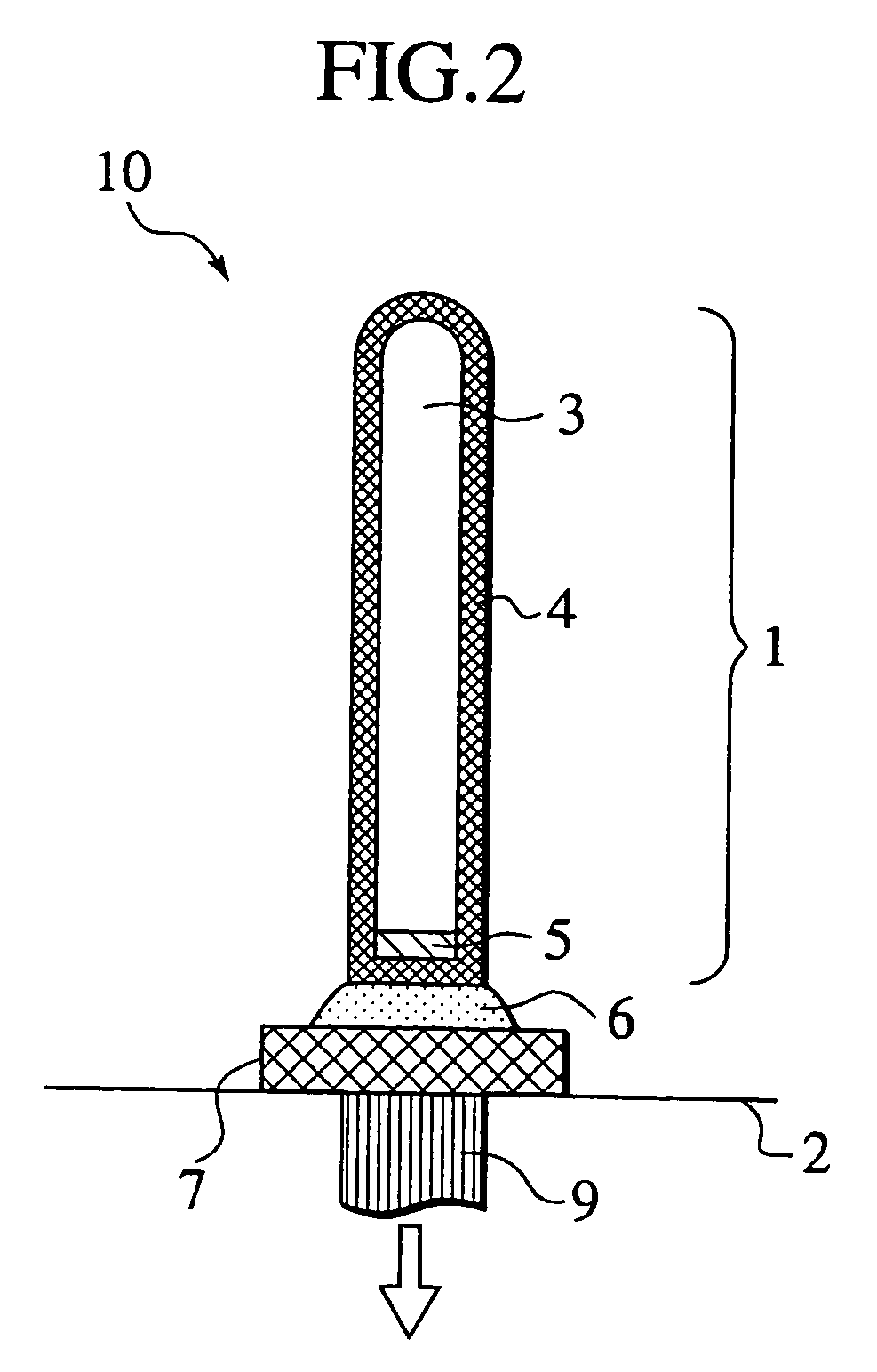

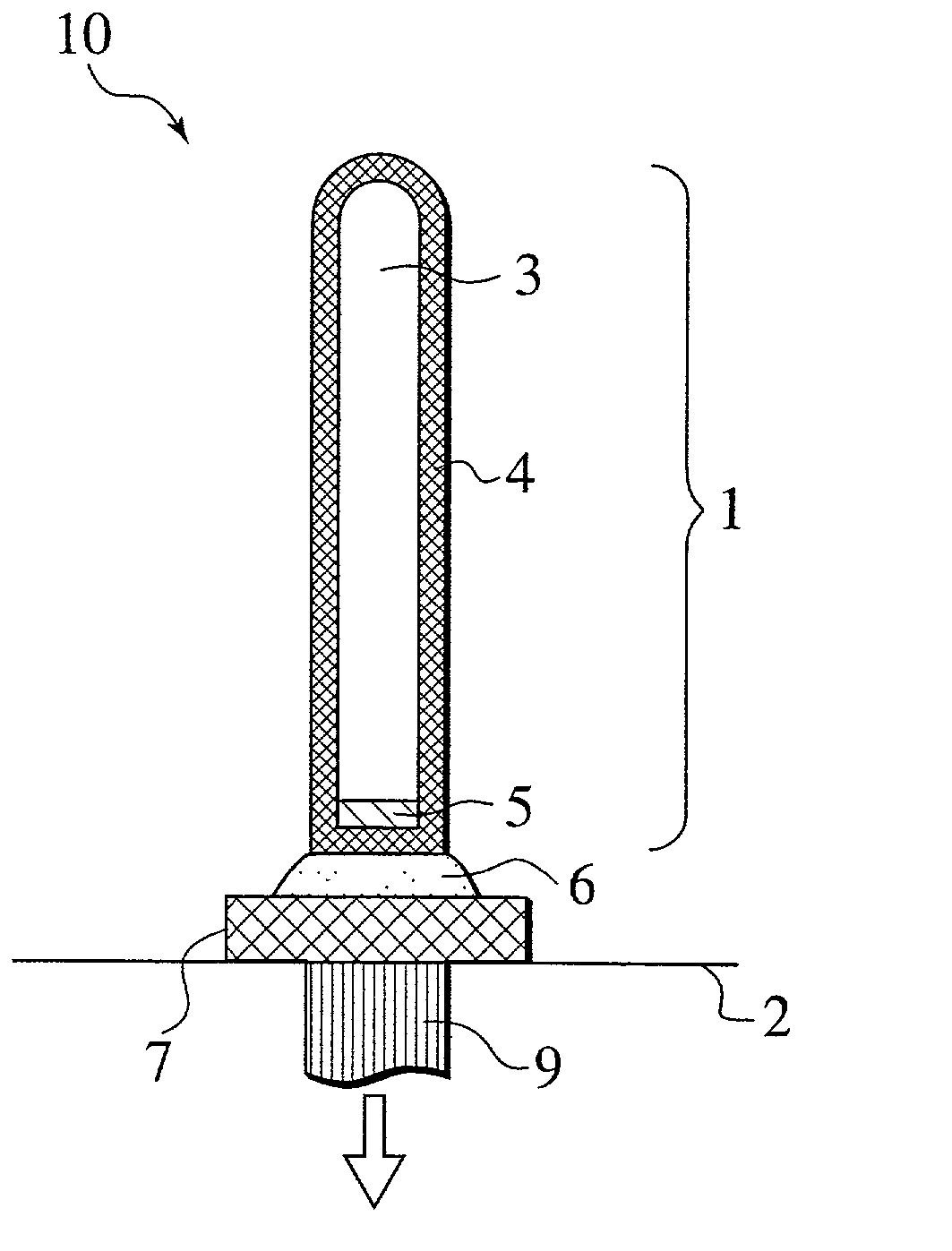

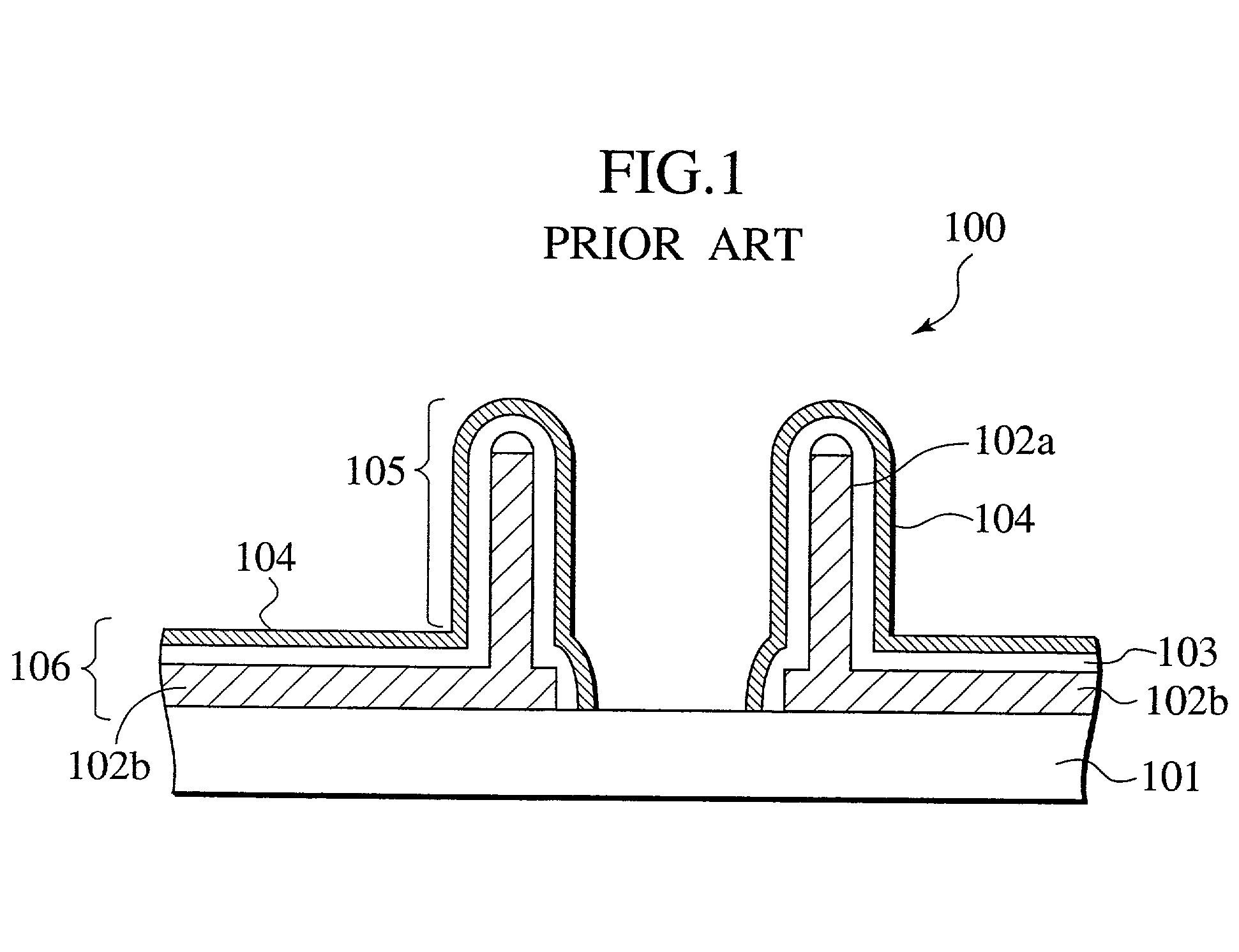

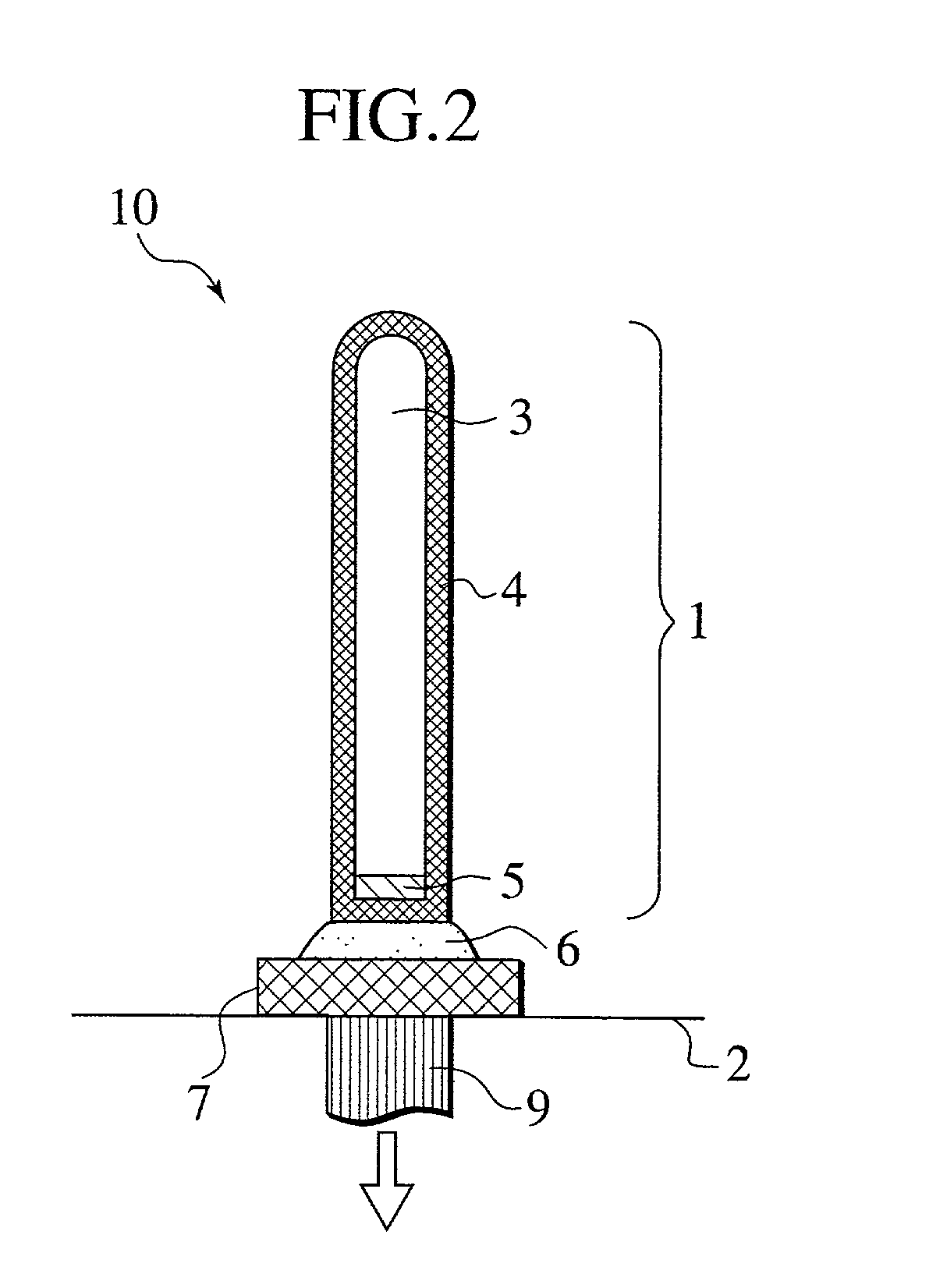

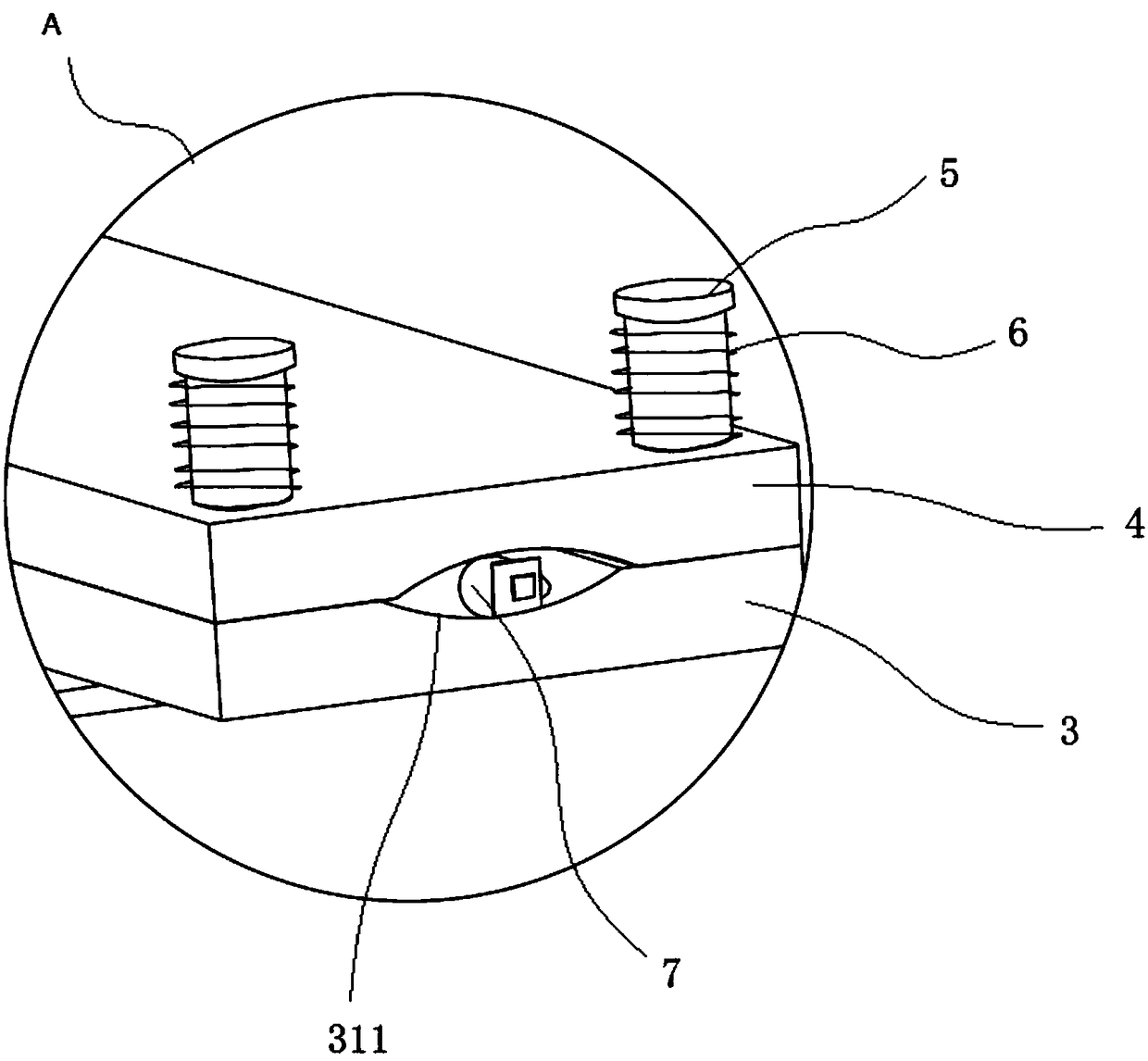

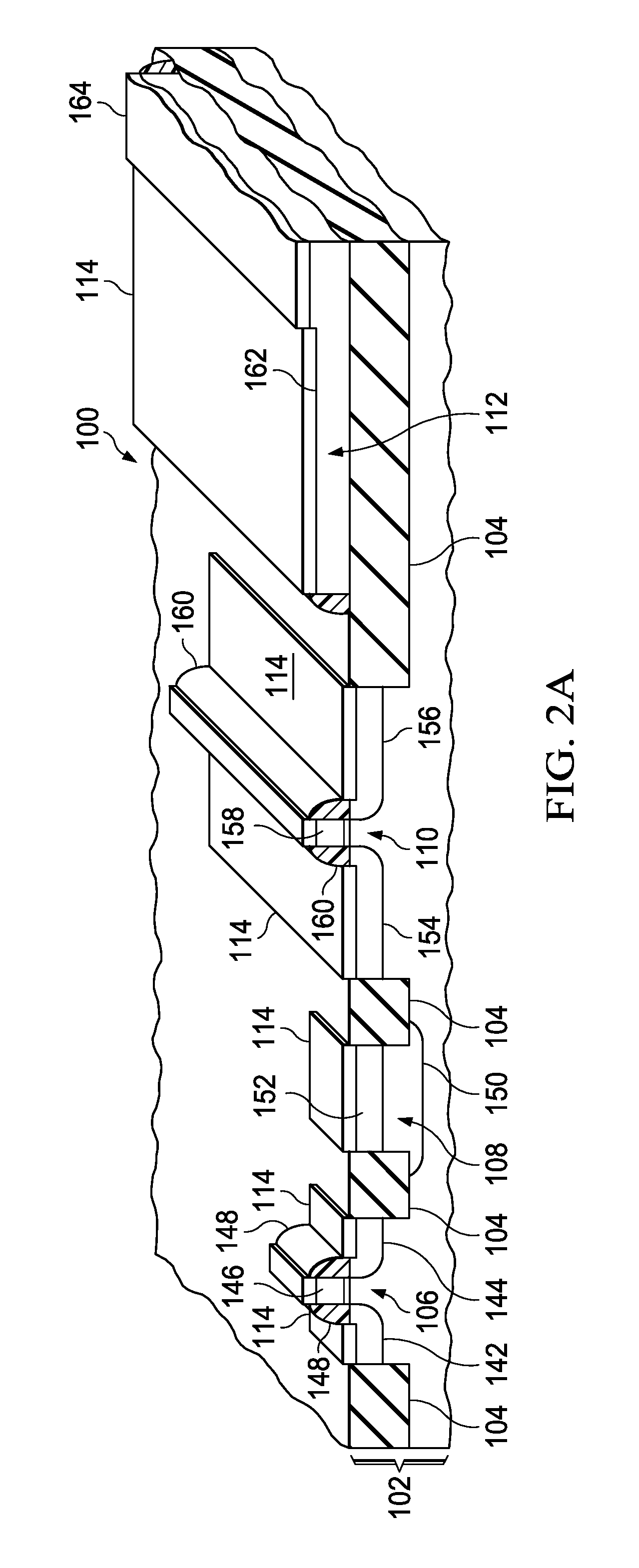

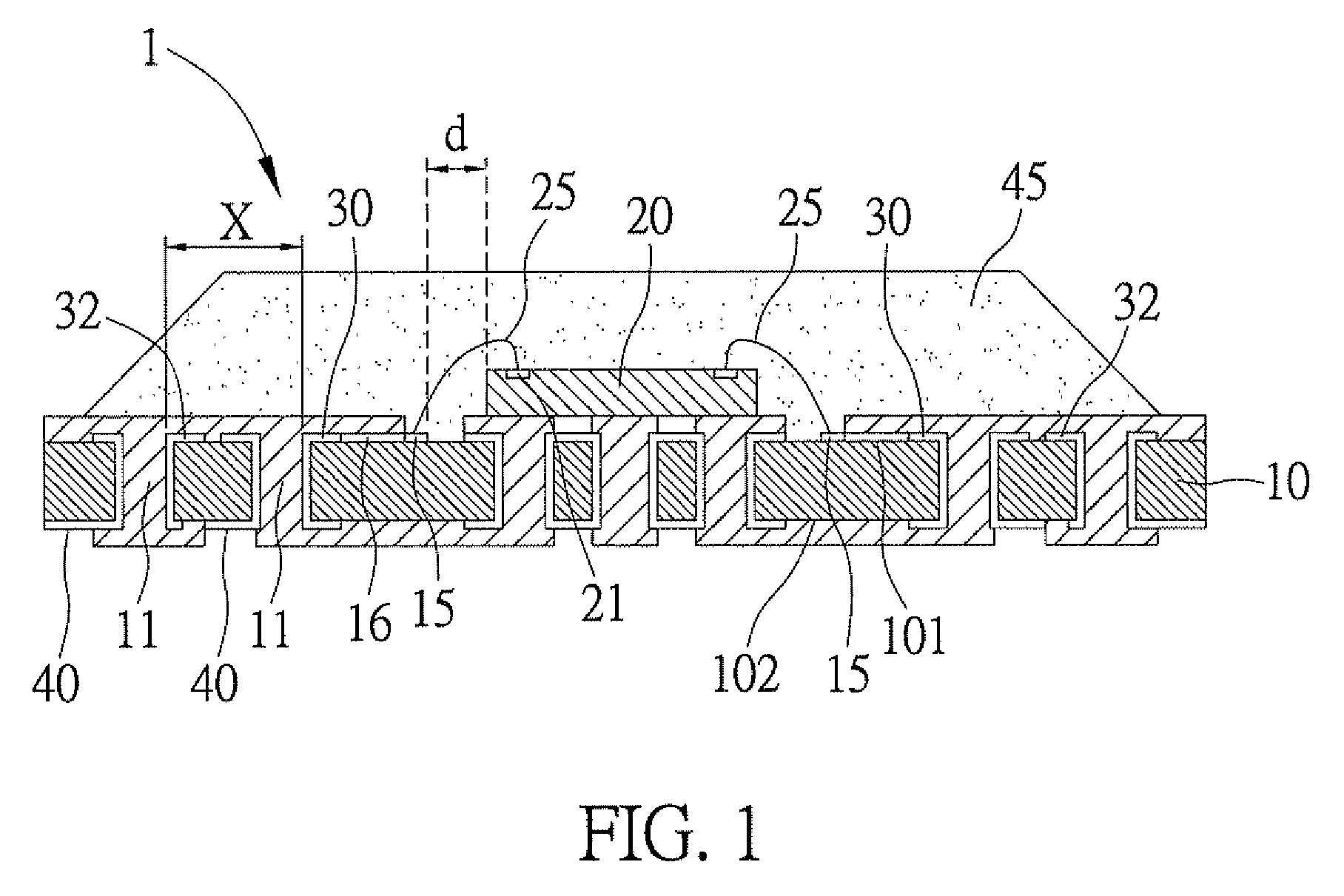

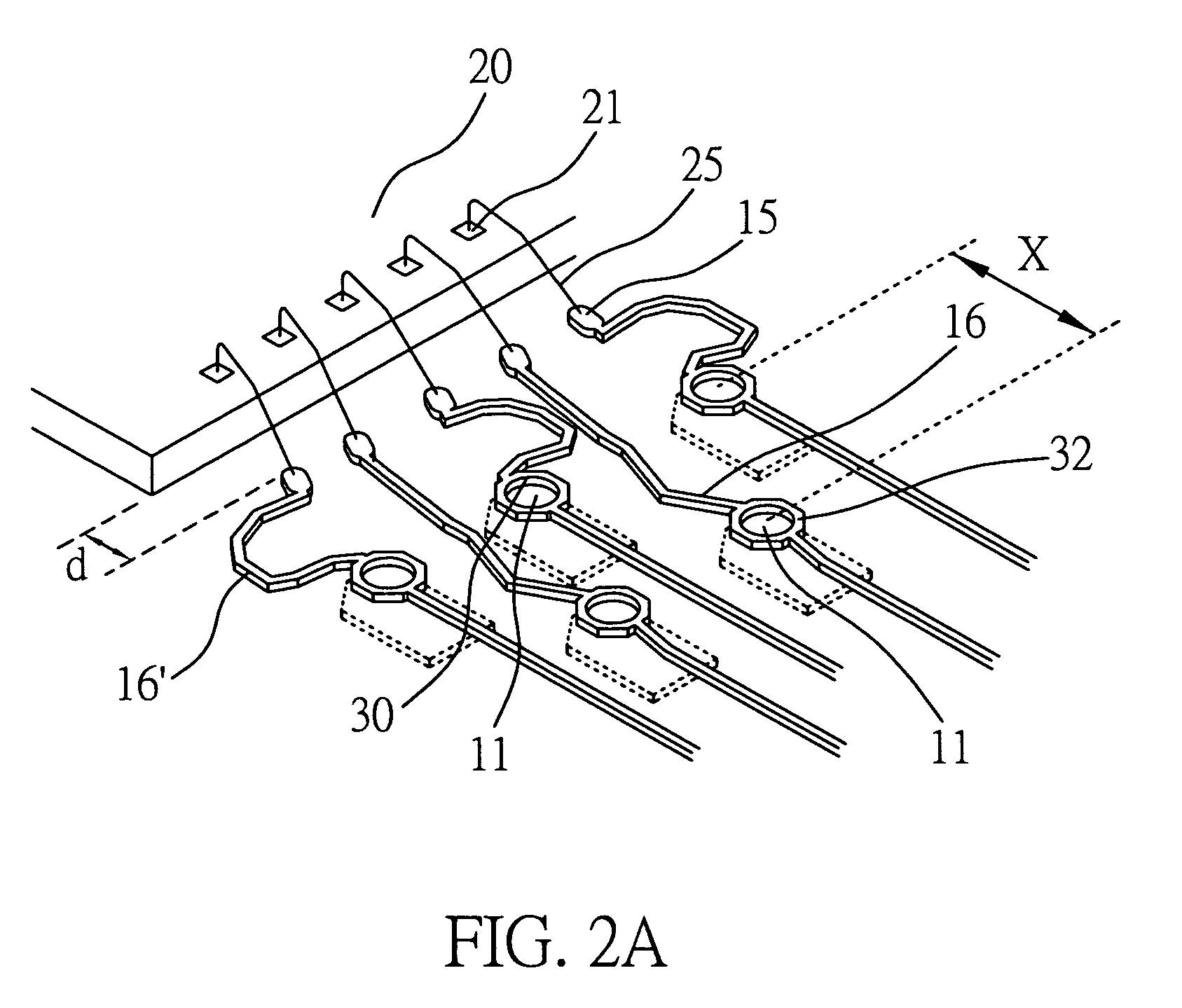

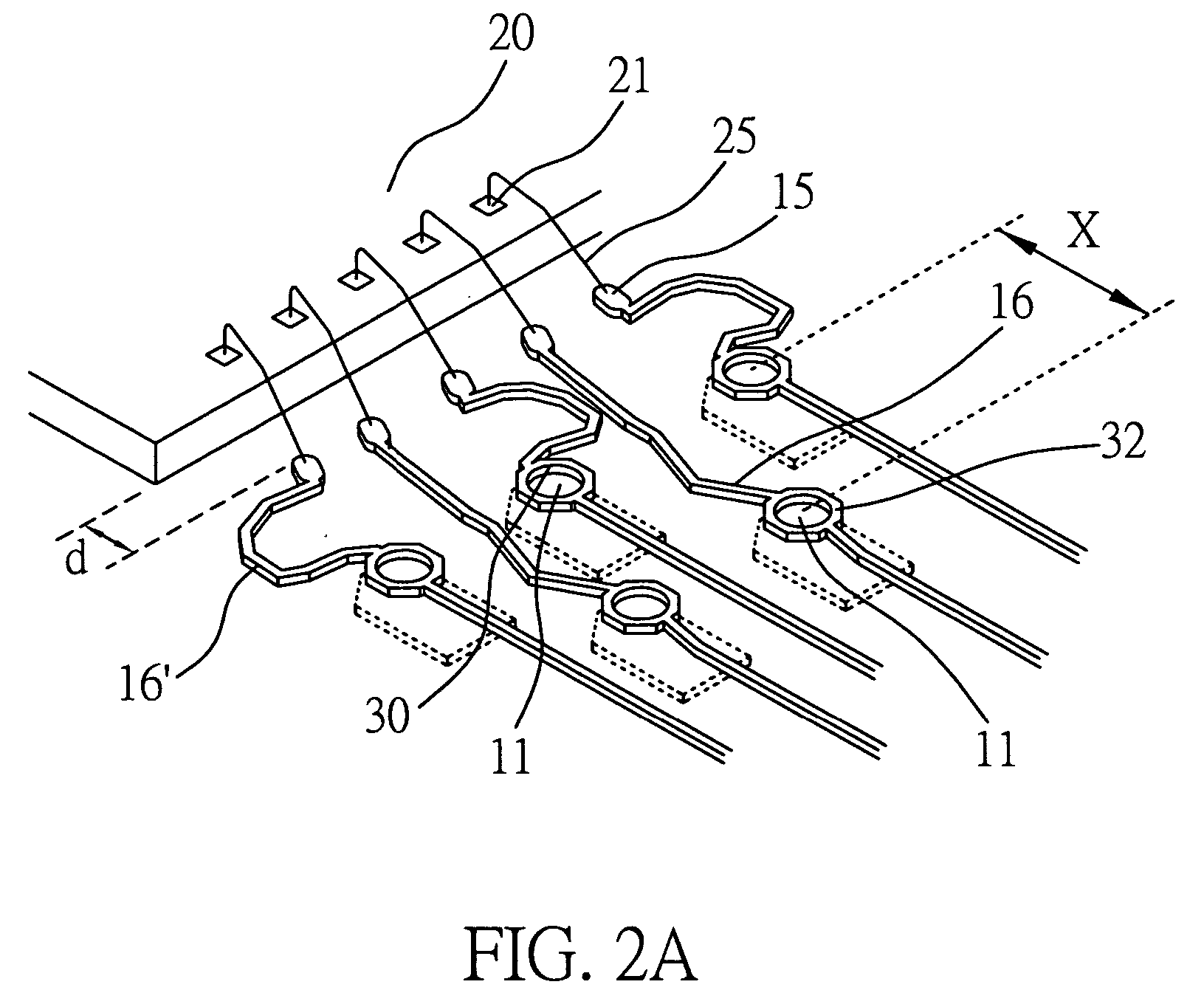

Method for fabricating a probe pin for testing electrical characteristics of an apparatus

InactiveUS7032307B2Reduce contact resistancePitch of probe pins to be reducedLine/current collector detailsSemiconductor/solid-state device testing/measurementProbe cardHigh density

A probe pin for testing electric characteristics of a semiconductor device comprises a silicon pin core (3, 23, 33), and a conductive film (4, 24, 34) covering the entire surface, including the bottom face, of the pin core. The bottom face of the probe pin is connected directly to an electrode (7, 37) positioned in or on a print wiring board. A number of probe pins can be connected to the associated electrodes at a high density, thereby forming a fine-pitch probe card having a superior high-frequency signal characteristic.

Owner:KK TOSHIBA

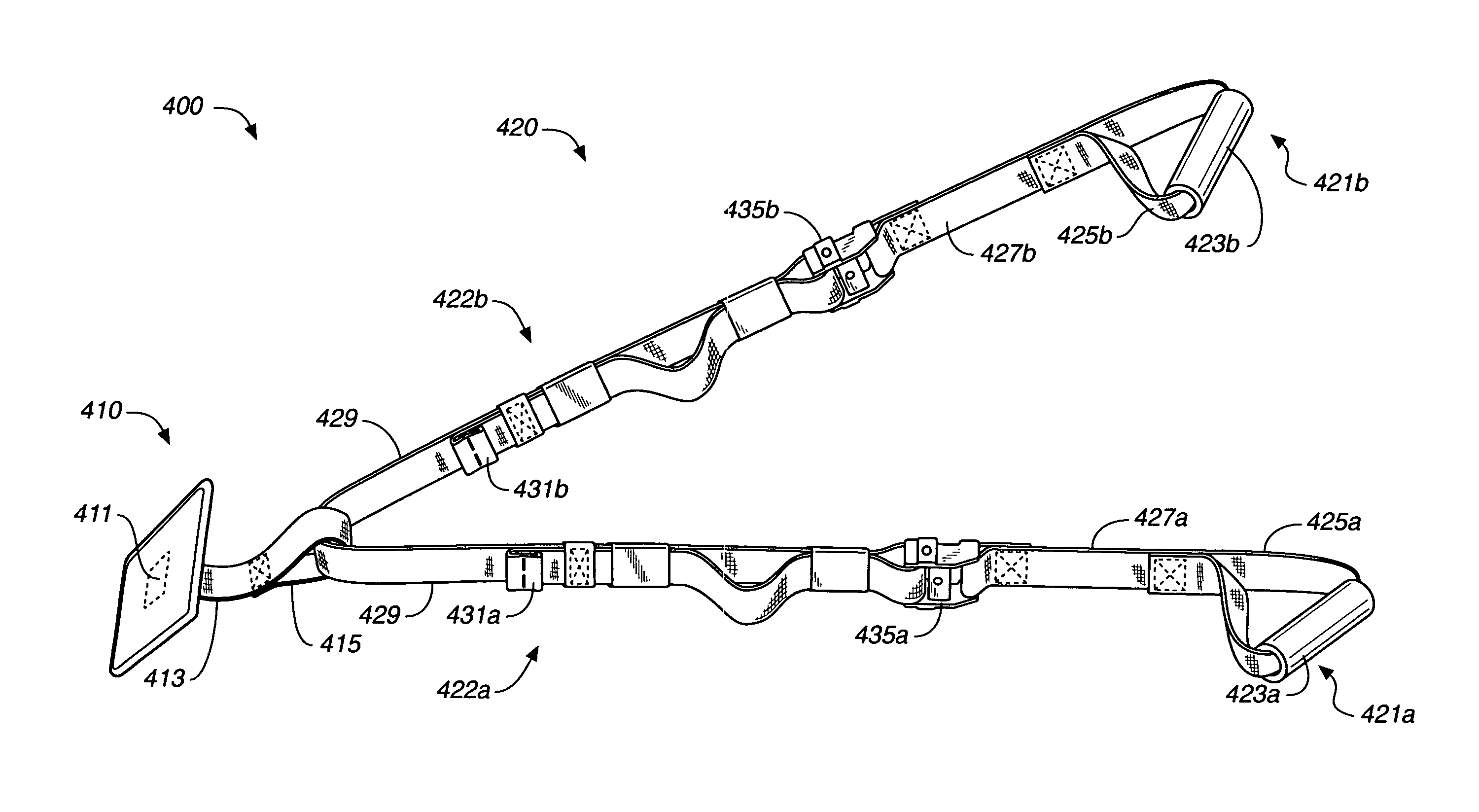

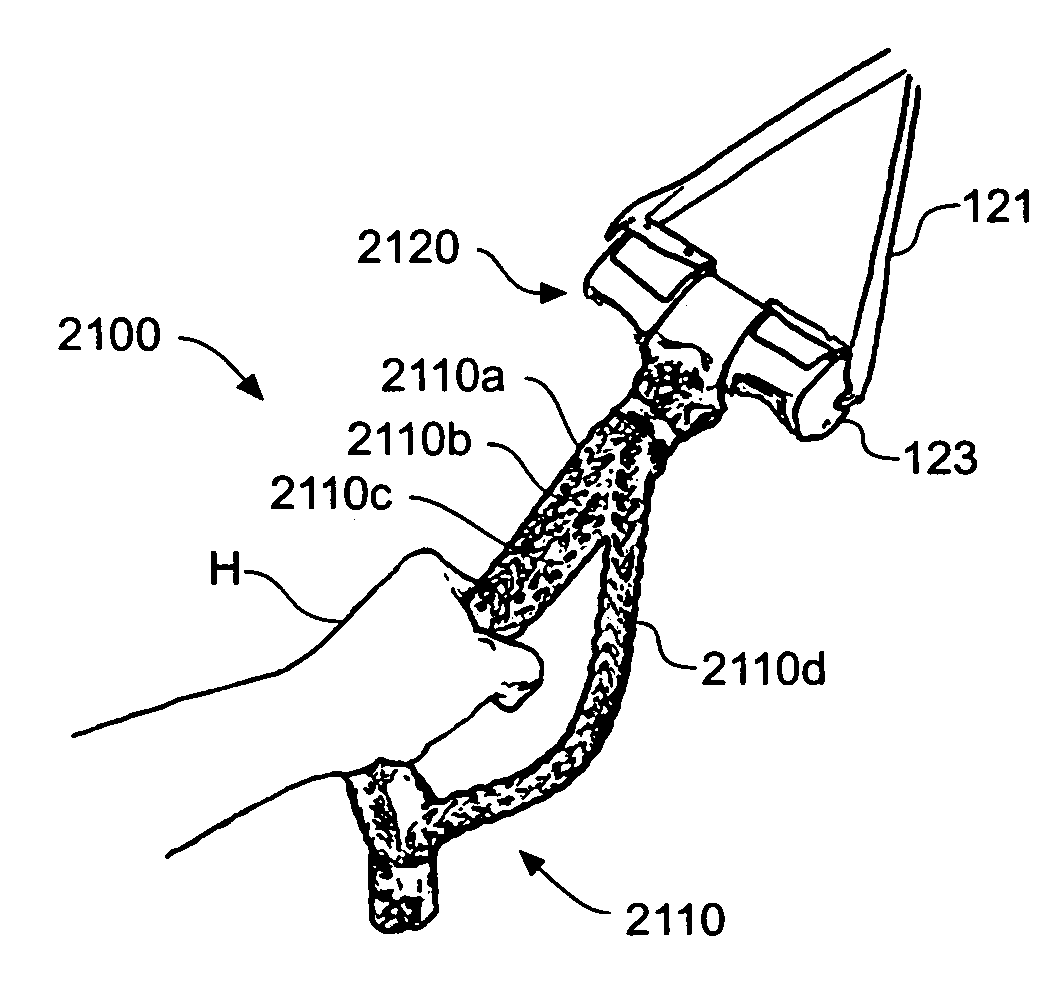

Exercise device grips and accessories for exercise devices

InactiveUS7090622B2Easy to adjustEasily vary length of deviceResilient force resistorsTherapy exerciseEngineeringBody Regions

An exercise device having many advantageous features is described, including the ability to provide a variety of different accessory grips to the user, and the ability to easily mount the device to a wall. One exercise device described is an inelastic resistance device having integral hand grips. The accessory grips are removably attachable to the integral grip of an exercising device, and provide for gripping by the hands, foot or other body parts. The selection of a specific accessory grip allows the user to exercise by specific body parts and provides for a greater number of possible exercises. Accessory grips are attachable to the integral grips, greatly adding to the flexibility of the device. In addition, a novel hand grip is described having a plurality of cords that can be selected for gripping, and a bracket for mounting a door jamb mountable exercise device to a wall is described.

Owner:JFXD TRX ACQ LLC

Method of using an adjustable exercise device

Owner:JFXD TRX ACQ LLC

Probe pin for testing electrical characteristics of apparatus, probe card using probe pins

InactiveUS20020127812A1Eliminates variation in signal transferHigh-dense structureSemiconductor/solid-state device testing/measurementDecorative surface effectsSignal characteristicTest facility

A probe pin for testing electric characteristics of a semiconductor device comprises a silicon pin core (3, 23, 33), and a conductive film (4, 24, 34) covering the entire surface, including the bottom face, of the pin core. The bottom face of the probe pin is connected directly to an electrode (7, 37) positioned in or on a print wiring board. A number of probe pins can be connected to the associated electrodes at a high density, thereby forming a fine-pitch probe card having a superior high-frequency signal characteristic.

Owner:KK TOSHIBA

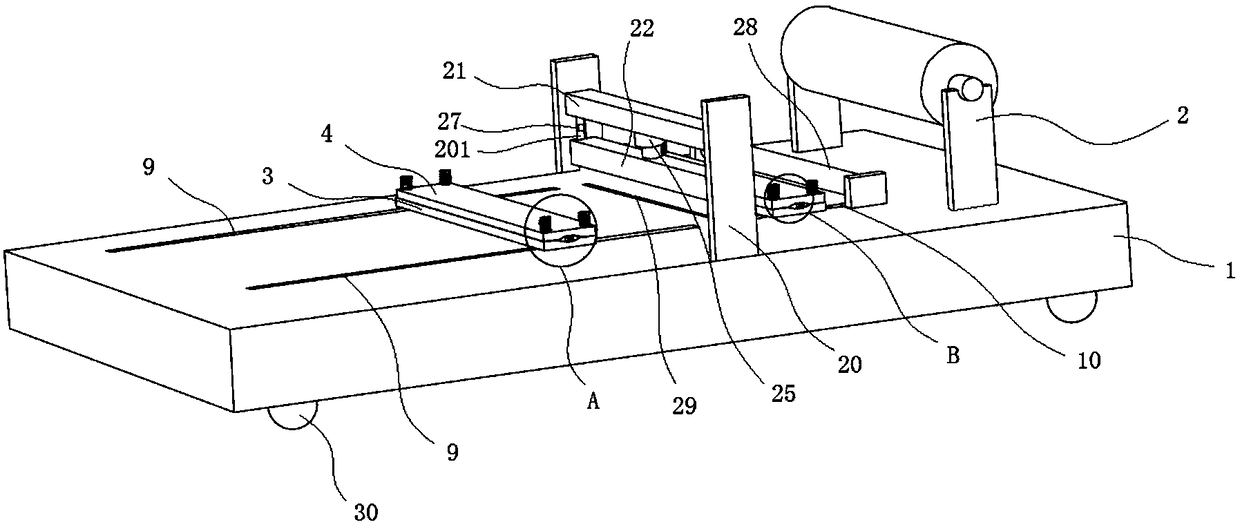

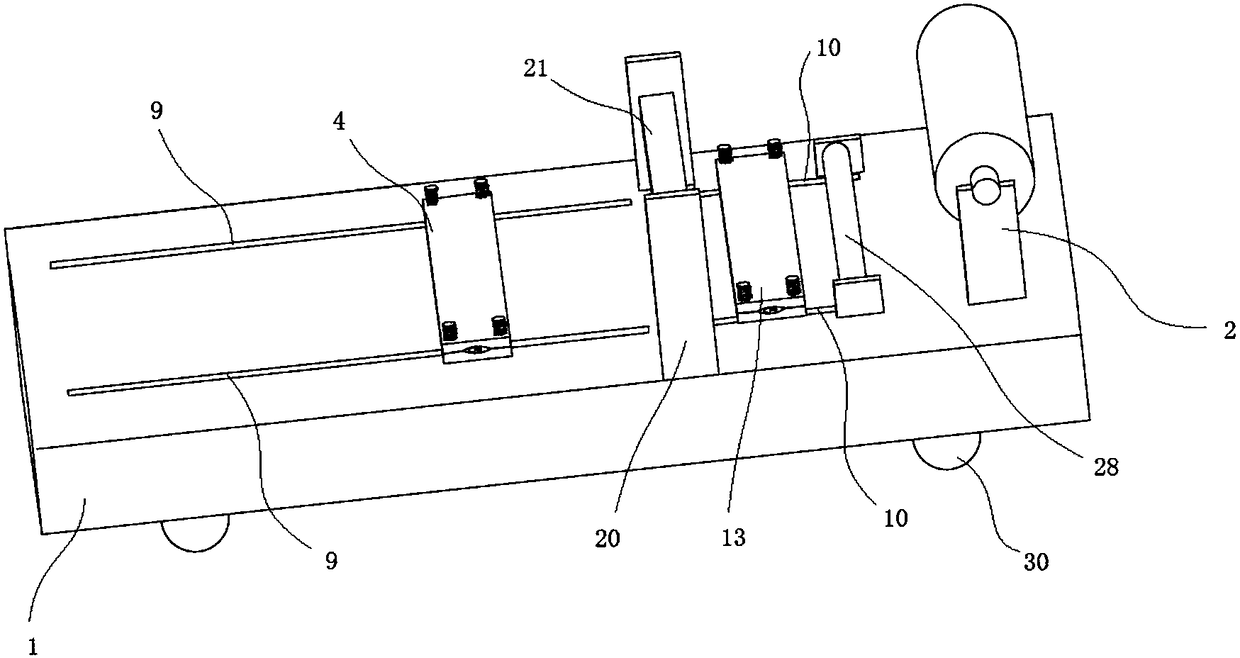

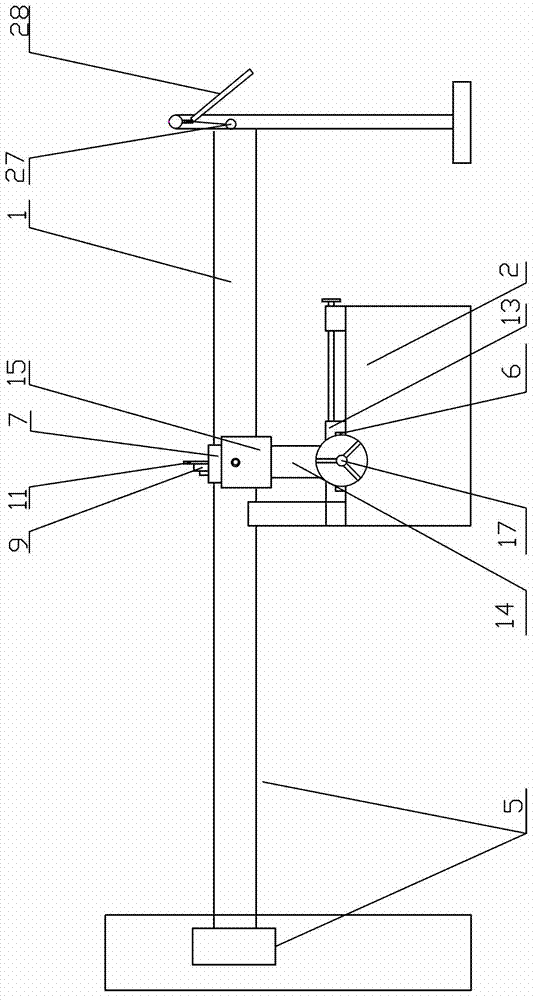

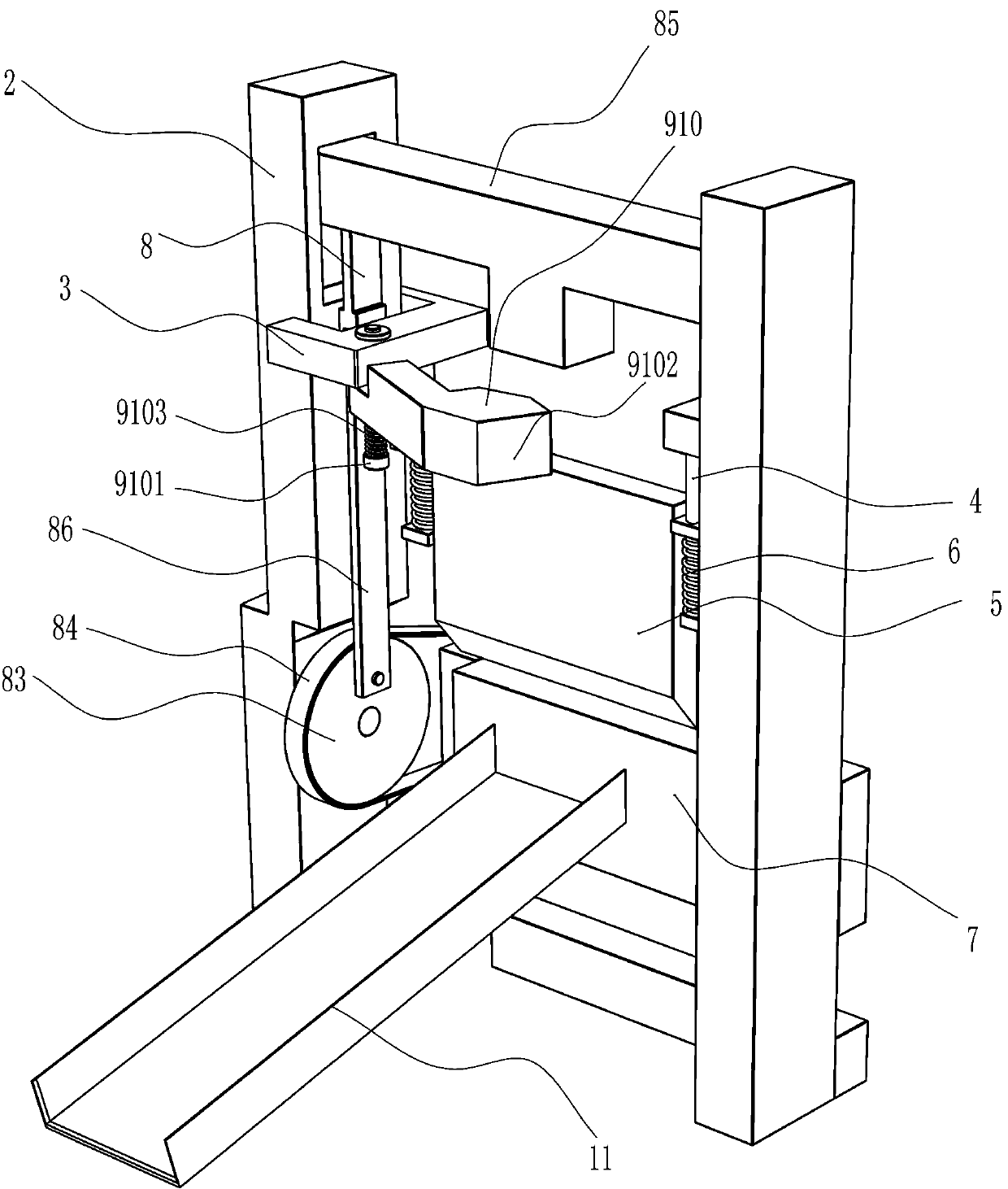

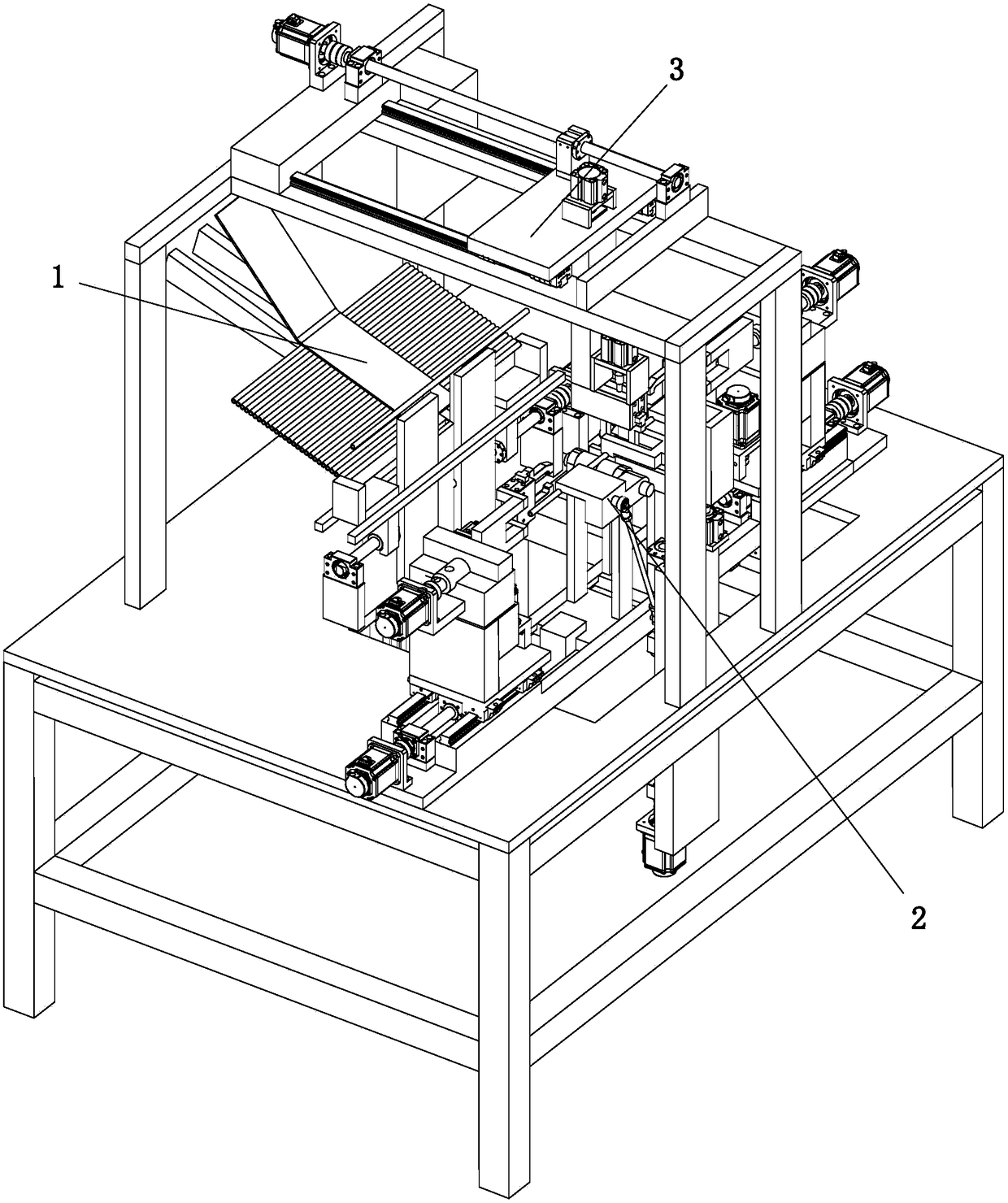

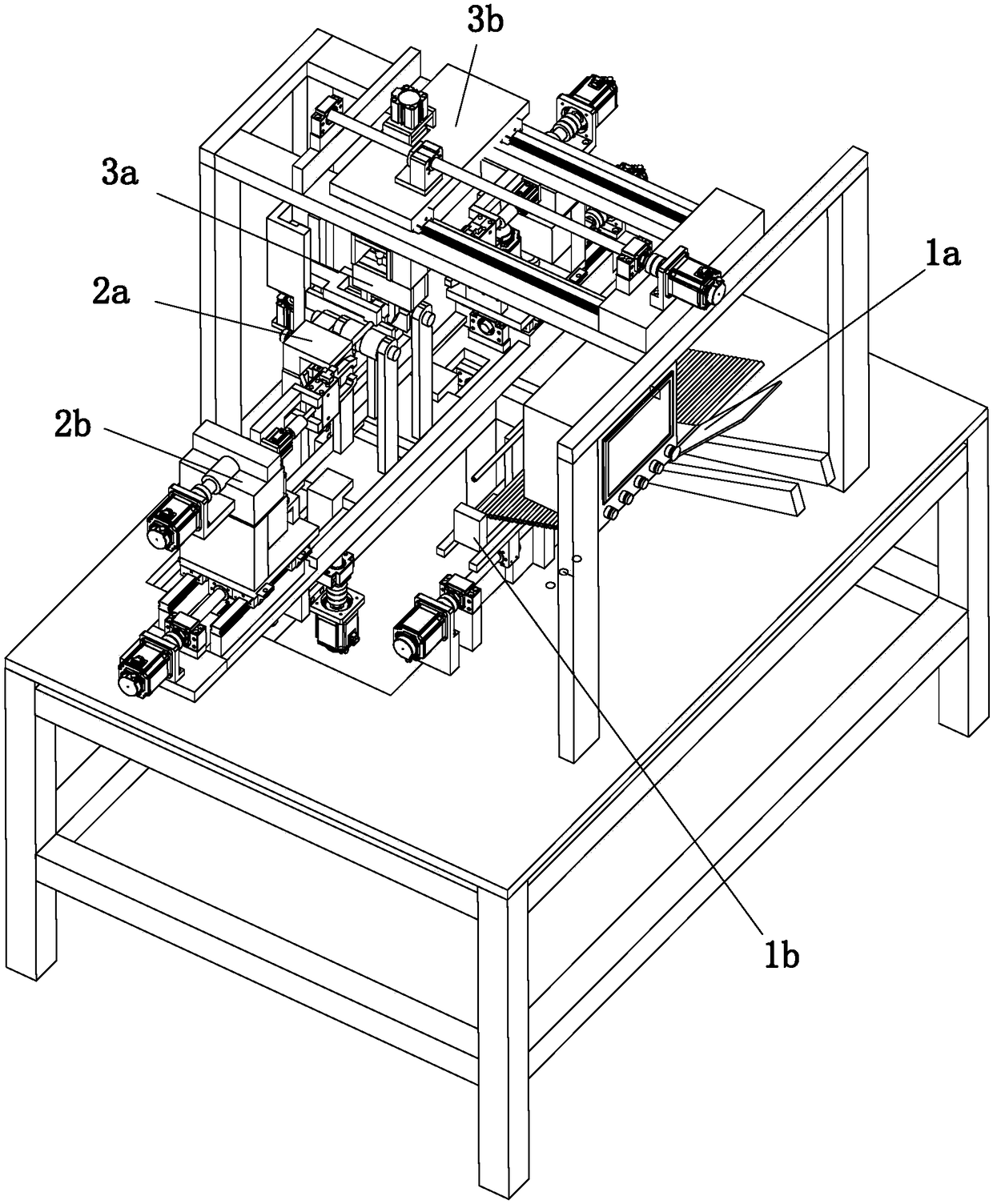

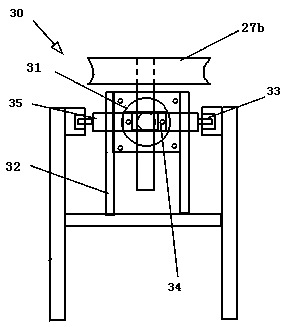

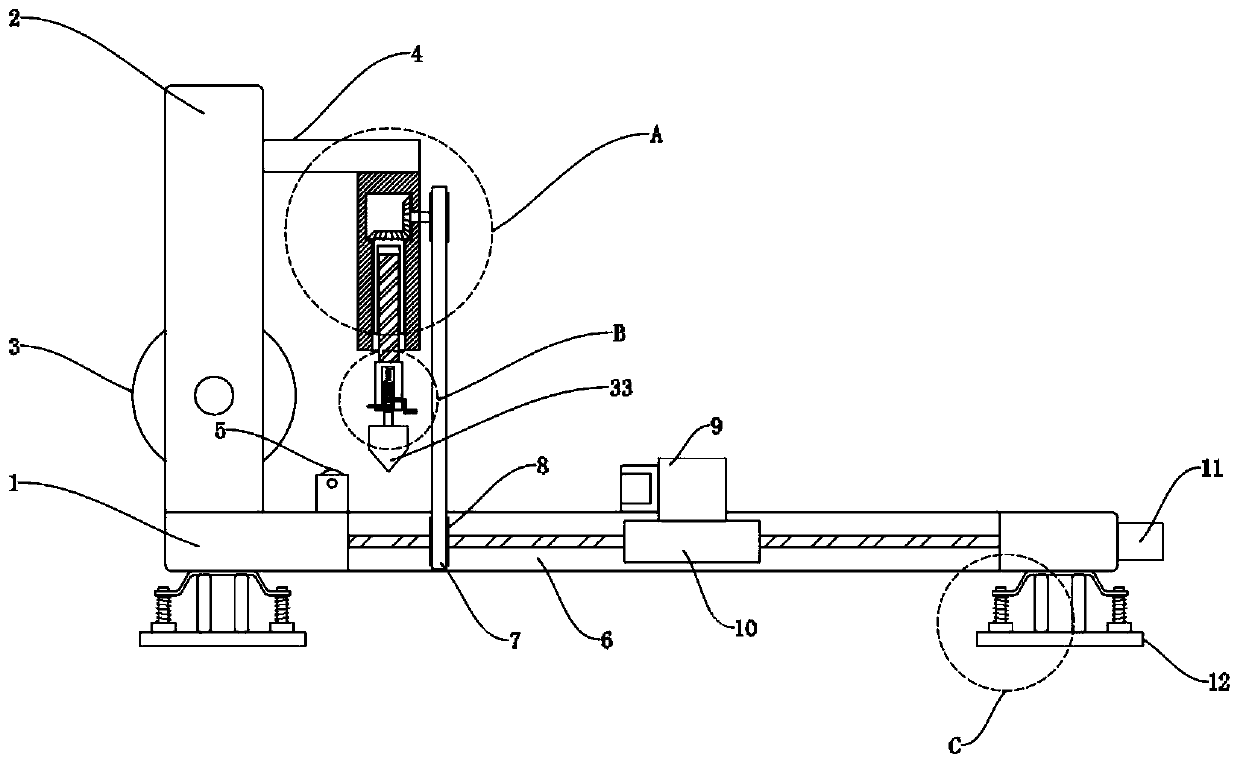

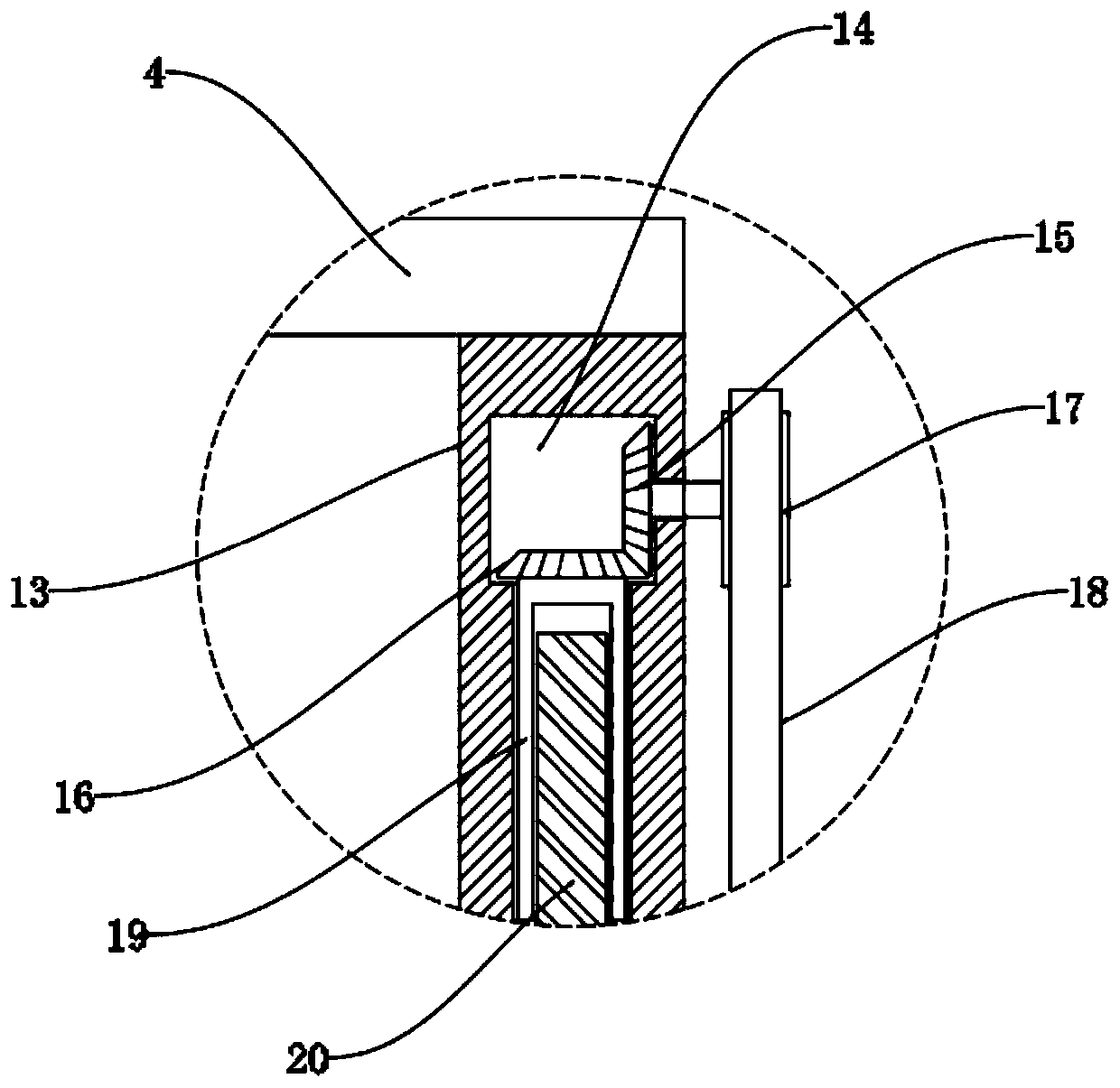

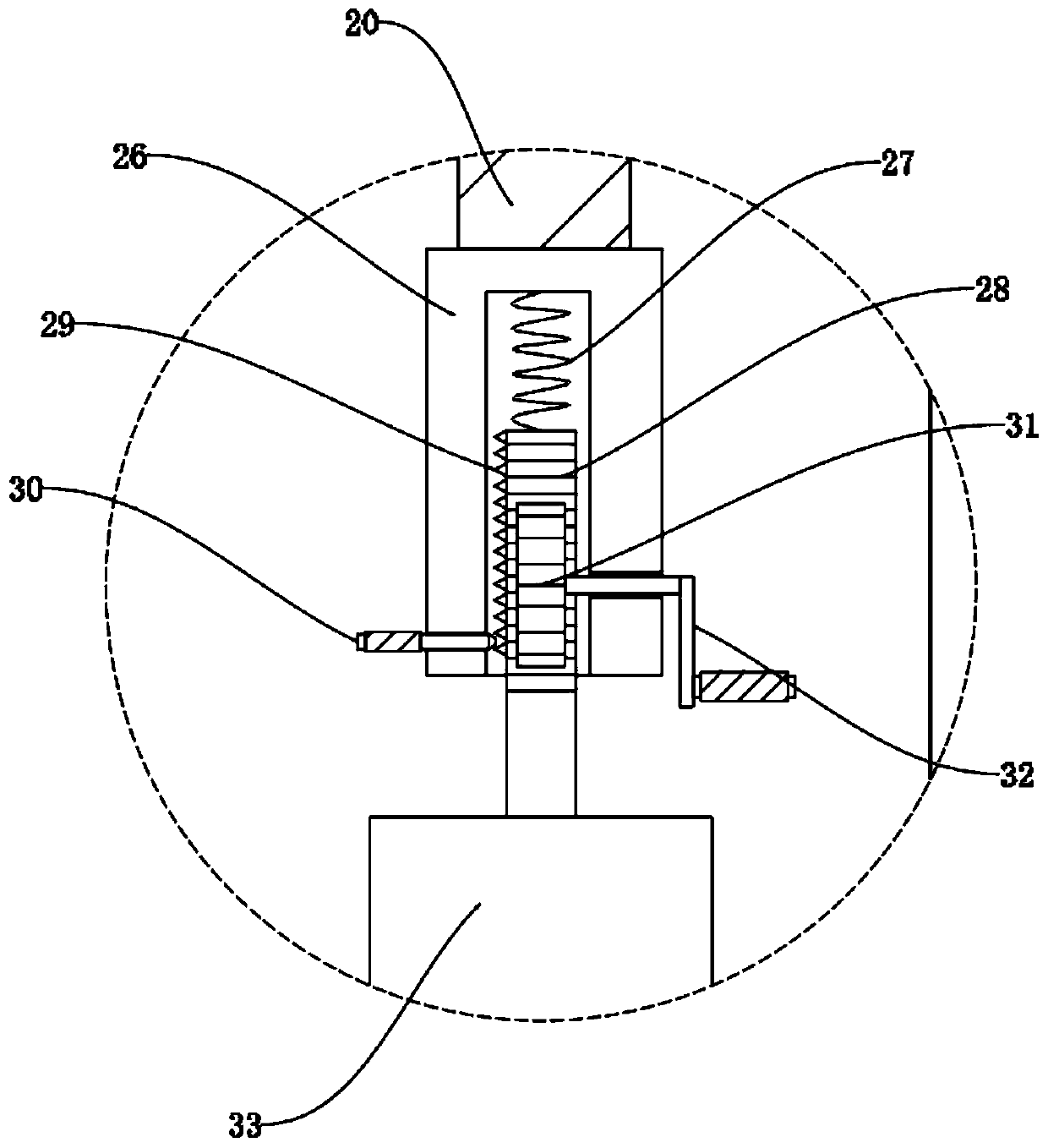

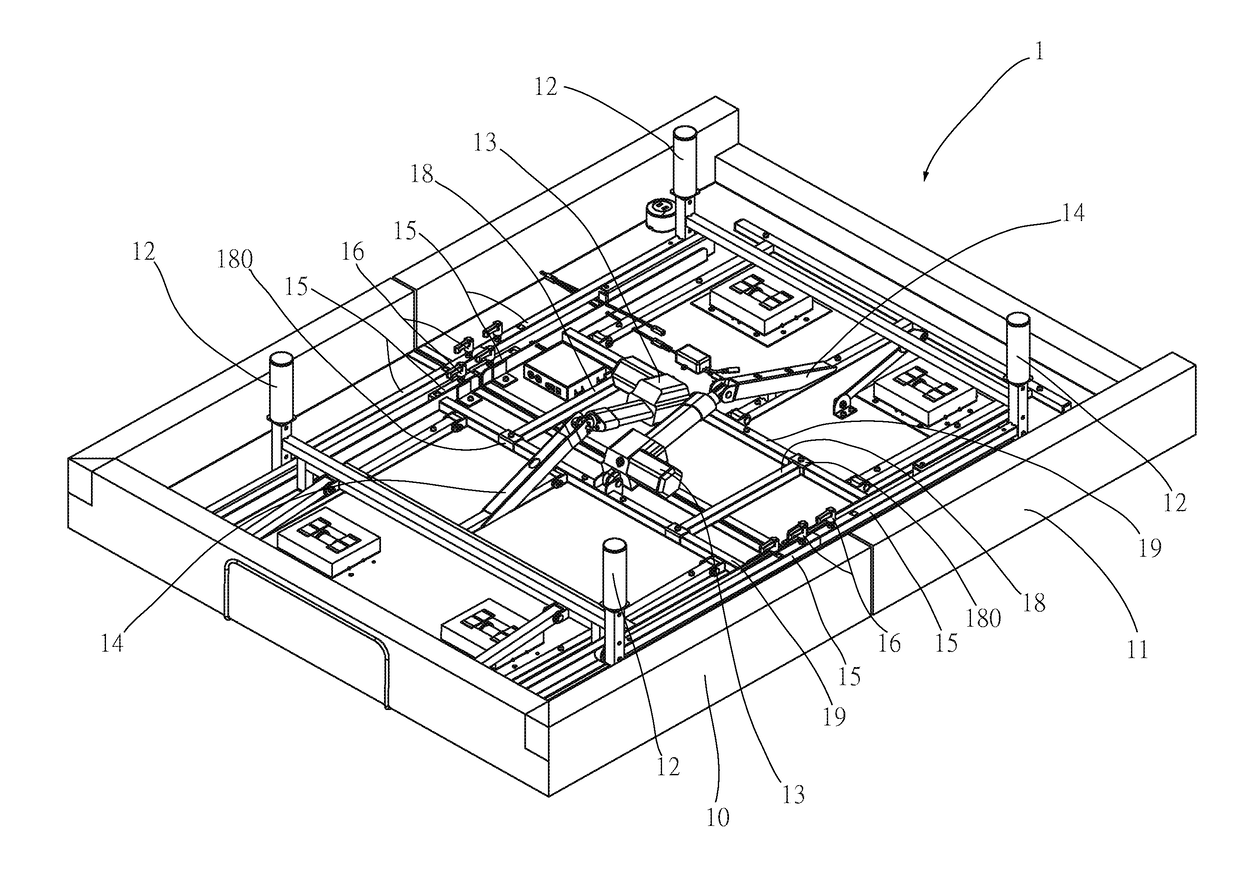

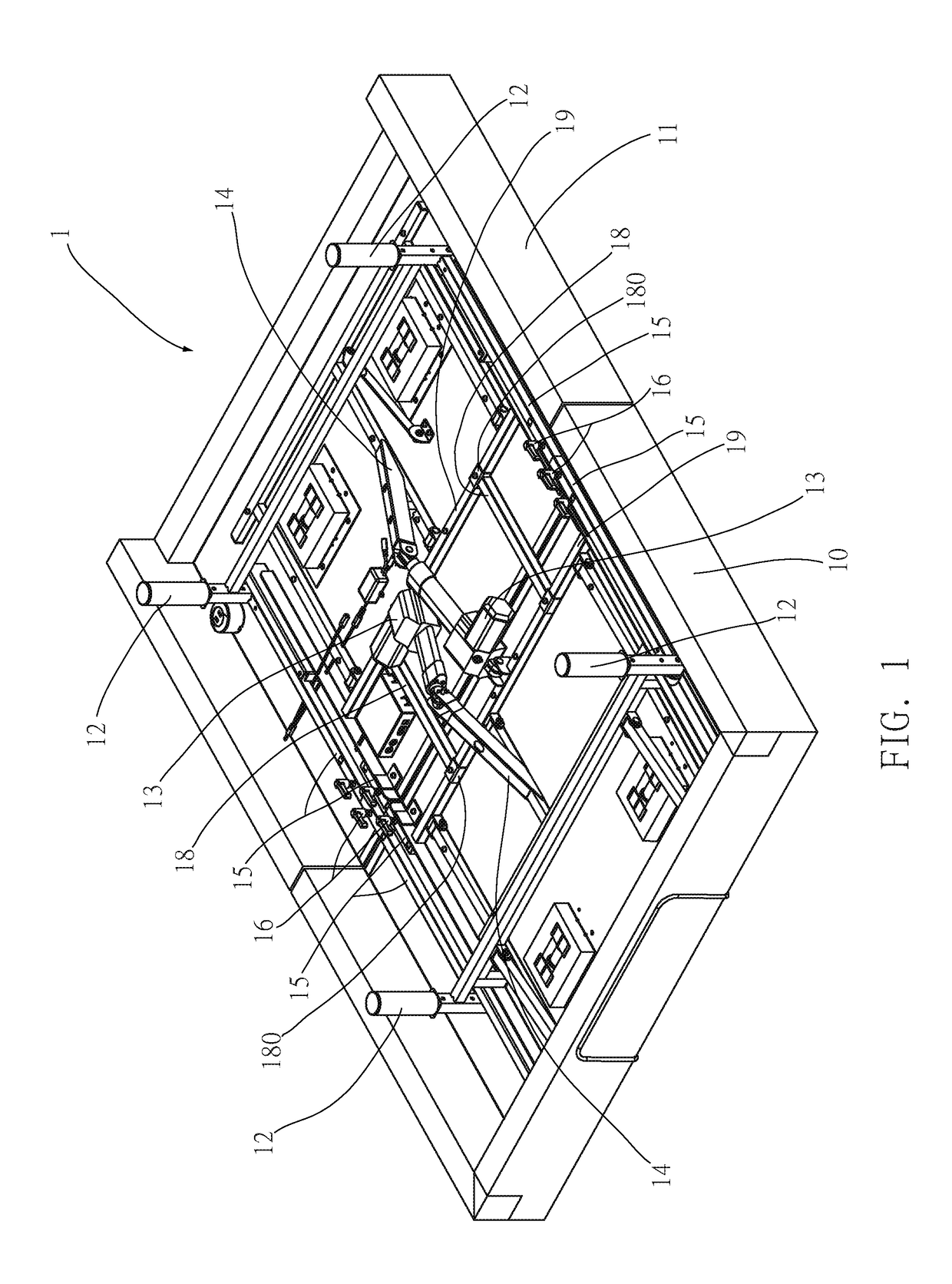

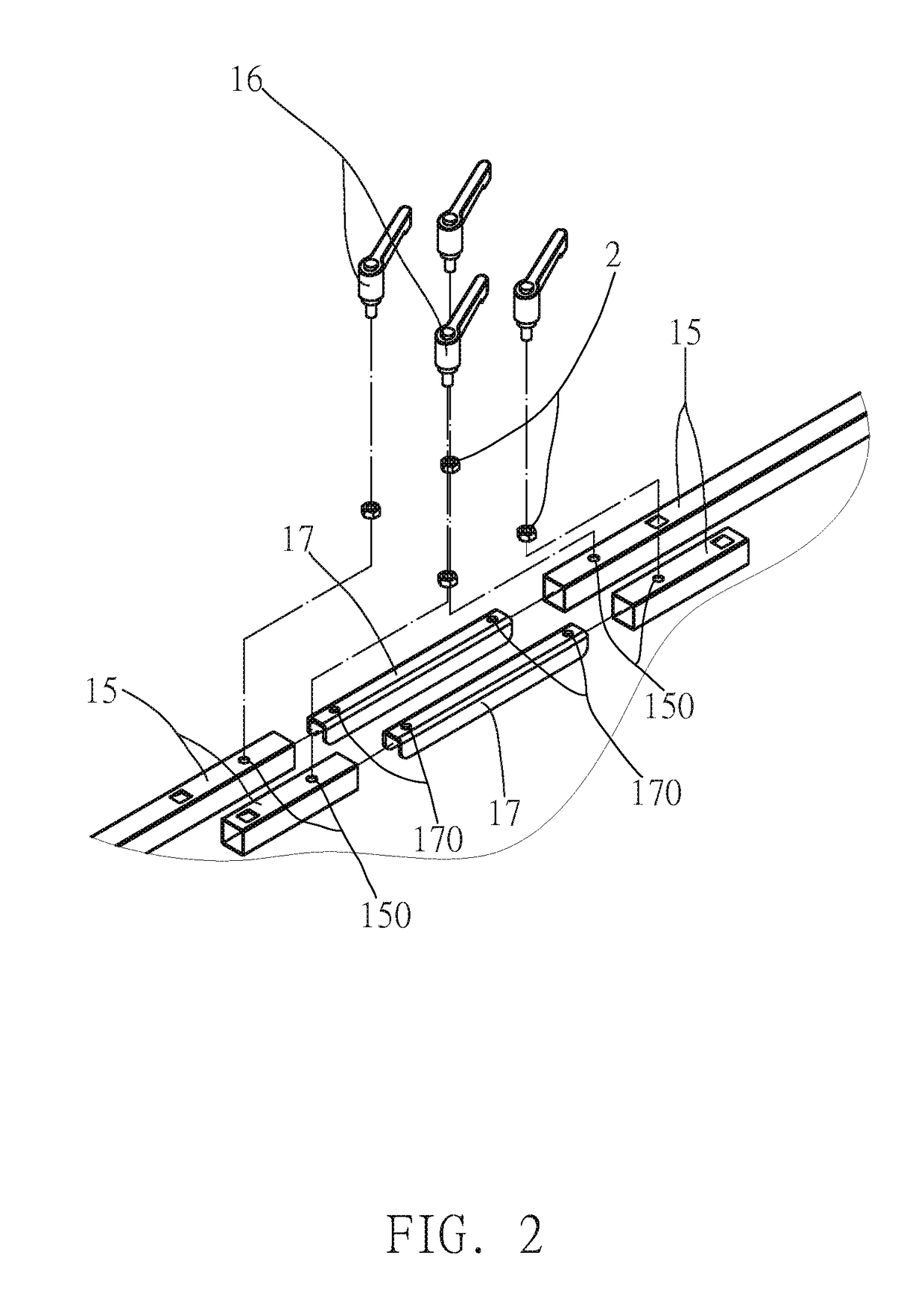

Intelligent cloth cutting device for garment processing

The invention discloses an intelligent cloth cutting device for garment processing and relates to the technical field of garment processing equipment. The device comprises a cutting table, a cutting mechanism, a first clamping mechanism, a second clamping mechanism and a yardage roll supporting rack; the cutting mechanism is fixedly arranged on the upper surface of the cutting table through a support; the first clamping mechanism and the second clamping mechanism are slidingly arranged on the upper surface of the cutting table, the first clamping mechanism is located at the left side of the cutting mechanism, and the second clamping mechanism is located at the right side of the cutting mechanism; infrared distance sensors are arranged at the opposite sides of the second clamping mechanismand the first clamping mechanism; the yardage roll supporting rack is fixedly arranged on the cutting table. According to the intelligent cloth cutting device, through cooperation of the first clamping mechanism and the second clamping mechanism, cloth is pulled out, the labor intensity of manually pulling the cloth by workers is reduced, the length of the cut cloth is determined according to theinfrared distance sensors, it can be guaranteed that the lengths of the cut cloth every time are identical, and the waste caused by different lengths of the cut cloth is avoided.

Owner:安徽上造智能设备科技有限公司

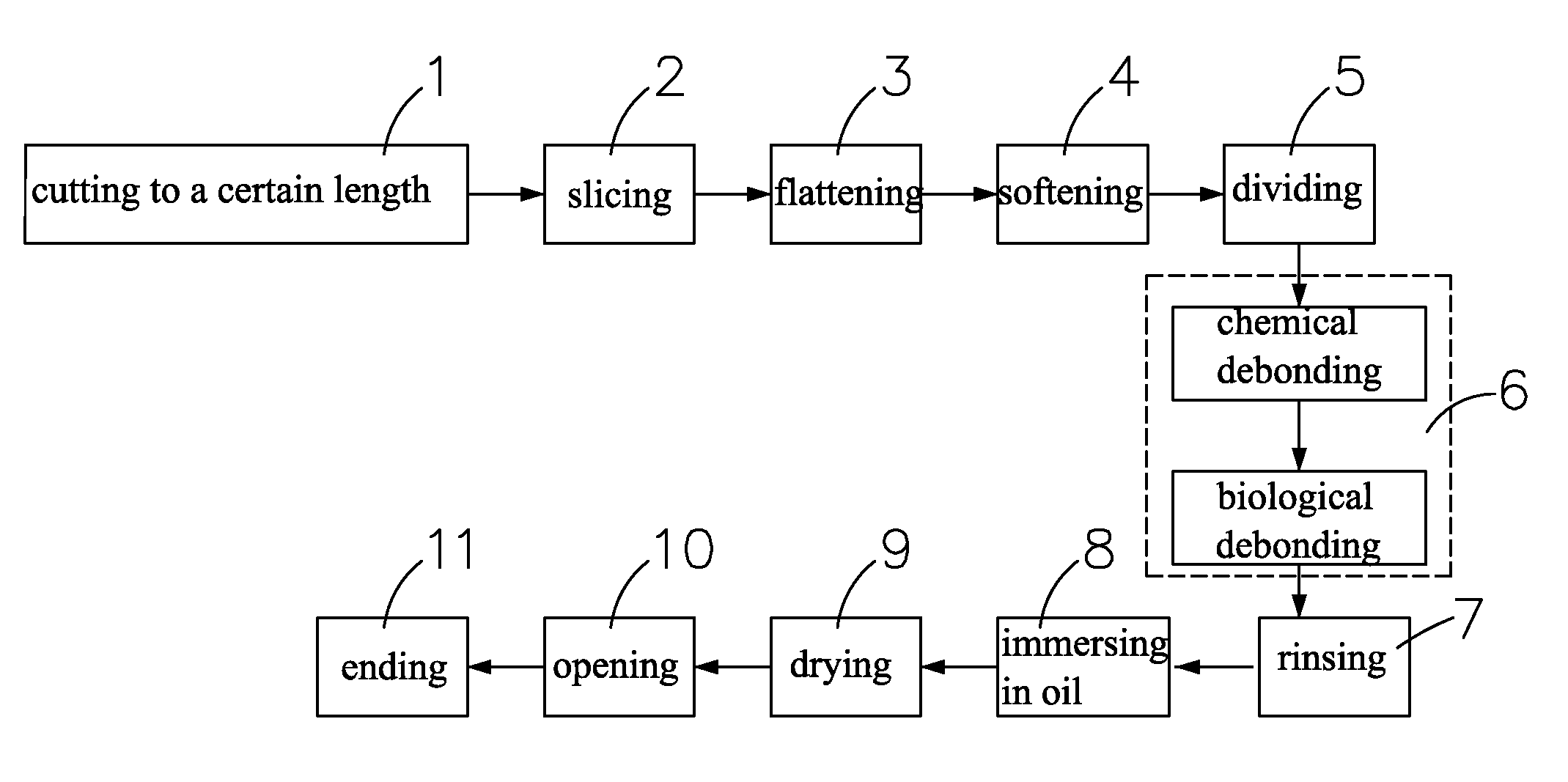

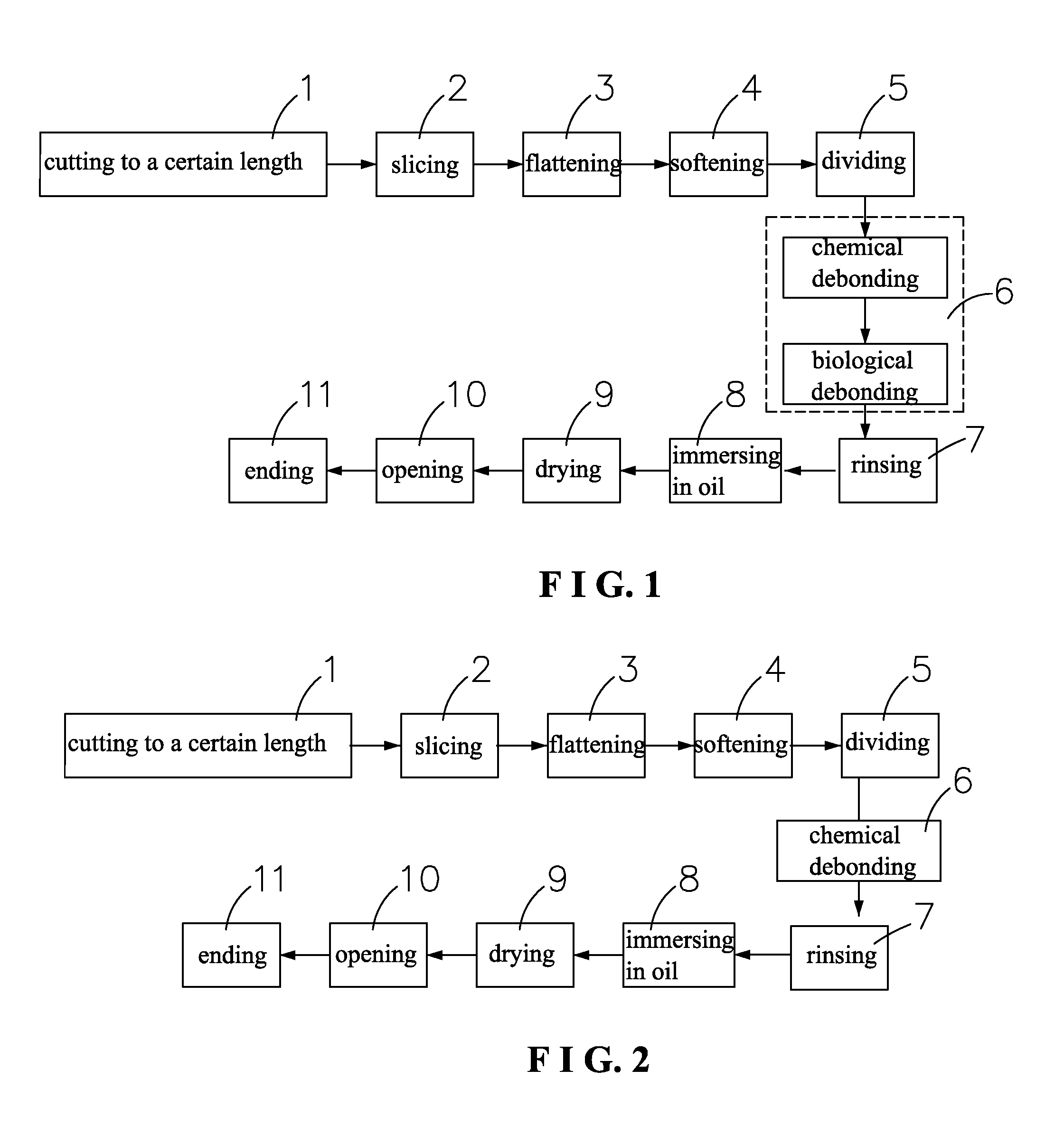

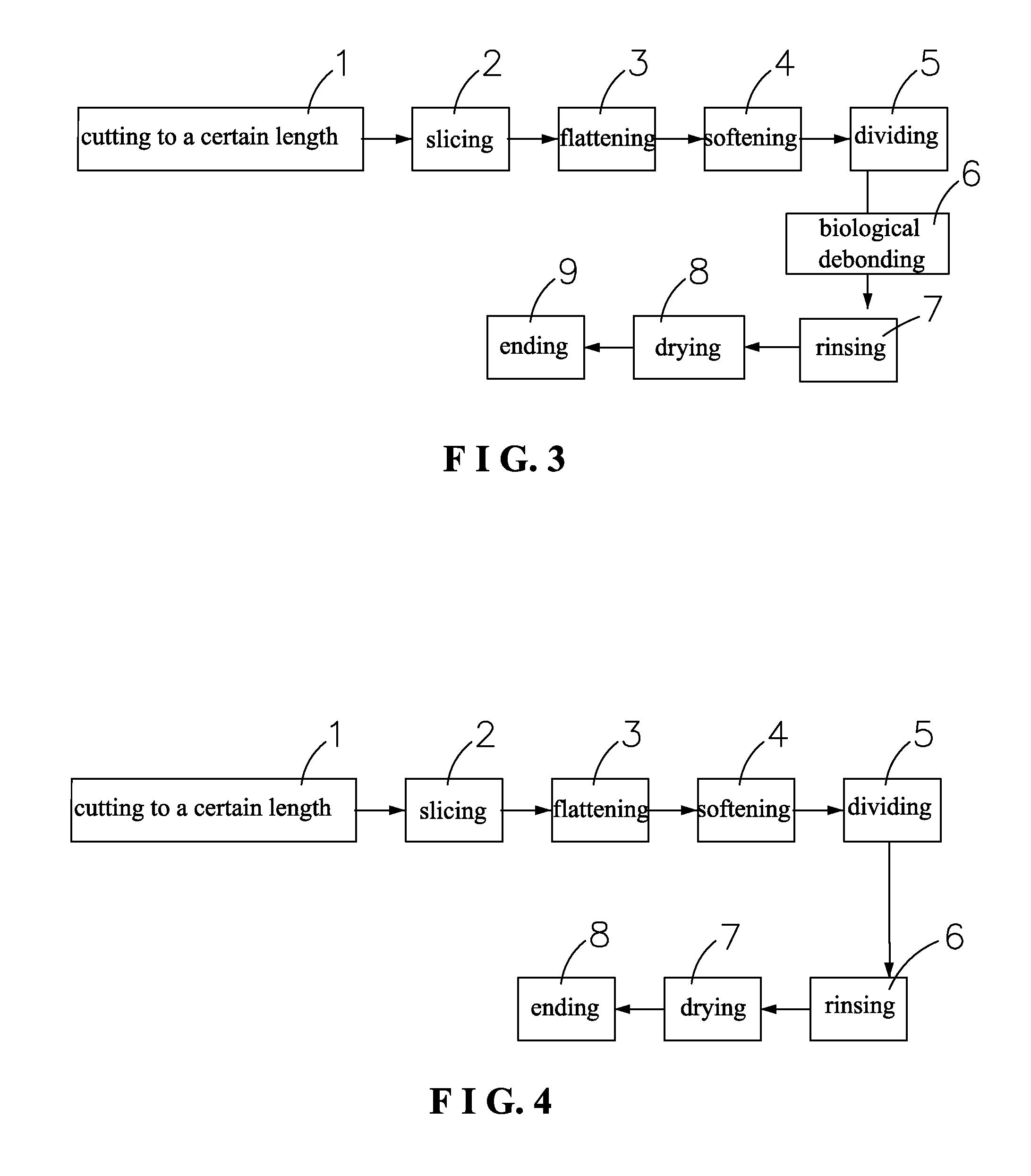

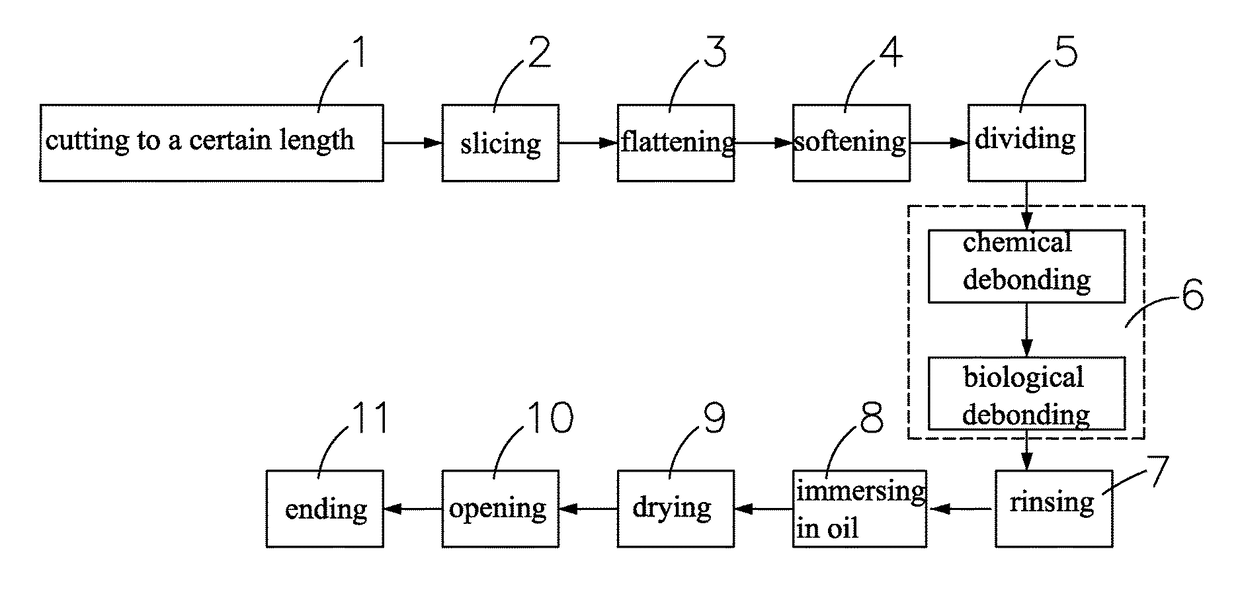

Production technology for natural bamboo fibers

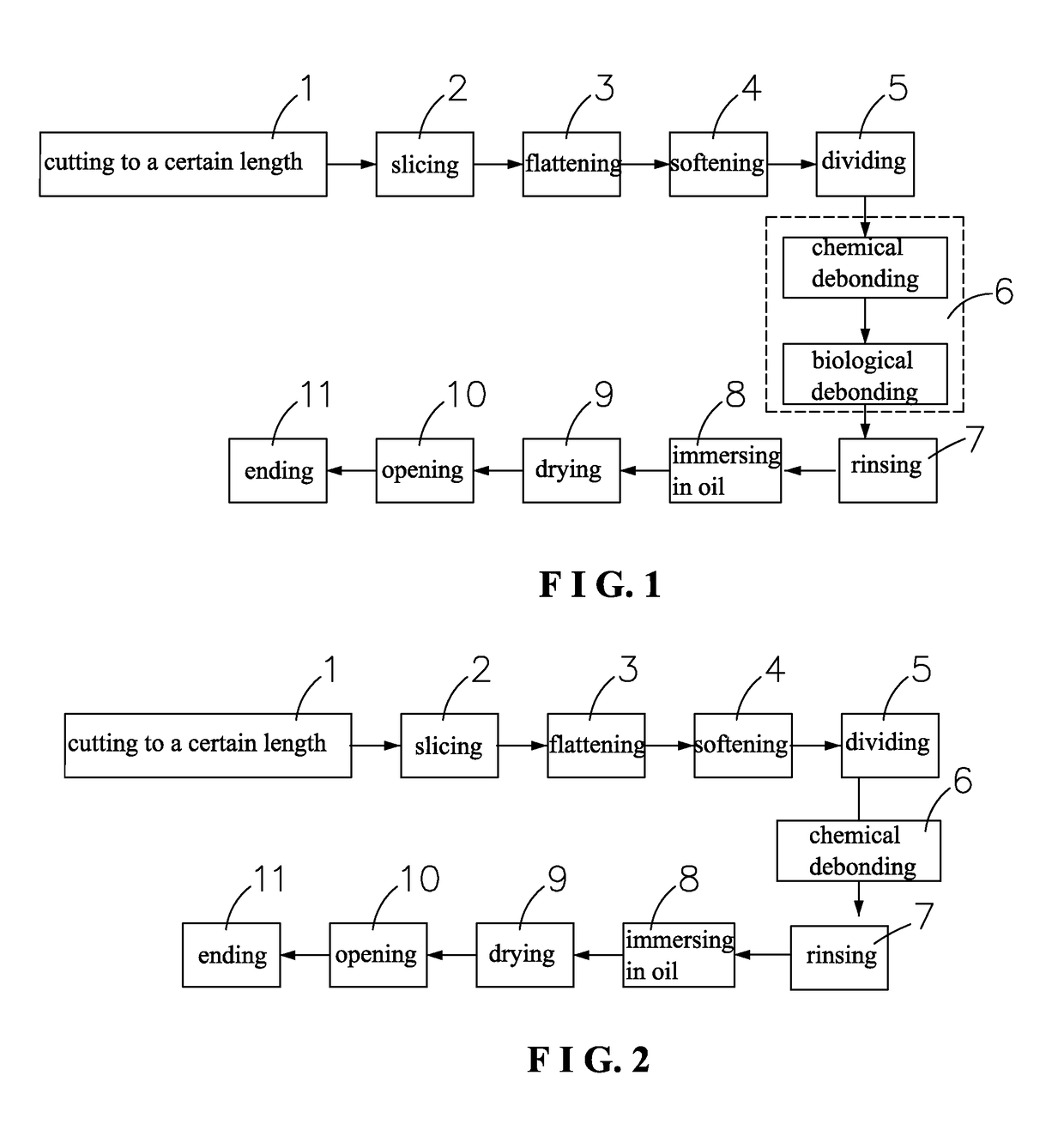

ActiveUS20140000761A1Simple and high-efficient producing methodImprove adaptabilityWood working apparatusPlant material mechanical workingFiberMaterials science

A production technology for natural bamboo fibers is applied in producing woven bamboo fibers, non-woven bamboo fibers, and reinforcing composite bamboo fibers. The woven bamboo fibers are produced by steps of cutting to a certain length, slicing, flattening, softening, dividing, debonding, rinsing, soaking in oil, drying, and opening. The non-woven bamboo fibers and the reinforcing composite bamboo fibers are produced by steps of cutting to a certain length, slicing, flattening, softening, dividing, debonding (optional), rinsing, and drying.

Owner:ZHANG YI

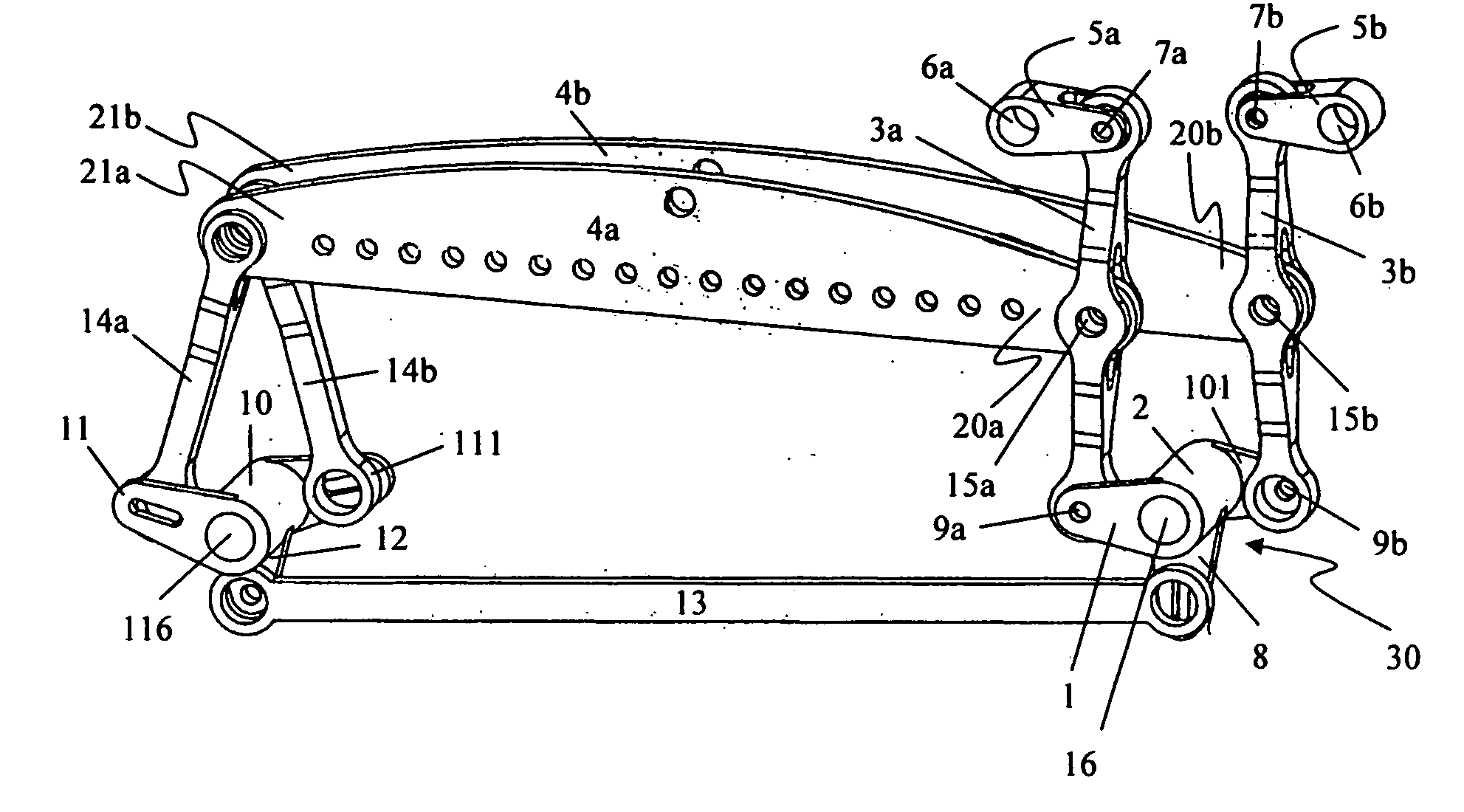

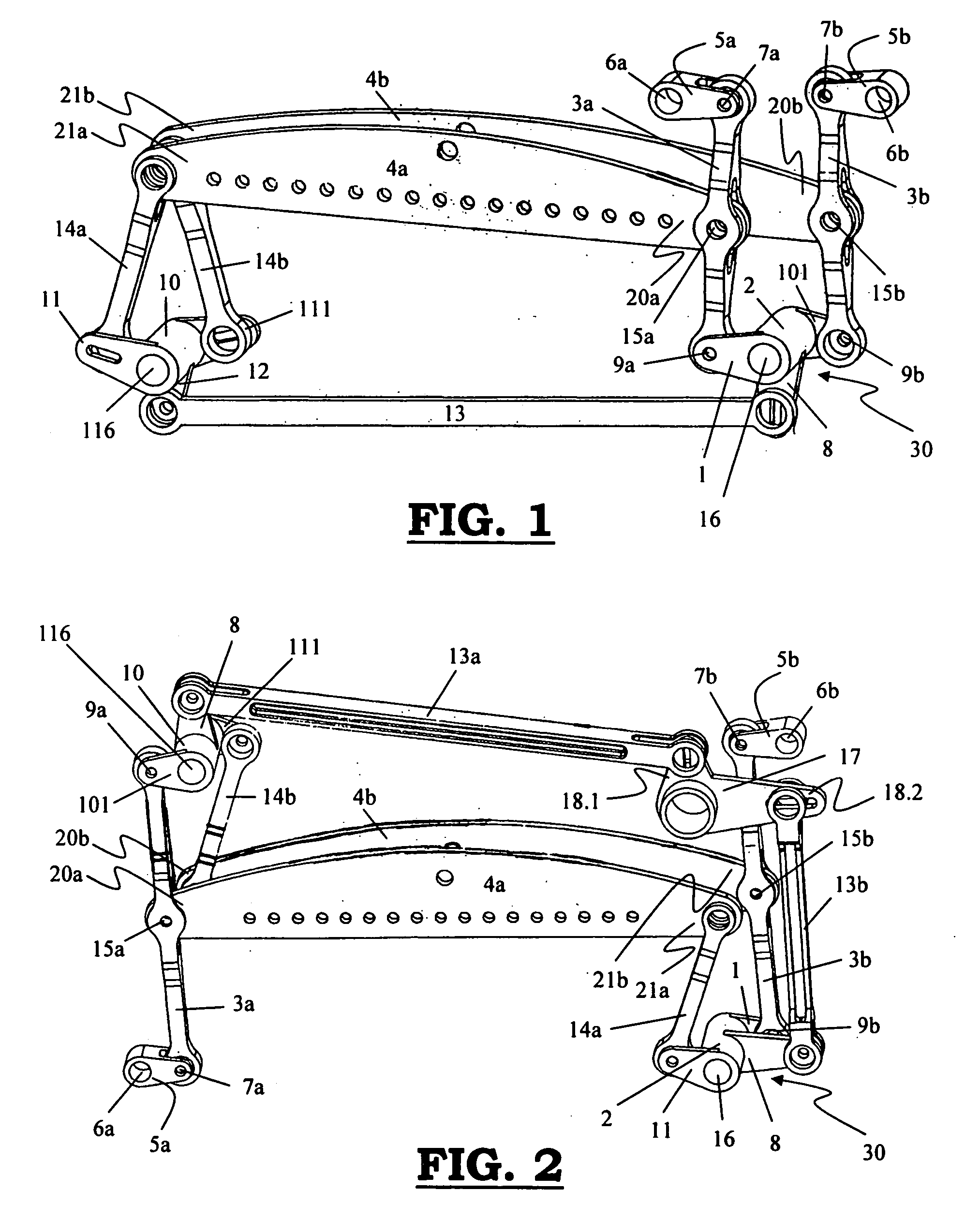

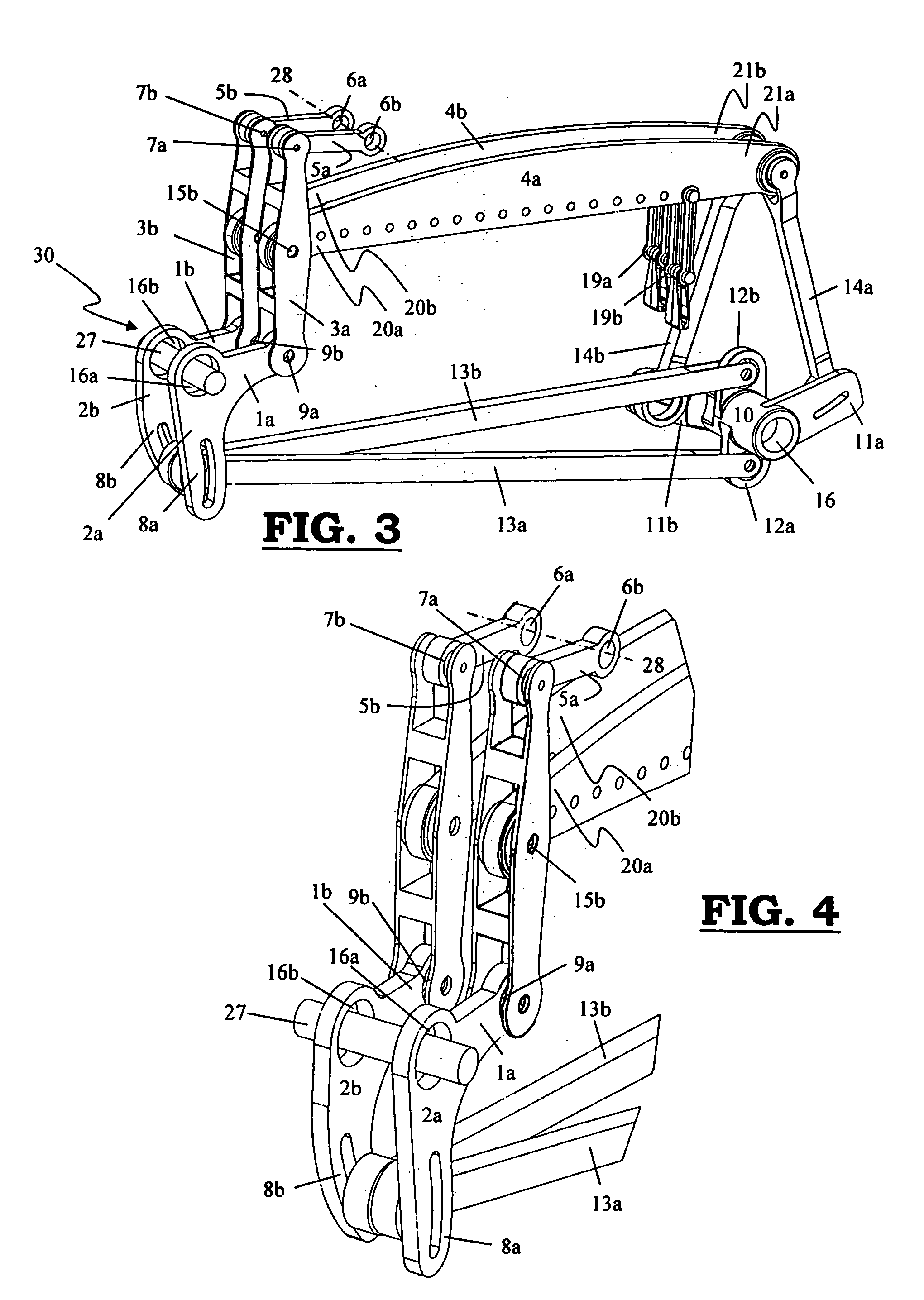

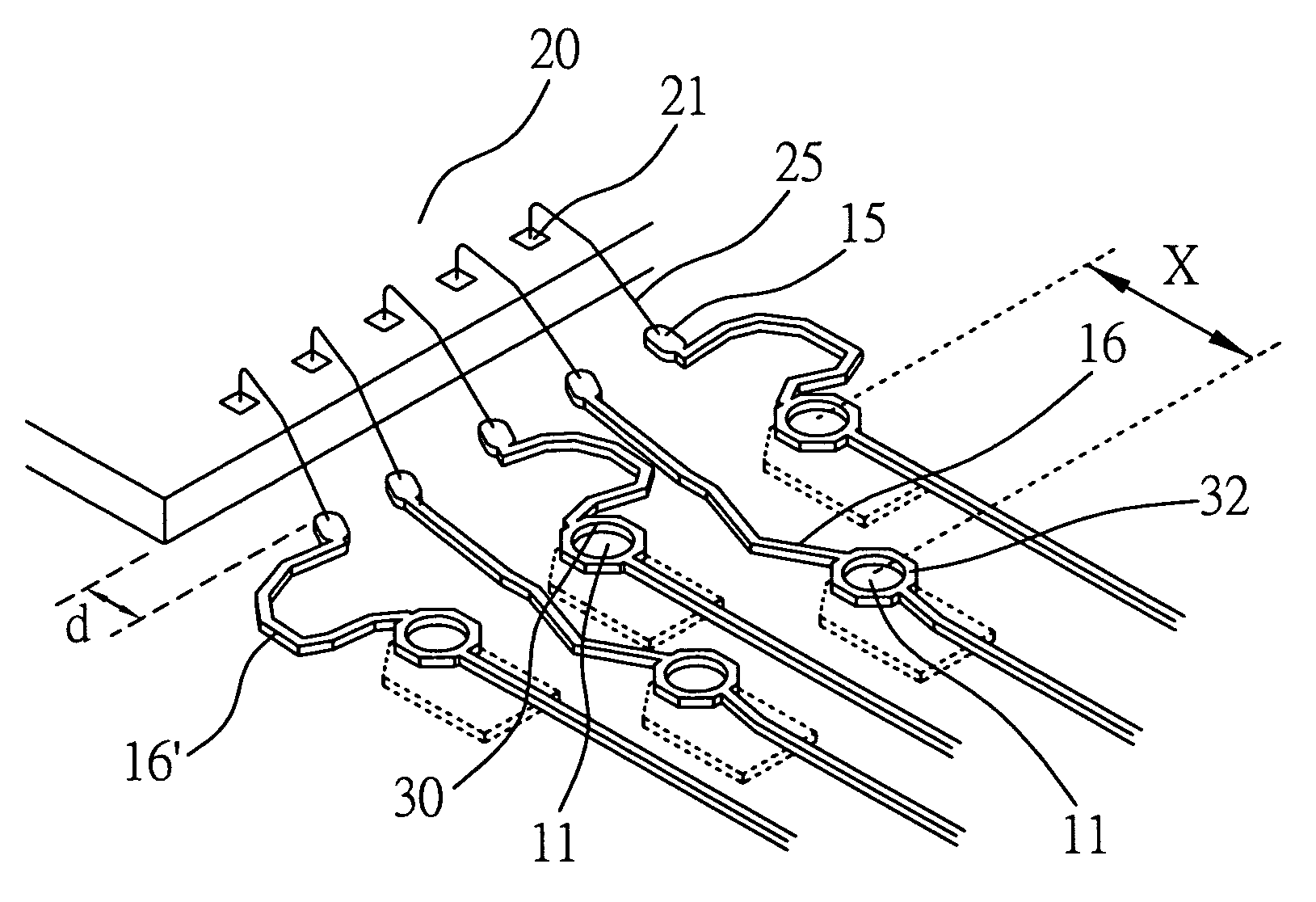

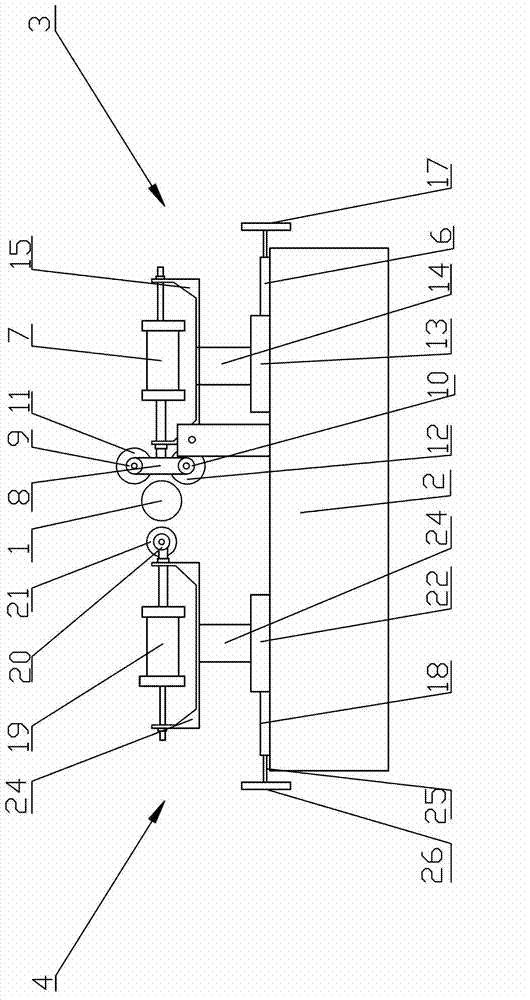

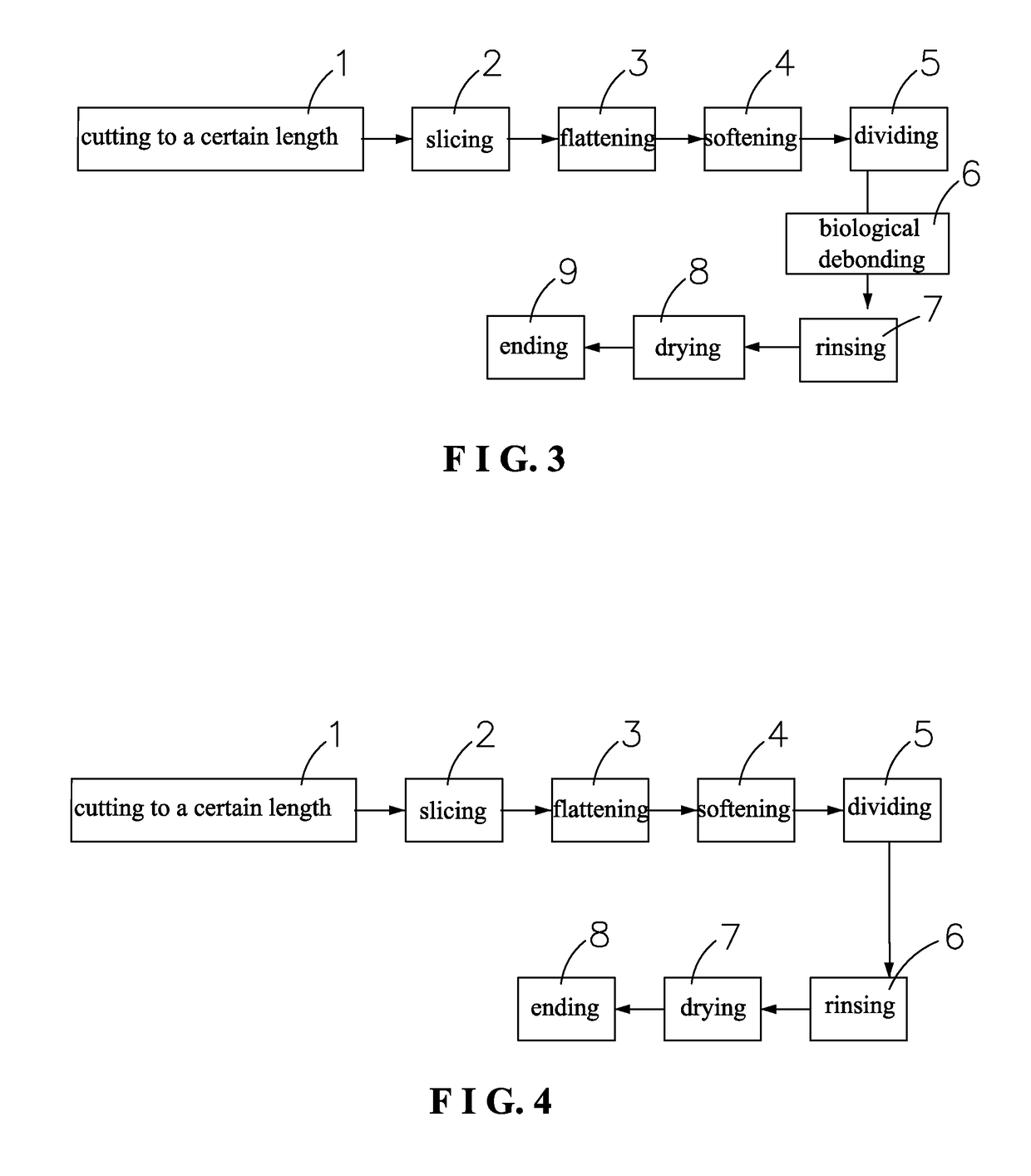

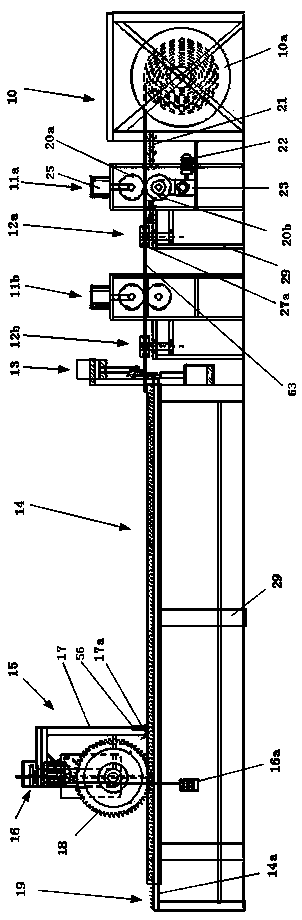

Jacquard machine

The invention relates to a Jacquard machine, comprising 2 sets of knifes moving up and down in opposition, which each, at each of their extremities, are taken up in separate knife grids (4a, 4b) being driven by a cinematic drive chain (30), and each, at one of their extremities (20a, 20b), being guided into a straight motion by means of a “Watt's linkage” rod system, the height of lift of each of these extremities (20a, 20b) of the knife grids (4a, 4b) being adjustable, and the knife grids (4a, 4b) each at their first extremities (20a, 20b) being linked with at least one first driving lever (2, 2a, 2b, 10) by means of a first linking rod (3a, 3b), and at their second extremities (21a, 21b) being linked with at least a second driving lever (2, 10) by means of a second linking rod (14a, 14b), wherein per knife grid (4a, 4b) one or several elements (1, 101, 1a, 1b, 3a, 3b) of the Watt's linkage rod system are part of the cinematic drive chain (30), and the amplitude of the motion of the said extremity (20a, 20b) of the knife grid (4a, 4b) is adjustable in the cinematic drive chain (30) before the linking point (9a, 9b) between the first rod (1, 101, 1a, 1b) and the third rod (3a, 3b) of the Watt's linkage rod system with respect to the drive motor.

Owner:VAN DE WIELE MICHEL

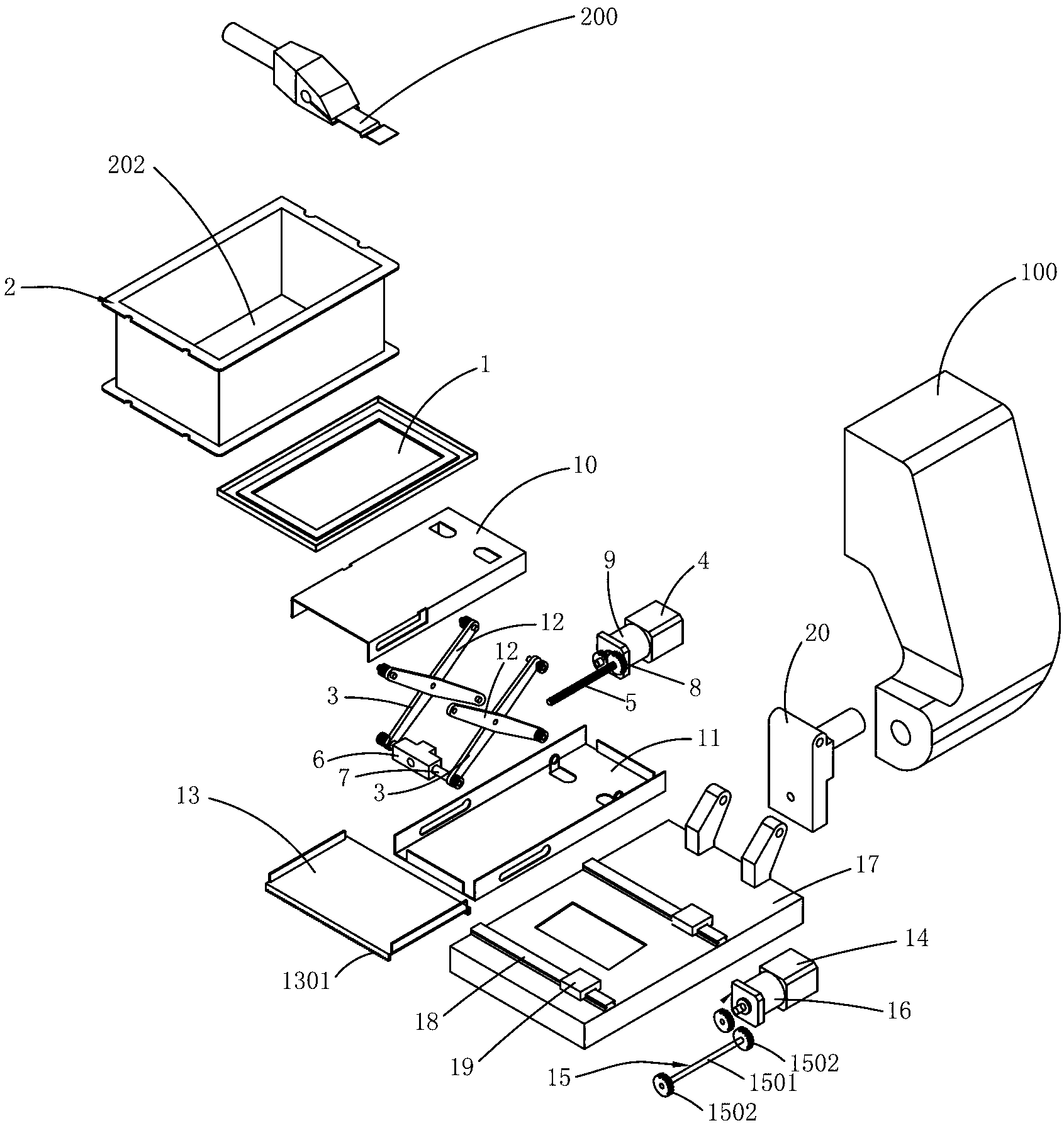

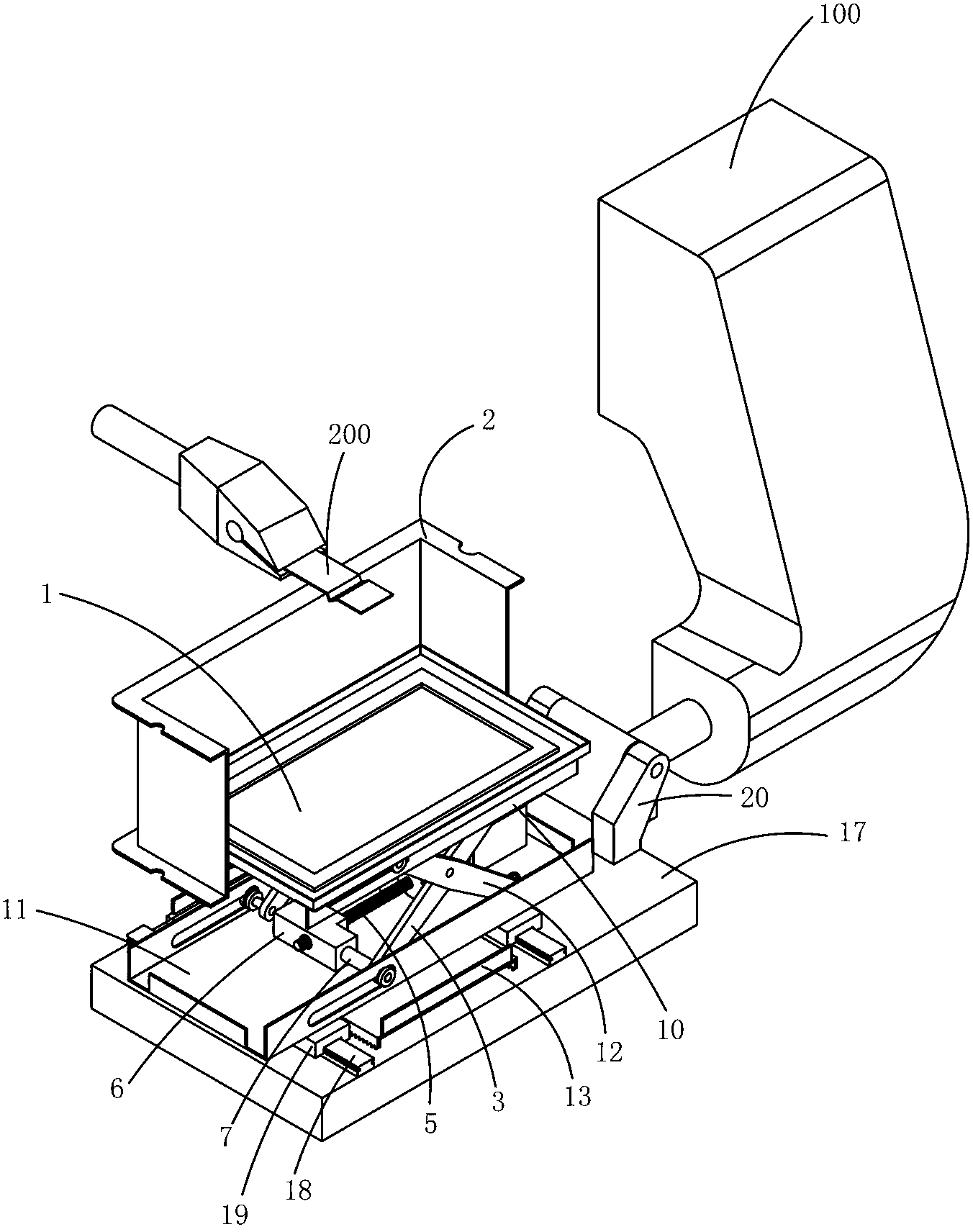

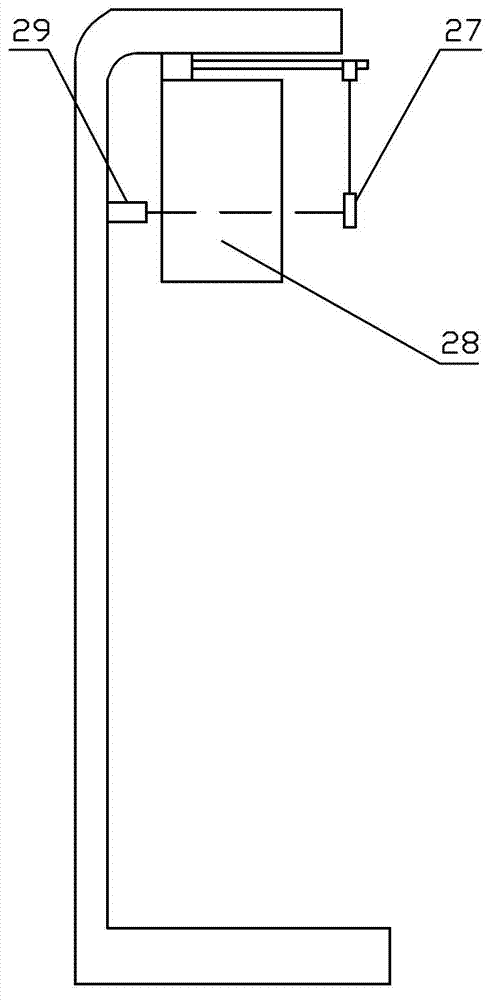

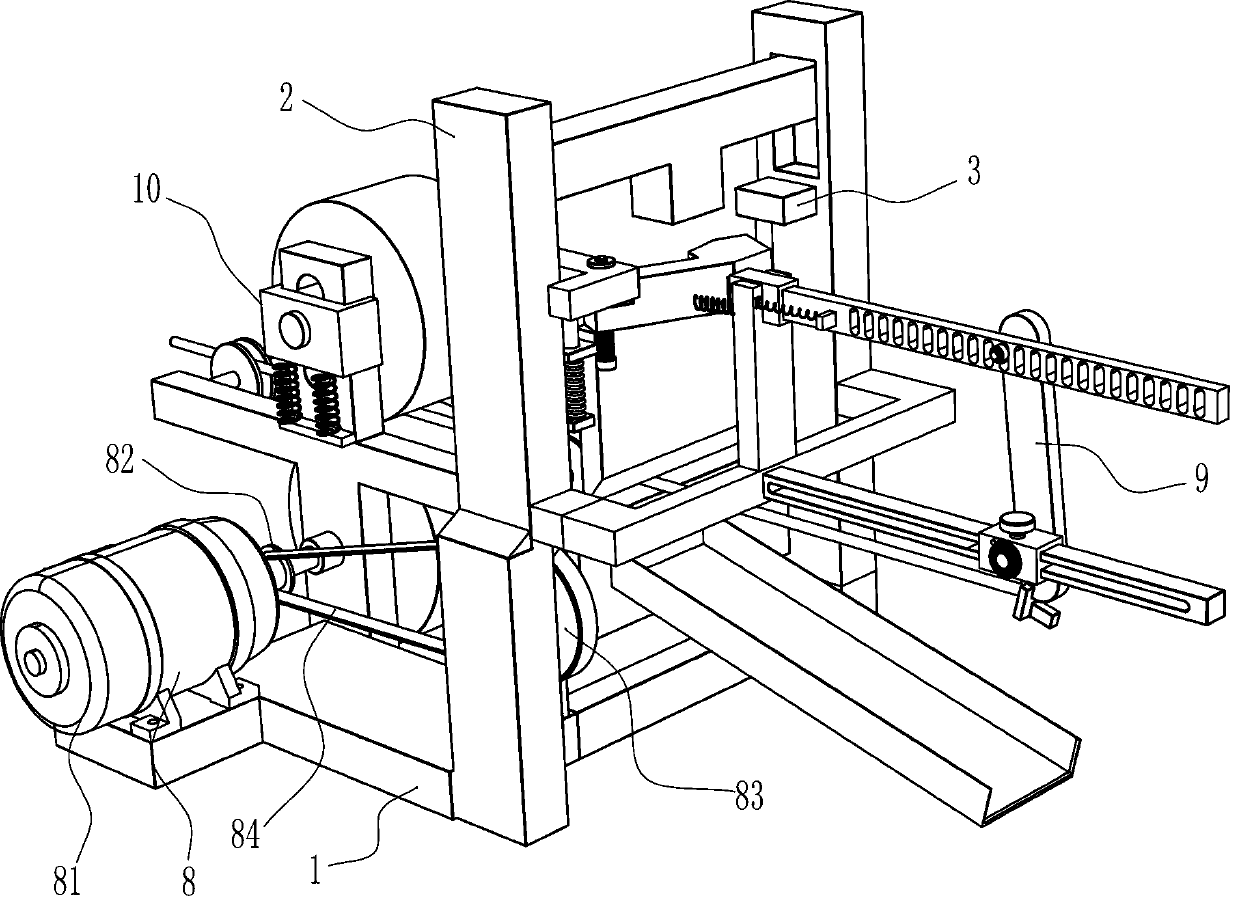

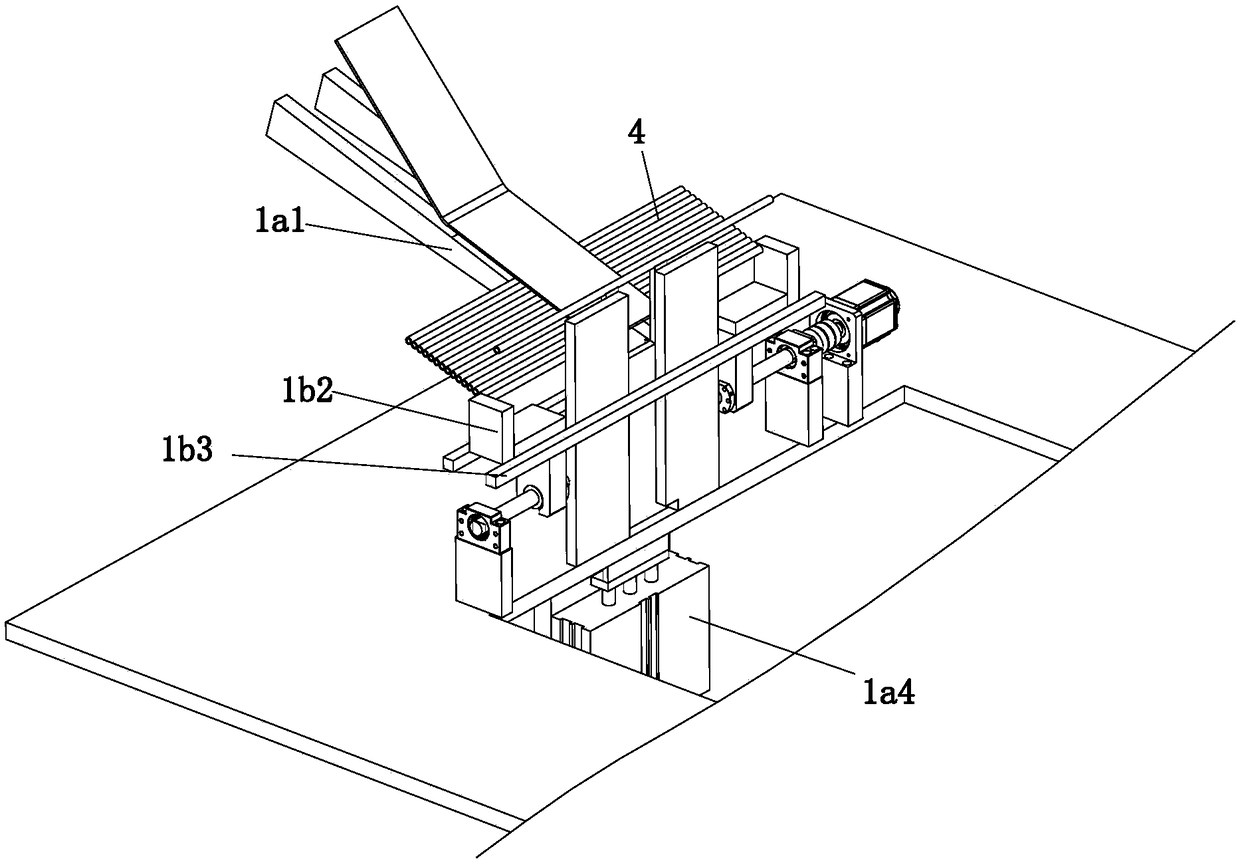

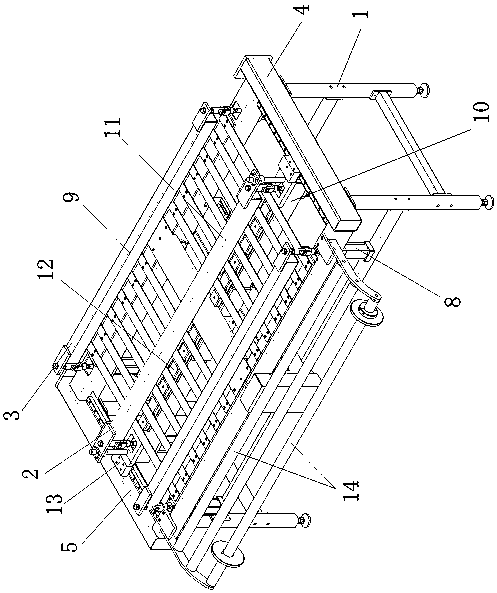

Precise automatic noodle transporting device and dough push control method of sliced noodle robot

ActiveCN103262874AAchieving Quantitative StandardsEqual lengthDough shaping and cutting apparatusDough processingEngineeringMechanical engineering

The invention relates to a precise automatic noodle transporting device and a dough push control method of a sliced noodle robot. The automatic noodle transporting device comprises a module guide mechanism for containing a dough, and a dough push device, wherein the module guide mechanism comprises a module guide frame and a support plate, the module guide frame is a rectangular container with an upper opening and a lower opening and is covers the support plate, and the support plate is arranged in a rectangular space of the module guide frame in a way of sliding up and down. The dough push device supports the support plate, and comprises a first push mechanism which enables the support plate to move along a first direction. Due to the size and shape controlling actions and the moulding of the module guide frame, the size of the dough can be standard, so that the natural settlement deformation of the dough caused by long placing time or in a noodle slicing process can be avoided. After the first push mechanism is arranged, and the preset movement displacement of the first push mechanism is controlled, the relative place between a noodle slicing cutter and the dough can be precisely controlled, so that noodles with certain thickness and shape can be produced, the uniform thickness of the sliced noodles can be guaranteed, and the standardized production of the noodles can be realized.

Owner:SHENZHEN ALLOVE INTELLIGENT CATERING TECH

Continuous production method of unit honeycomb paper core

The invention discloses a continuous production method of a unit honeycomb paper core. The production method is characterized by comprising the following steps of: 1) feeding a plurality of rolls of core paper, and vertically coating a glue line on the core paper; 2) after gluing the core paper, combining and drying a plurality of the layers of the core paper; 3) after a plurality of the layers of the core paper are combined to be the paper core board, discontinuously gluing the paper core board by using an batch-type gluing device; 4) transversely cutting the paper core board into paper core strips after continuously gluing; and 5) collecting and solidly pressing the paper core strips, so as to obtain a continuous unit honeycomb paper core. With the adoption of the continuous production method provided by the invention, after the core paper is composited to be the paper core board, the paper core board is glued by using a continuous gluing manner, so that the unit type continuous honeycomb paper core is formed. With the adoption of the production method provided by the invention, the paper consumption is reduced; the operation is simpler and more convenient; and the continuous production method is more environment-friendly in a machining process.

Owner:启东市美迅机械有限公司

Exercise device including adjustable, inelastic straps

InactiveUS20060116252A1Easily vary length of deviceEffective centeringTherapy exerciseStiltsWhole bodyEngineering

Owner:JFXD TRX ACQ LLC

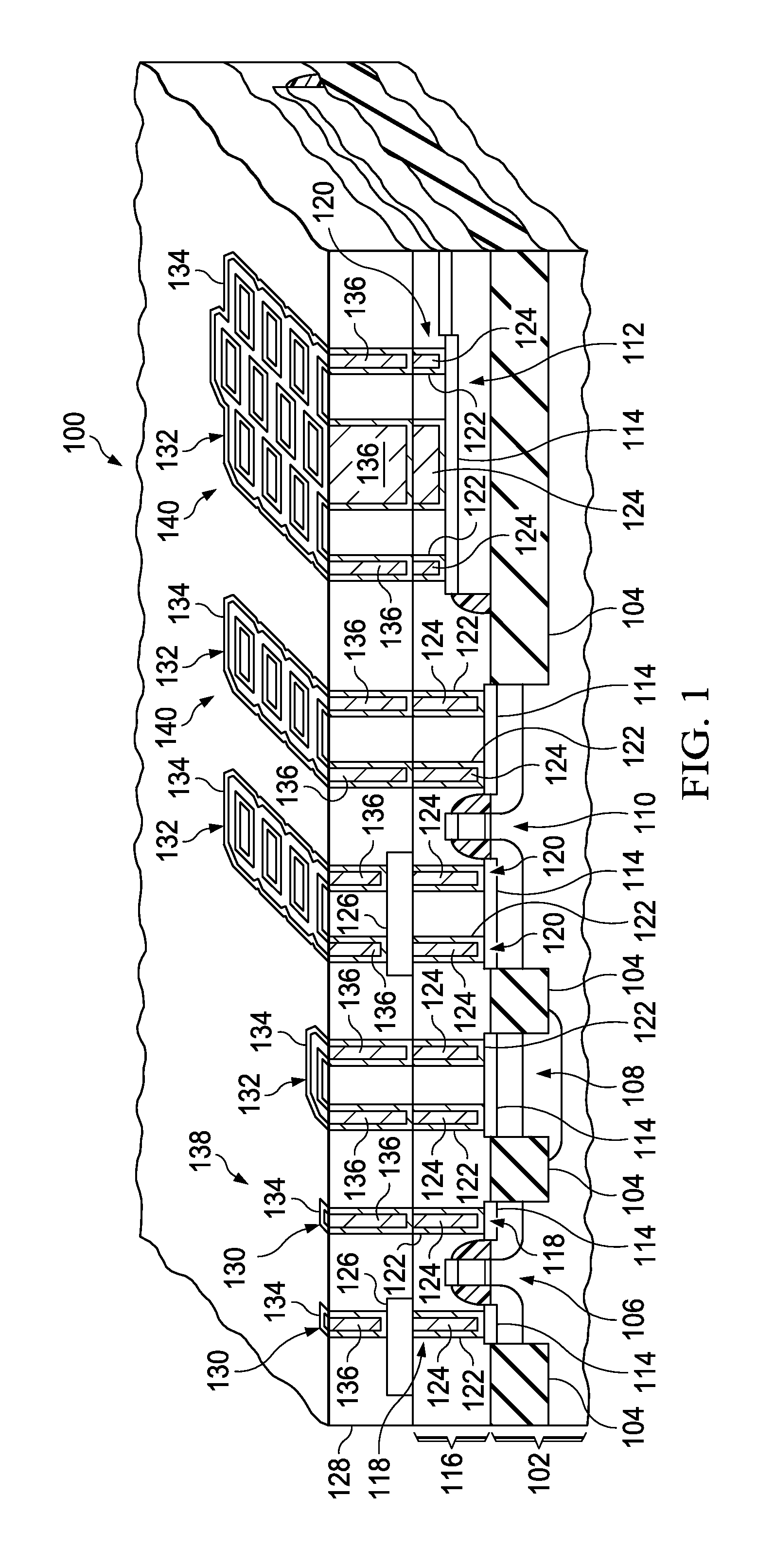

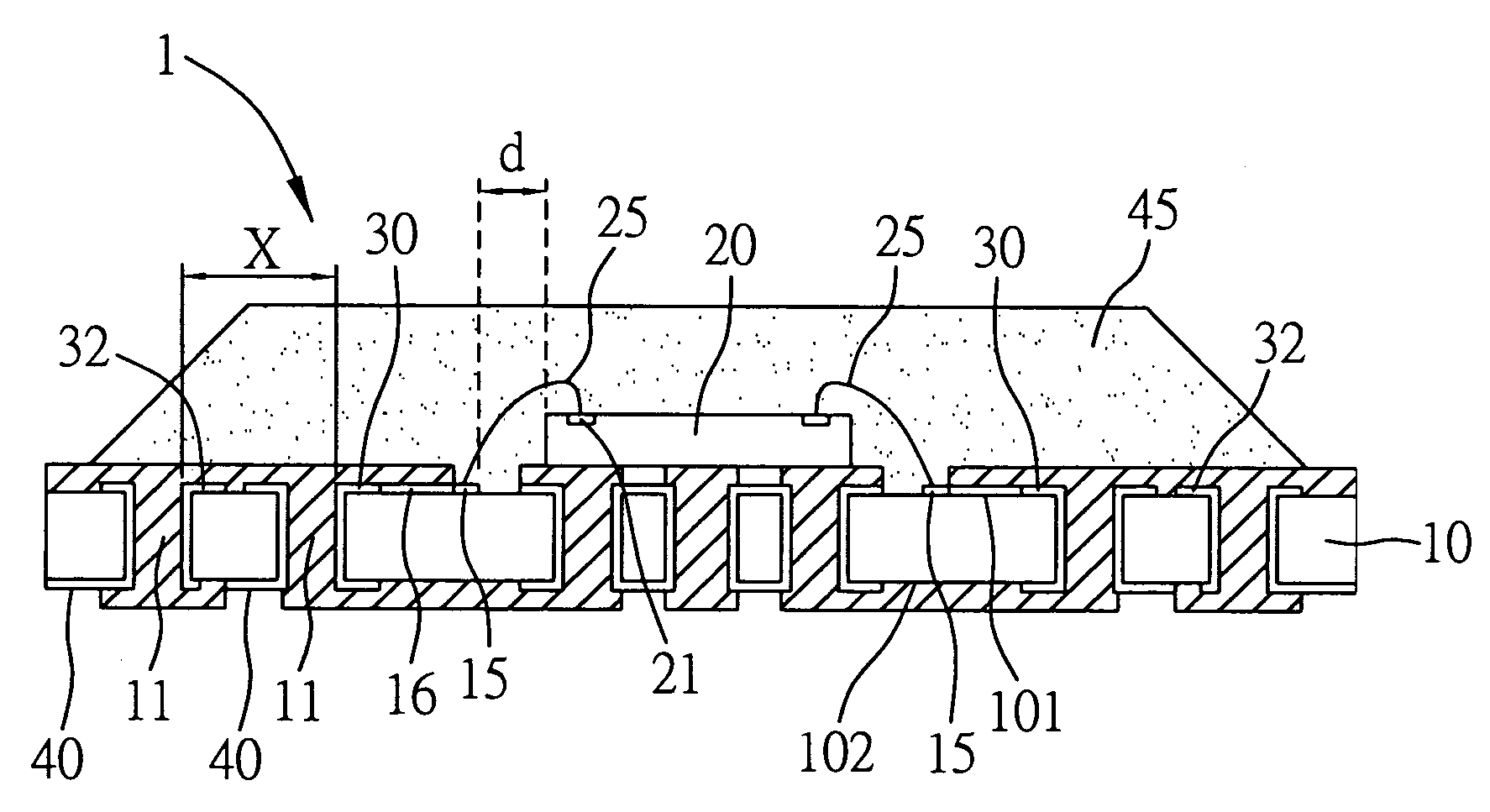

Low resistance stacked annular contact

ActiveUS20130082314A1Equal lengthEqual widthTransistorSemiconductor/solid-state device detailsMetal interconnectEngineering

An integrated circuit contains lower components in the substrate, a PMD layer, upper components over the PMD layer, lower contacts in the PMD layer connecting some upper components to some lower components, an ILD layer over the upper components, metal interconnect lines over the ILD layer, and upper contacts connecting some upper components to some metal interconnect lines, and also includes annular stacked contacts of lower annular contacts aligned with upper annular contacts. The lower contacts and upper contacts each have a metal liner and a contact metal on the liner. The lower annular contacts have at least one ring of liner metal and contact metal surrounding a pillar of PMD material, and the upper contacts have at least one ring of liner metal and contact metal surrounding a pillar of ILD material. The annular stacked contacts connect the metal interconnects to the lower components.

Owner:MIDWEST COMMUNITY DEV FUND IV +1

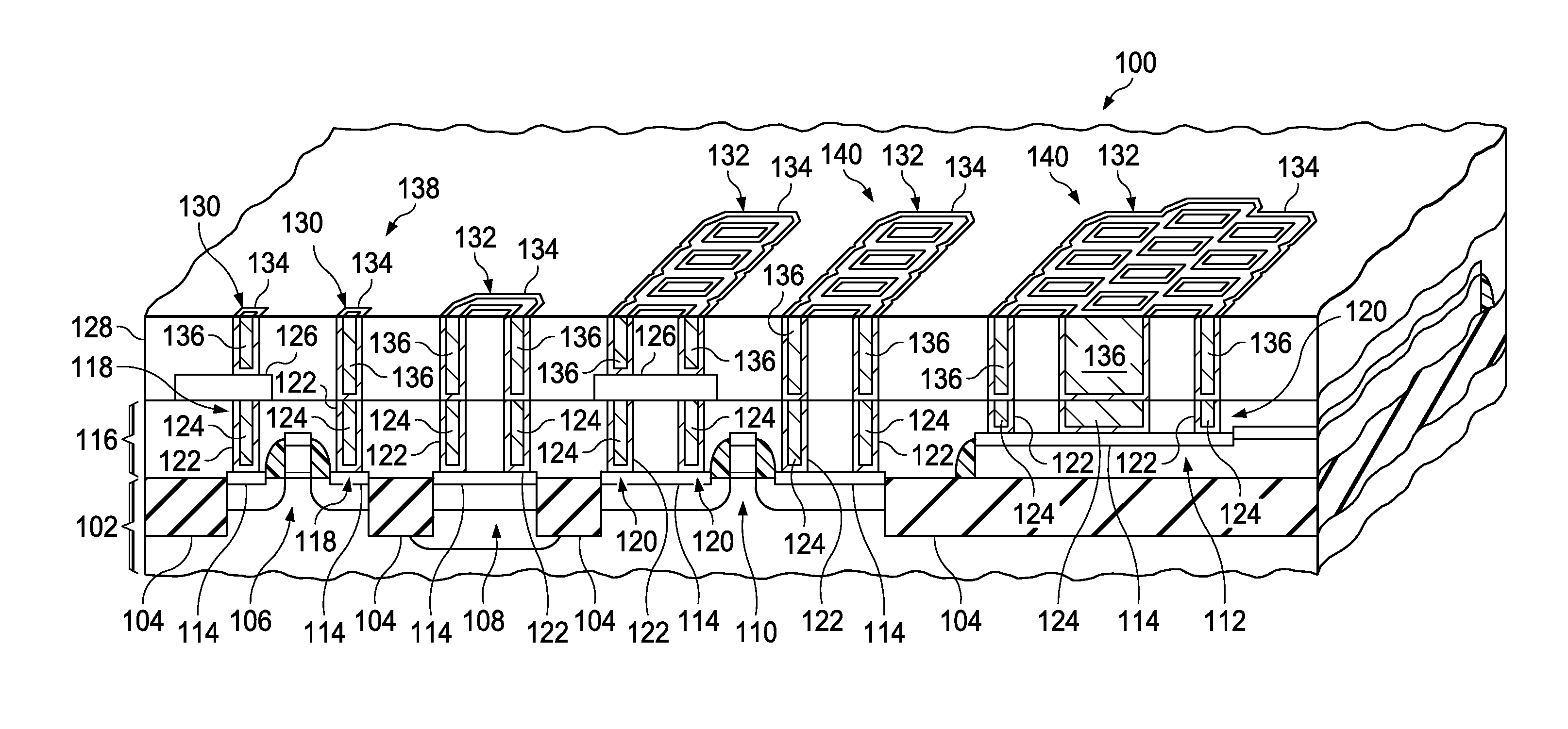

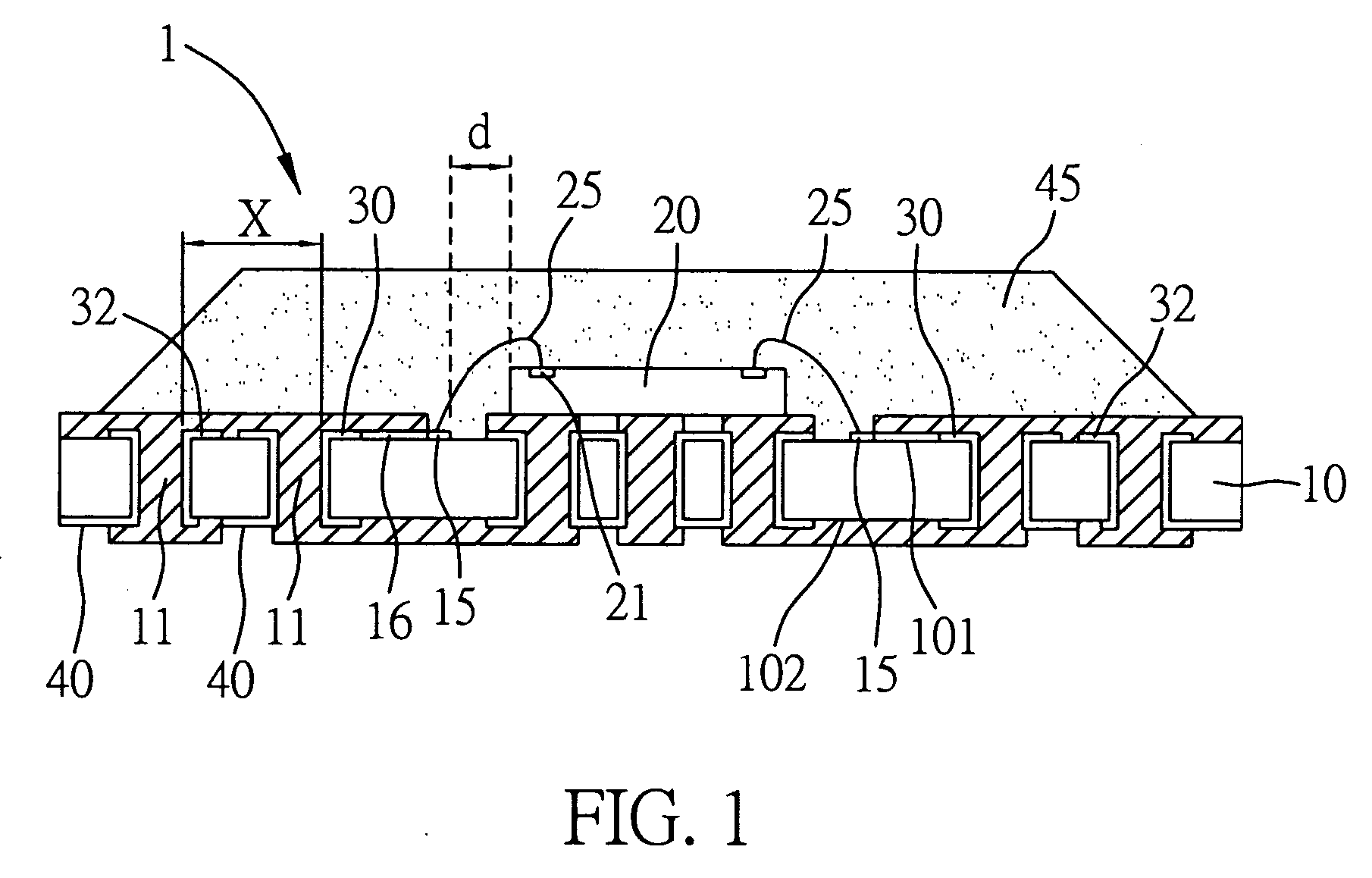

High electrical performance semiconductor package

ActiveUS7361846B2Improve electrical performanceShorten the lengthSemiconductor/solid-state device detailsPrinted electric component incorporationSemiconductor packageElectrical performance

A high electrical performance semiconductor package is proposed. A carrier is provided having a first surface, an opposite second surface, and conductive vias for electrically connecting the first surface to the second surface. A chip is attached to the first surface of the carrier. A plurality of via lands are disposed peripherally on the first surface of the carrier and electrically connected to the vias. A plurality of conductive regions are disposed on the second surface of the carrier and electrically connected to the vias. A plurality of fingers are disposed around the chip and electrically connected to the via lands by conductive traces formed on the first surface of the carrier. A plurality of bonding wires electrically connect the chip to the fingers. Lengths of the wires for transmitting differential pair signals are substantially equal, and lengths of the traces for transmitting the differential pair signals are substantially equal.

Owner:SILICONWARE PRECISION IND CO LTD

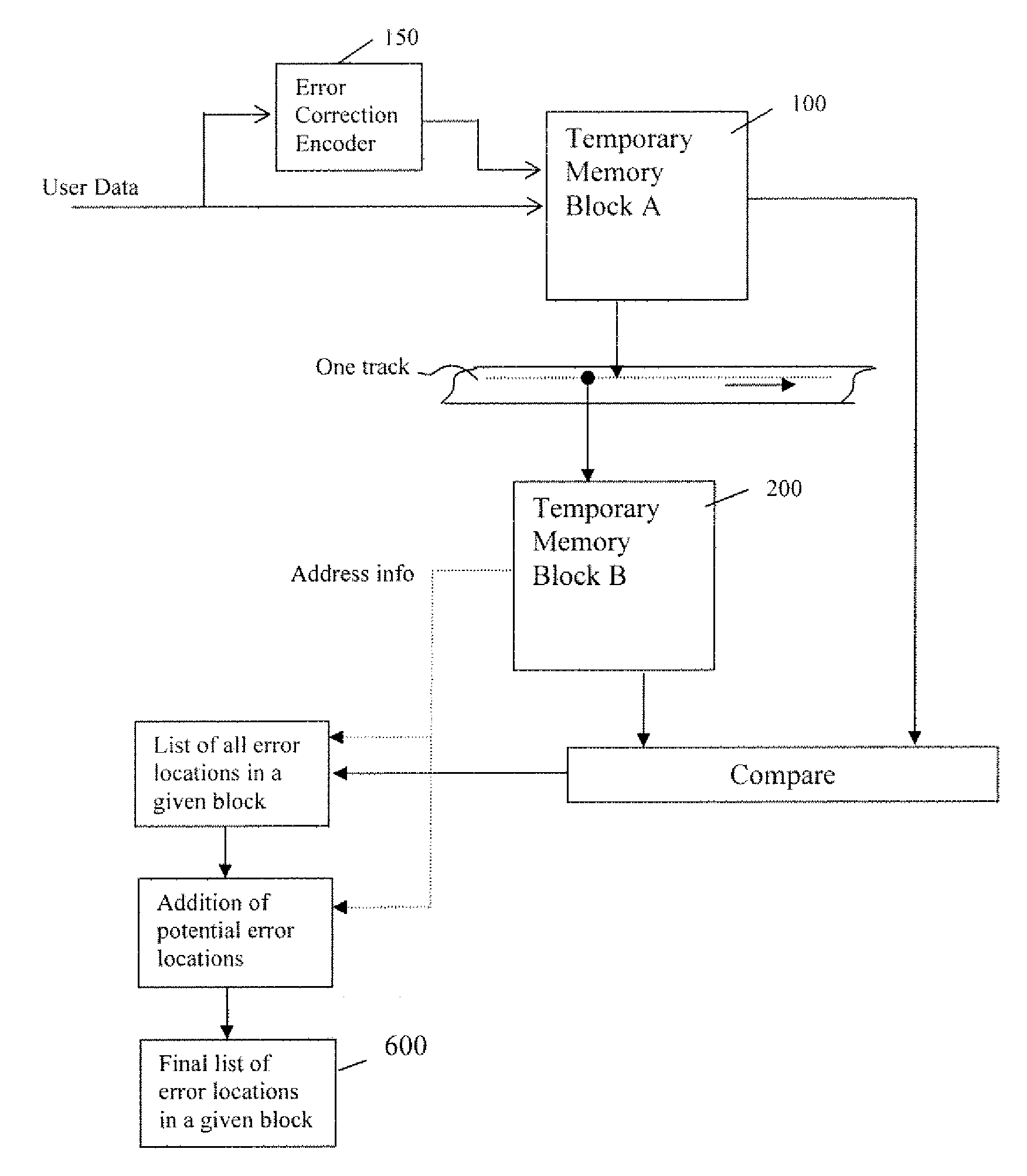

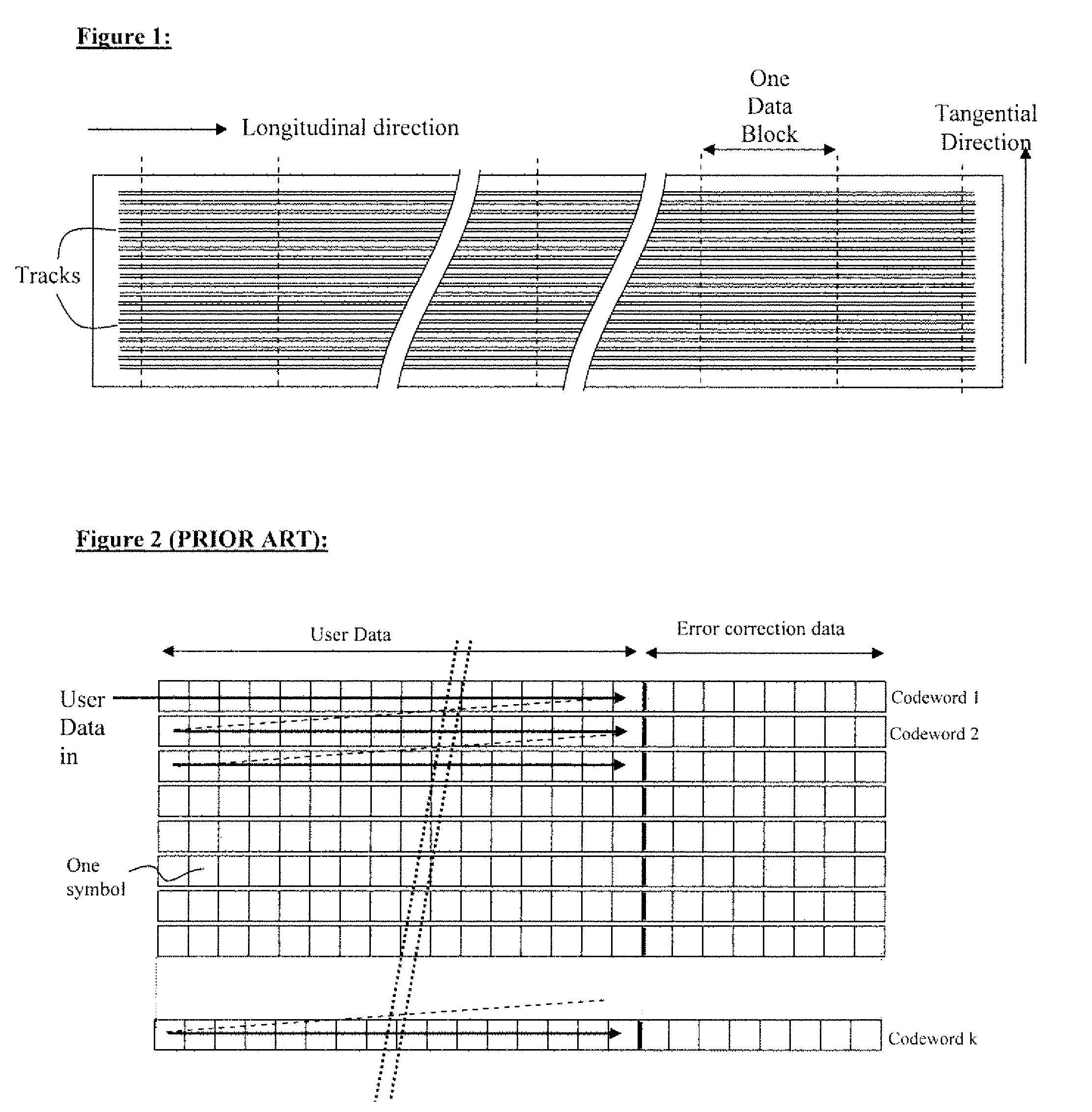

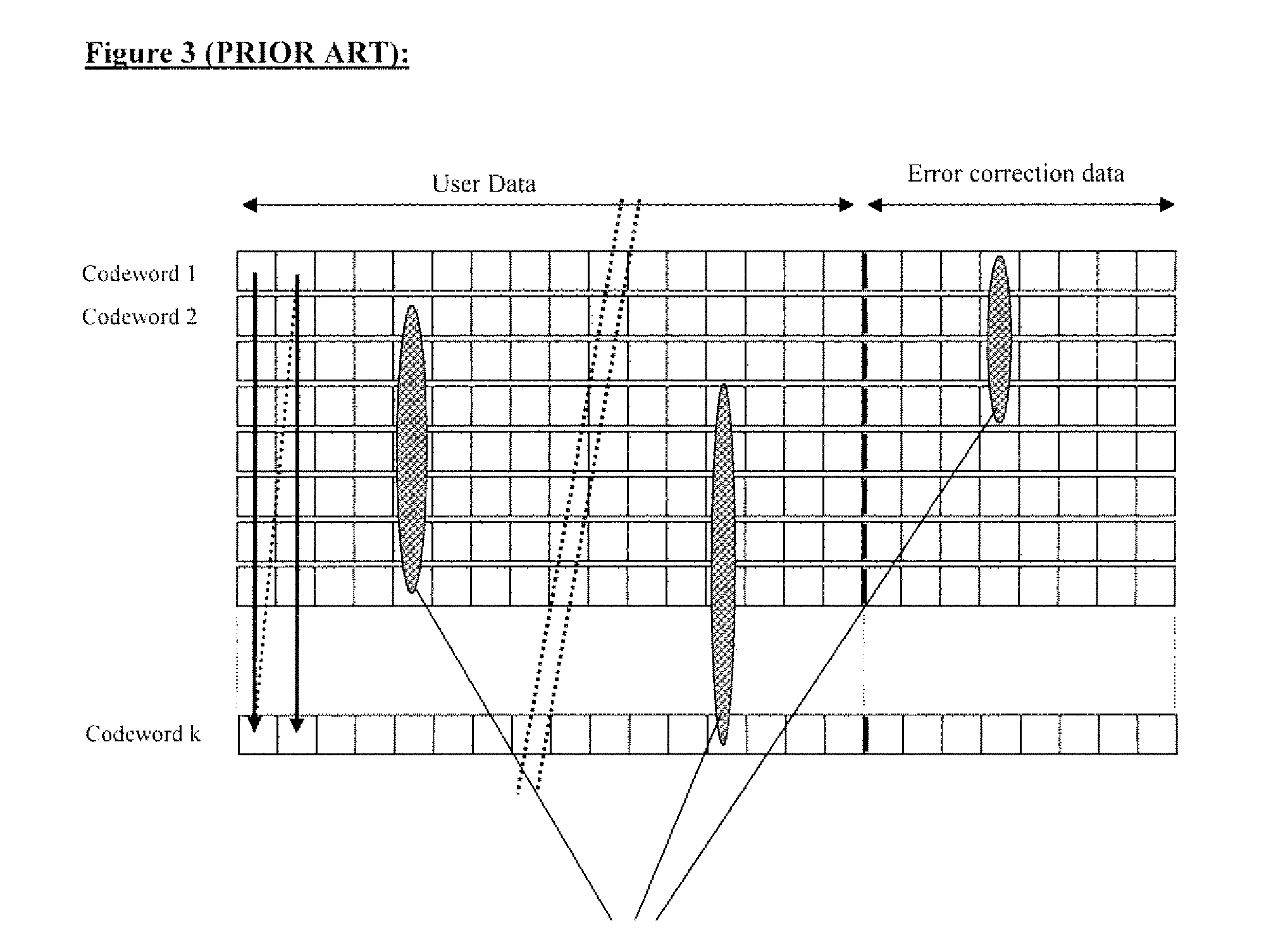

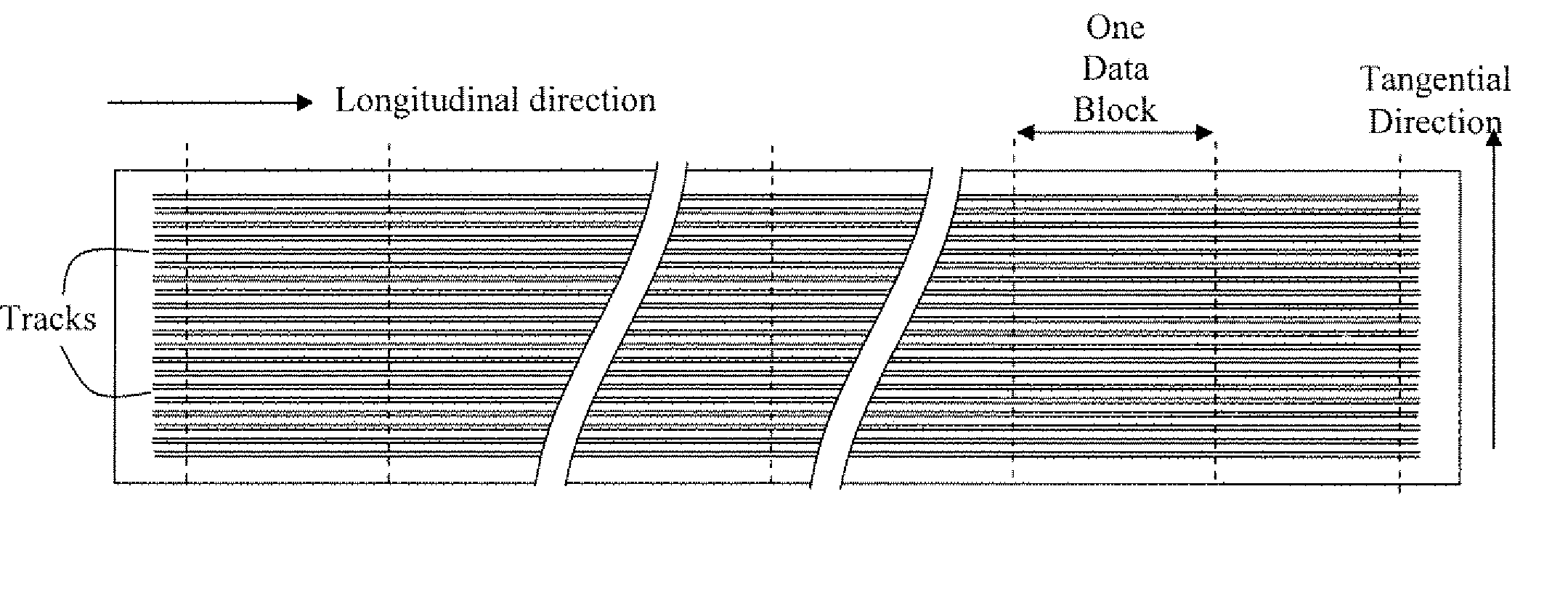

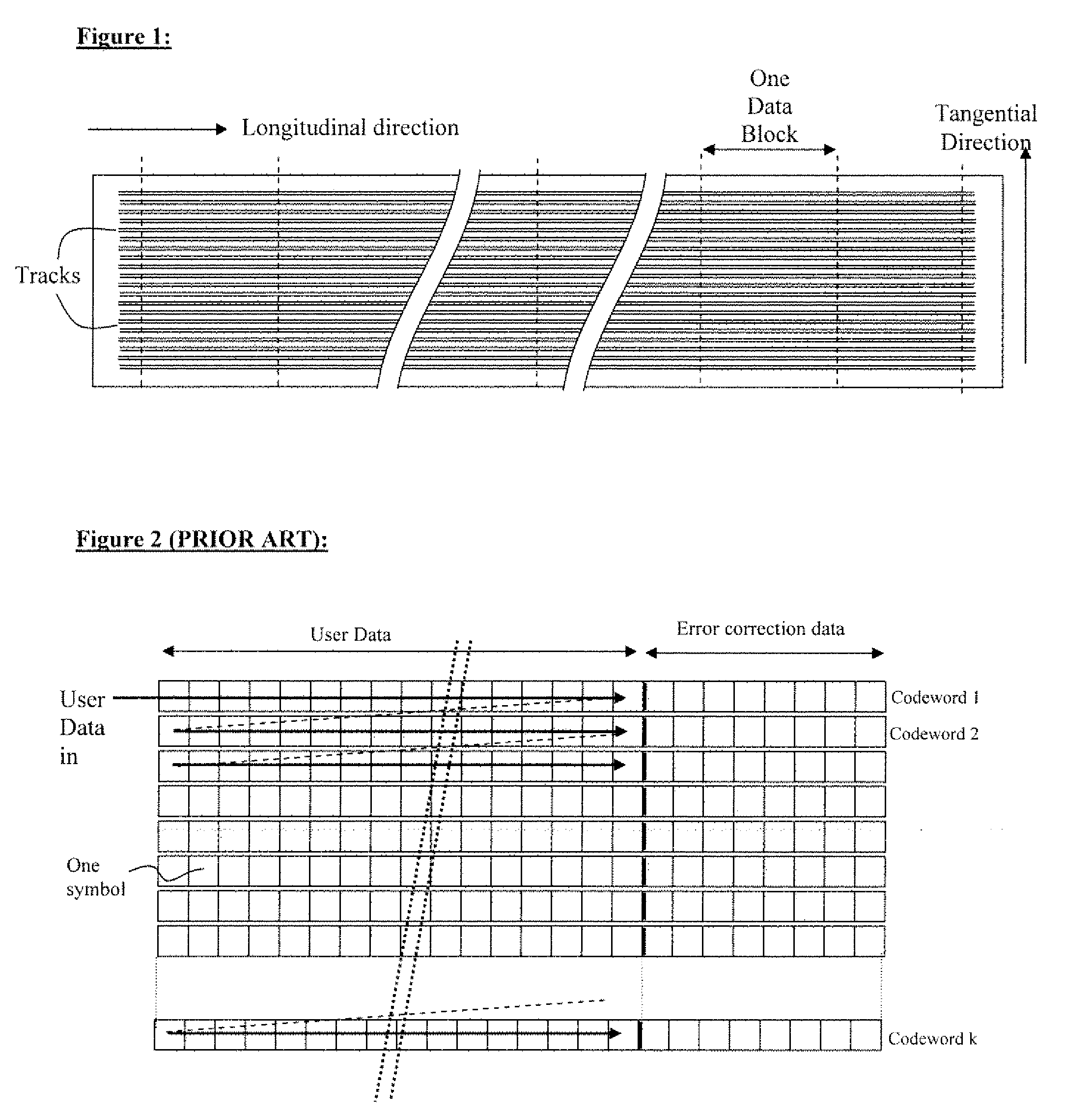

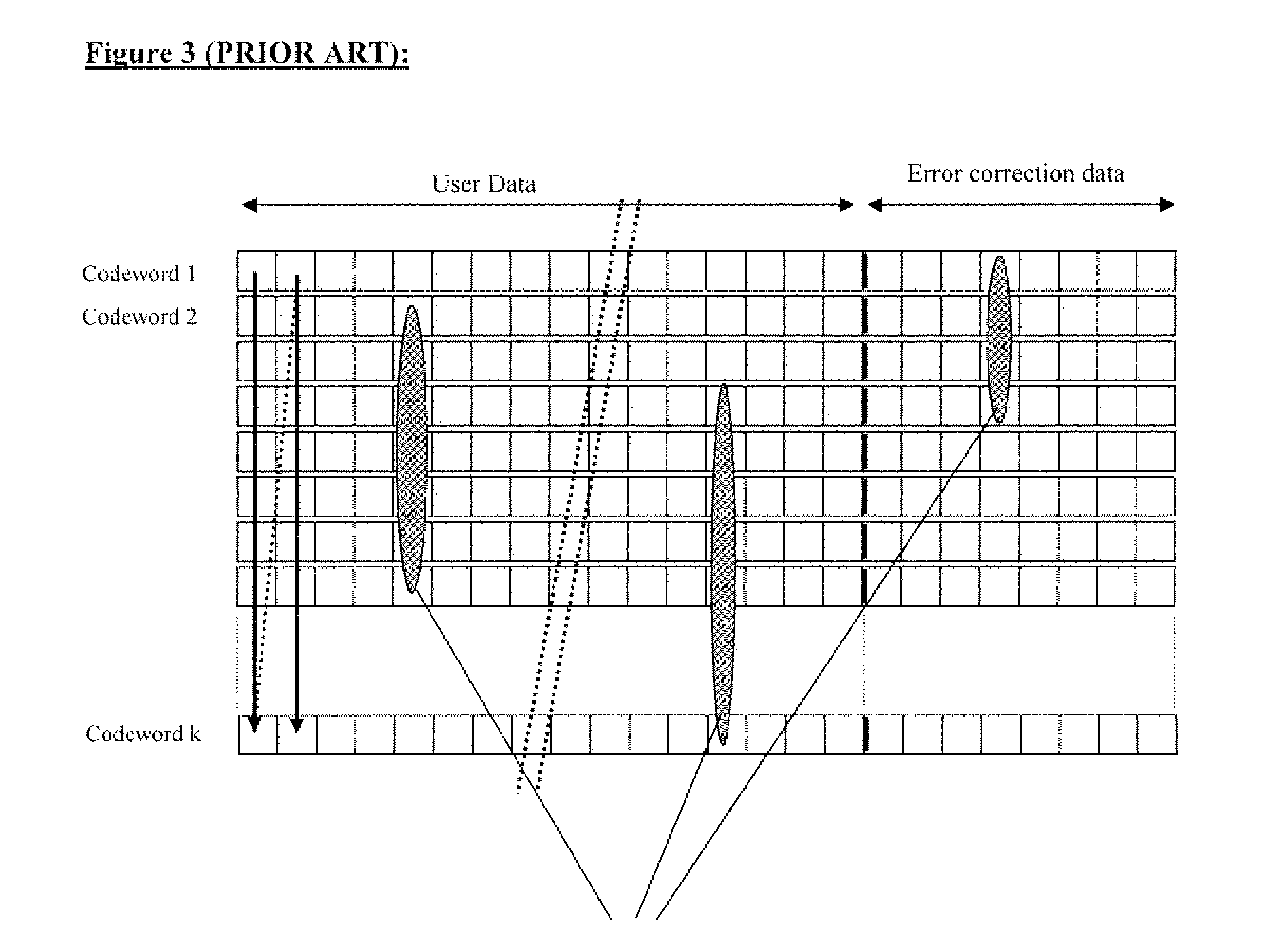

Rewrite strategy and methods and systems for error correction in high-density recording

ActiveUS7814395B2Equal lengthIncrease storage spaceData buffering arrangementsRecord information storageHigh densityAlgorithm

Owner:OPTERNITY STORAGE

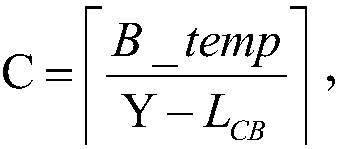

Method, apparatus and device for determination of size of transport block

ActiveCN109392100AGuaranteed performanceSame performanceNetwork traffic/resource managementTransmission format adaptationComputer science5G

The present invention provides a method, an apparatus and a device for determination of the size of a transport block, and relates to the technical field of communication. The method, the apparatus and the device for determination of the size of the transport block are used for ensuring the performances of a transport block in an NR (New Radio) system. The method comprises the steps of: determining the initial size of a transport block; comparing the initial size of the transport block with a threshold value to obtain a comparison result; according to the comparison result, performing quantification of the initial size of the transport block to obtain the initial size of the transport block after quantification; and according to the initial size of the transport block after quantification,determining the final size of the transport block. The method, the apparatus and the device for determination of the size of the transport block are mainly applied in the 5G NR.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Cutting mechanism for paper tubes

The invention relates to a cutting mechanism for paper tubes. The cutting mechanism is used for cutting the wound paper tubes in a tube winding machine into sections, and the paper tubes are conveyed through a conveying device. The cutting mechanism for the paper tubes comprises a cutting device, a driving device and a sensing device which are arranged sequentially in a conveying direction of the paper tube, wherein the driving device is used for driving the cutting device to move synchronously with the paper tubes in the conveying direction of the paper tubes; the sensing device is electrically connected with the driving device and the cutting device and produces control signals to be transmitted to the driving device and the cutting device; and the cutting device comprises a base, a first cutting device and a second cutting device, the base is horizontally arranged below the paper tape, and the first cutting device and the second cutting device are arranged on the base and located on two sides of each paper tube. According to the cutting mechanism for the paper tubes, the first cutting device and the second cutting device are arranged on two sides of a core roller for synchronous cutting, so that the cutting efficiency is improved greatly; and at the same time, the sensing device adopting a simple structure is arranged, so that the driving device and the cutting device can be well controlled, the lengths of the cut paper tubes are guaranteed to be equal, and notches are parallel and level.

Owner:WUJIANG MEISHENG MACHINERY EQUIP

High electrical performance semiconductor package

ActiveUS20050253253A1Shorten the line lengthShortening wire bondSemiconductor/solid-state device detailsPrinted electric component incorporationSemiconductor packageEngineering

A high electrical performance semiconductor package is proposed. A carrier is provided having a first surface, an opposite second surface, and conductive vias for electrically connecting the first surface to the second surface. A chip is attached to the first surface of the carrier. A plurality of via lands are disposed peripherally on the first surface of the carrier and electrically connected to the vias. A plurality of conductive regions are disposed on the second surface of the carrier and electrically connected to the vias. A plurality of fingers are disposed around the chip and electrically connected to the via lands by conductive traces formed on the first surface of the carrier. A plurality of bonding wires electrically connect the chip to the fingers. Lengths of the wires for transmitting differential pair signals are substantially equal, and lengths of the traces for transmitting the differential pair signals are substantially equal.

Owner:SILICONWARE PRECISION IND CO LTD

PPR pipefitting uniform cutting device

ActiveCN111531592AEasy to operateSave human effortMetal working apparatusEngineeringStructural engineering

The invention relates to cutting equipment, in particular to a PPR pipefitting uniform cutting device. The PPR pipefitting uniform cutting device is easy to operate, capable of effectively saving manpower, capable of saving consumed time during work, and capable of improving the work efficiency. The PPR pipefitting uniform cutting device comprises a base, a cutter and a cutter holder, a rack is connected to the base, fixed blocks are connected to the upper portions of the two sides of the rack, the bottoms of the fixed blocks are connected with guide rods, the cutter is in sliding connection to the position between the guide rods on the two sides, first reset springs are connected between the cutter and the guide rods, the cutter holder is connected to the lower portion in the rack, and the cutter holder is located below the cutter. Through a power mechanism, the cutter is driven to cut a PPR pipeline, and the effect of cutting the PPR pipeline is achieved.

Owner:马云艳

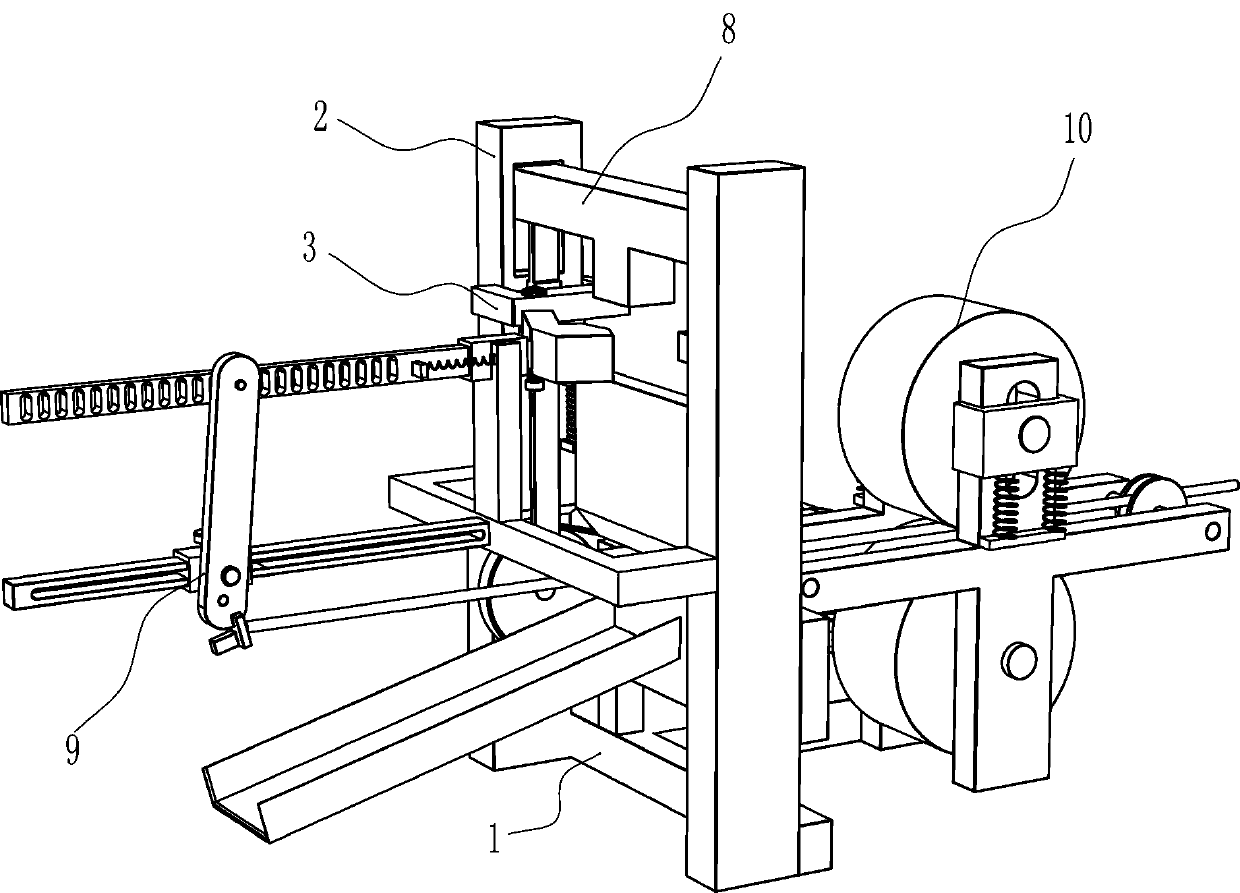

Automobile seat U-shaped handle bending machine

InactiveCN108380714AEqual lengthFree laborMetal-working feeding devicesPositioning devicesStraight tubeEngineering

The invention relates to the technical field of automobile part machining, in particular to an automobile seat U-shaped handle bending machine. The automobile seat U-shaped handle bending machine comprises a straight pipe feeding device, a bending device and a conveying device used for conveying straight pipes to the bending device from the straight pipe feeding device; the straight pipe feeding device comprises a feeding assembly for allowing the straight pipes to be arranged, and an aligning assembly used for aligning the straight pipes; the bending device comprises a bending mechanism and alimiting mechanism used for limiting the straight pipes on the bending mechanism; and the conveying device comprises a conveying assembly for clamping the straight pipes, and a driving assembly for driving the conveying assembly to move back and forth between the straight pipe feeding device and the bending device. According to the automobile seat U-shaped handle bending machine, the labor forceis liberated, unnecessary manpower cost wasting is avoided, the effect that the bending lengths of the two ends of each straight pipe are equal is ensured, the defective rate is decreased, and the production cost is reduced.

Owner:罗必锋

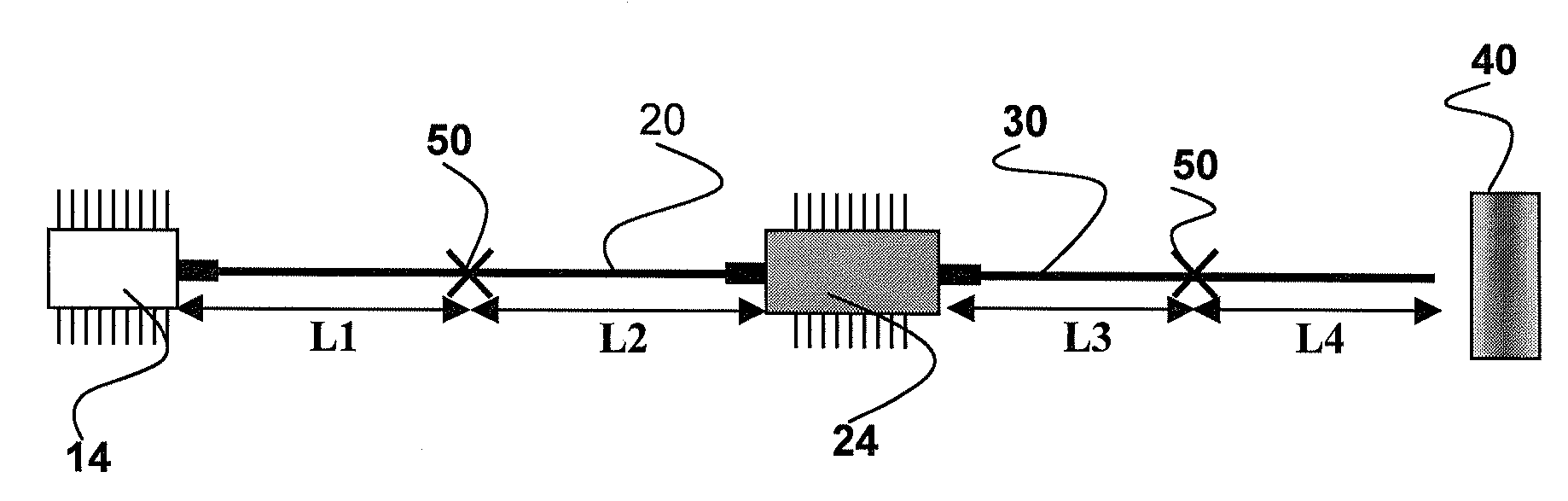

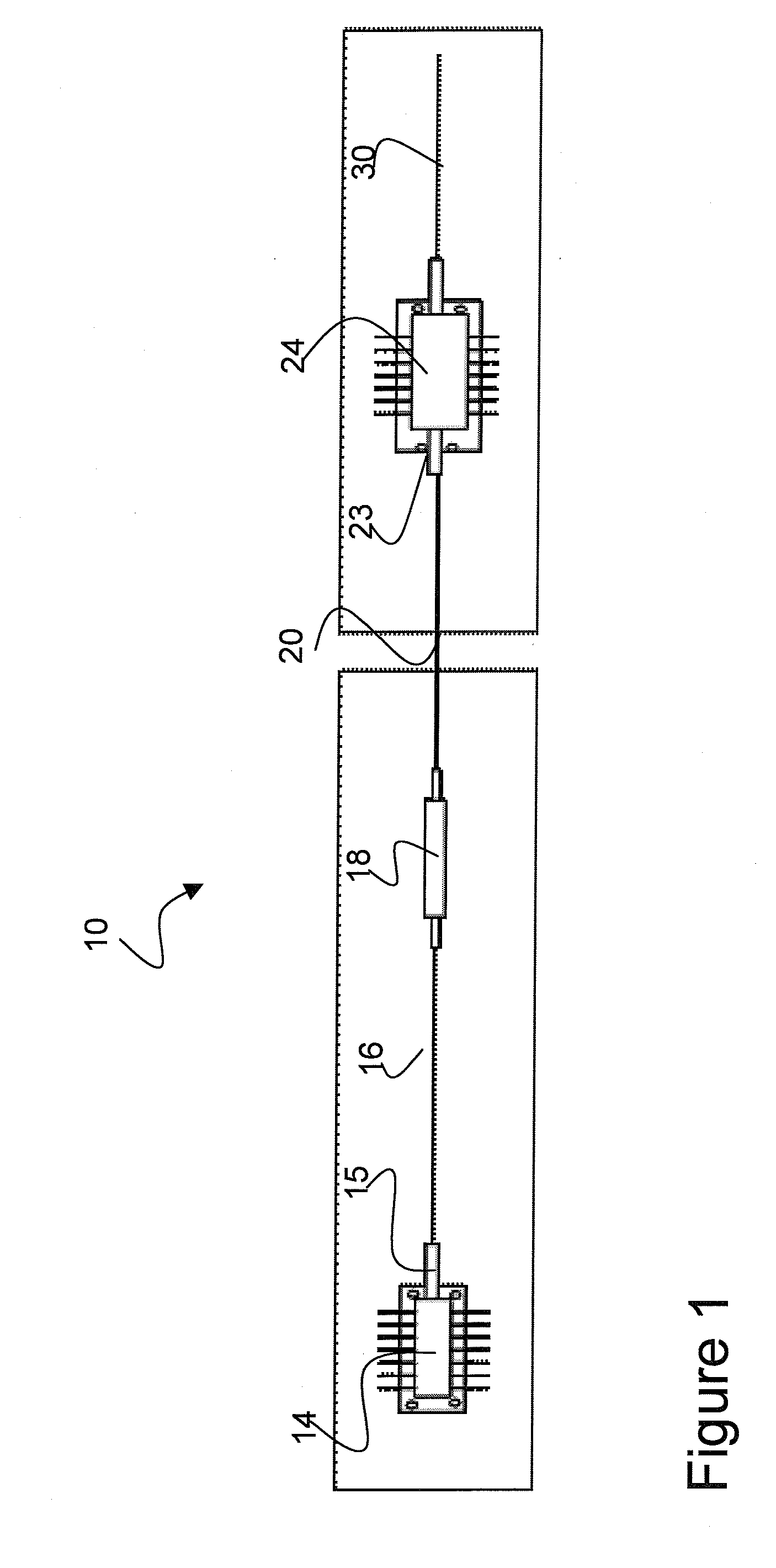

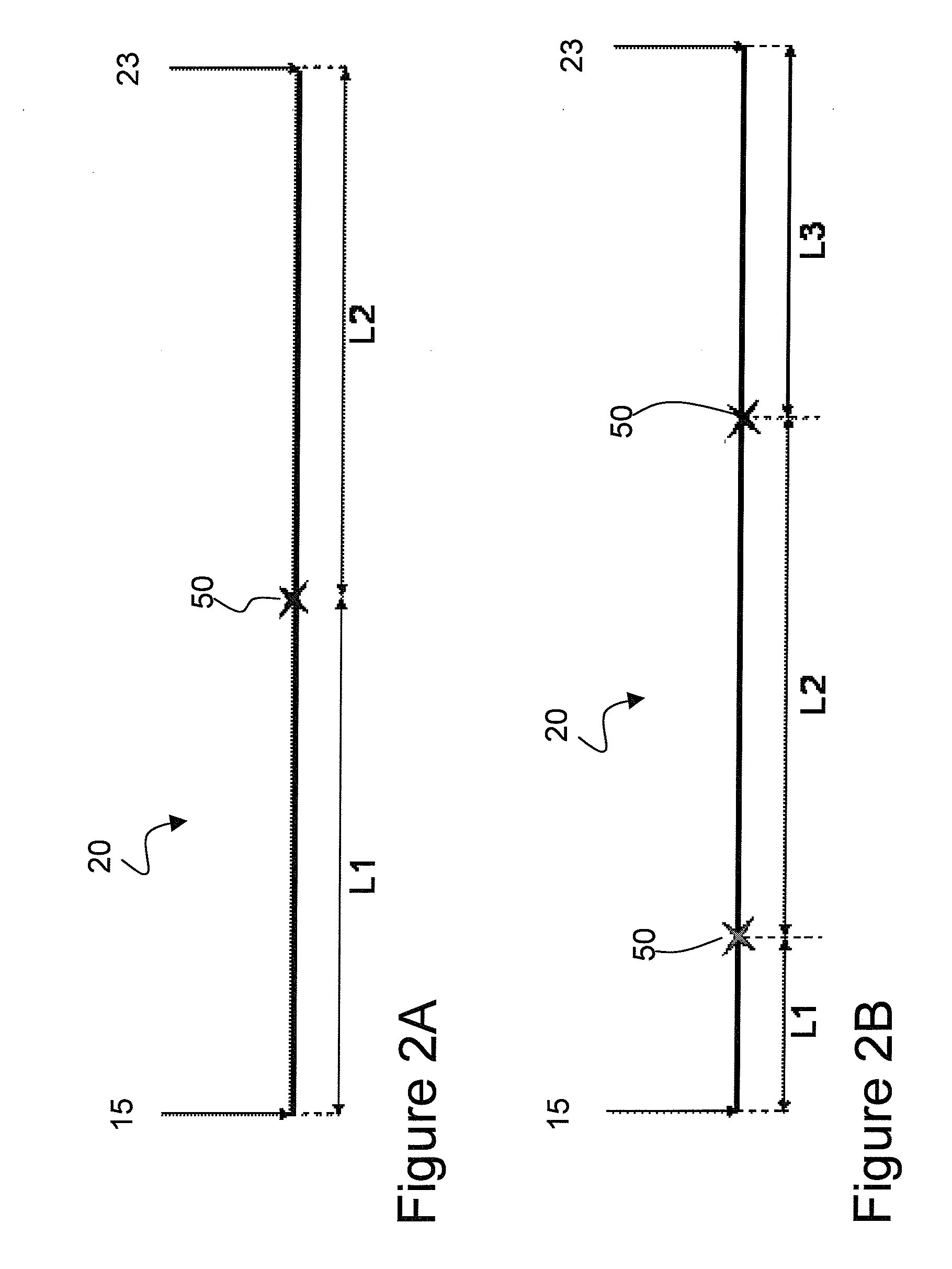

Power Stabilization Of Semiconductor Laser Harmonic Frequency Conversion Modules

ActiveUS20080124023A1Eliminate output amplitude fluctuationReduce in quantityCoupling light guidesLight demodulationHarmonicFrequency conversion

The invention relates to a fiber laser and harmonic frequency conversion module incorporating a 90 degree Polarization Maintaining (PM) fiber fusion splice therebetween for providing temperature insensitive power stabilization. The present invention has found that incorporating at least one 90 degree splice of the transmission axes of the PM fiber, coupling a fast axis to a slow axis, to create substantially equal optical path lengths of the two transmission axes of the fiber coupling can nearly eliminate output amplitude fluctuation within a practical operating temperature range.

Owner:LUMENTUM OPERATIONS LLC

Production technology for natural bamboo fibers

ActiveUS9630337B2Simple and high-efficient producing methodImprove adaptabilityPlant material mechanical workingVegetable materialFiberMaterials science

A production technology for natural bamboo fibers is applied in producing woven bamboo fibers, non-woven bamboo fibers, and reinforcing composite bamboo fibers. The woven bamboo fibers are produced by steps of cutting to a certain length, slicing, flattening, softening, dividing, debonding, rinsing, soaking in oil, drying, and opening. The non-woven bamboo fibers and the reinforcing composite bamboo fibers are produced by steps of cutting to a certain length, slicing, flattening, softening, dividing, debonding (optional), rinsing, and drying.

Owner:ZHANG YI

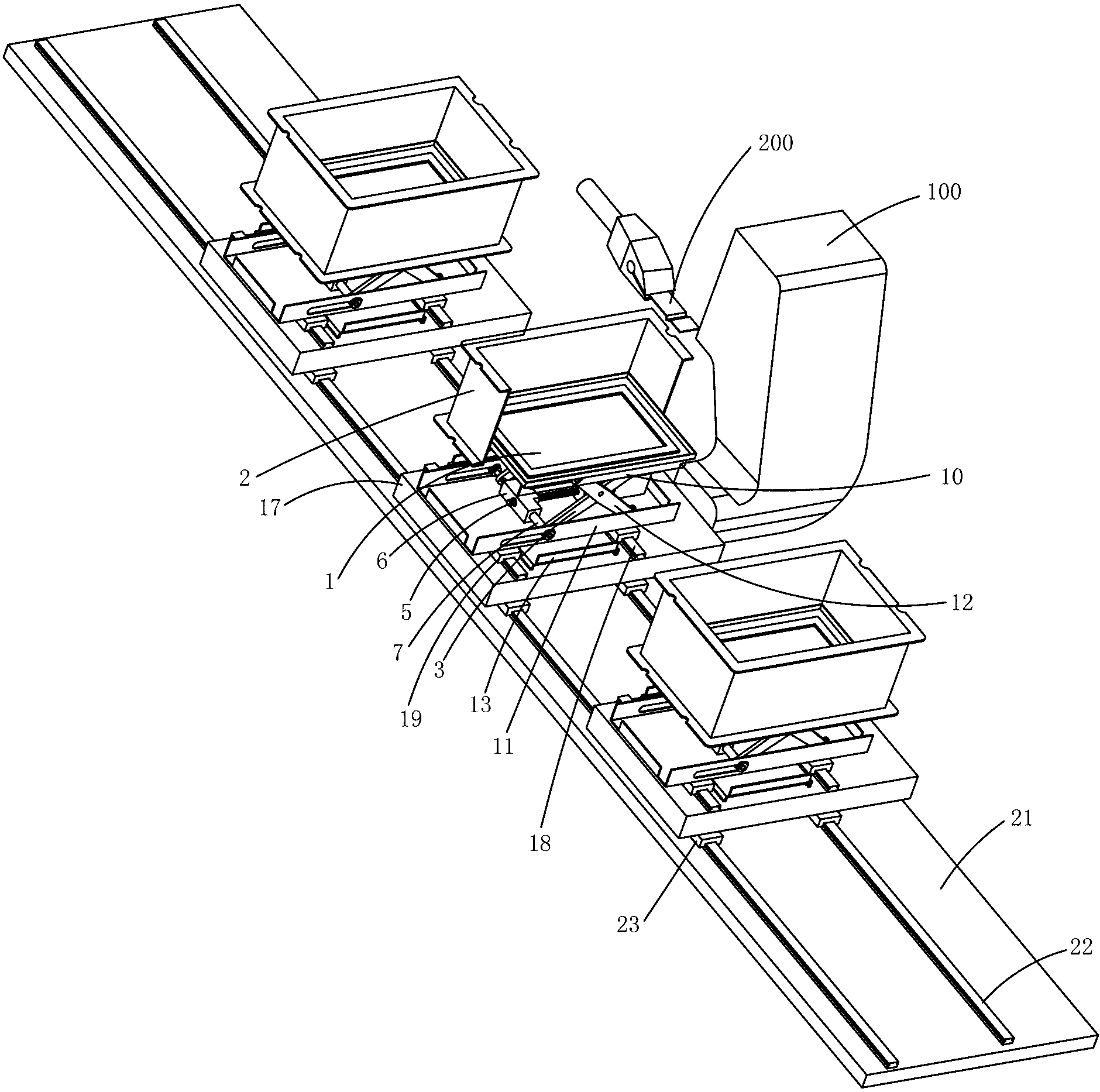

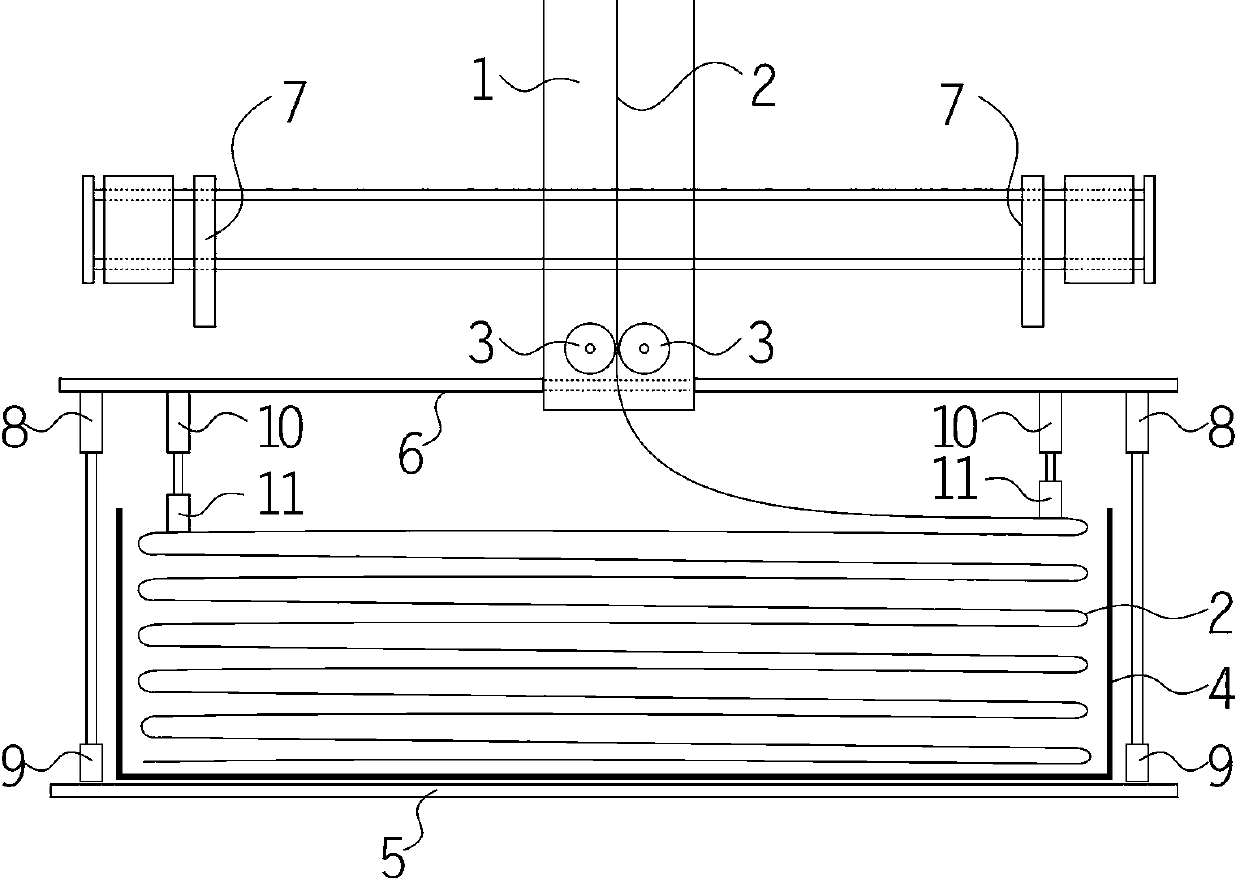

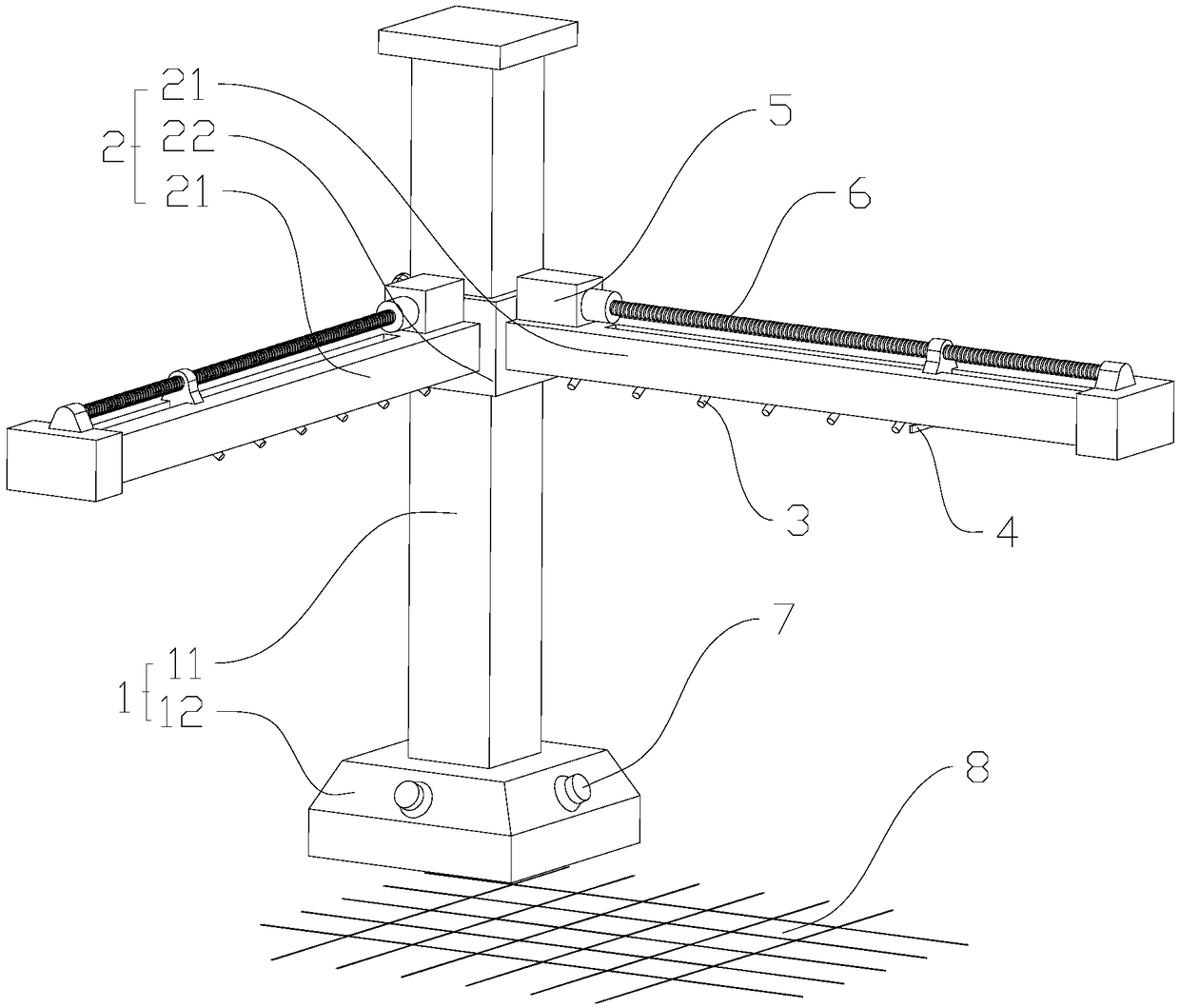

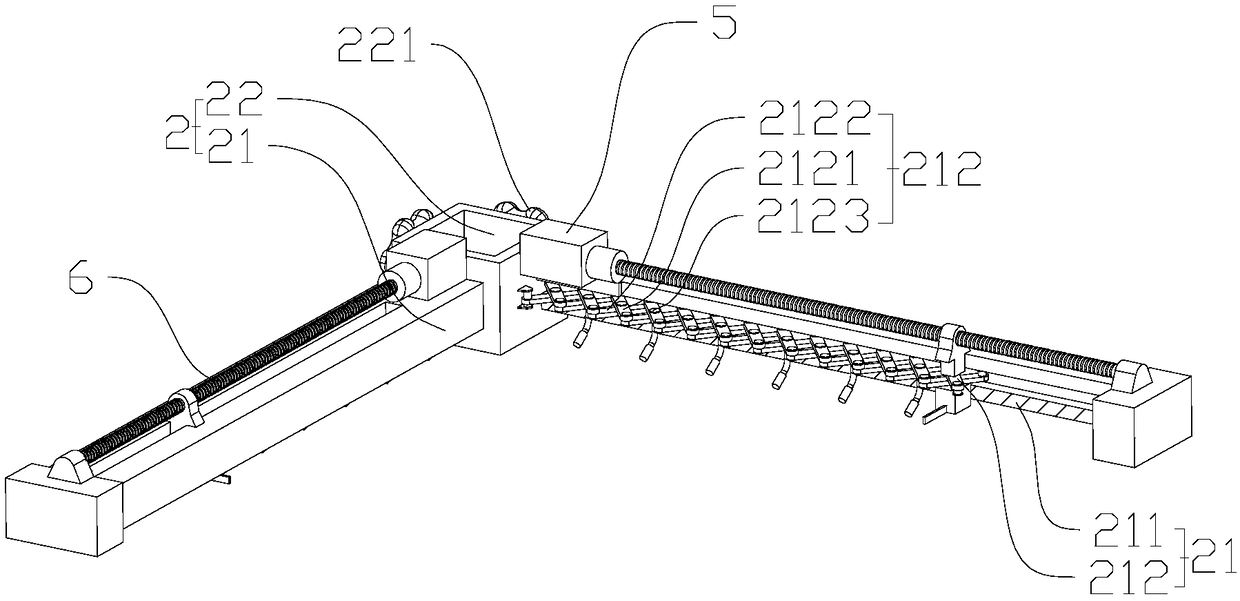

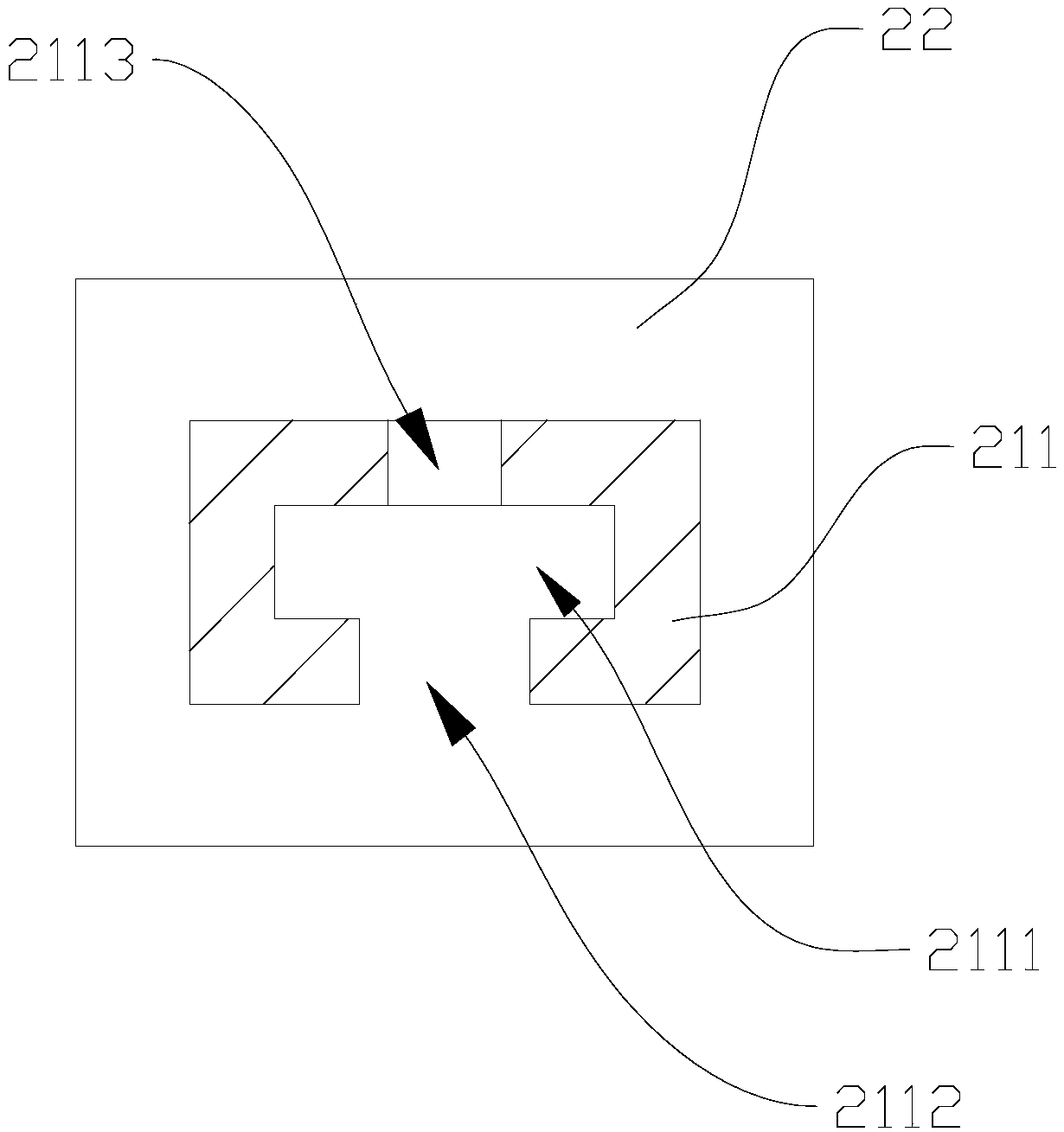

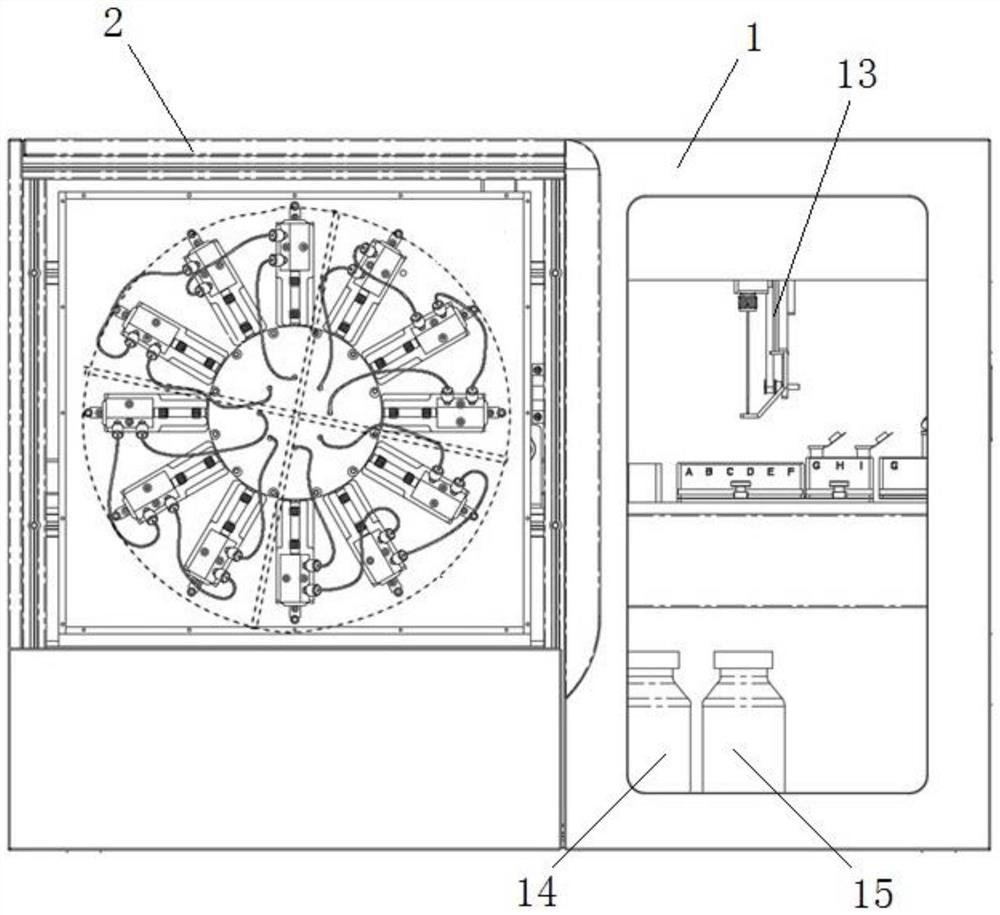

Supply device and method for long reinforcing steel bars in four-side-ribbed high-speed-rail reinforcing steel bar meshes

PendingCN110947881AEqual lengthPrevent problems such as bending and deformationMetal working apparatusMesh reinforcementRebar

The invention discloses a supply device and method for long reinforcing steel bars in four-side-ribbed high-speed-rail reinforcing steel bar meshes, and belongs to the field of cold-rolled reinforcingsteel bars. The supply device comprises a reinforcing steel bar coil unwinding device, a reinforcing steel bar straightening roller device, one or more hydraulic reinforcing steel bar shearing devices, a rib arranging stand of a reinforcing steel bar mesh welding device and a moving frame which are arranged sequentially; the moving frame is arranged on the rib arranging stand; a long reinforcingsteel bar fixed-length baffle is arranged on the moving frame; the one or more hydraulic reinforcing steel bar shearing devices are arranged in front of the rib arranging stand; at least one driving roller is arranged in the reinforcing steel bar straightening roller device; and multiple sensors and a controller are arranged in the supply device. By the aid of the supply device, production links of the reinforcing steel bar are reduced, the problem of inconsistency of the parallelism of the reinforcing steel bars during bundling and carrying of the reinforcing steel bars is reduced, the alarming, shutdown or maintenance time of the device is shortened, the running rate of the device is increased, and the percent of pass of the yield strength of the straightened reinforcing steel bars is increased.

Owner:河南省鼎鼎实业有限公司

Sizing cutting device for plastic pipe production of venous blood collector

InactiveCN111331669AEqual lengthImprove qualityFilament handlingMetal working apparatusVeinVenous blood

The invention discloses a sizing cutting device for plastic pipe production of a venous blood collector. The device comprises a base, wherein two supporting plates are fixedly connected to the upper end of the base, a winding roller is rotationally connected between the two supporting plates, damping supporting legs are fixedly connected to the lower end of the base, a hollow sliding groove is formed in the upper end surface of the base in a penetrating manner, a sliding block is slidably connected in the hollow sliding groove, a driving motor is fixedly connected to the side wall of the base,and an output shaft of the driving motor is fixedly connected with a first threaded rod. According to the device, the pulling length of a plastic pipe is equal to each time, so that the quality of the product is improved, the pulling and cutting-off adopts the driving motor for controlling, so that the size of the equipment is reduced, the energy consumption is reduced, by arranging a rack, a gear and a hand wheel, the height of a cutter blade can be adjusted, and plastic pipes with different specifications can be cut.

Owner:杨世伟 +2

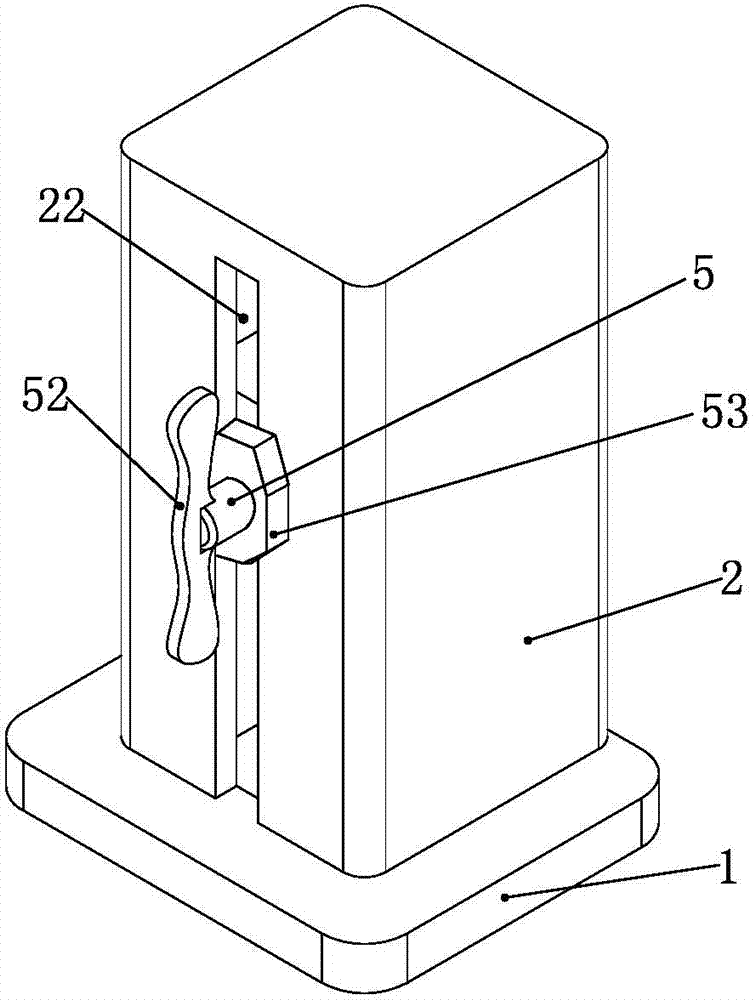

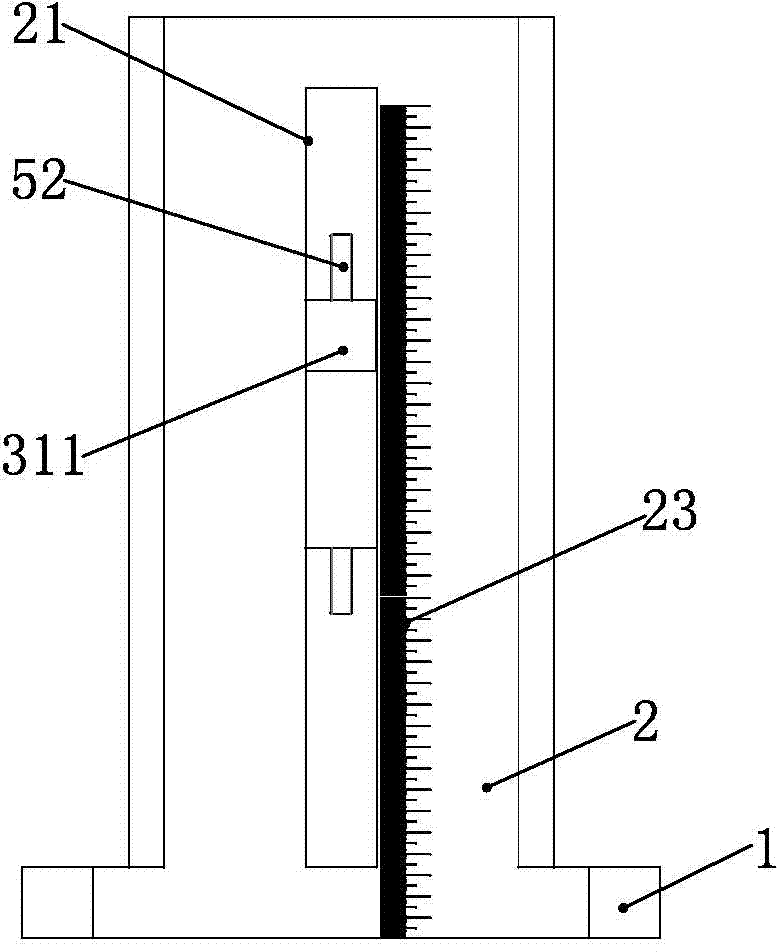

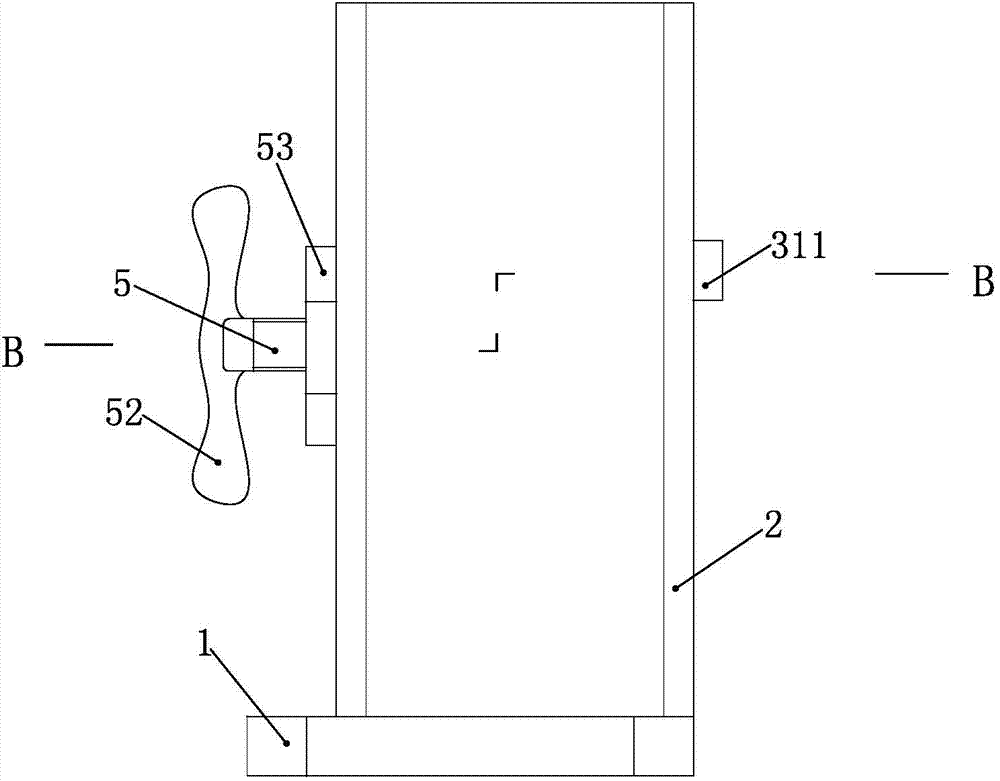

Clamping device and method used for guaranteeing equality of extension lengths of two ends of through bolt

ActiveCN104723092AControl lengthEqual lengthMetal working apparatusArchitectural engineeringEngineering

The invention provides a clamping device and method used for guaranteeing equality of the extension lengths of the two ends of a through bolt. The clamping device and method mainly solve the problem that the extension lengths of the two ends of a through bolt are not equal when the through bolt is mounted manually. The clamping device comprises a magnetic base and a shell, wherein the magnetic base can be attracted to a flange, and the shell is perpendicularly arranged on the base; the shell is internally provided with a first cavity communicated with a through hole in the base, and the two opposite side faces of the shell are symmetrically provided with a first slot hole and a second slot hole; a ruler is arranged at one side of the first slot hole in the shell, and the zero graduation line of the ruler is flush with the bottom face of the base; the first cavity is internally provided with a first V-shaped block and a second V-shaped block which are provided with opposite openings; a threaded rod capable of rotating along the second slot hole is arranged at one side of the second slot hole; the part, on the outer side of the second slot hole, of the threaded hole is provided with a movable nut; the threaded rod is rotated, the first V-shaped block moves towards the second V-shaped block and clamps the through bolt, and the position of the threaded rod is fixed through the movable nut. The clamping device is simple in structure, convenient to use and capable of effectively guaranteeing the equality of the extension lengths of the two ends of the through bolt.

Owner:STATE GRID CORP OF CHINA +1

Automatic feeding device of abrasive paper cutting machine

InactiveCN108058219AEqual lengthAvoid undercutAbrasion apparatusMetal working apparatusPulp and paper industryEmery paper

The invention discloses an automatic feeding device of an abrasive paper cutting machine. The automatic feeding device comprises a rack, a movable clamping mechanism and two fixed clamping mechanisms;the two fixed clamping mechanisms are distributed on the two sides of the movable clamping mechanism and fixedly connected with the rack, and the movable clamping mechanism is slidably arranged on ascrew rack fixedly connected with the rack in a sleeving mode; and linear guide rails used for ensuring that the movable clamping mechanism linearly slides on the rack are fixedly installed on the rack, a front travel switch and a back travel switch are detachably connected to the lower end of the rack, distributed on the two sides of the movable clamping mechanism respectively and electrically connected with an electric appliance control cabinet, and the electric appliance control cabinet is electrically connected with the movable clamping mechanism and clamping executing parts arranged on the fixed clamping mechanisms. According to the automatic feeding device of the abrasive paper cutting machine, it can be guaranteed that the length of abrasive paper pushed every time is equal, and notonly can an undercut phenomenon be avoided between the last time of abrasive paper cutting and the next time of abrasive paper cutting, but also unnecessary waste of raw materials can be avoided.

Owner:YANCHENG HUASEN MACHINERY

Rewrite strategy and methods and systems for error correction in high-density recording

ActiveUS20070150793A1Equal lengthIncrease storage spaceData buffering arrangementsRecord information storageHigh densityAlgorithm

Owner:OPTERNITY STORAGE

Separated bottom bed structure

A separated bottom bed structure mainly includes a front bottom bedplate, a rear bottom bedplate, reinforcing bars and screw handles; the structure is detached, separated and assembled through two hollow frames and an inverted U-shaped frame, allowing the front, rear bottom bedplates are kept equal in size, thereby being convenient for packaging and shipping. Furthermore, the screw handle includes a grip, screw head and button, where the button is used to separate the grip and screw head, allowing the grip to be adjusted to an arbitrary angle, thereby turning the screw head back and forth.

Owner:APEX HEALTH CARE MFG

Automatic tape folding mechanism

The invention discloses an automatic tape folding mechanism. The automatic tape folding mechanism comprises a feeding plate, a resistance adhesive tape, a tape discharging servo motor roller, a tape loading pot, a tray support, a guide rail, a guide rail sensor, a tray cylinder, a tray ejection rod, a tape pressing cylinder and a tape pressing ejection rod, wherein the lower end of the feeding plate is provided with the tape discharging servo motor roller and the guide rail, the guide rail sensor is arranged above the guide rail, the tape loading pot is arranged under the guide rail, the tray cylinder and the tape pressing cylinder are arranged at two ends of the guide rail, the tape pressing cylinder is connected with the tape pressing ejection rod, the tray cylinder is connected with the tray ejection rod, and the tray is connected at the lower end of the tray ejection rod. The automatic tape folding mechanism can realize automatic folding and packing of the resistance adhesive tape.

Owner:太仓吉井机械有限公司

Laser calligraphy mesh division ruler and control system thereof

The invention relates to a laser calligraphy mesh division ruler which comprises a vertical support. The vertical support comprises a vertical supporting rod, the two ends of the vertical supporting rod are provided with a supporting base and a horizontal support, the horizontal support comprises two orthogonal horizontal supporting rods, the horizontal supporting rods are provided with a plurality of laser emitters distributed at intervals, and the laser emitters are arranged on the horizontal support an in inclined manner and irradiate within a horizontal face to form a line type light spot.The horizontal support is arranged above the horizontal face in parallel through the vertical supporting rods, the multiple laser emitters distributed on the horizontal support at intervals irradiatethe horizontal face to form the line type light spot, the laser emitters located on one horizontal supporting rod emit parallel light, the laser emitters located on the different horizontal supporting rod emit orthogonal light, light grids formed by laser radiation is formed on the horizontal ace, grids used for writing therein are divided on Chinese art paper in the horizontal face, the traditional manner that the Chinese art paper is folded for forming the grids used for writing therein is replaced, folding of the Chinese art paper is avoided, and the good writing paper is provided for a writer.

Owner:夏逸帆

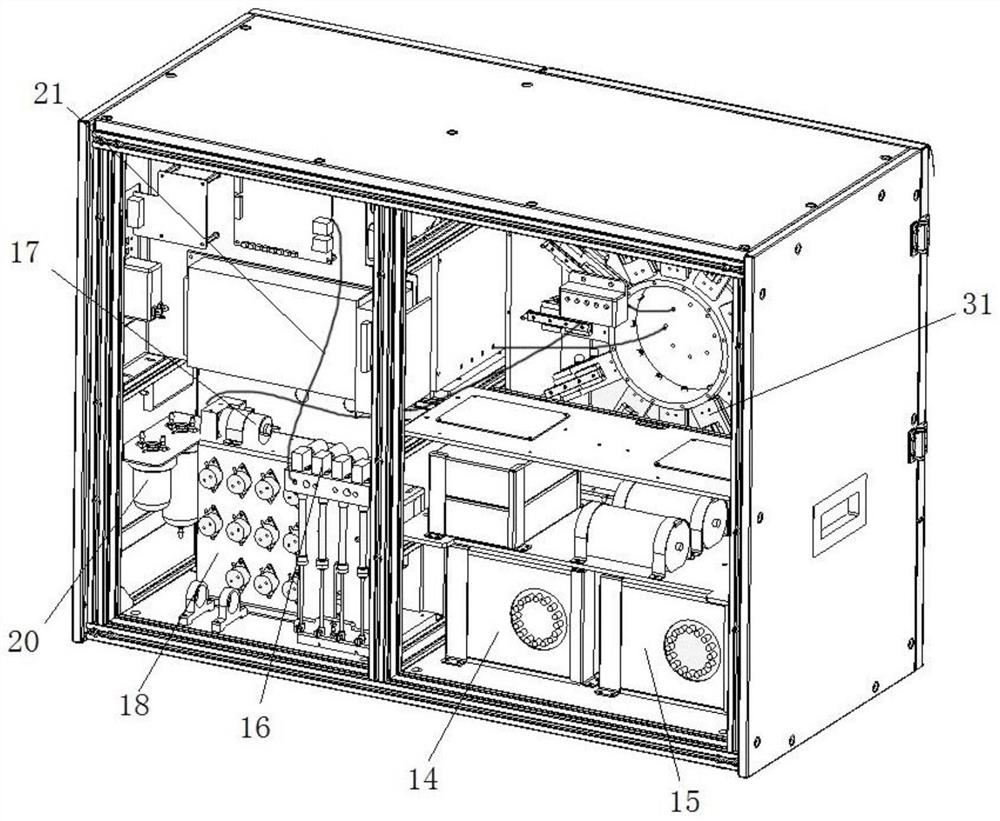

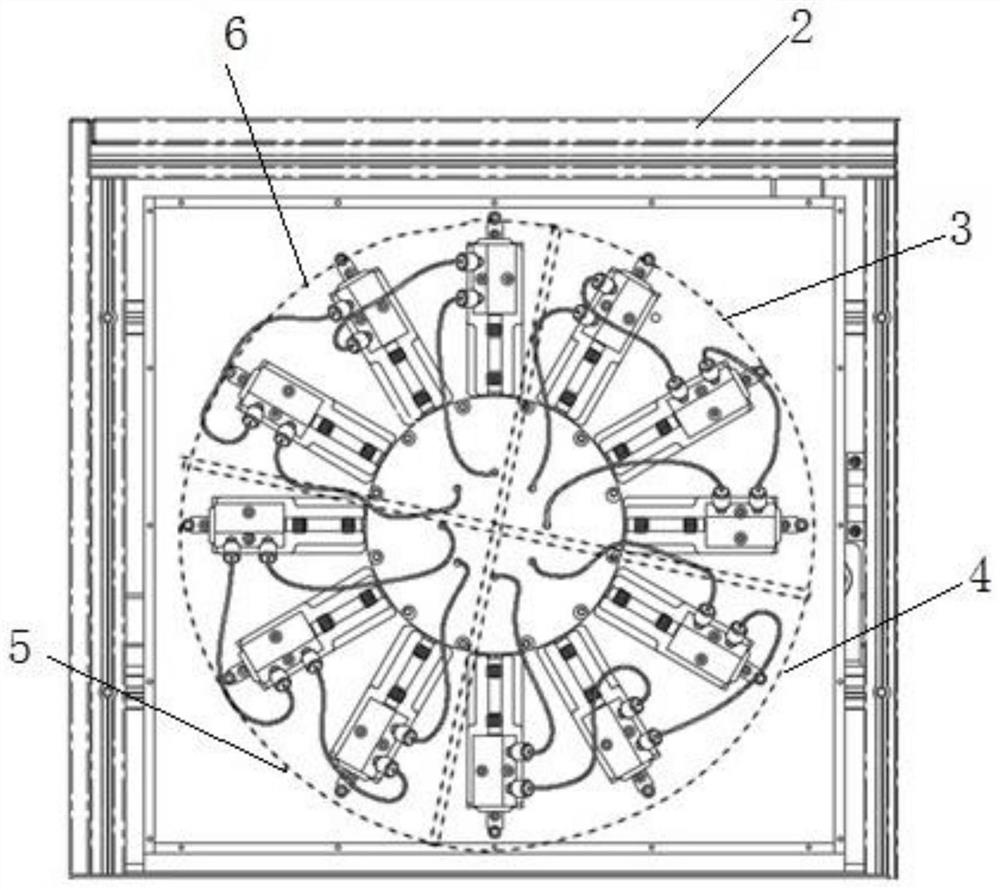

Sampling system suitable for multi-channel terminal reflection type optical fiber SPR sensor and using method thereof

PendingCN112834464AReduce consumptionEqual lengthMaterial analysis by optical meansEngineeringFibre Channel

The invention discloses a sampling system suitable for a multi-channel terminal reflection type optical fiber SPR sensor. The system comprises a shell, a sample injection mechanism which is mounted in the shell and is used for collecting and conveying a sample to be detected, an optical fiber SPR detection mechanism which is used for detecting the sample to be detected and is positioned at a terminal reflection type optical fiber SPR detection end, and a liquid discharge mechanism which is used for self-cleaning and discharging detection waste liquid, and the sample injection mechanism is arranged at the front side sample injection end of the optical fiber SPR detection mechanism; and the liquid discharge mechanism is arranged at the rear side sample outlet end of the optical fiber SPR detection mechanism. The optical fiber channels connected in parallel are distributed on the same plane along the circumference at equal angles, it is guaranteed that sample flow paths of all the internal liquid paths are equal in length and small in dead volume, at least two optical fiber sensors are arranged in each optical fiber channel, the same sample can be sampled and detected at the same time or multiple samples can be sampled and detected, detection data of multiple groups of optical fiber sensors are detected, each internal liquid path is relatively independent and has parallelism, the consumption of samples is reduced, and the detection efficiency is improved.

Owner:NINGBO HEIGER ELECTRICAL APPLIANCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com