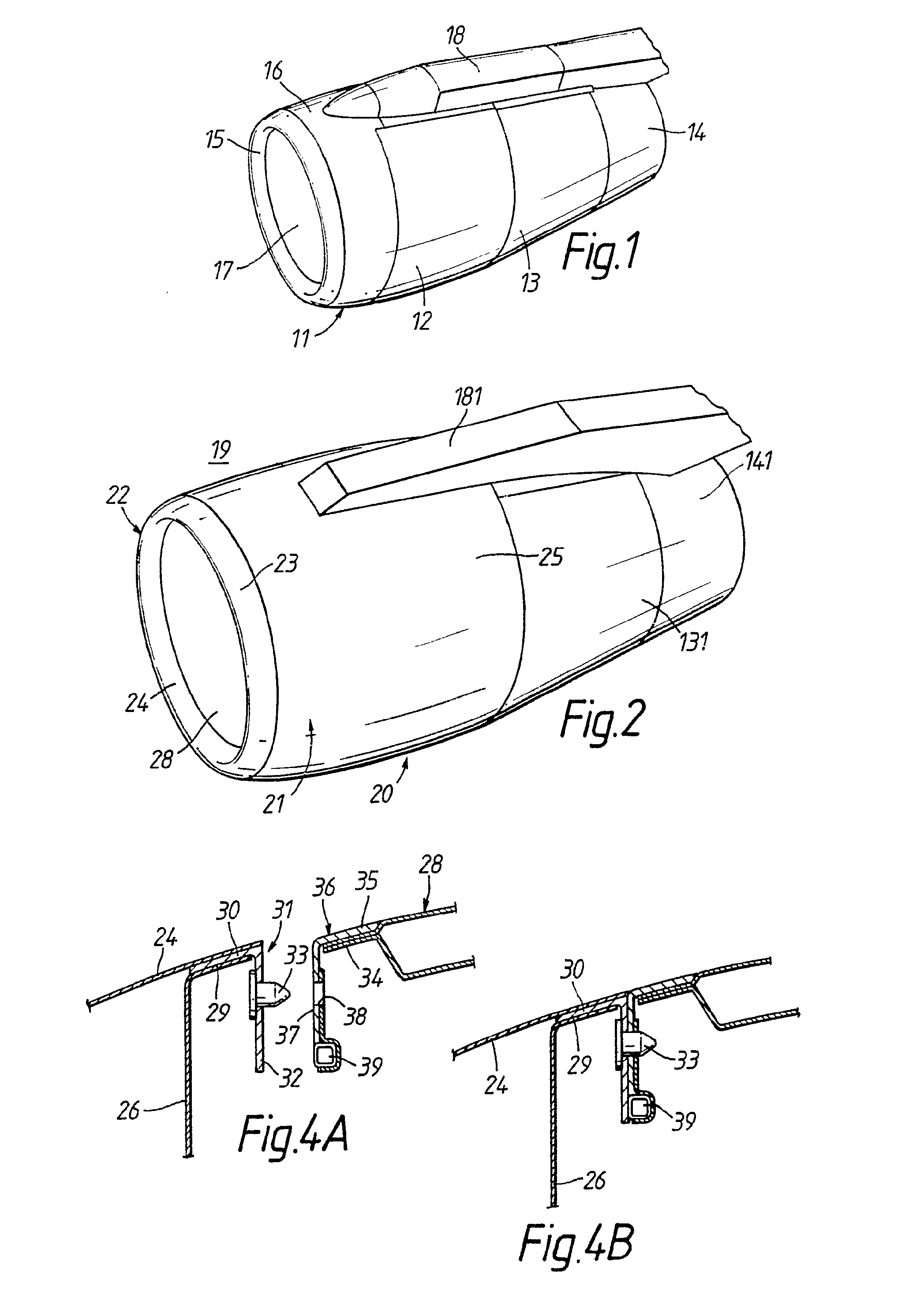

Patents

Literature

31results about How to "Effective centering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

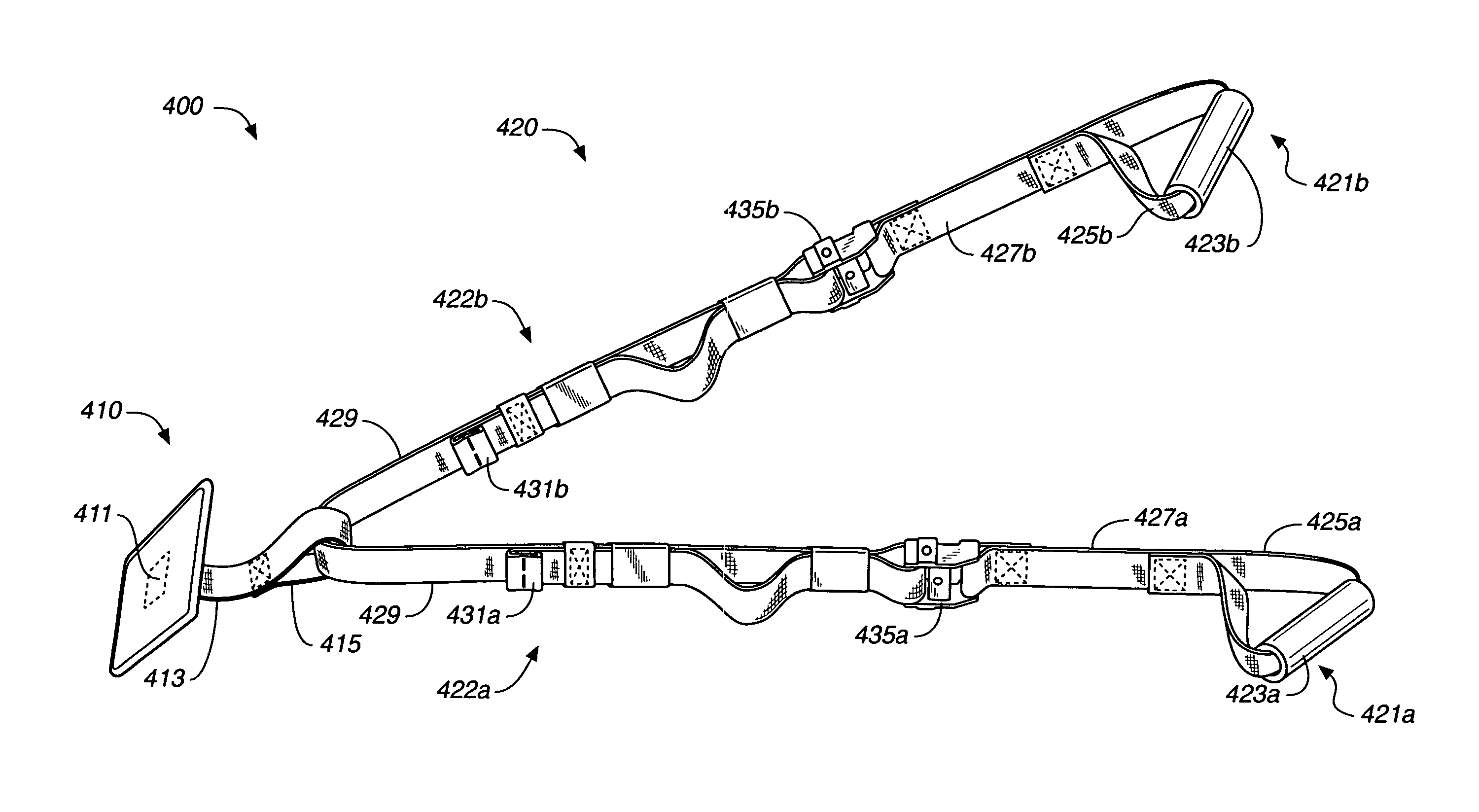

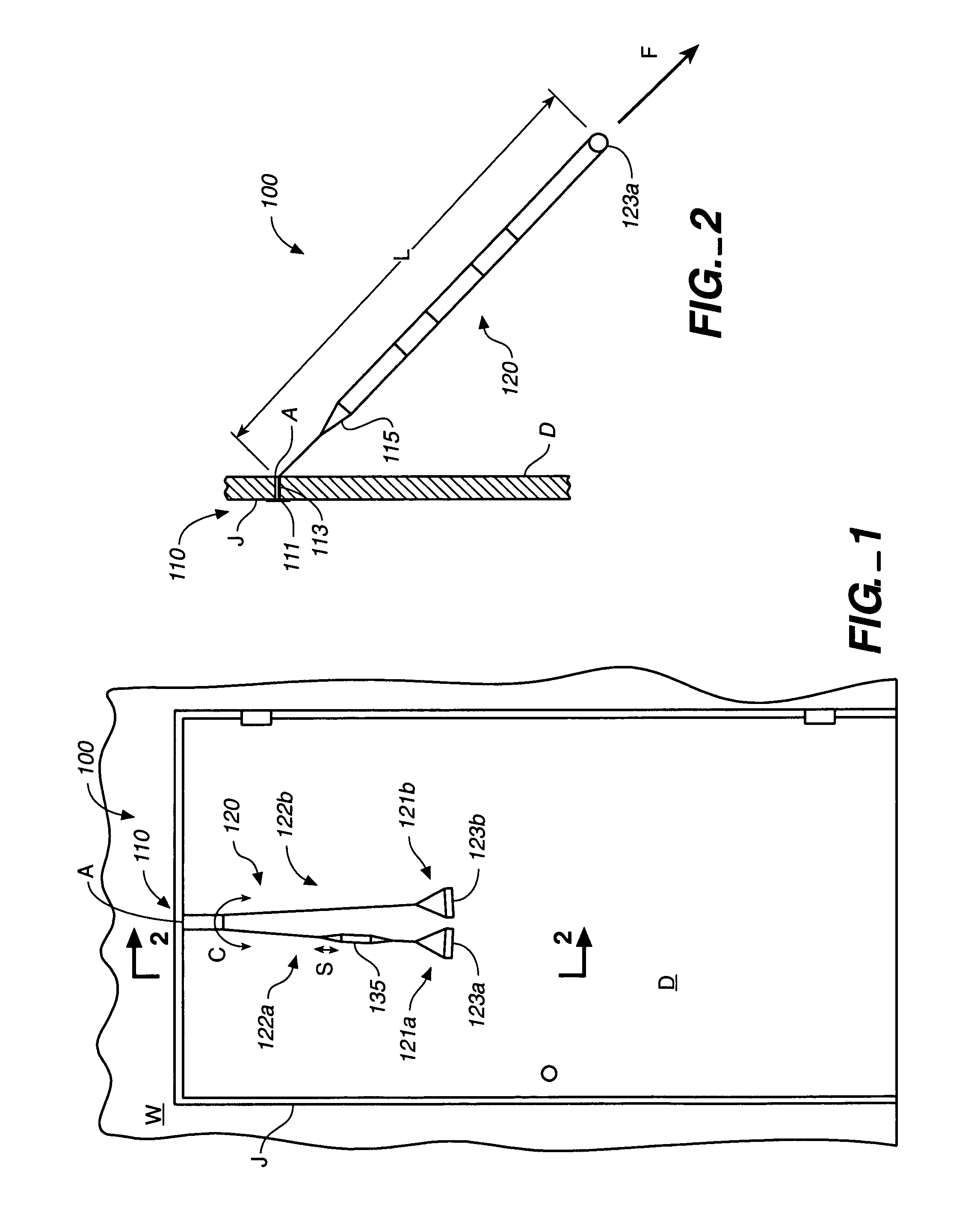

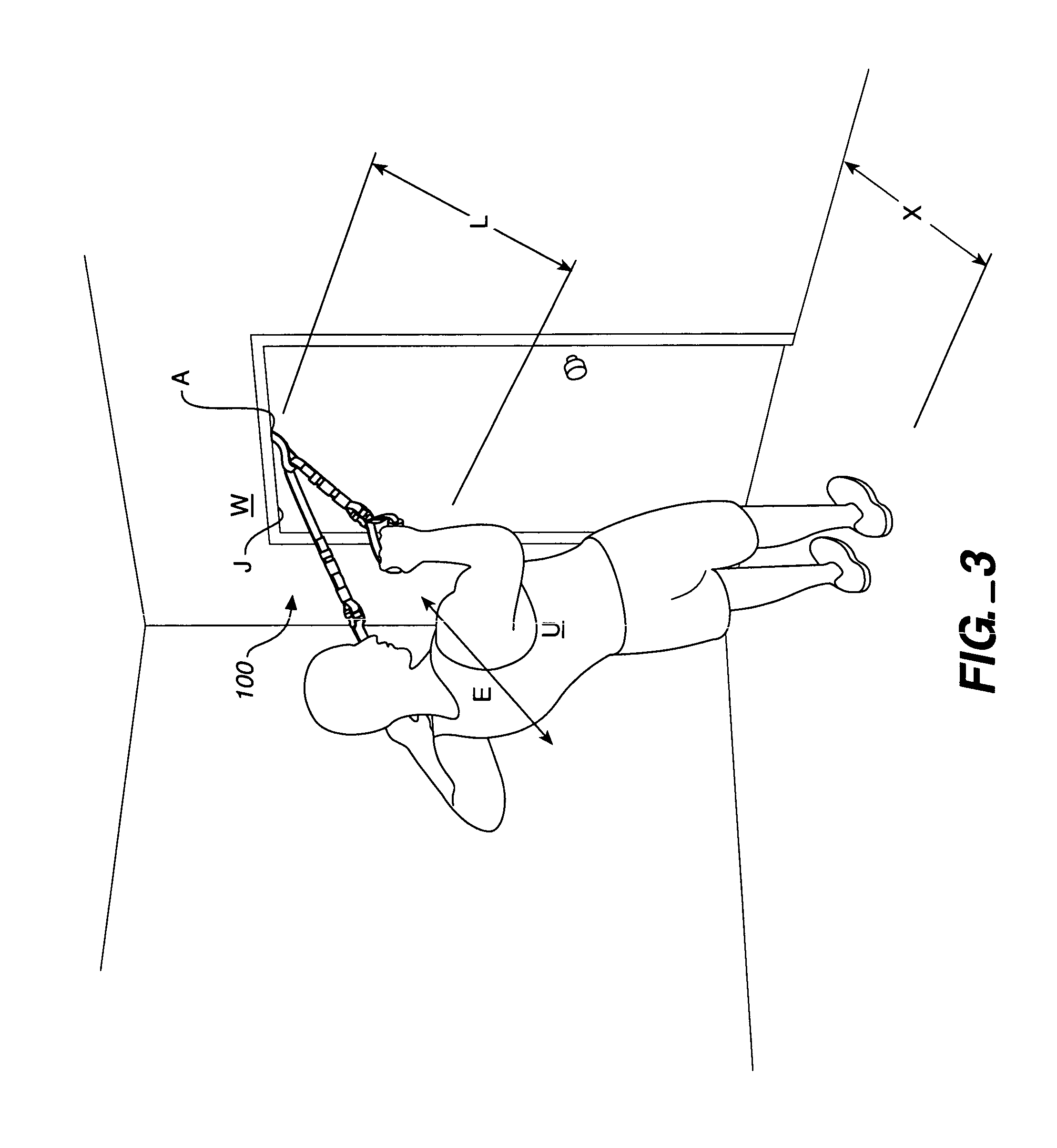

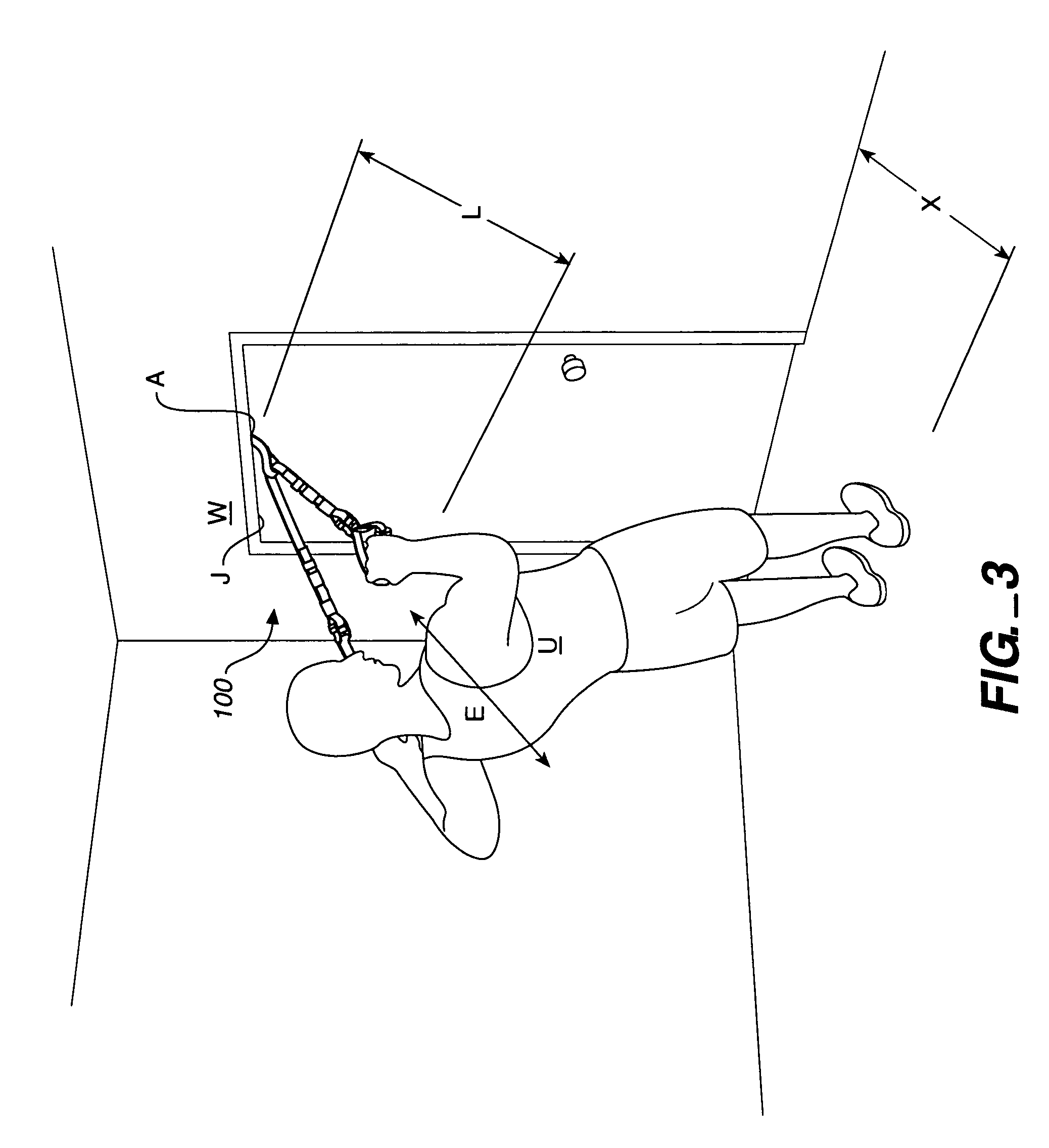

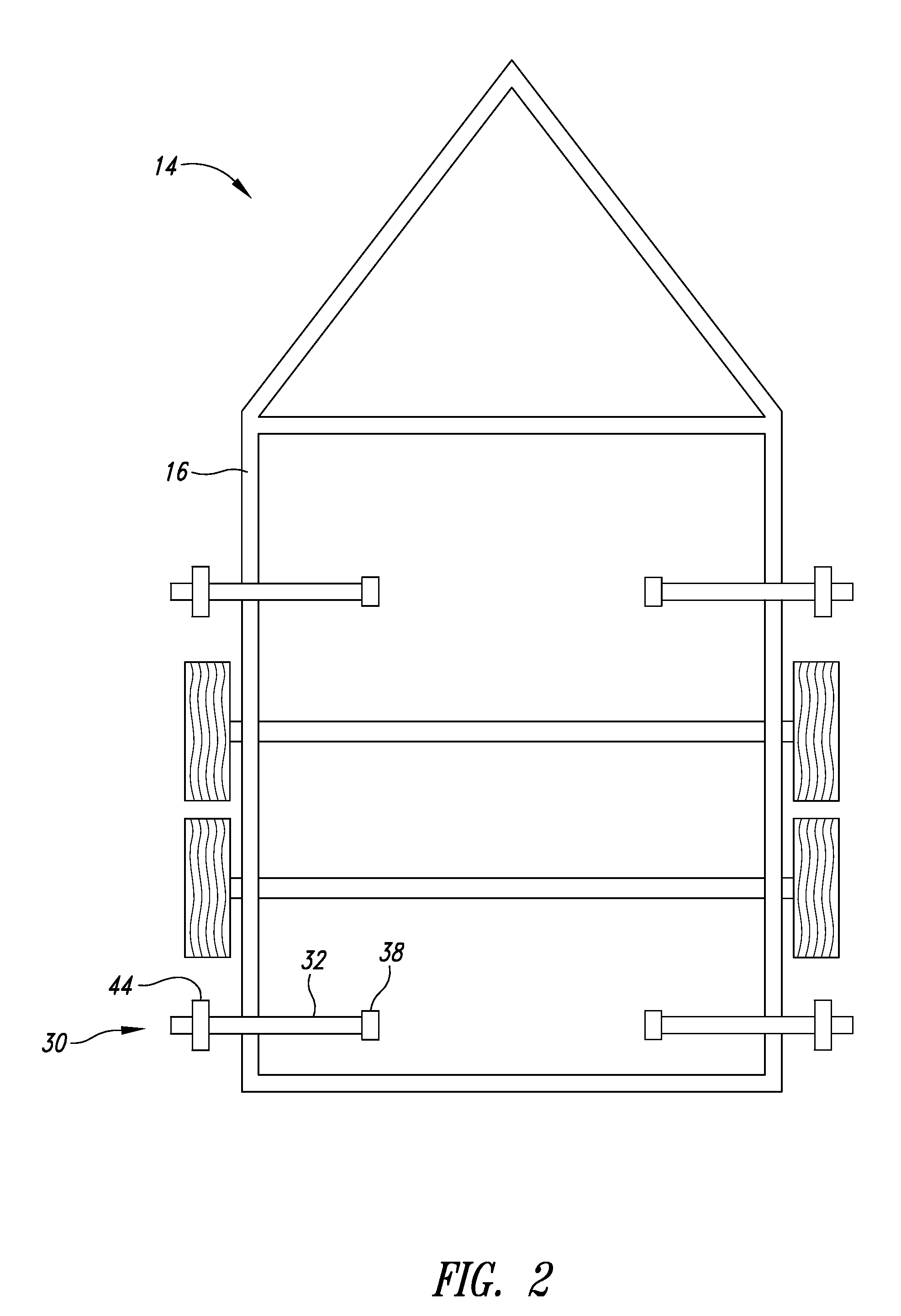

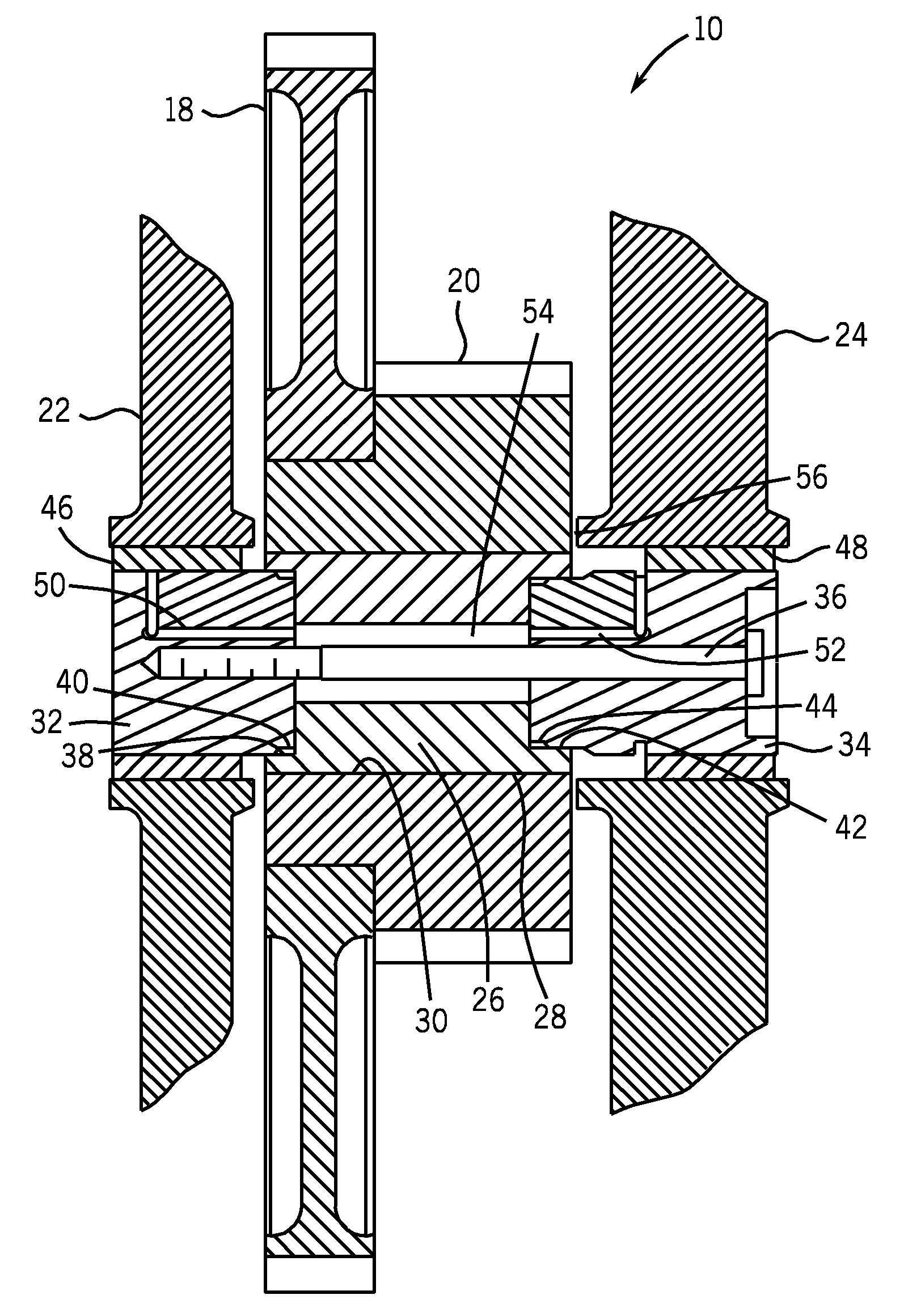

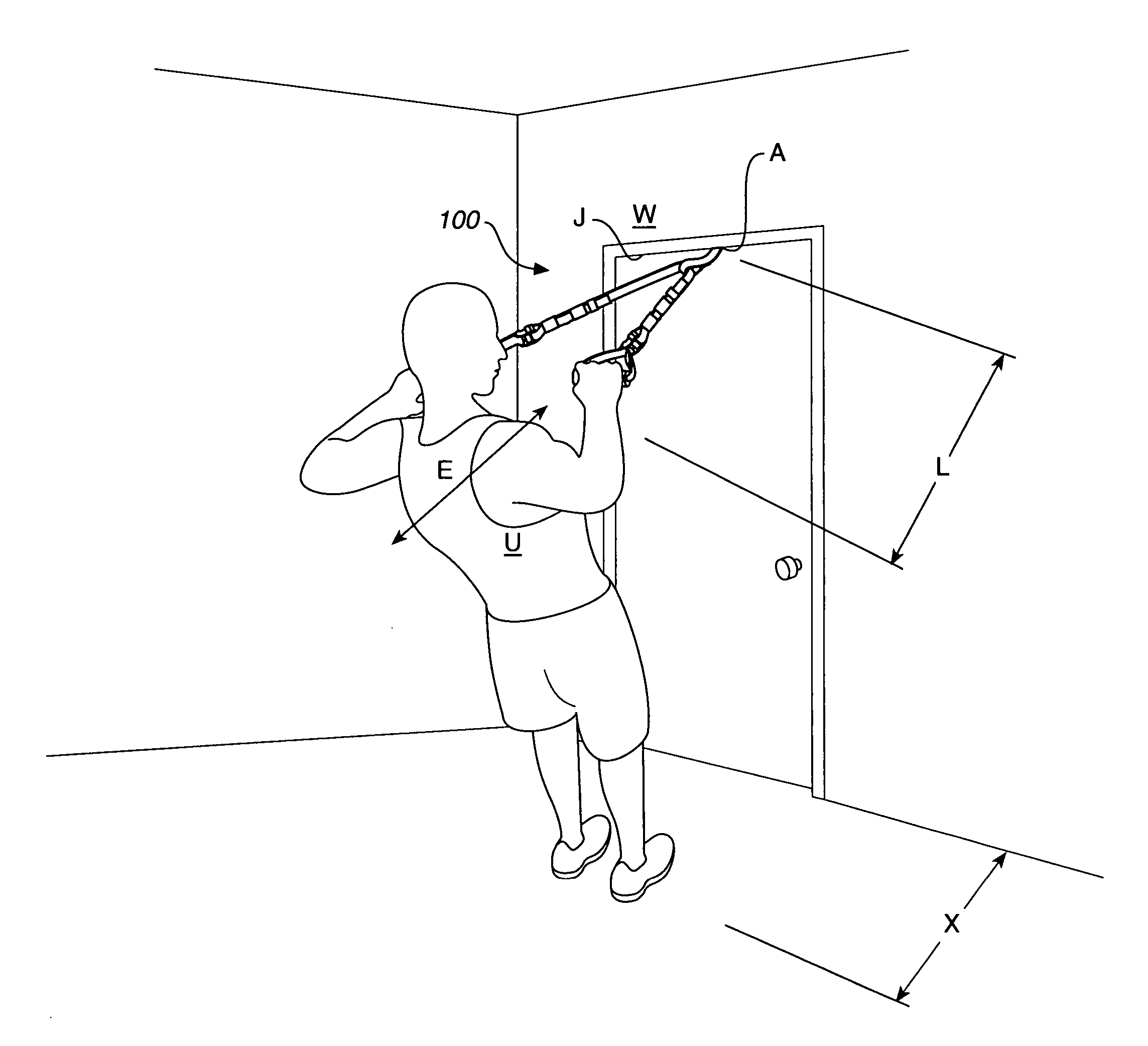

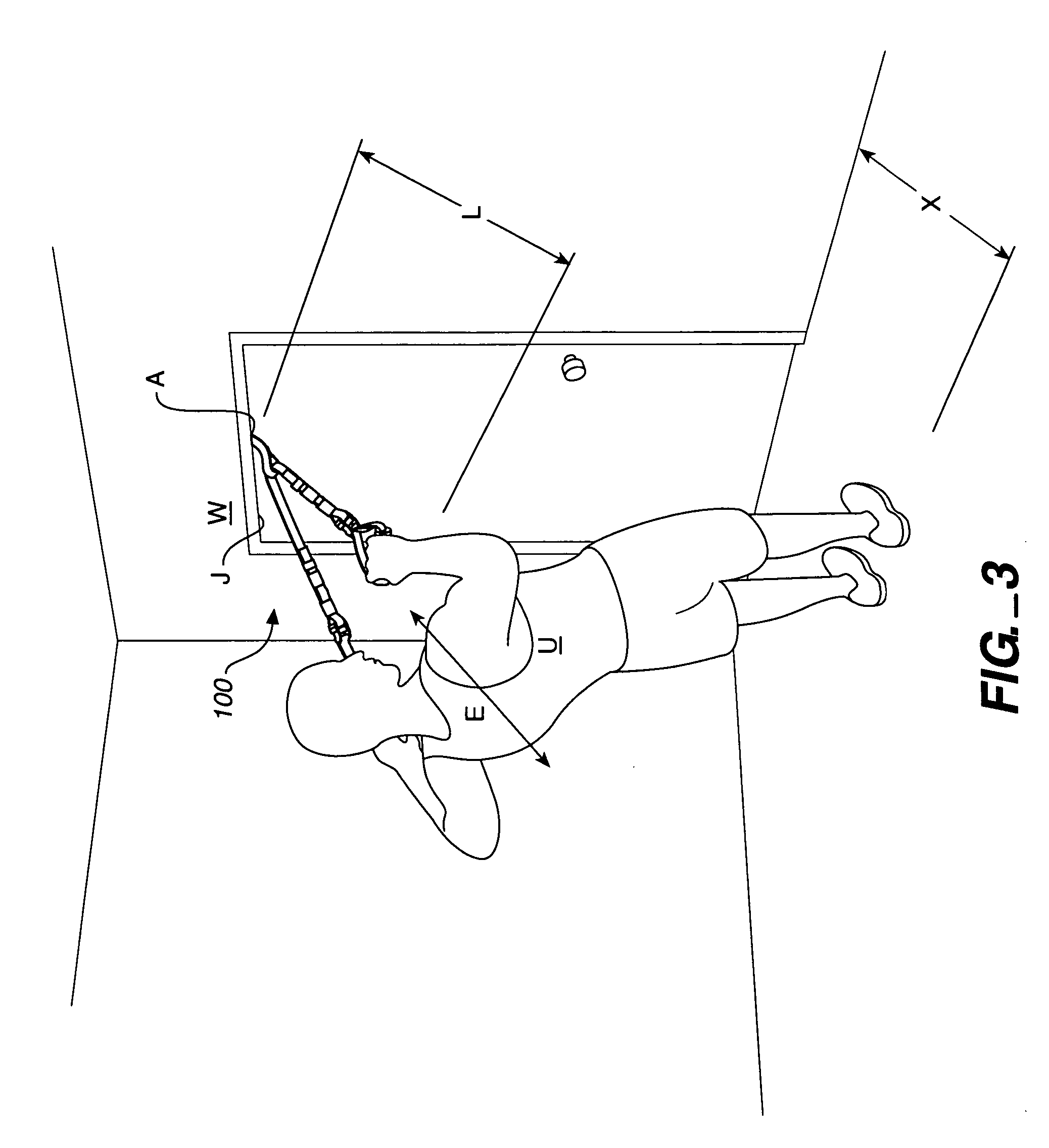

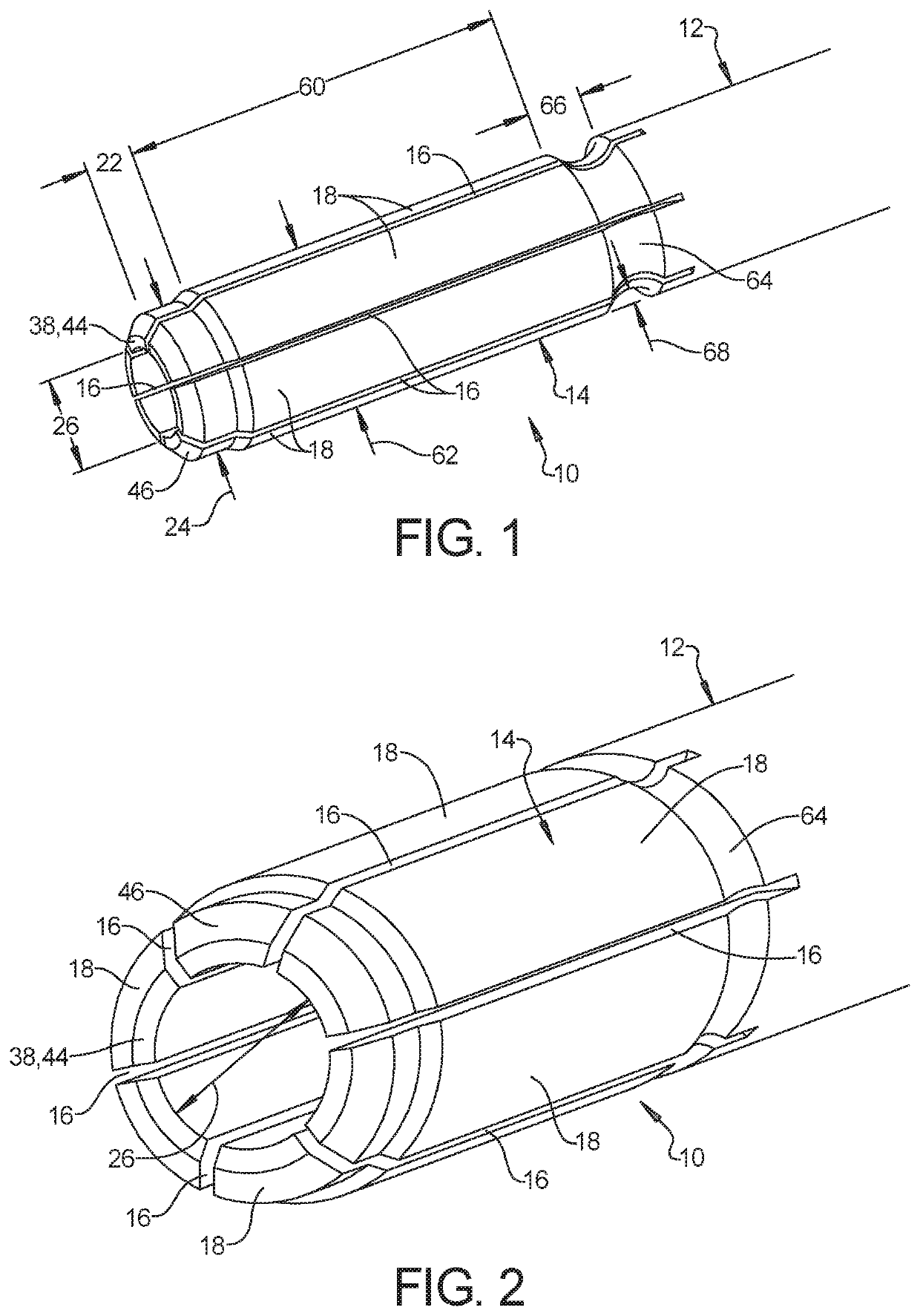

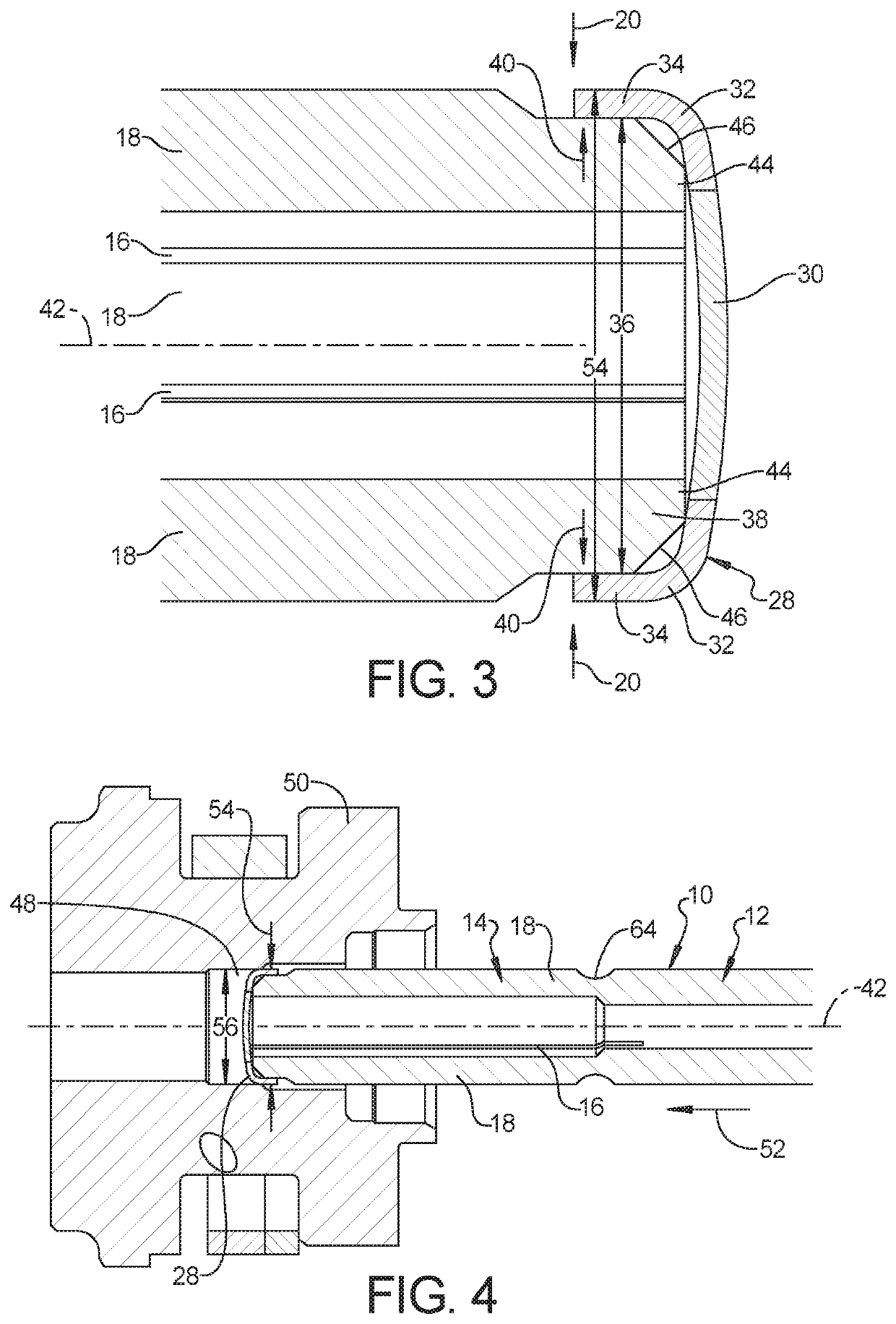

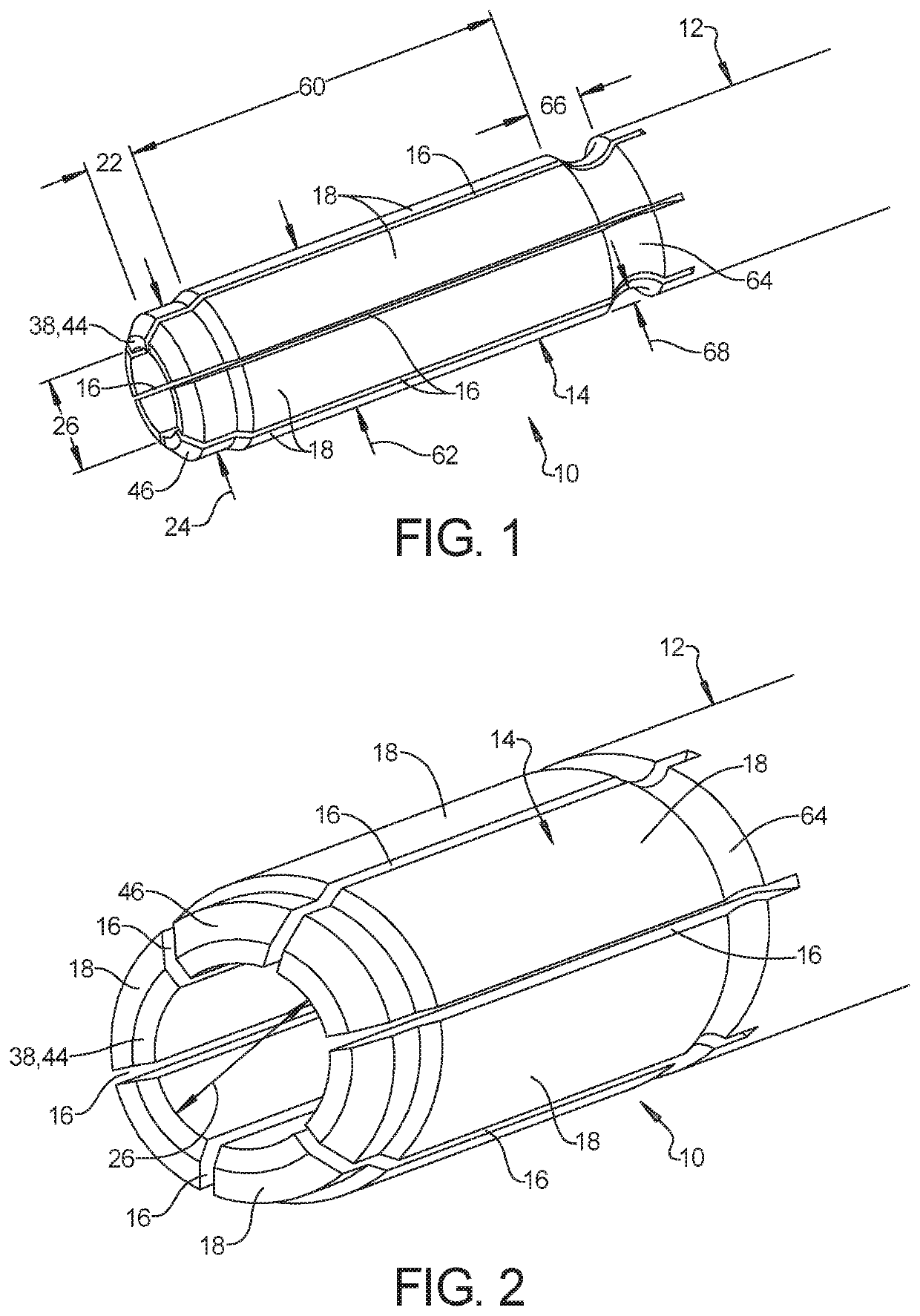

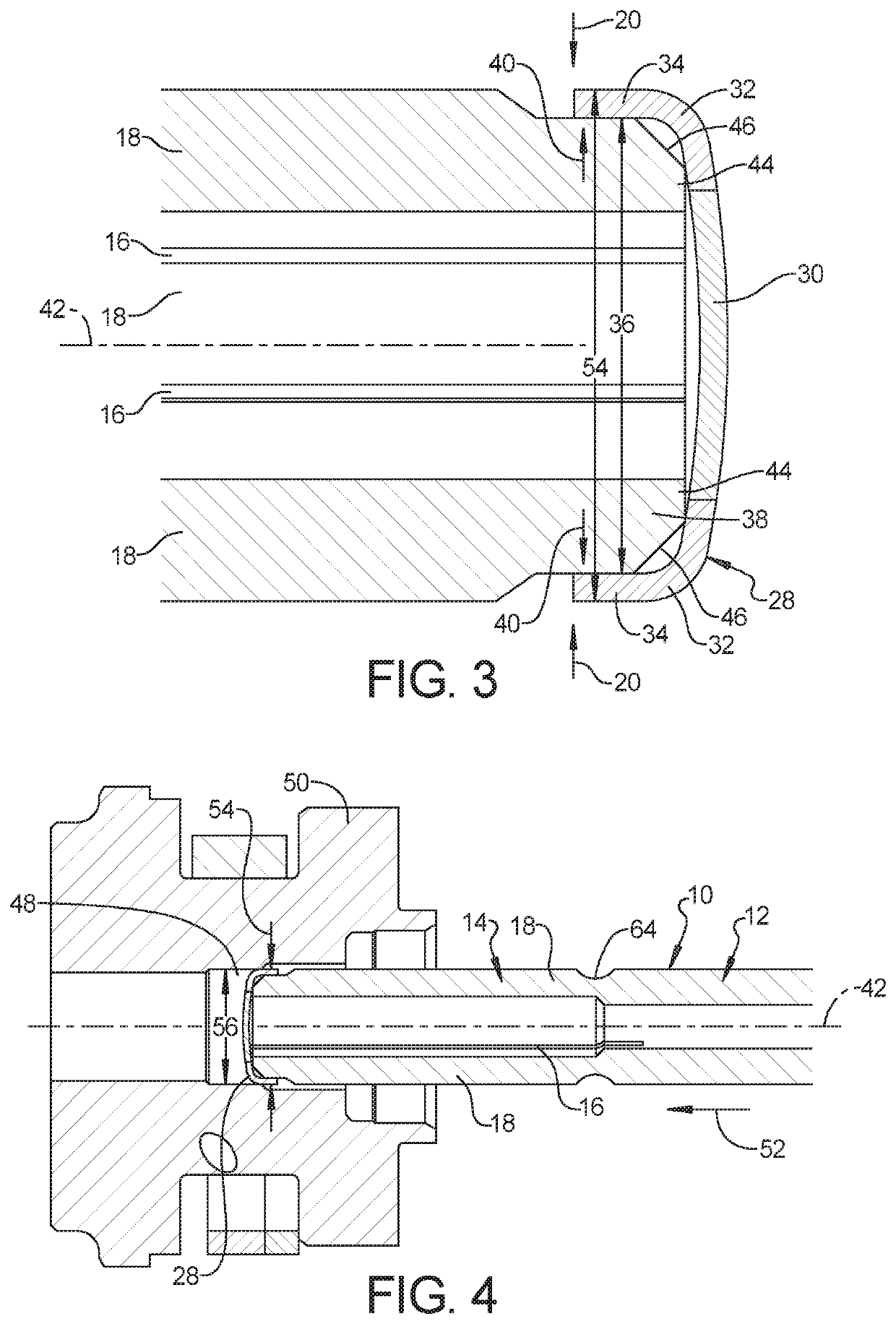

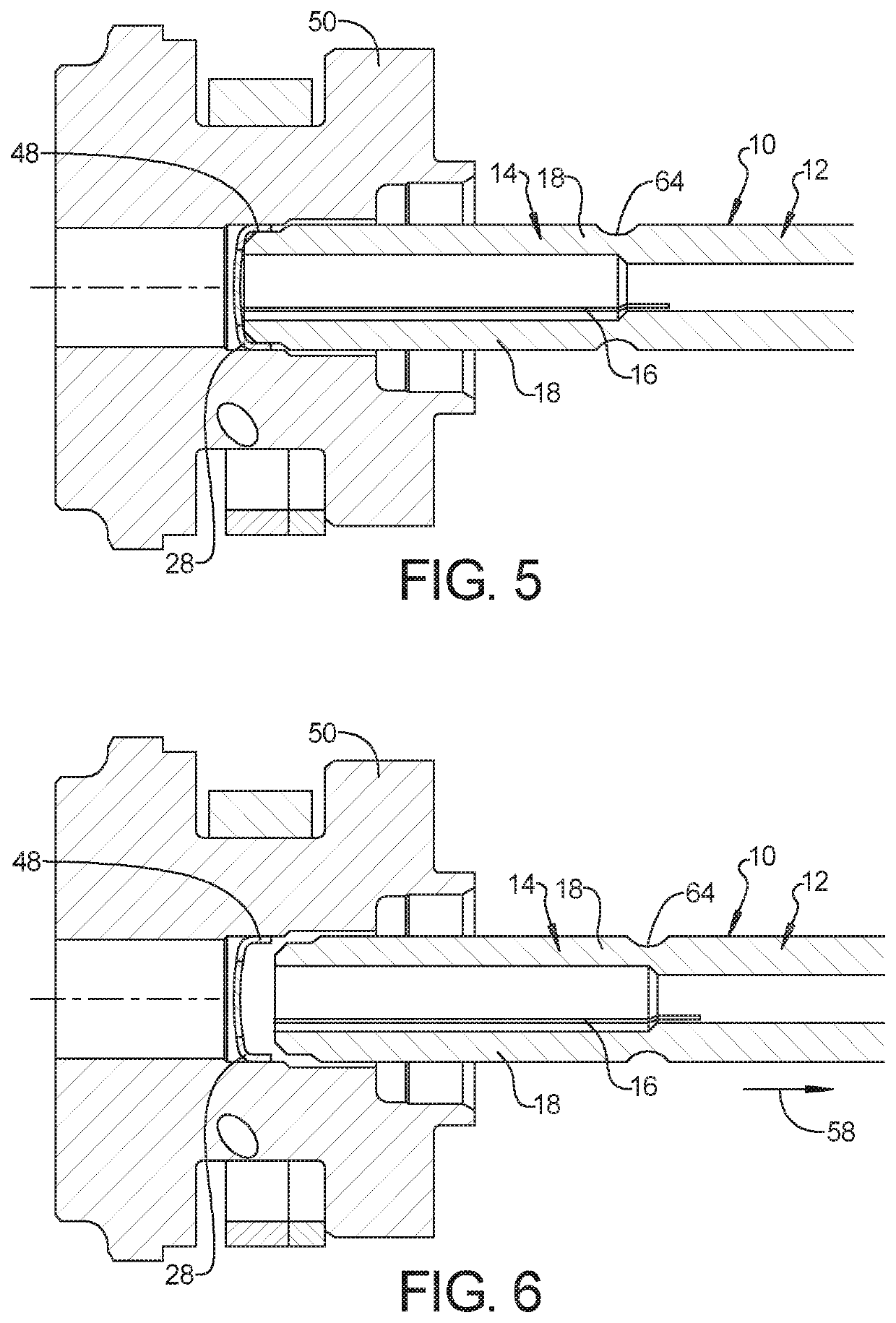

Exercise device including adjustable, inelastic straps

InactiveUS7044896B2Easy to adjustEffective centeringResilient force resistorsTherapy exerciseWhole bodyEngineering

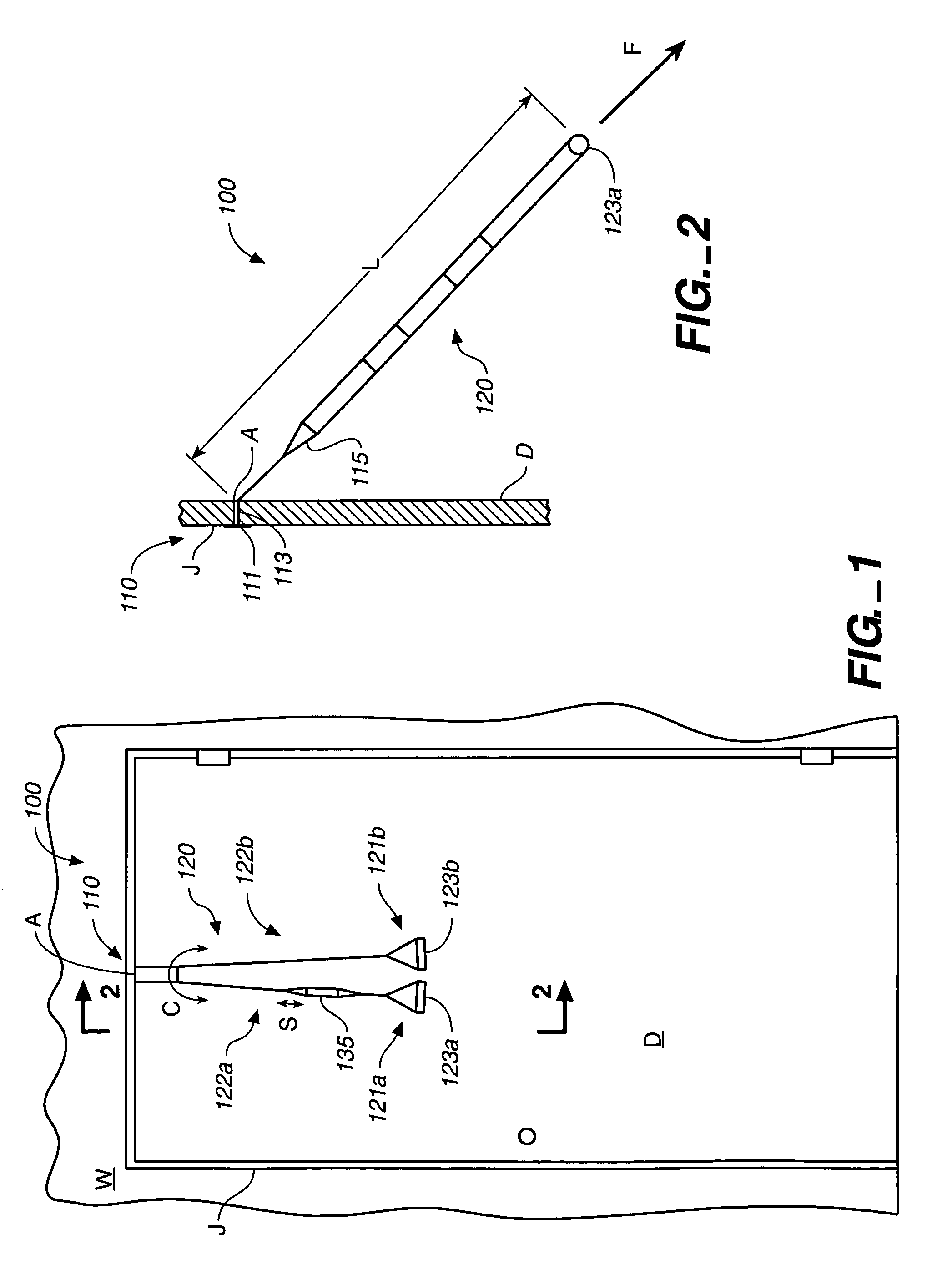

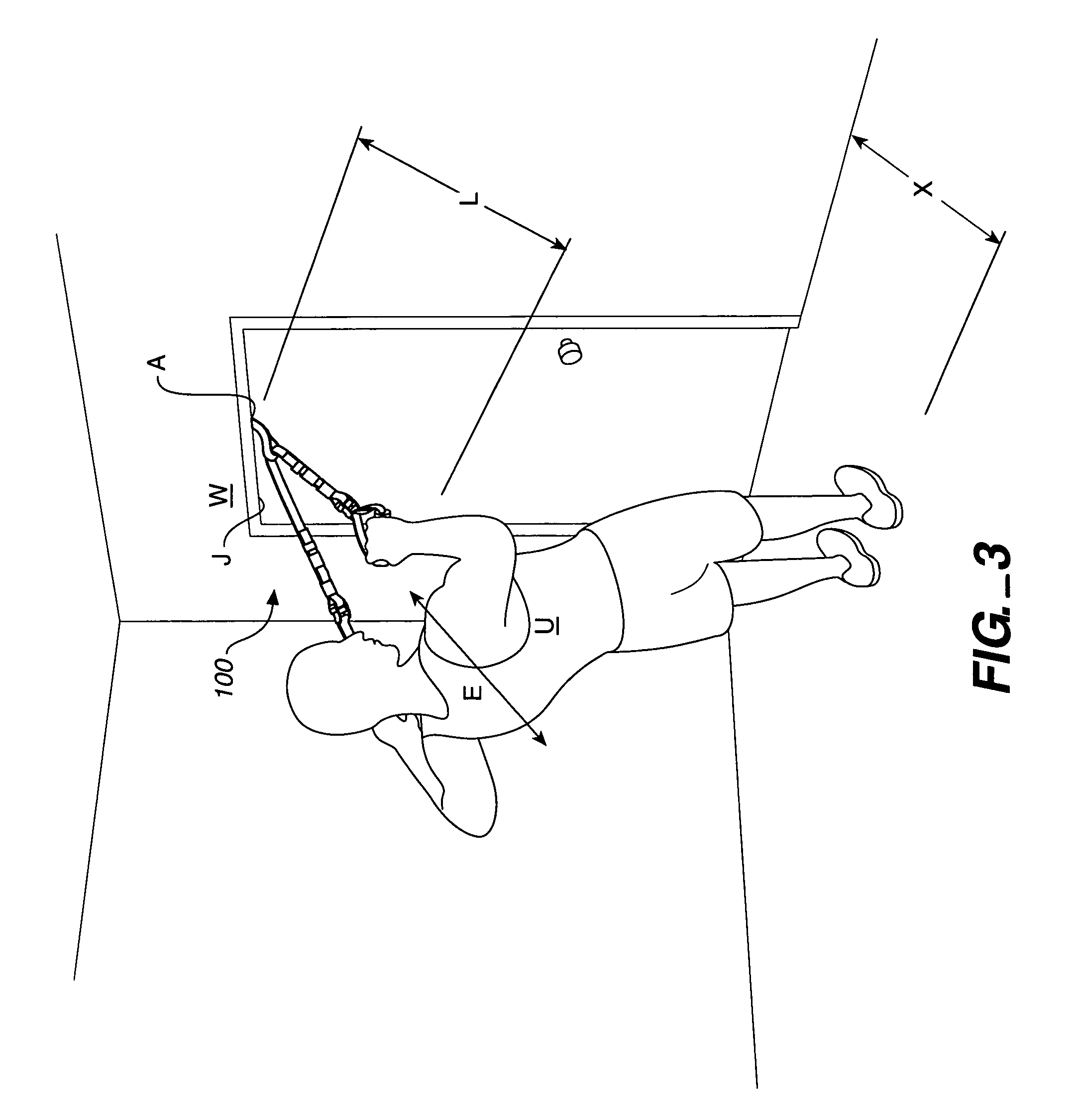

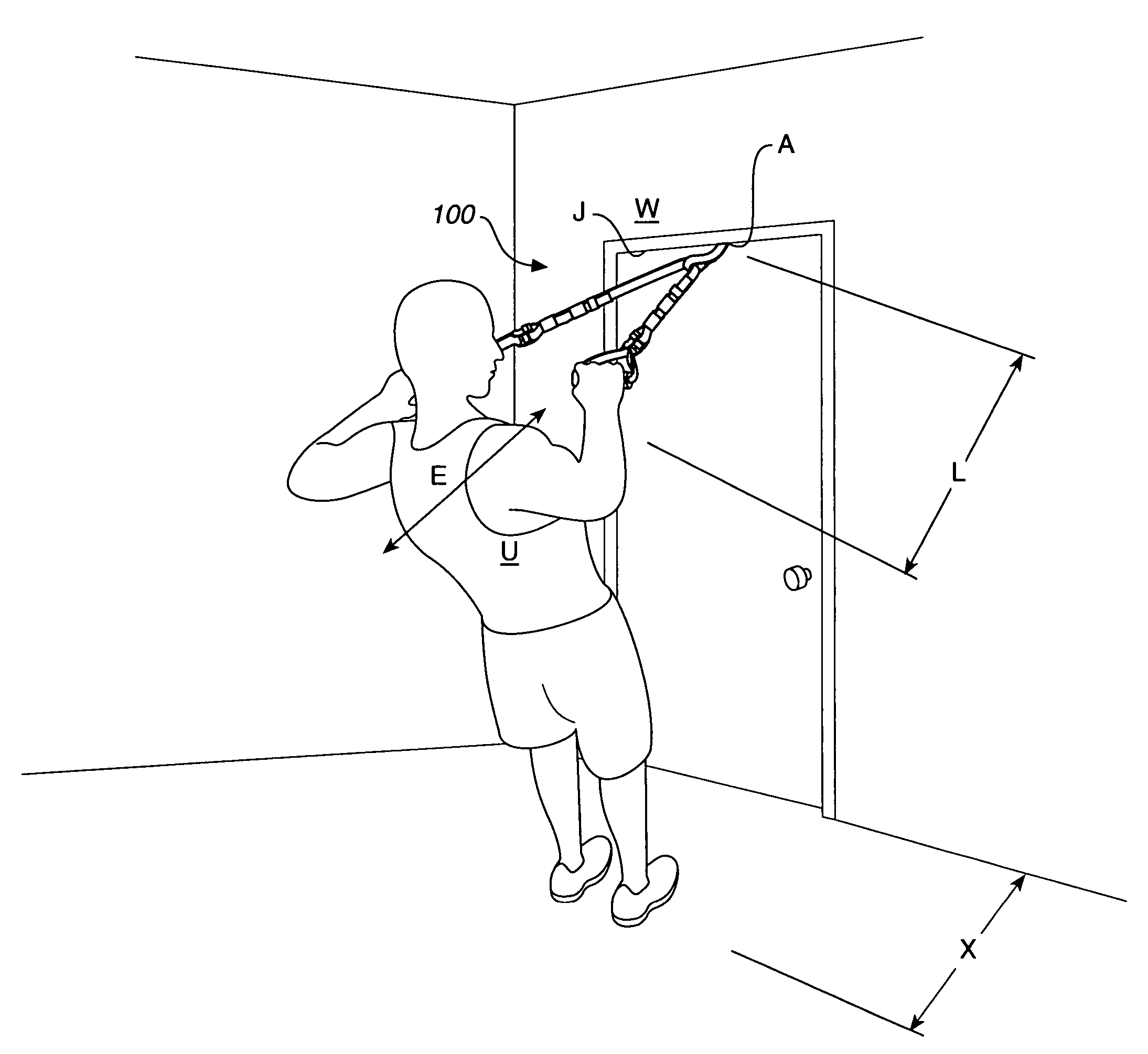

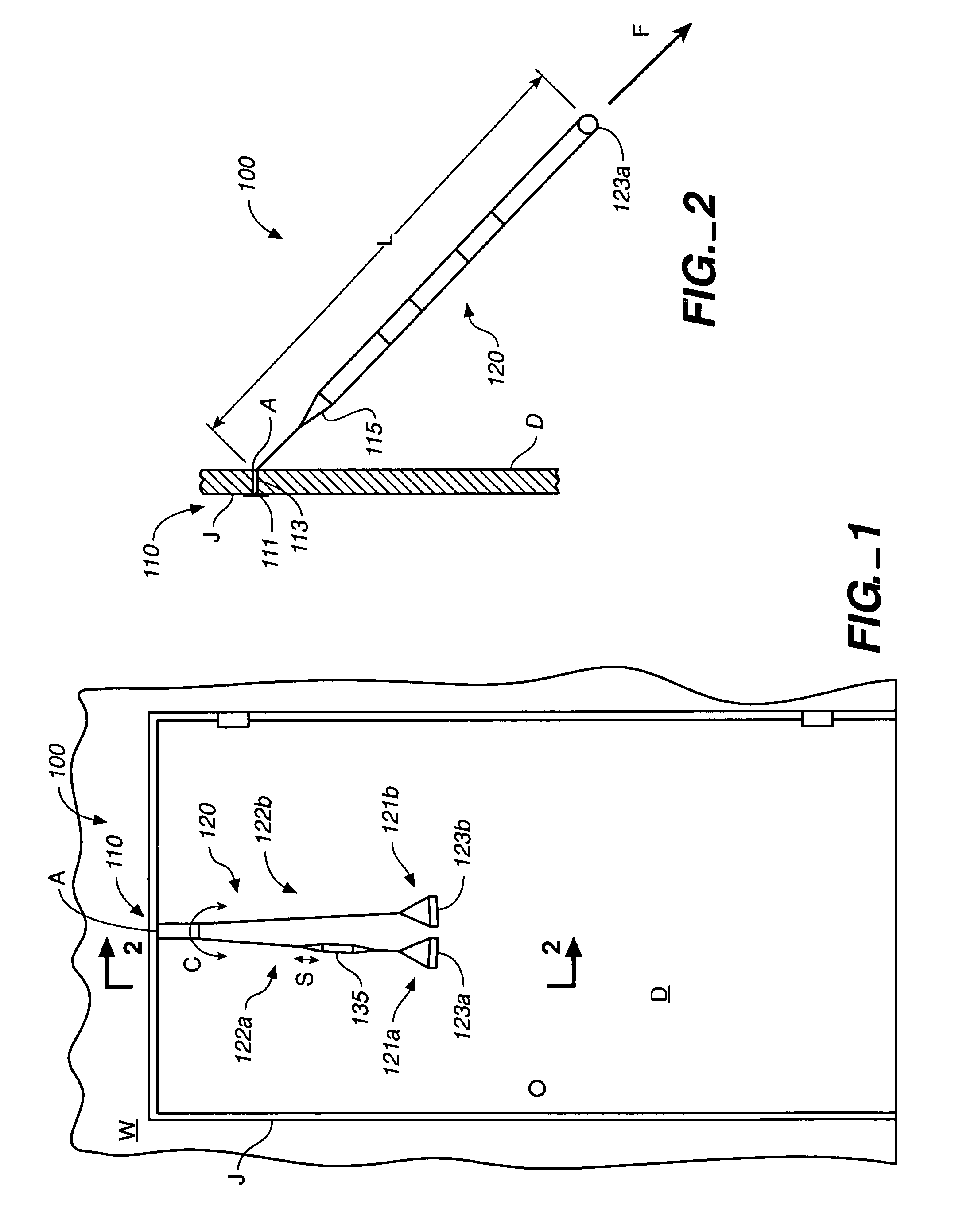

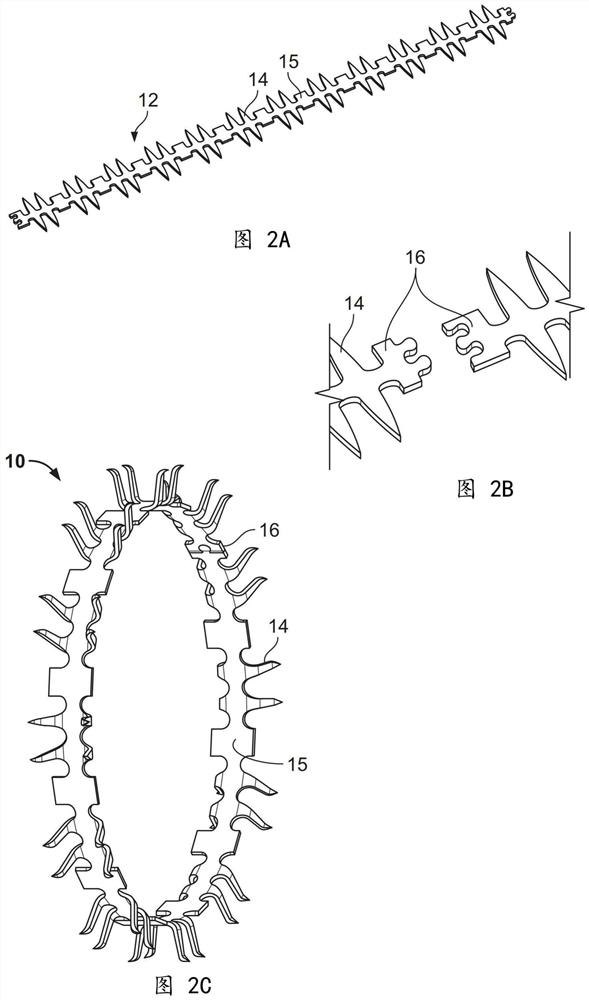

An exercise device having many advantageous features is described, including the ability to provide a user selected resistance from nearly zero resistance to the user's full body weight, the ability to easily adjust between exercises and between users, and the ability to balance the device between reconfigurations to provide for ease-of-use. The device includes an inelastic adjustable length member with two arms and a grip at both ends, and a centrally located anchor that provides for a distribution of the length between the arms. In one embodiment, the exercise device is compact and can be removably attached to a door frame. When grabbing each of the grips and uniformly pulling away from the anchor, the arms of the device center on the anchor.

Owner:JFXD TRX ACQ LLC

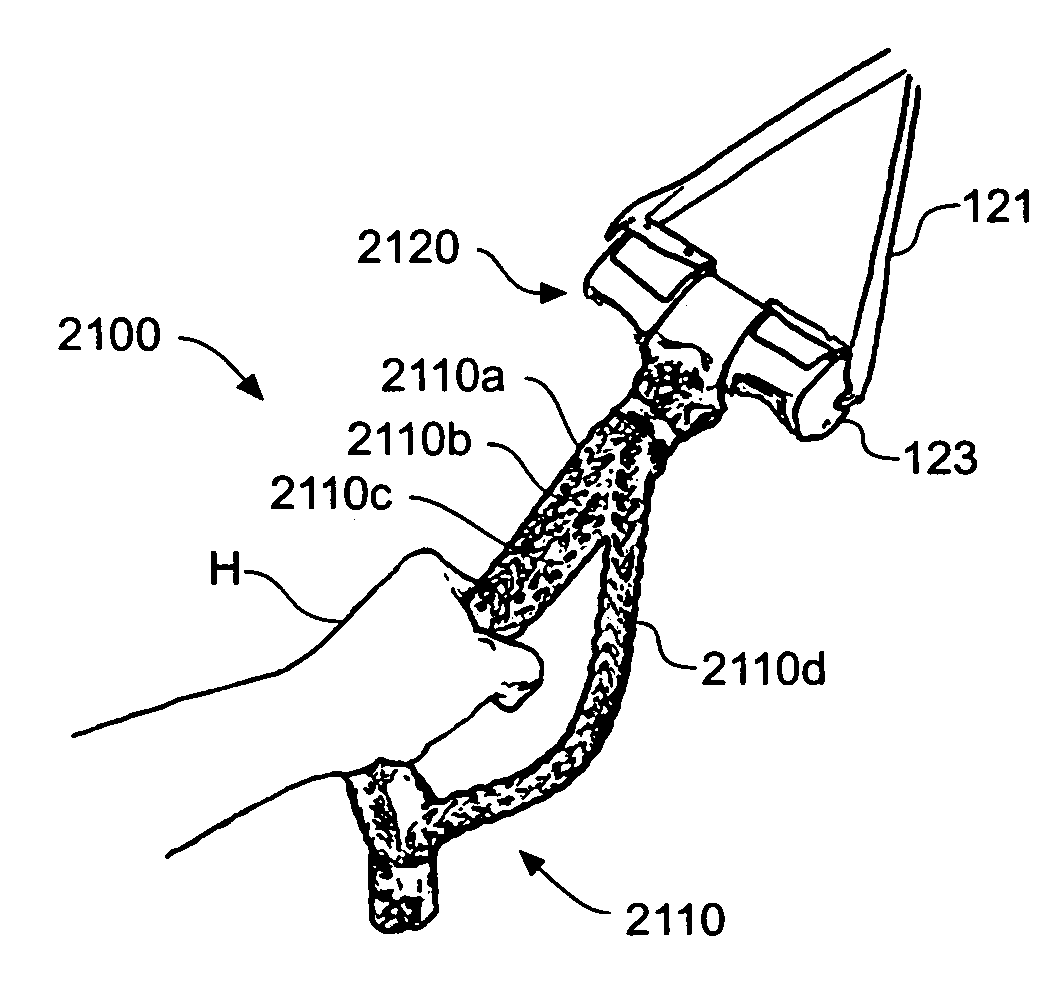

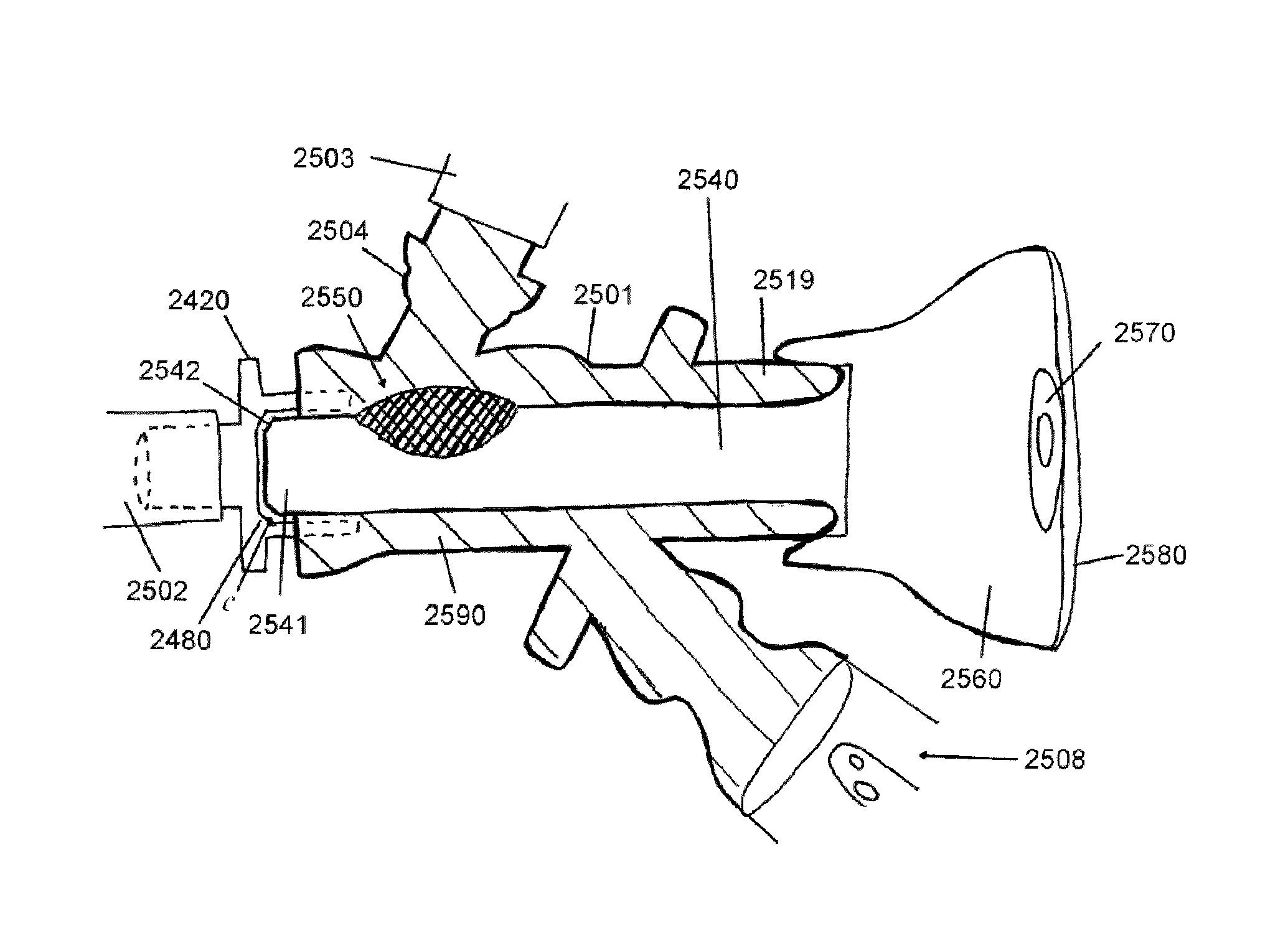

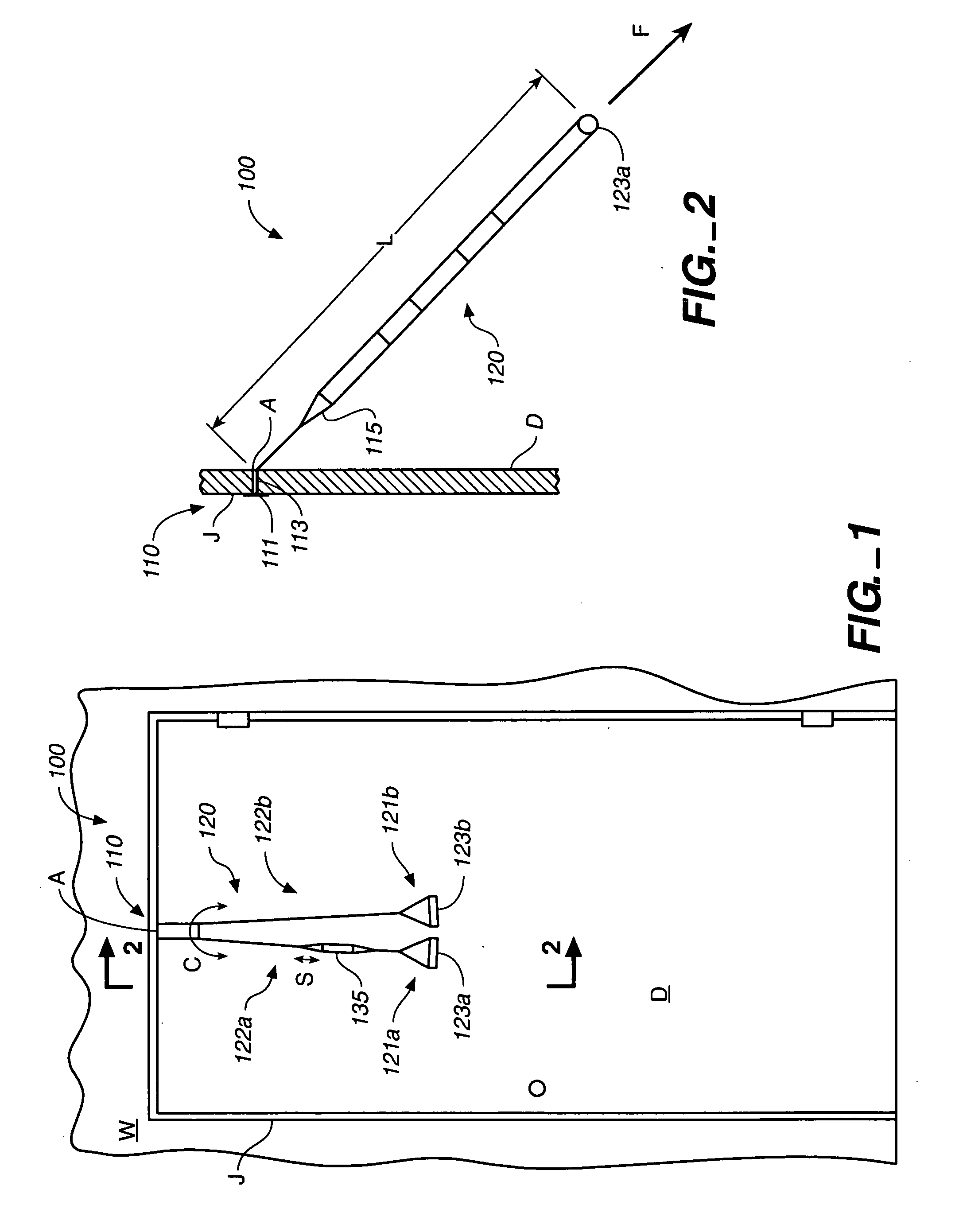

Exercise device grips and accessories for exercise devices

InactiveUS7090622B2Easy to adjustEasily vary length of deviceResilient force resistorsTherapy exerciseEngineeringBody Regions

An exercise device having many advantageous features is described, including the ability to provide a variety of different accessory grips to the user, and the ability to easily mount the device to a wall. One exercise device described is an inelastic resistance device having integral hand grips. The accessory grips are removably attachable to the integral grip of an exercising device, and provide for gripping by the hands, foot or other body parts. The selection of a specific accessory grip allows the user to exercise by specific body parts and provides for a greater number of possible exercises. Accessory grips are attachable to the integral grips, greatly adding to the flexibility of the device. In addition, a novel hand grip is described having a plurality of cords that can be selected for gripping, and a bracket for mounting a door jamb mountable exercise device to a wall is described.

Owner:JFXD TRX ACQ LLC

Method of using an adjustable exercise device

Owner:JFXD TRX ACQ LLC

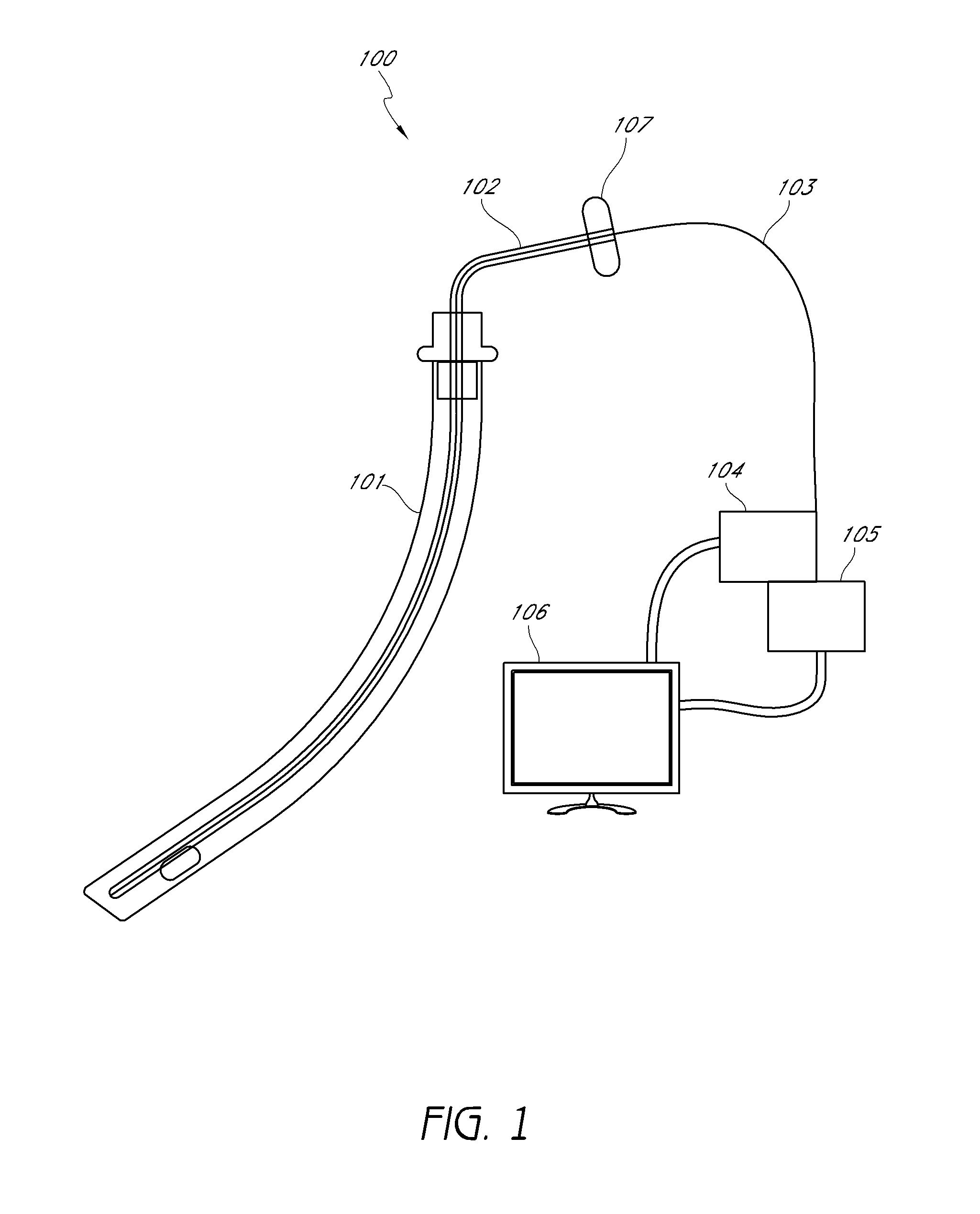

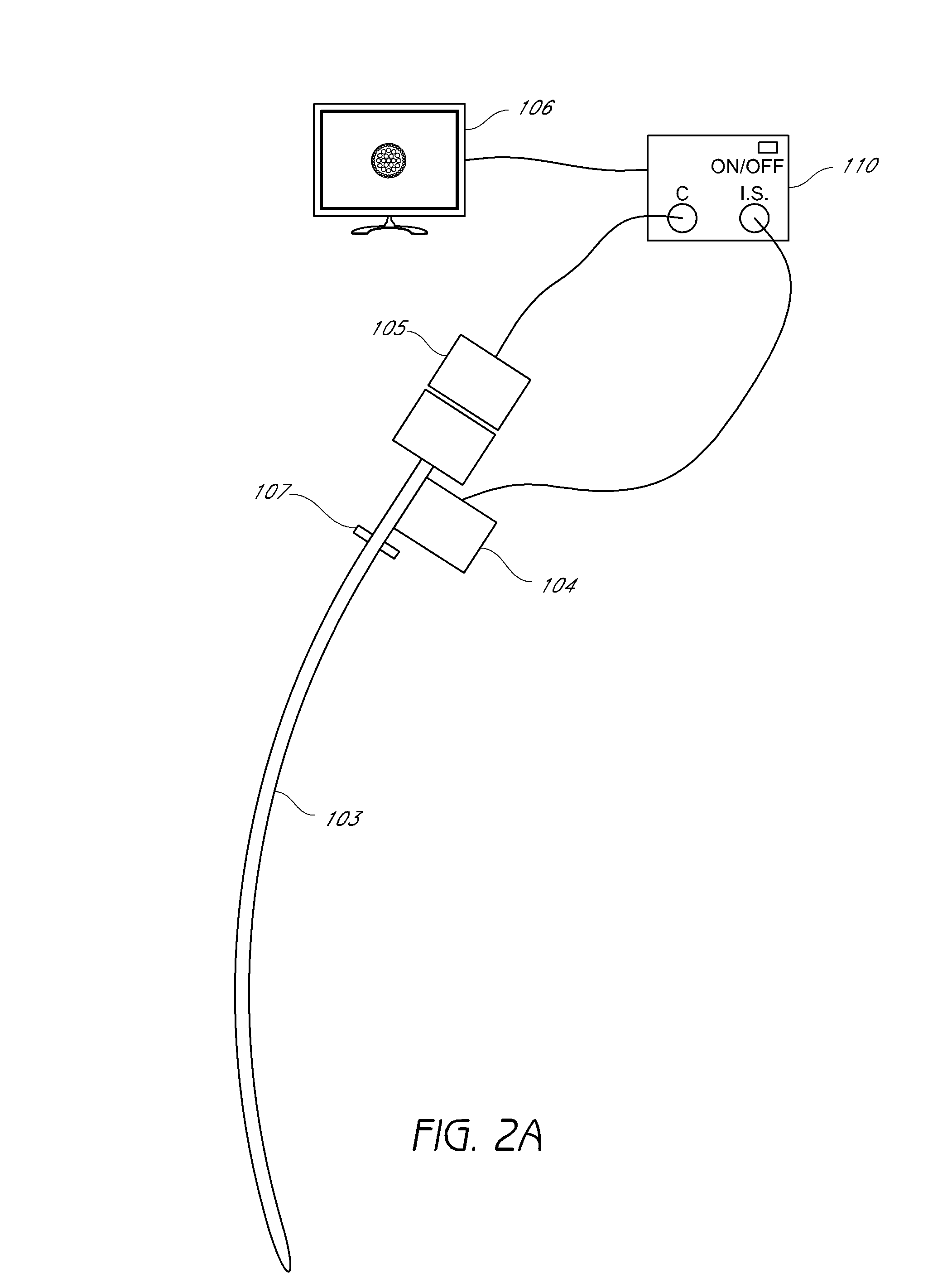

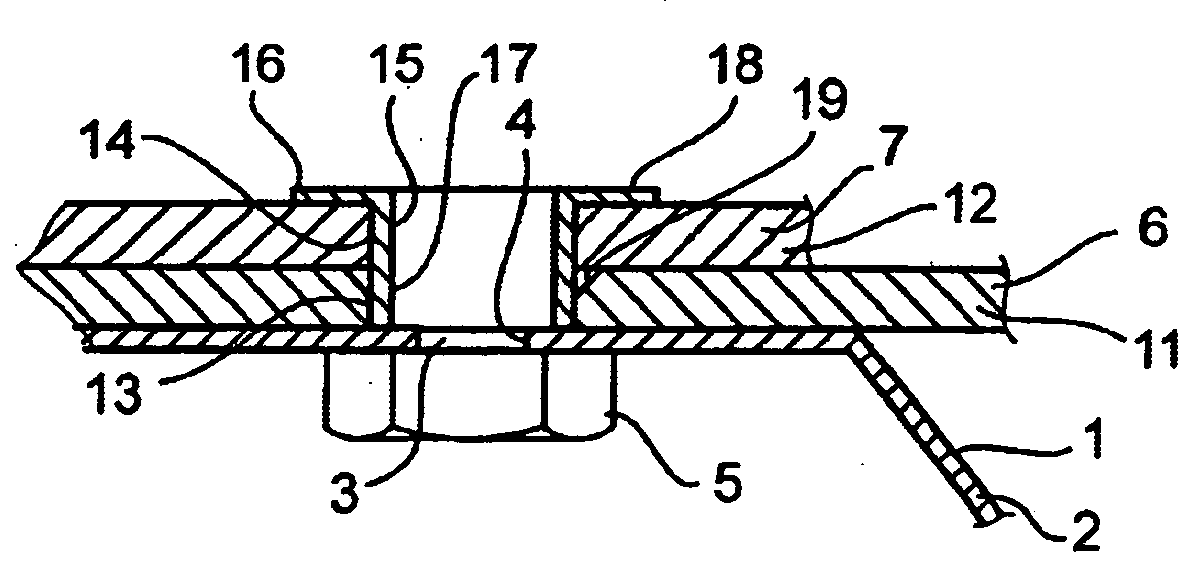

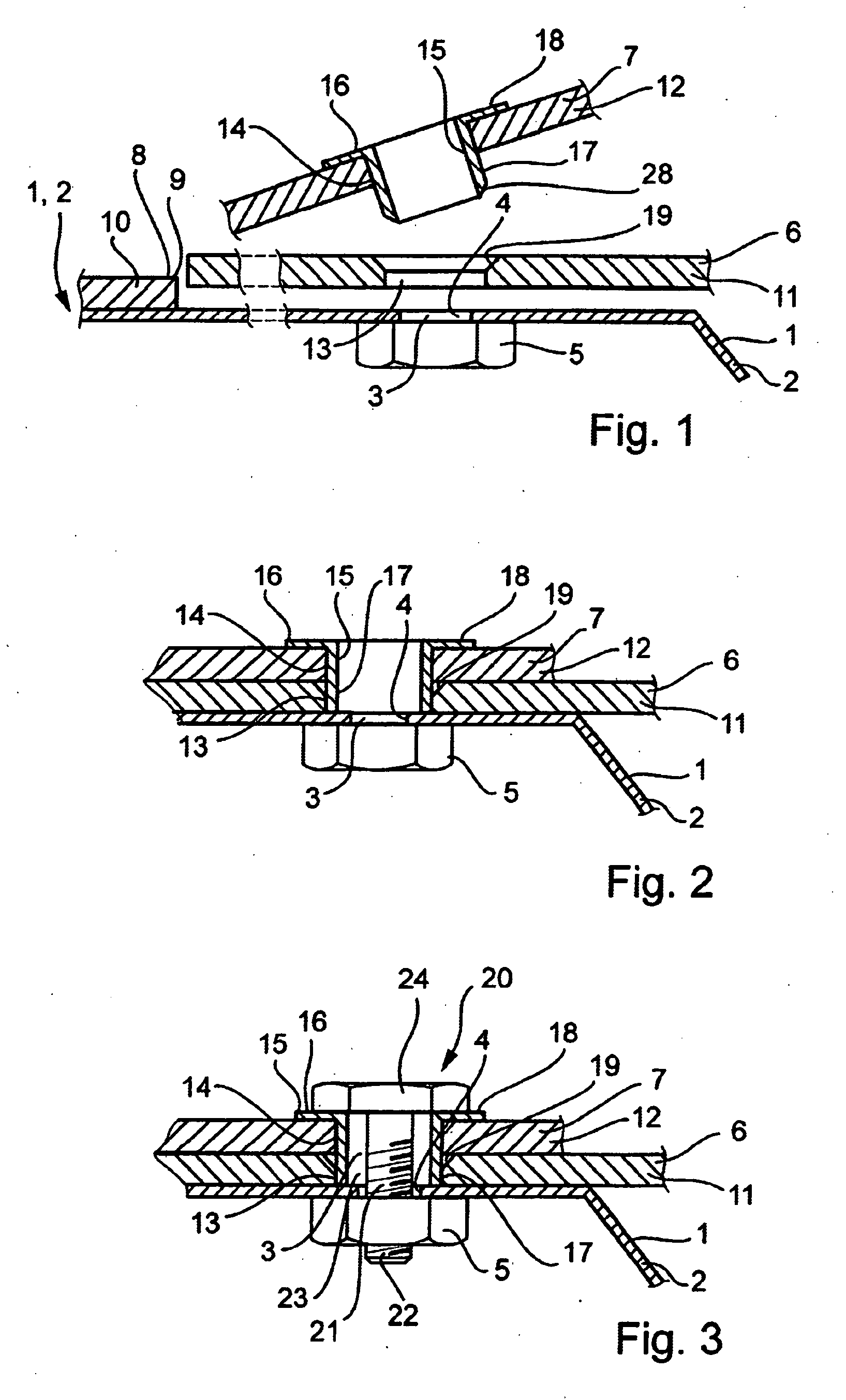

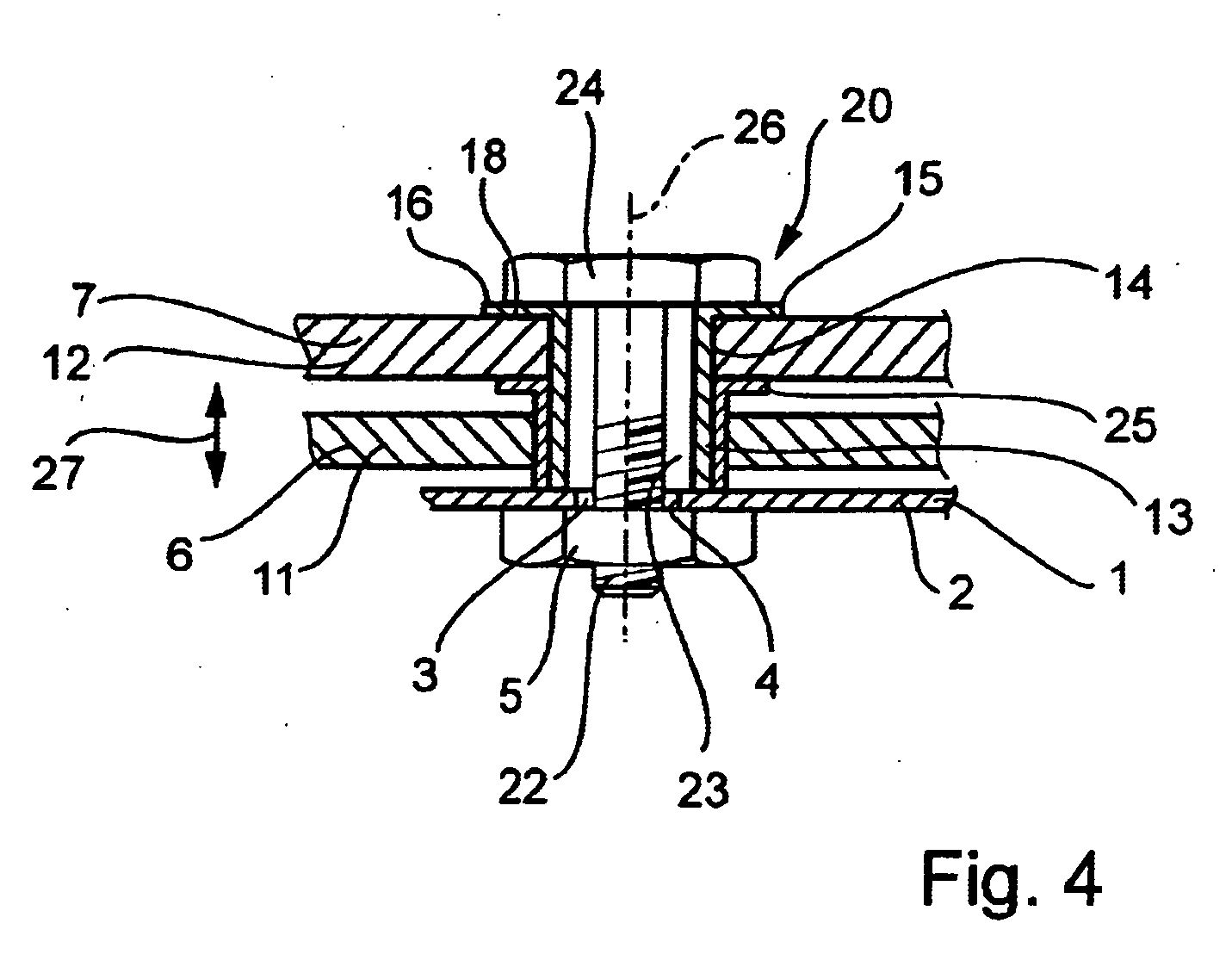

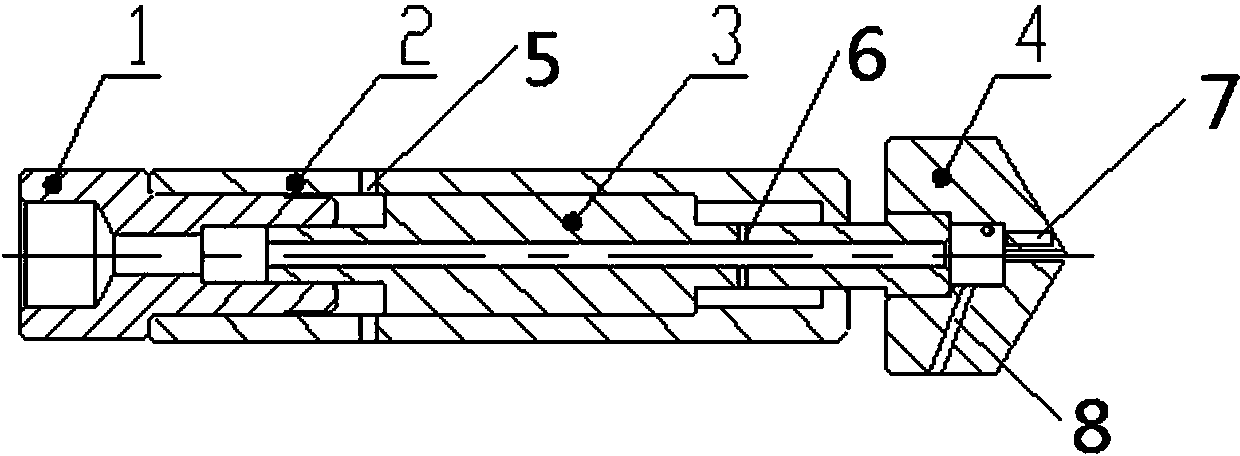

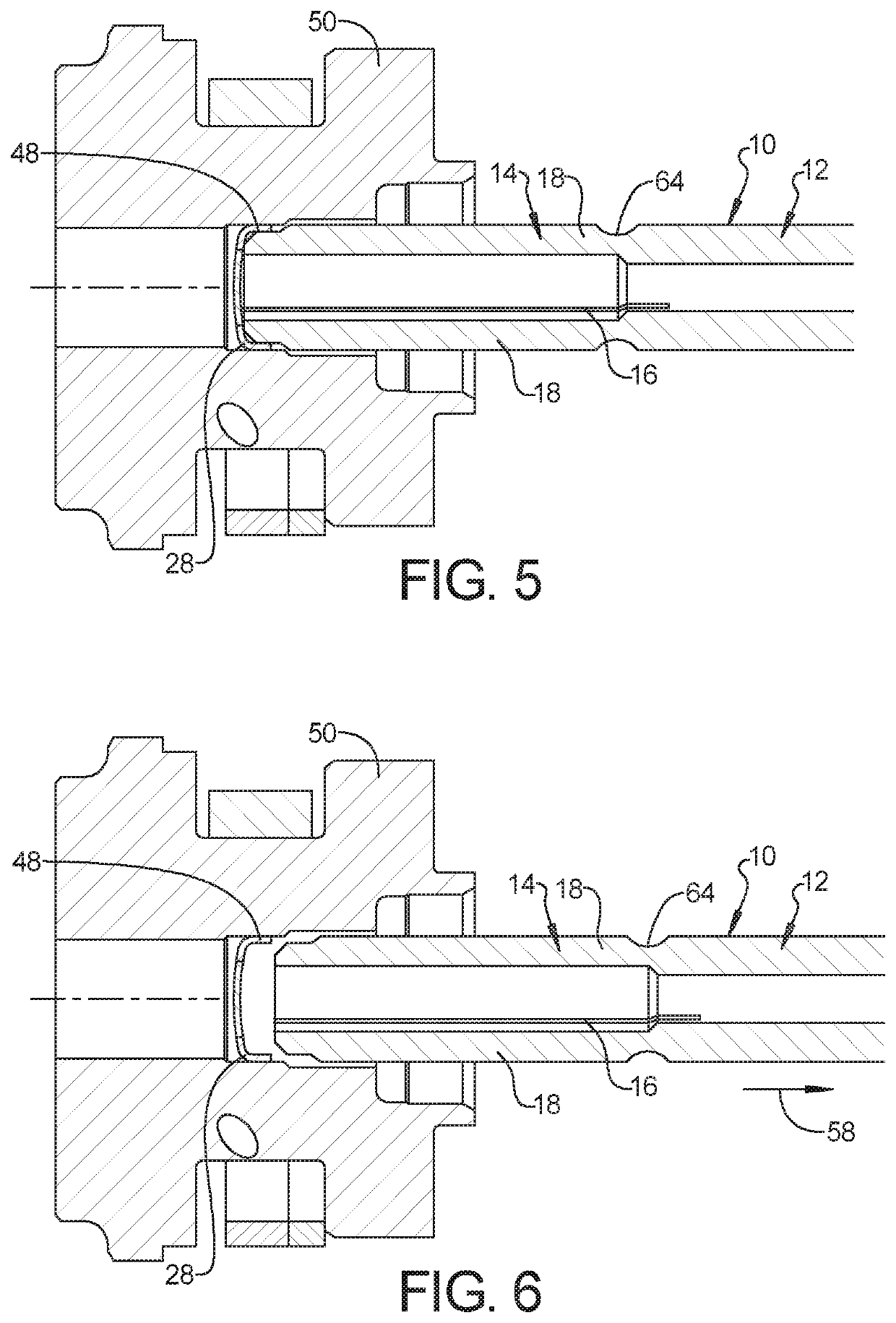

Endotracheal tube coupling adapters

ActiveUS9445714B2Reduce manufacturing costEasy to useTracheal tubesBronchoscopesBiofilmTracheal tube

Endotracheal tube coupling adapters for facilitating collection and removal of biofilm or any debris from endotracheal tubes for disposal or laboratory testing are disclosed. The endotracheal tube coupling adapters may be adapted for use in closed suction systems. The endotracheal tube coupling adapters may be configured to remain coupled to an endotracheal tube from the time of intubation until the time of removal and to receive visualization, cleaning, and / or biofilm collection devices or members without being removed from the endotracheal tube.

Owner:AVENT INC

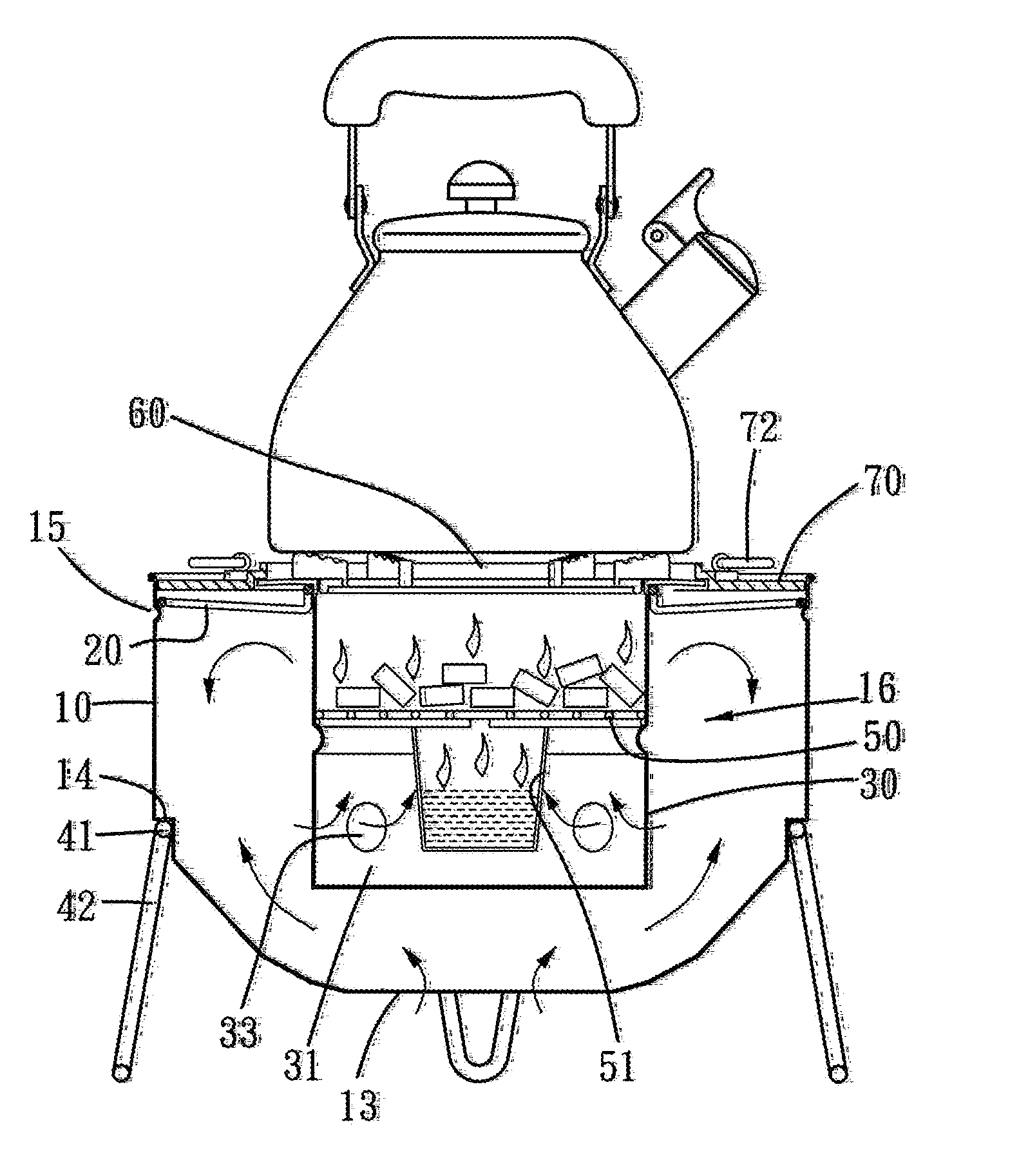

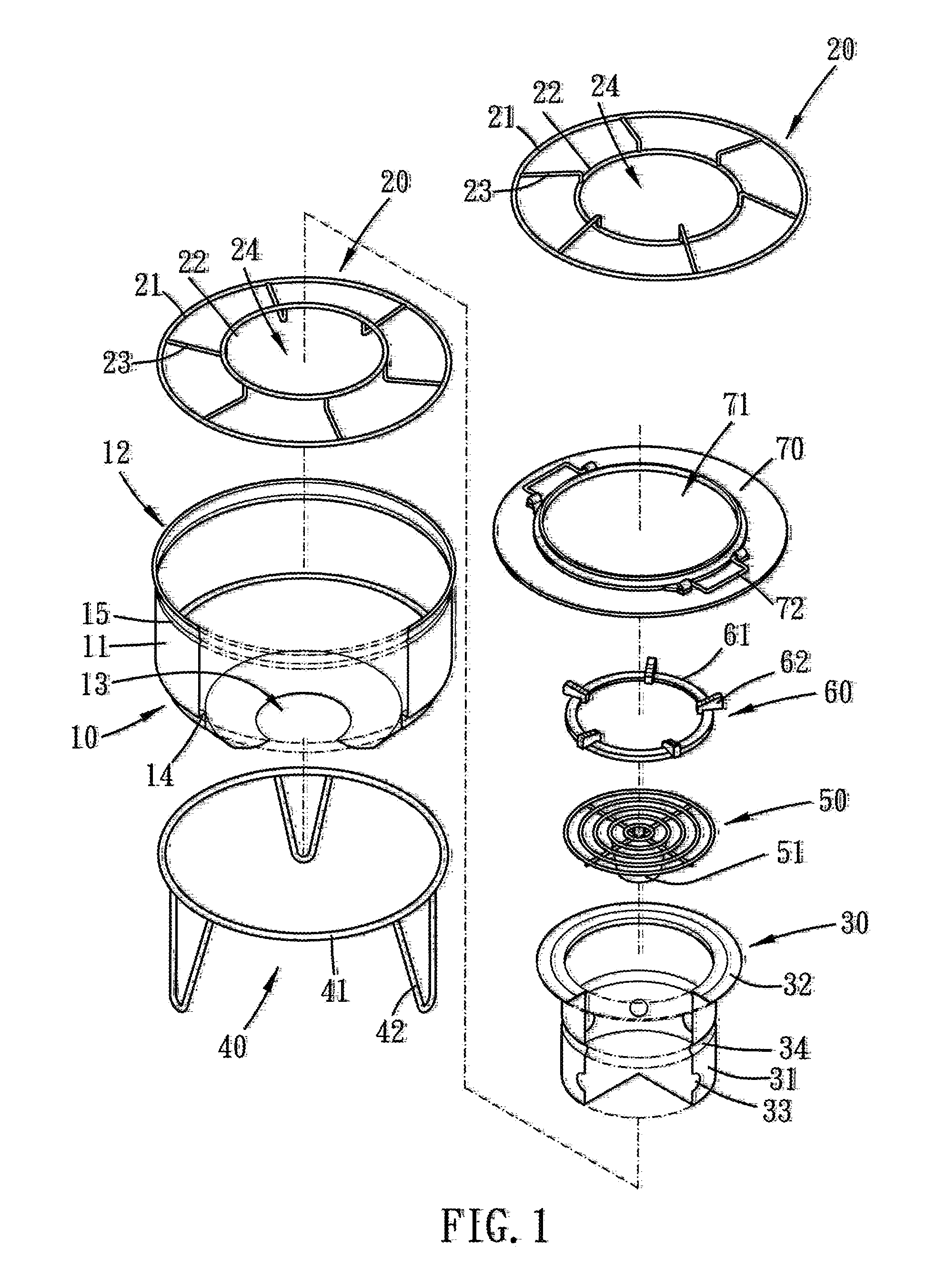

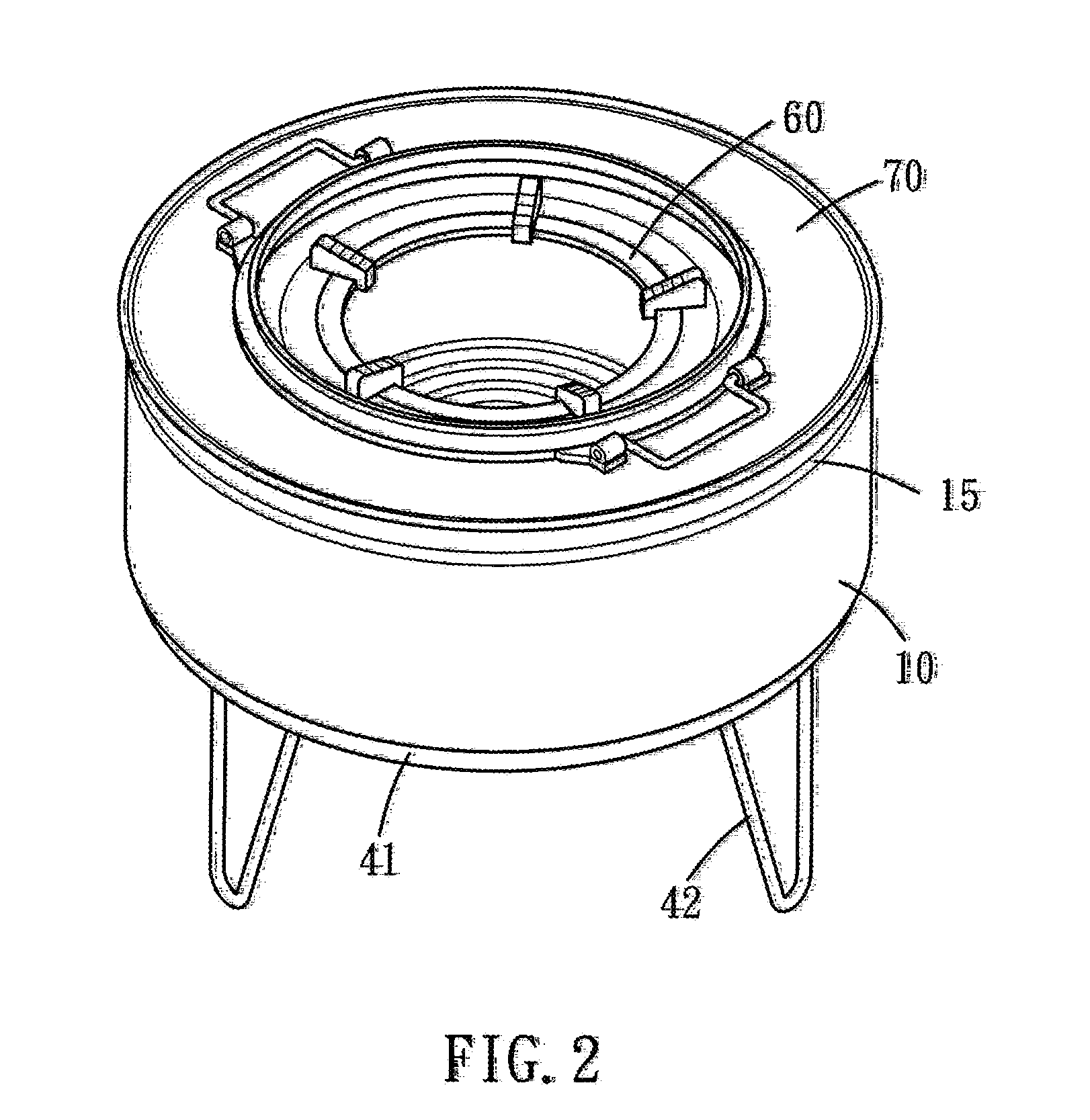

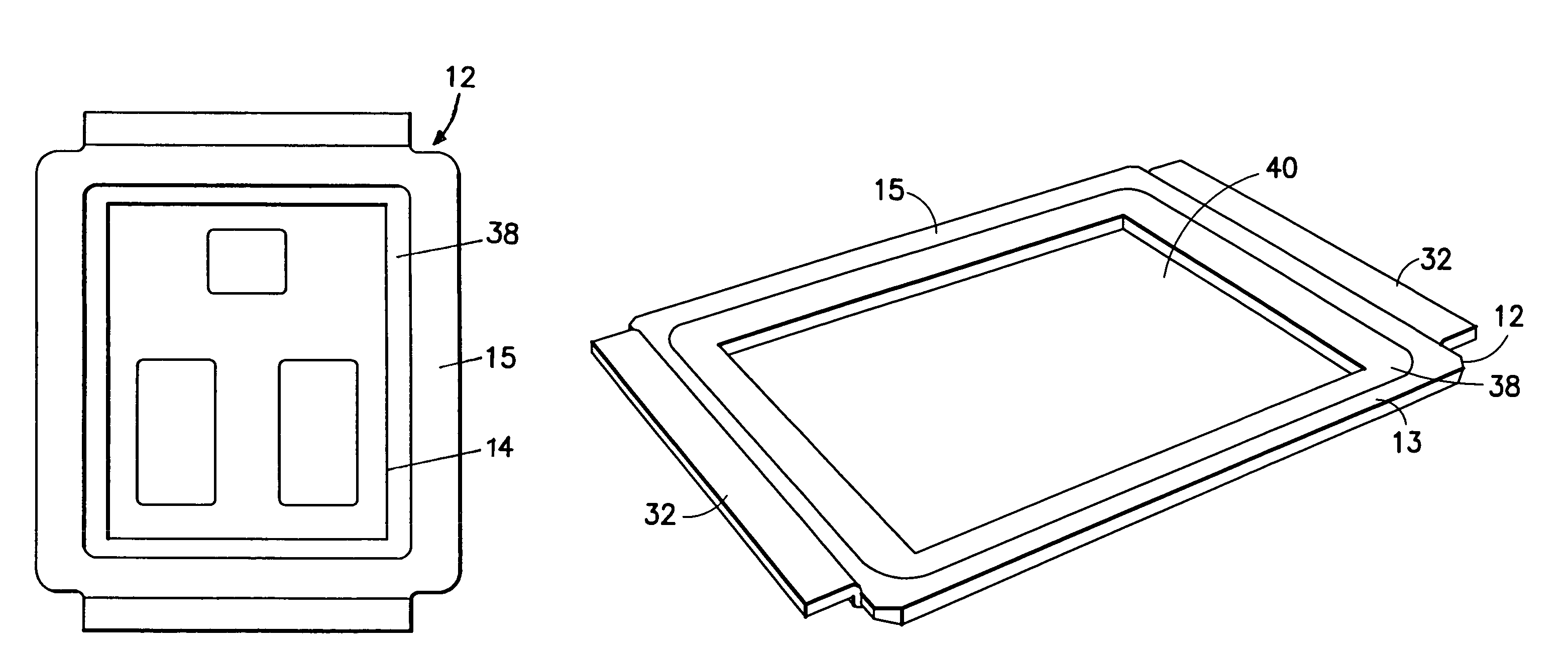

Multi-functional cooking stove

InactiveUS20110073098A1Efficient thermal energyEasy to catch fireDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

A multi-functional cooking stove of the present invention includes a stove body, a position frame and a stove element. The stove body has an annular shell which defines an upper opening and a lower opening. The lower opening is smaller than the upper one. The position frame is disposed in the stove body and defines a through hole at its center for a container body of the stove element to pass therethrough. The stove element is adapted for fuel to dispose therein. A convection space is defined between the stove body and the stove element. At least one convection bore is formed on a periphery of the container body to communicate the convection space with an interior of the container body.

Owner:AFIRE

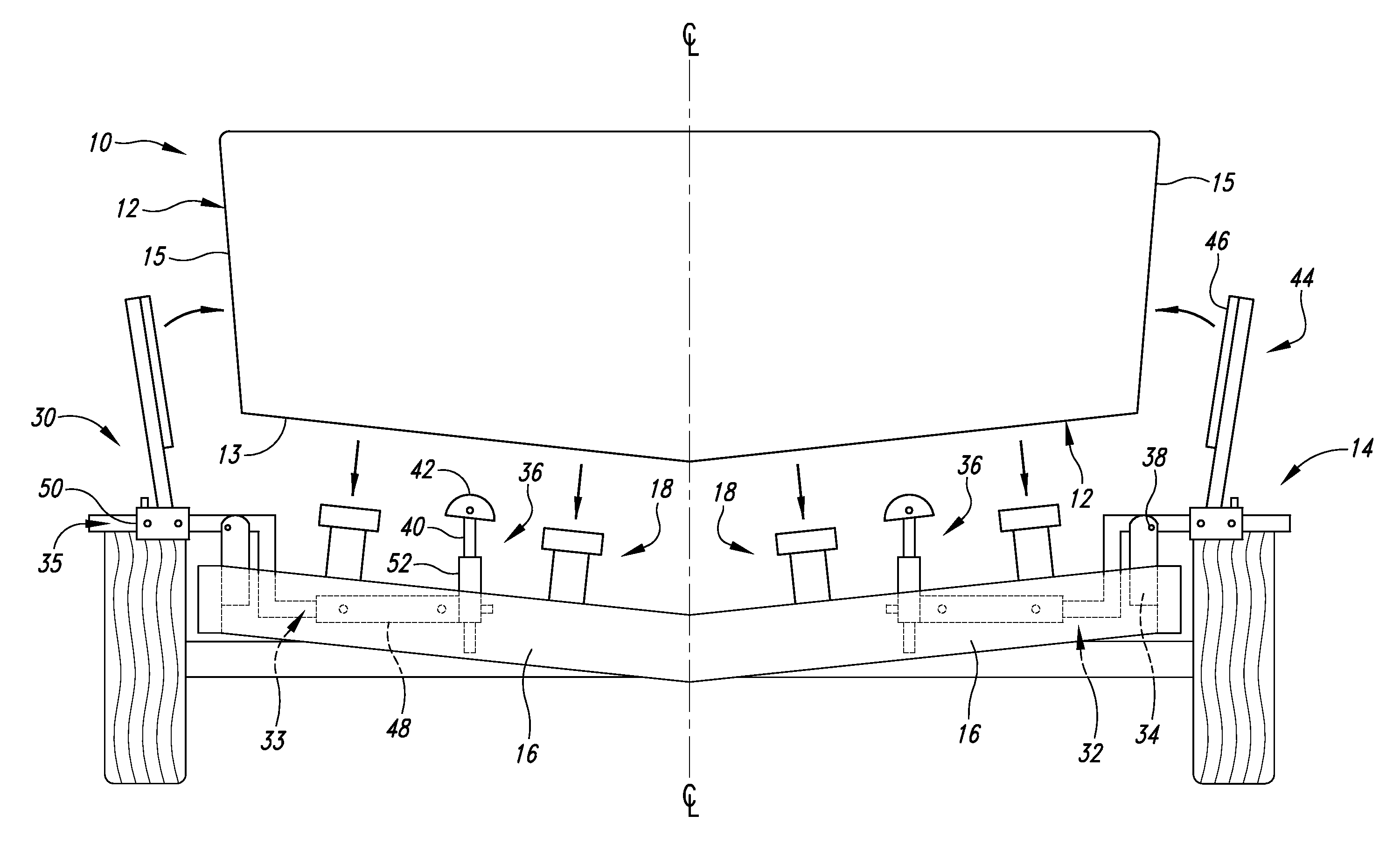

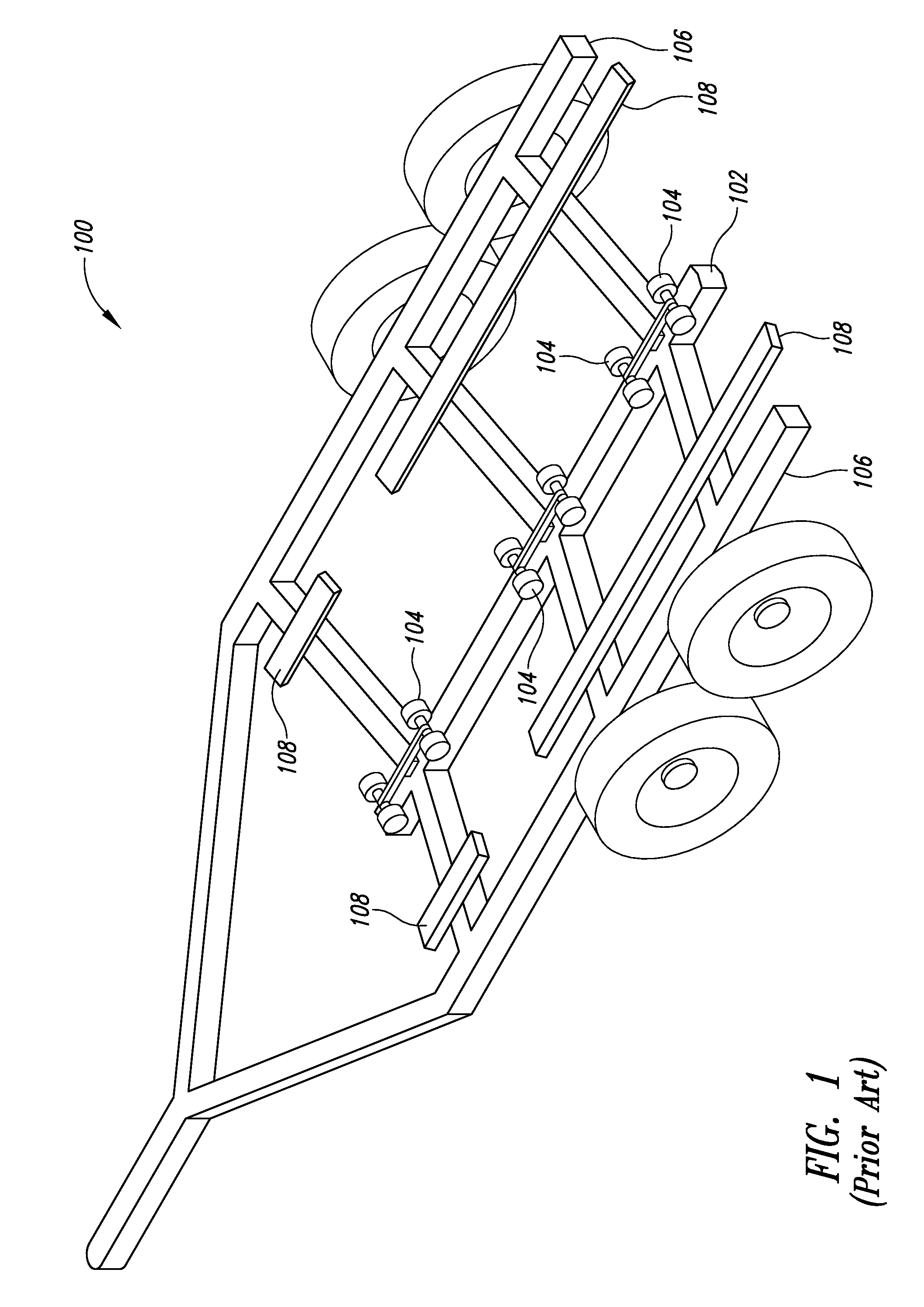

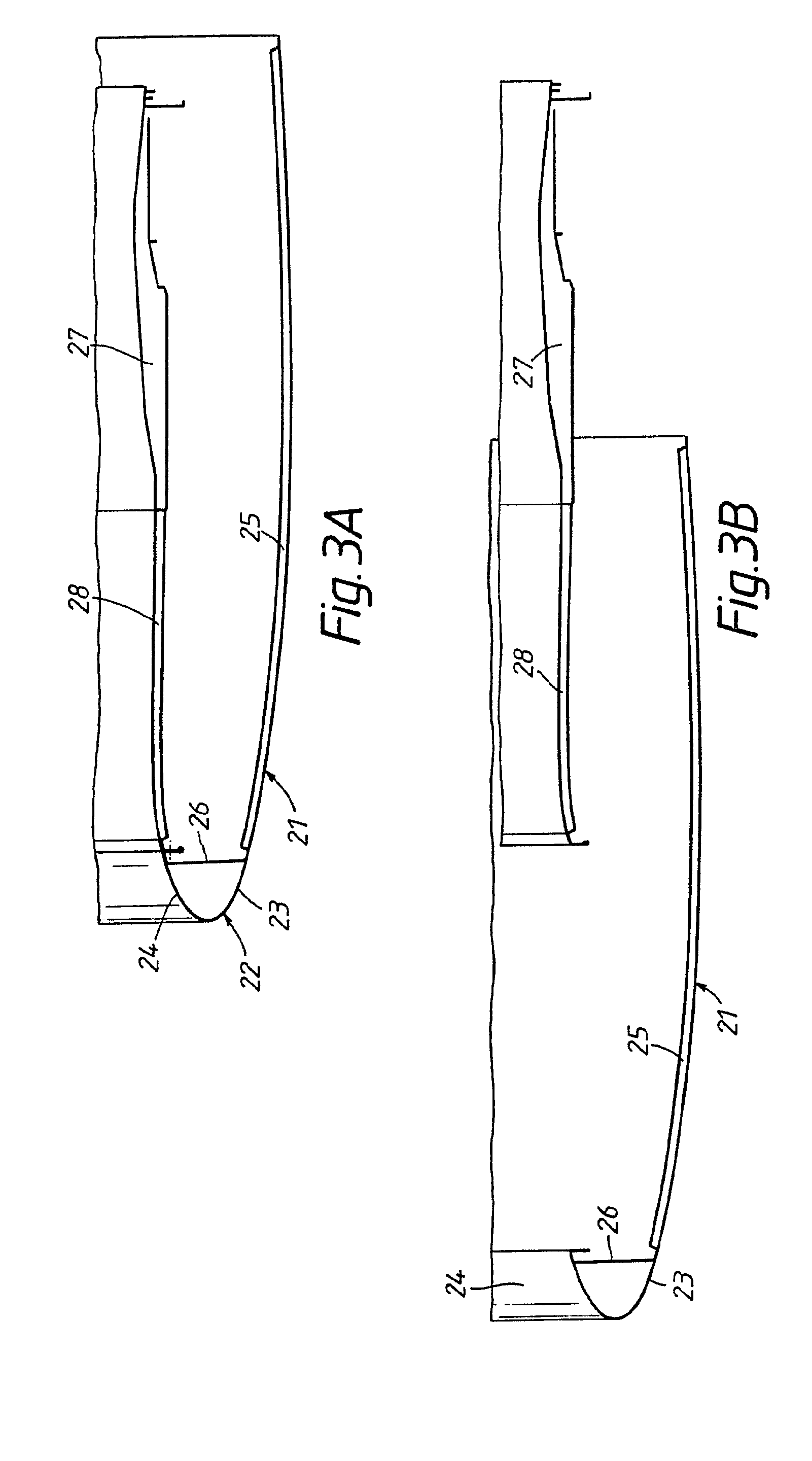

Device for guiding a boat on a trailer

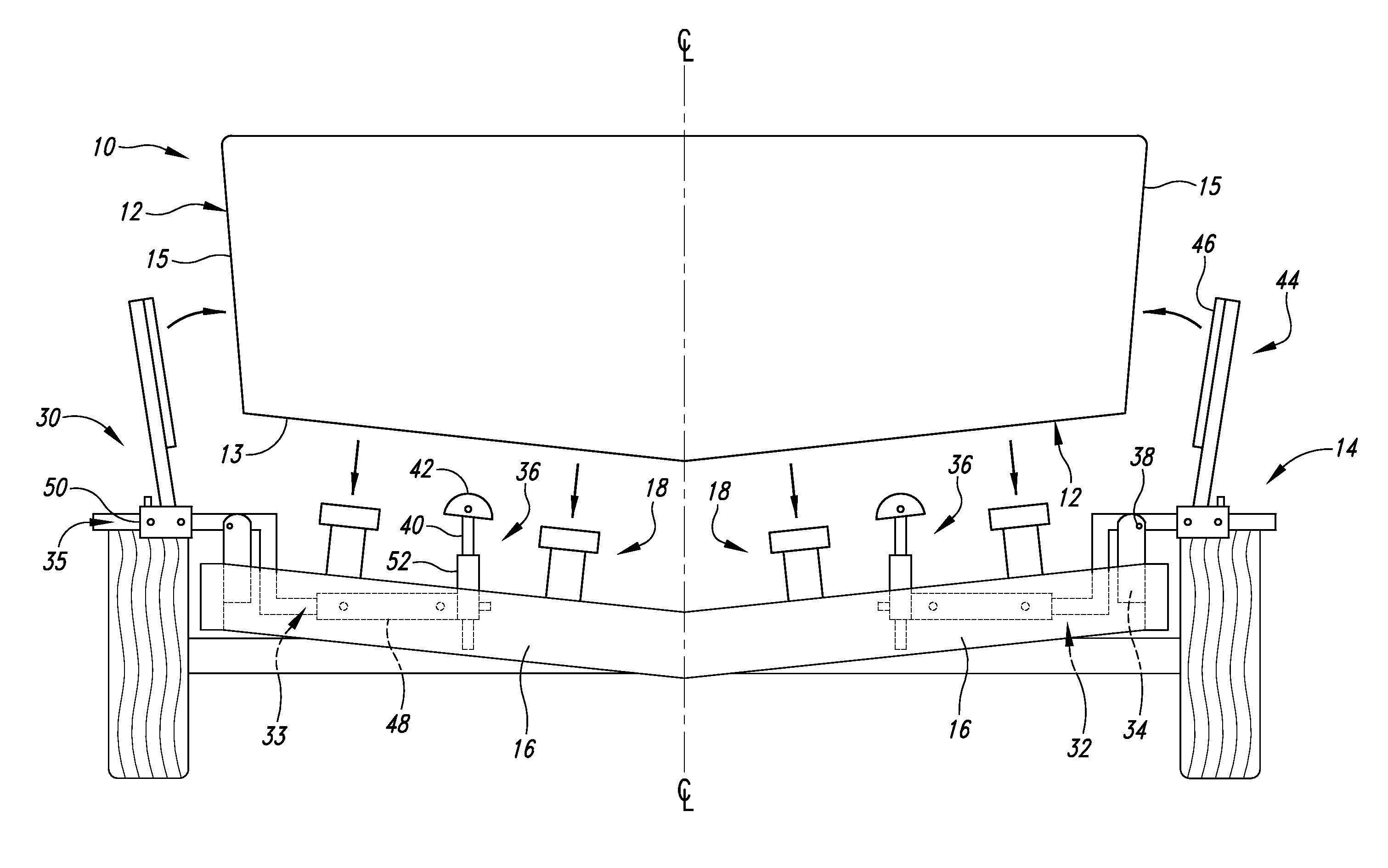

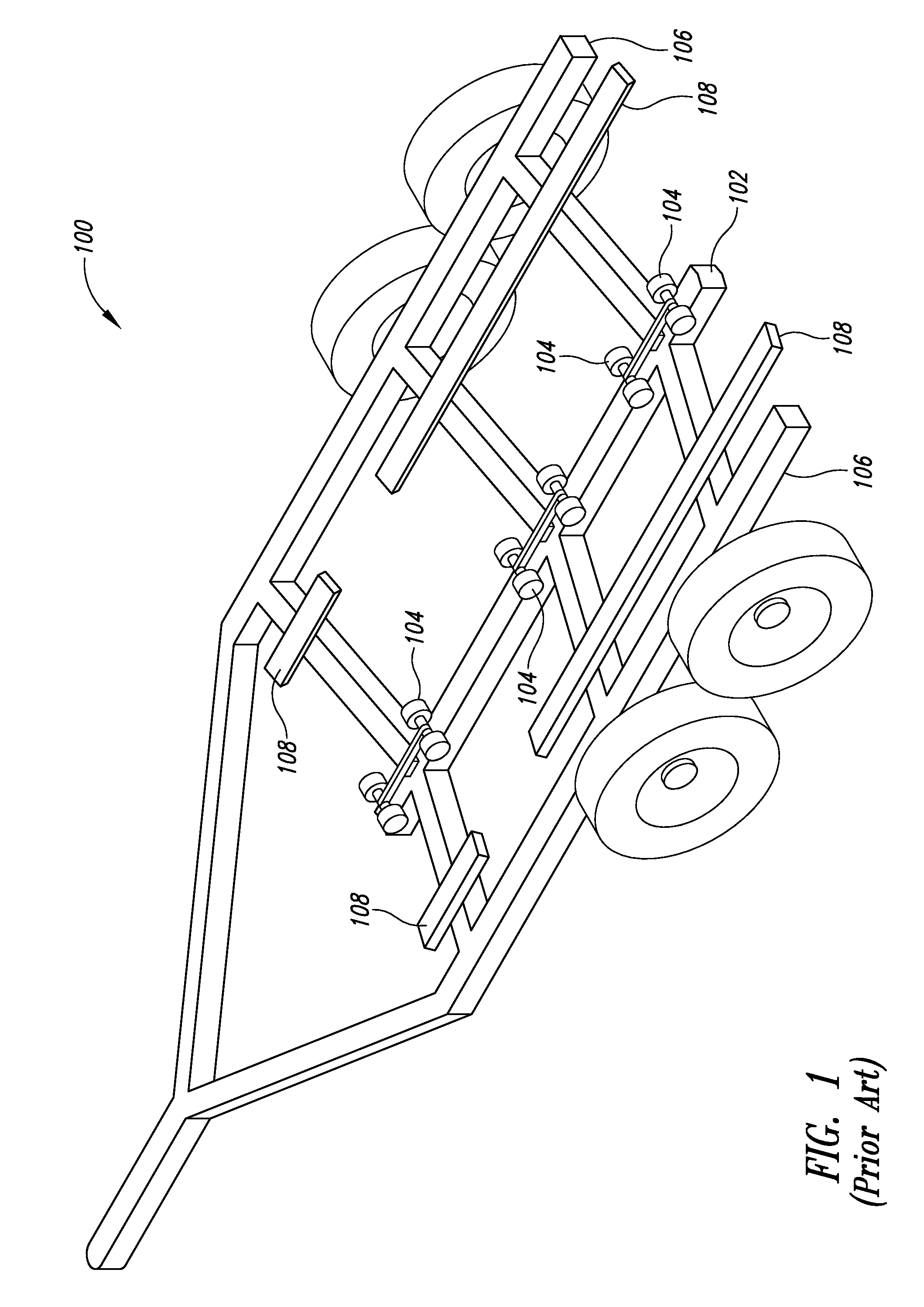

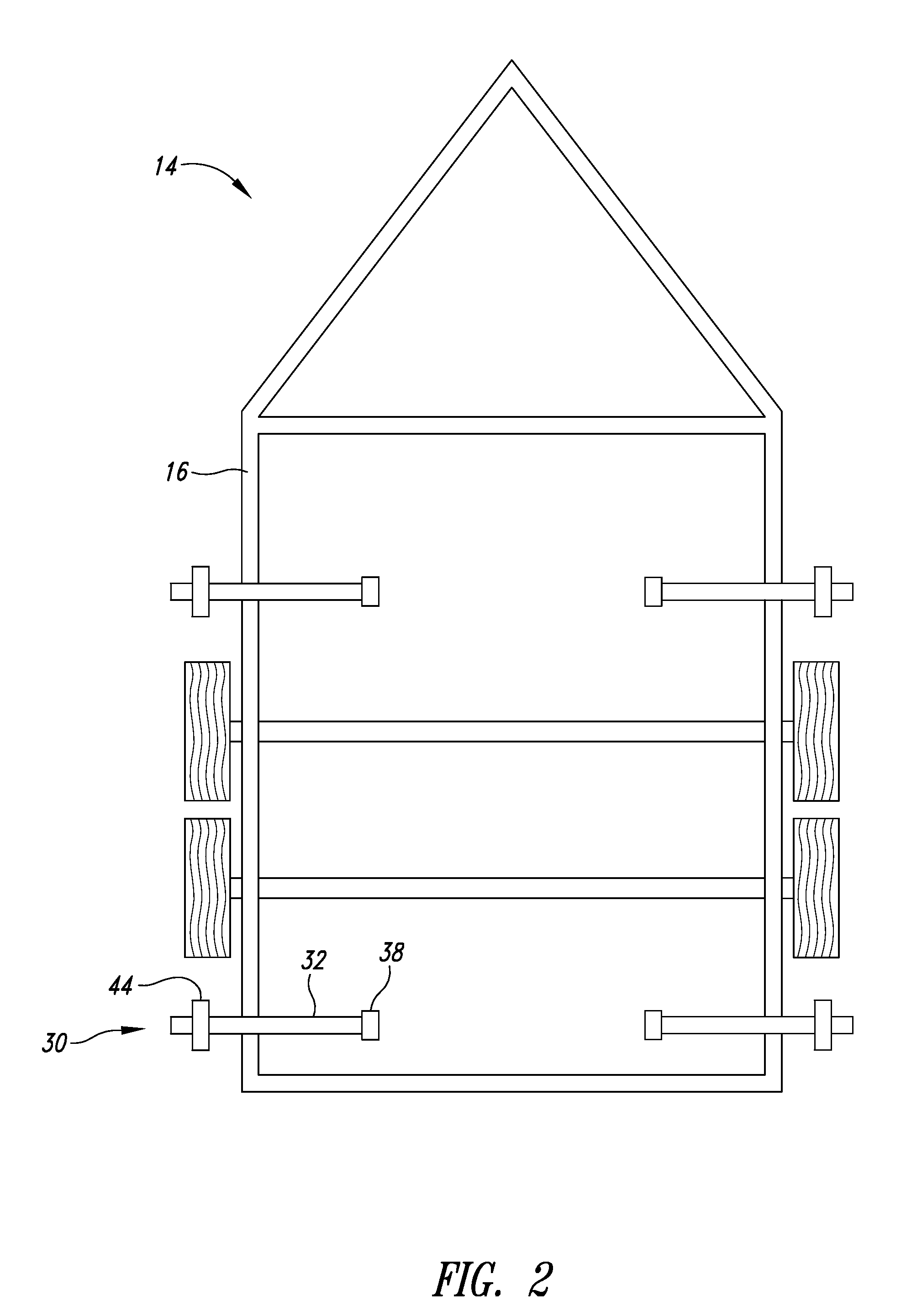

ActiveUS20090302572A1Easy to adaptPrevents scraping along the boat hullRefuse receptaclesLoading/unloading vehicle arrangmentEngineeringMechanical engineering

A device for guiding a boat onto a trailer, the trailer having at least two longitudinal side rails, the device including a mounting assembly for attachment to a side rail to provide for transverse adjustment relative to the side rail's longitudinal axis and a bumper assembly attached to the mounting assembly and having at least one bumper mechanism that moves between an engaged position in which the device guides the boat into an aligned position on the trailer and a disengaged position in which the bumper mechanism is moved away from the boat to avoid contact with the boat.

Owner:BRYANT II CHARLES E

Method for aligning and mounting two components on a support member in a positionally accurate manner

InactiveUS20050074276A1Easy to manufactureHigh degree of process reliabilityScaffold connectionsSoil-working equipmentsEngineeringMechanical engineering

Owner:DAIMLER AG

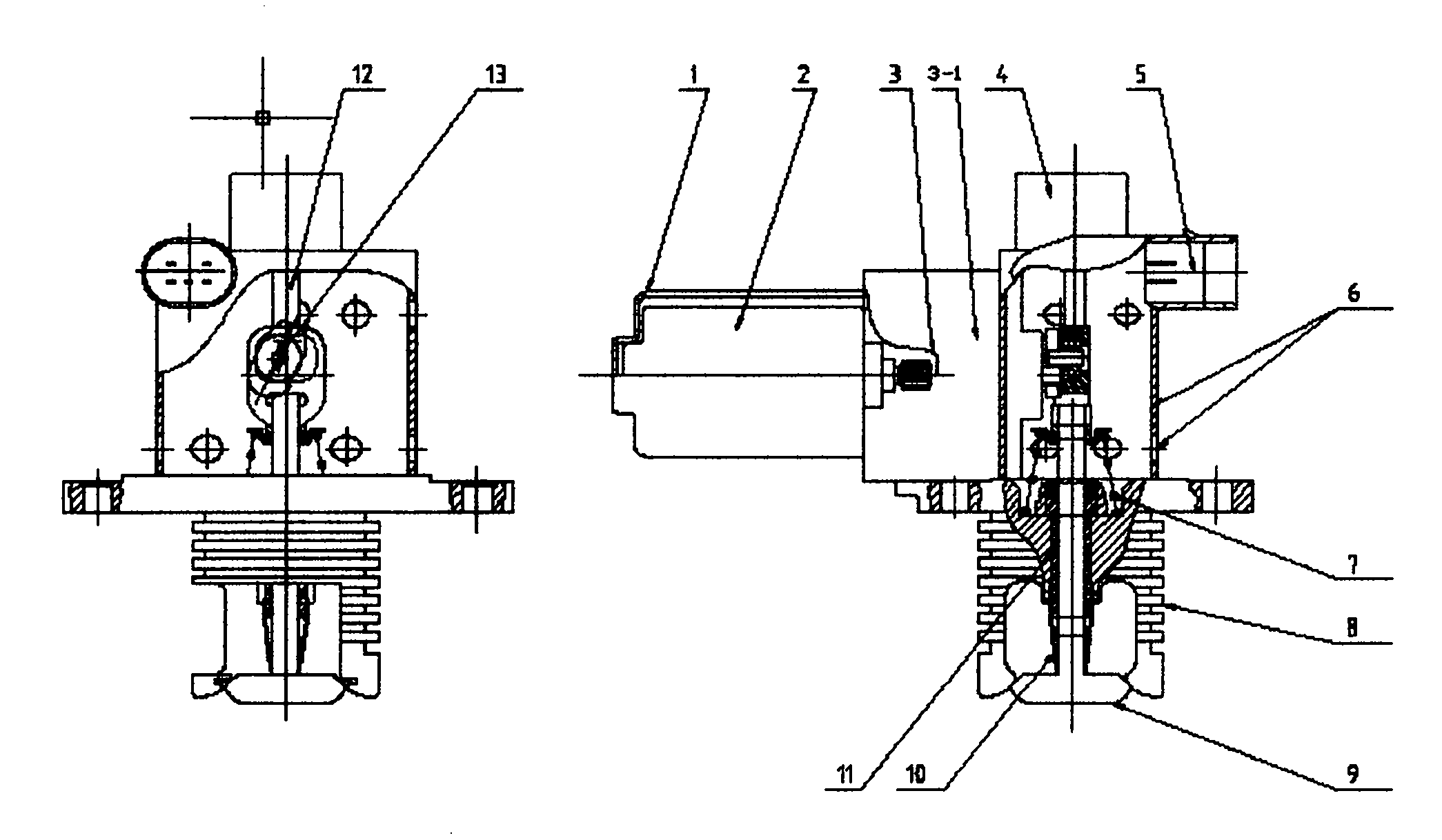

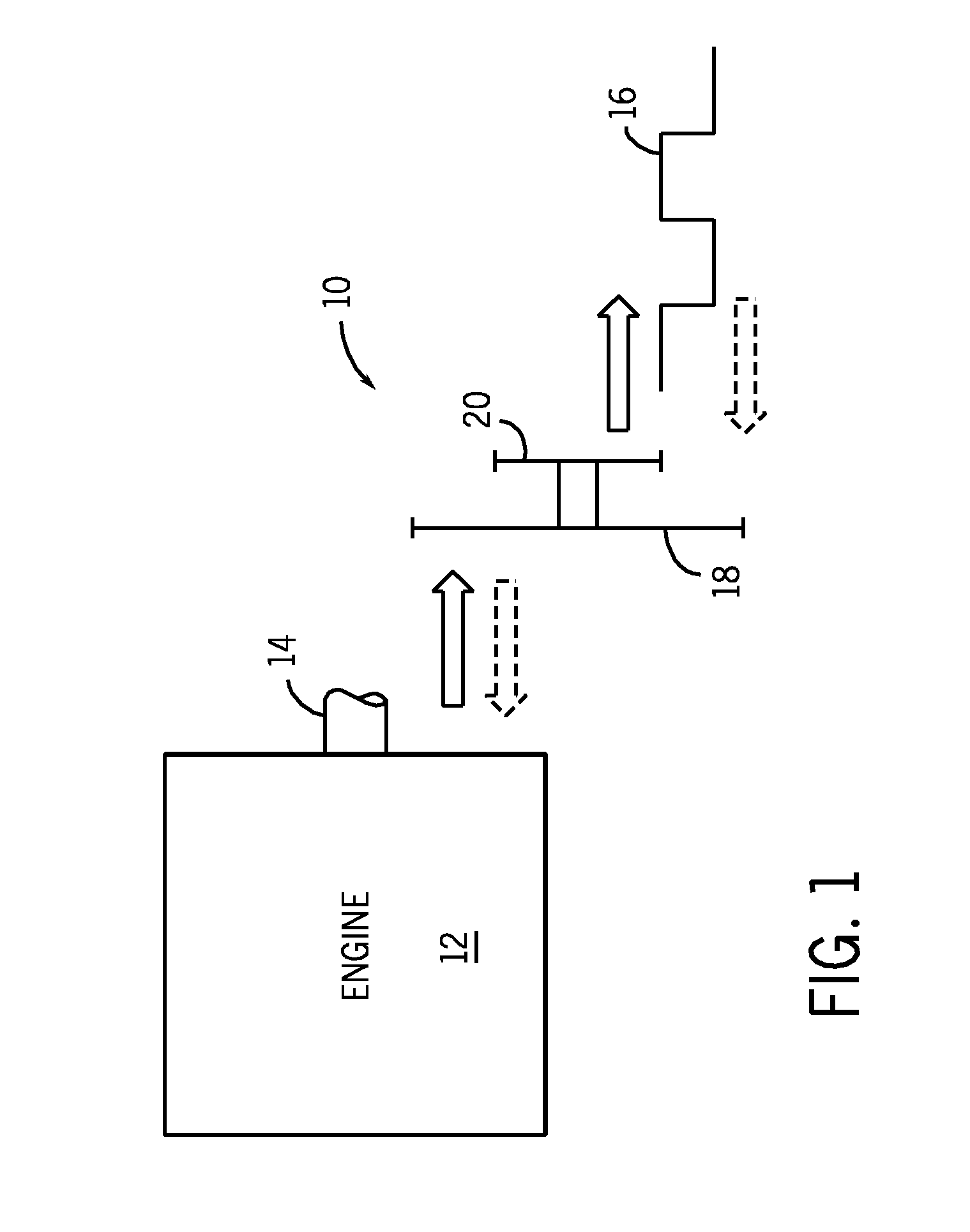

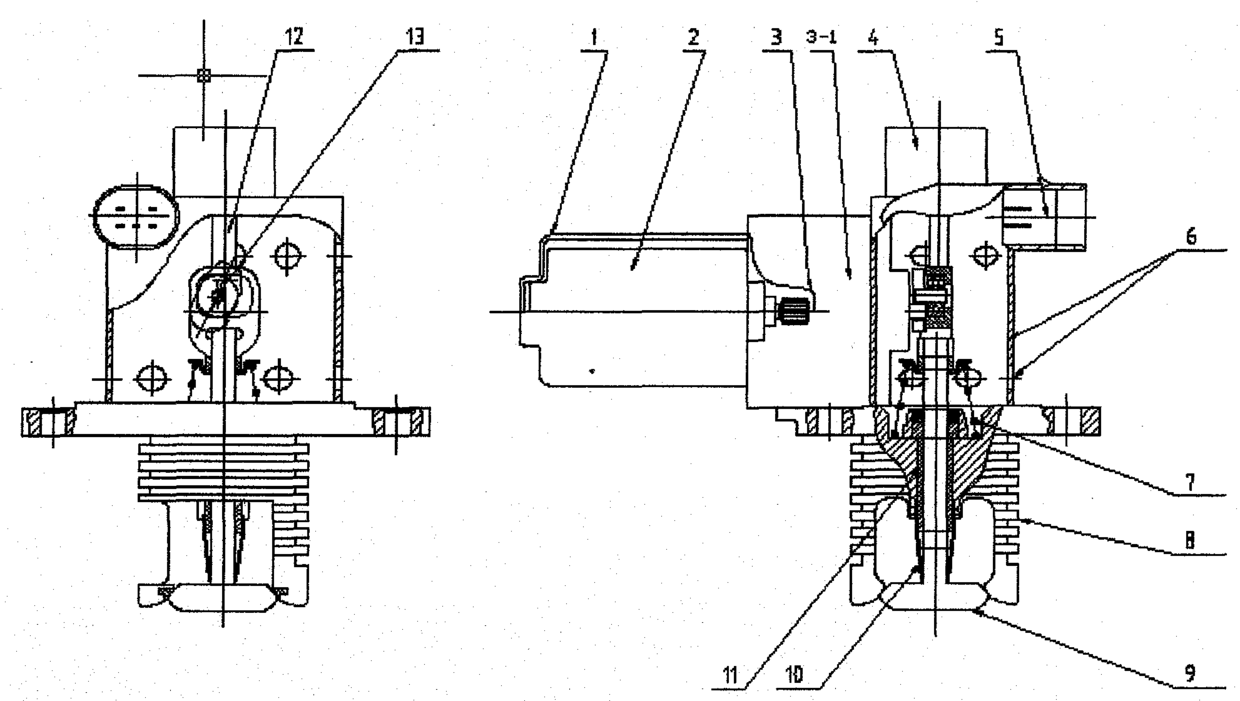

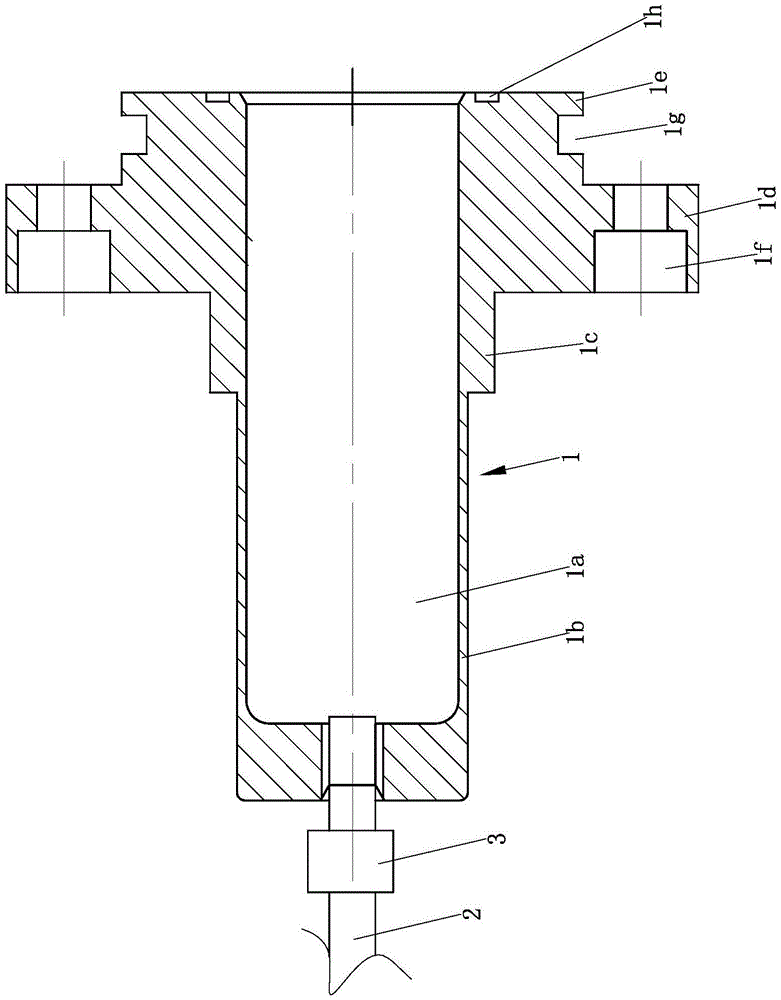

Electrical control EGR valve for reducing working temperature and improving working reliability

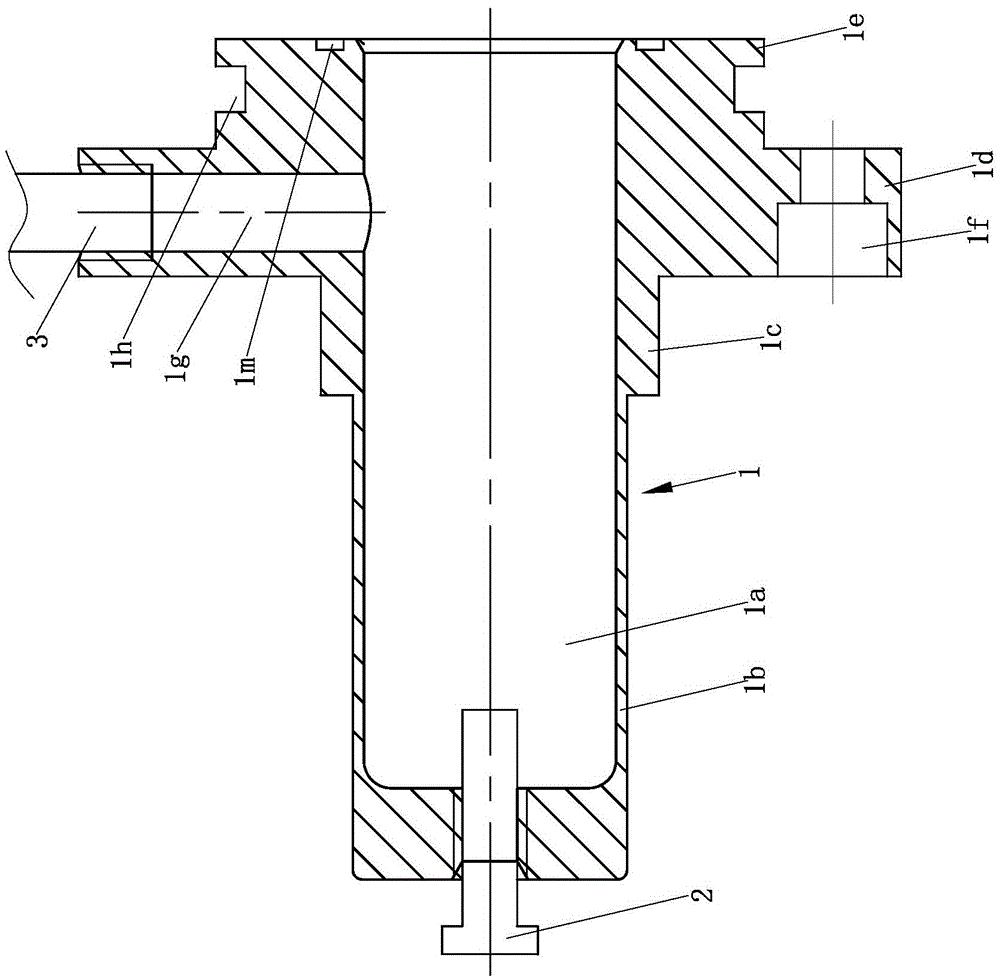

ActiveCN101949340AEffective centeringLower working temperatureOperating means/releasing devices for valvesNon-fuel substance addition to fuelDrive shaftWorking temperature

The invention discloses an electrical control EGR valve for reducing working temperature and improving working reliability. A diesel engine electrical control EGR technique is one of main techniques for eliminating discharge pollution. For an electrical control EGR structure, a fin structure is adopted to reduce the working temperature of an executing mechanism by enlarging the radiating area of a cold-end air inlet pipe; a cylindrical isolation cover is arranged on a butterfly valve transmission rod and is used for isolating convection and radiating heat transfer of high-temperature air inflow to the driving executing mechanism; an inlet / outlet hole is formed on a dustproof cover of a transmission mechanism to take heat of a transmission component away by utilizing natural convection so as to reduce the working temperature thereof; a metal scraper ring outside a transmission rod scraps carbon deposition attached to a centered transmission shaft so as to protect transmission centering reliability and the linear contact of the surface of a spherical valve and a valve body, and the peripheral contact of the valve rod and the valve body is ensured under eccentric and deflective states so as to realize sealing; and good seal is simultaneously realized under the conditions of oil dirt, carbon deposition and the like on the valve. The structure has the advantages of reducing the electrical control EGR working temperature and improving the working reliability.

Owner:哈尔滨安龙迪环保科技有限公司

Device for guiding a boat on a trailer

ActiveUS8256789B2Prevents scraping along the boat hullAvoid damageRefuse receptaclesLoading/unloading vehicle arrangmentEngineeringMechanical engineering

Owner:BRYANT II CHARLES E

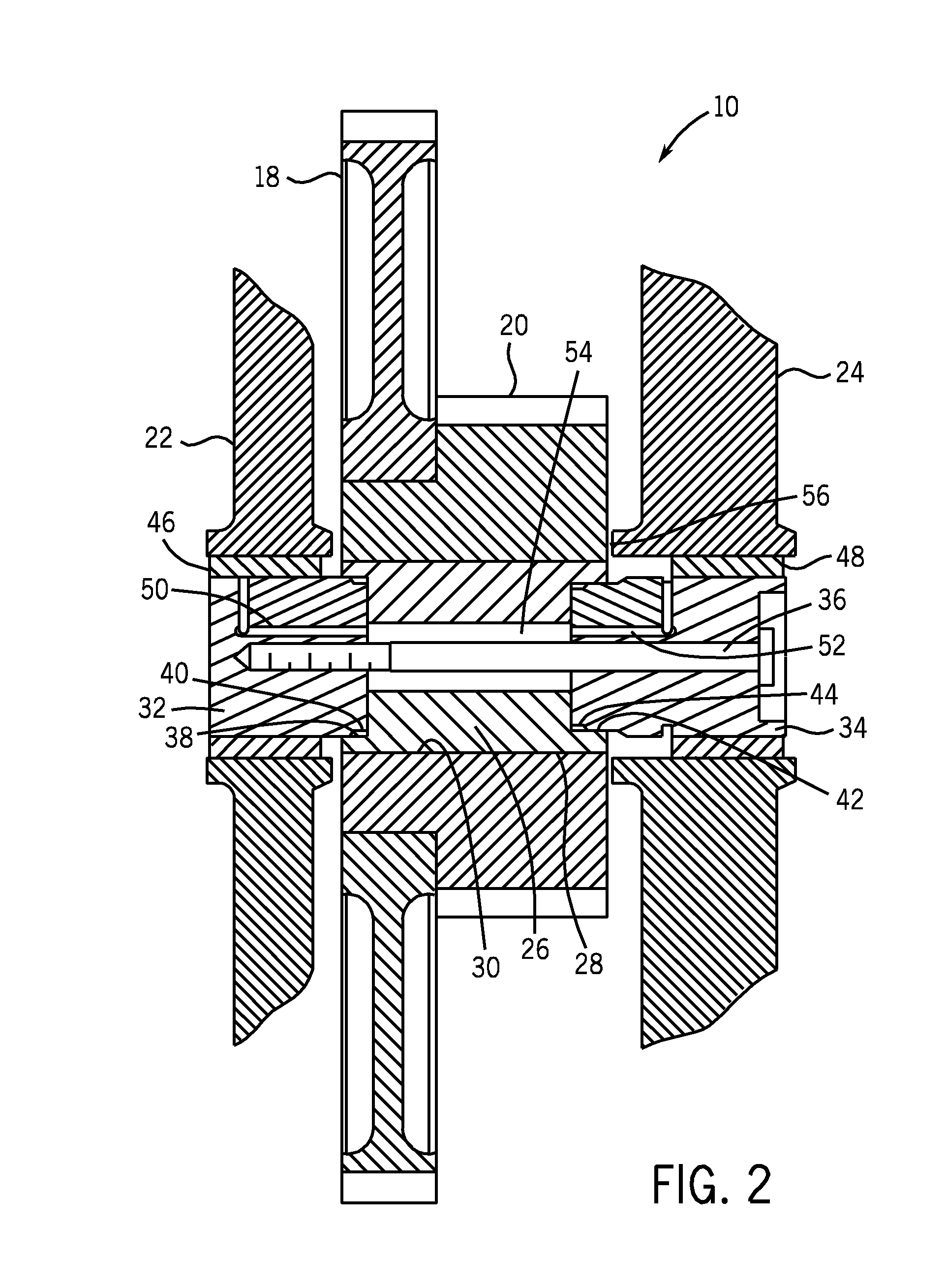

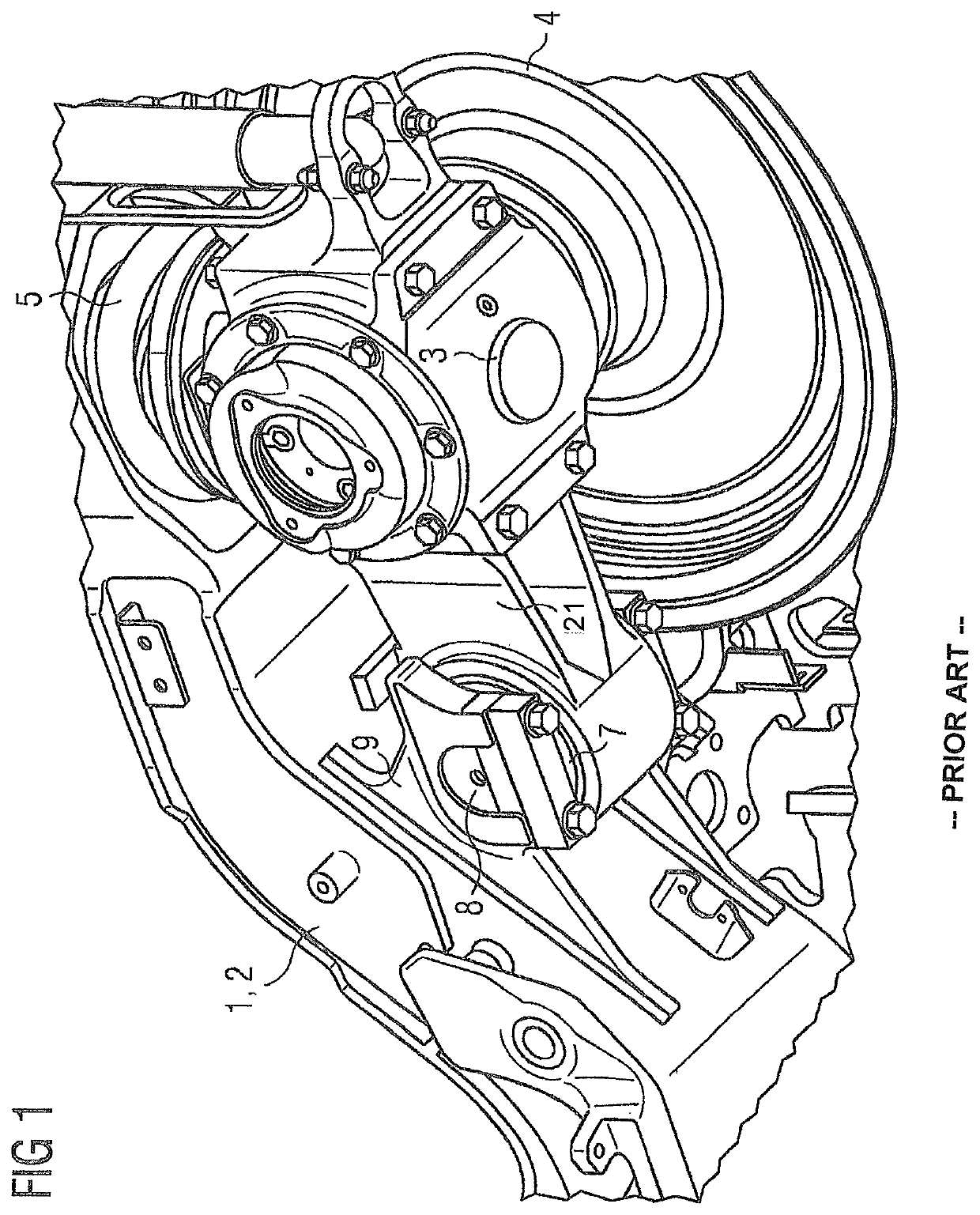

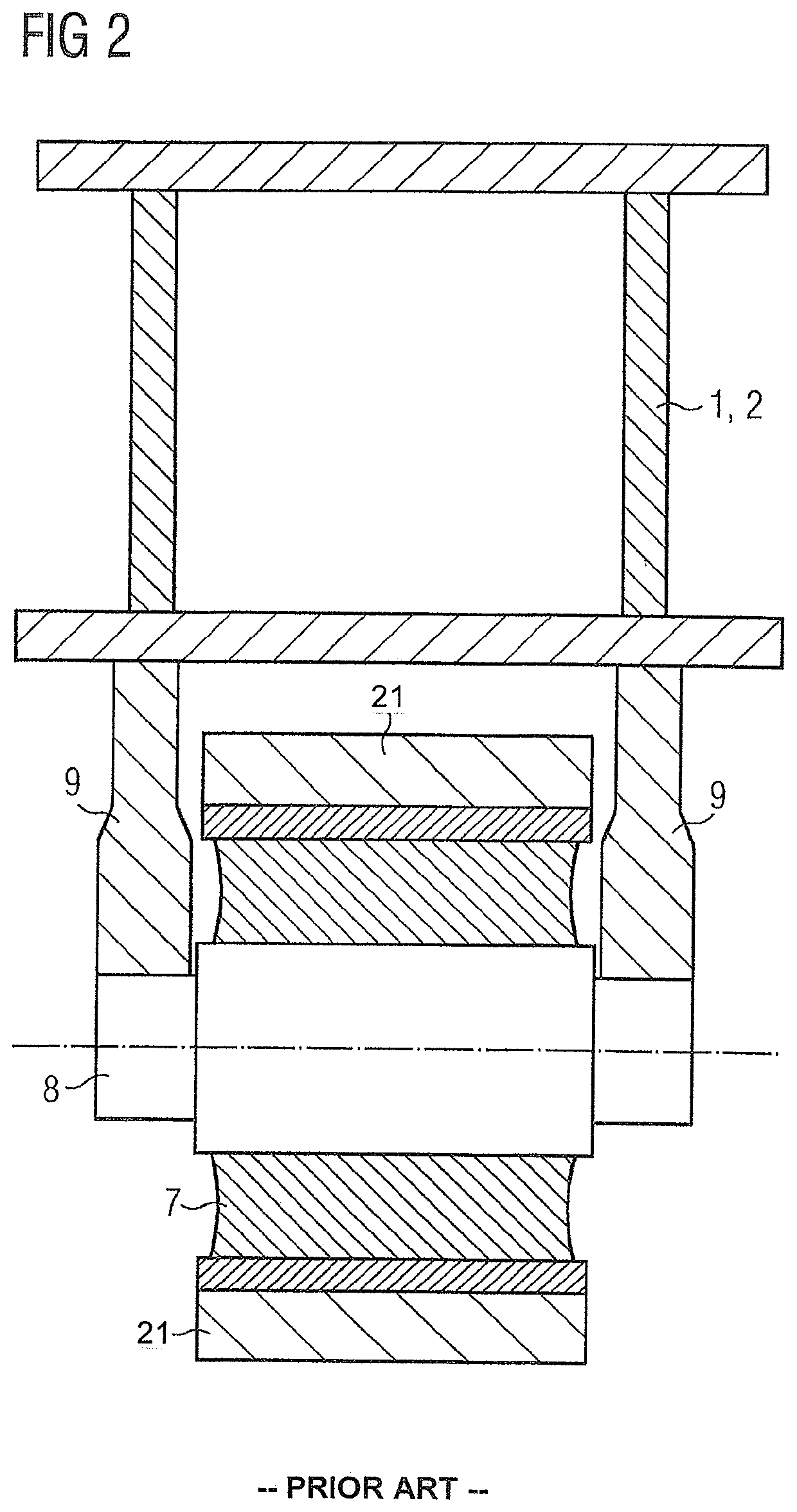

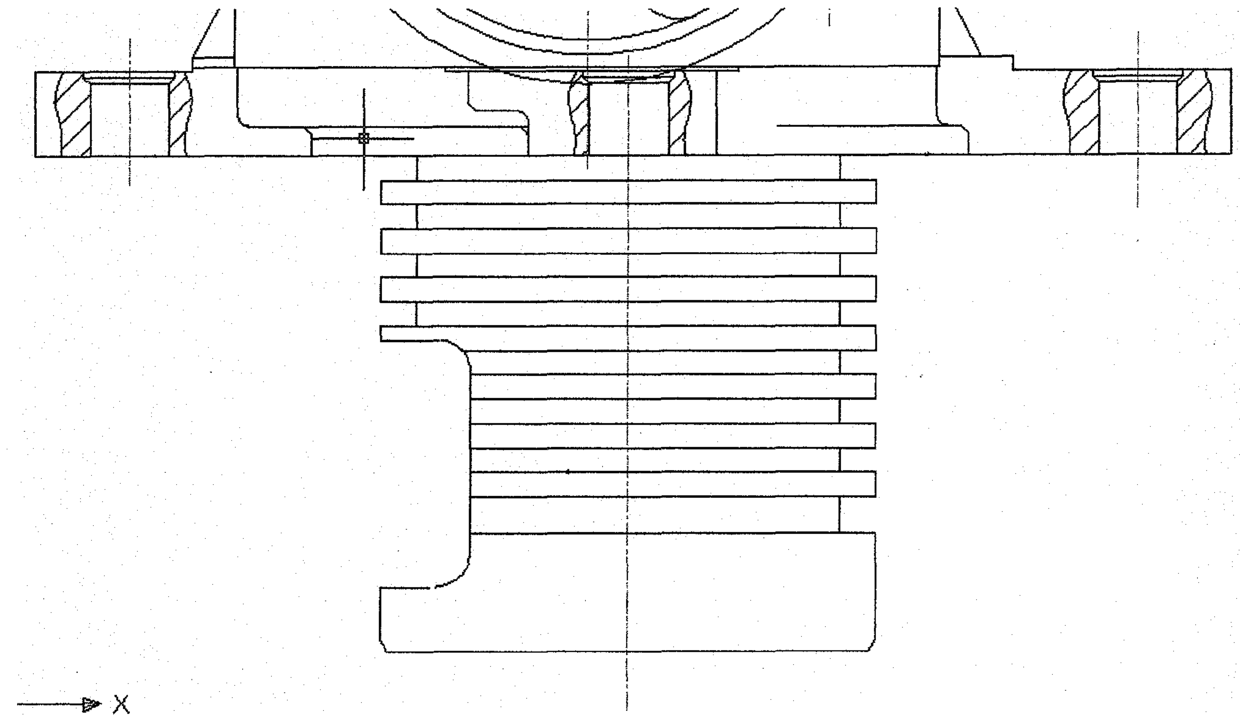

Split shaft for high power diesel engine

InactiveUS20090084207A1Easy to assembleEffective centeringValve arrangementsToothed gearingsLubricationFastener

An idler shaft assembly is disclosed suitable for internal combustion engines, such as the heavy duty engines. The assembly may transmit power between a crank shaft and a cam shaft. The assembly includes a hollow shaft which can be interference fit within a small idler gear, with a large idler being mounted on a shoulder of the small idler gear. Idler hubs on either side of the hollow shaft are centered with respect to the idler shaft and are held firmly in place by fasteners that extend through one of the hubs and the hollow shaft, and are threaded into the other hub. Lubrication may be provided by an internal reservoir formed in the hollow shaft, and oil passages in fluid communication with this reservoir that extend to journal bearings mounted between the idler hubs and the support structure for the overall assembly.

Owner:GENERAL ELECTRIC CO

Exercise device including adjustable, inelastic straps

InactiveUS20060116252A1Easily vary length of deviceEffective centeringTherapy exerciseStiltsWhole bodyEngineering

Owner:JFXD TRX ACQ LLC

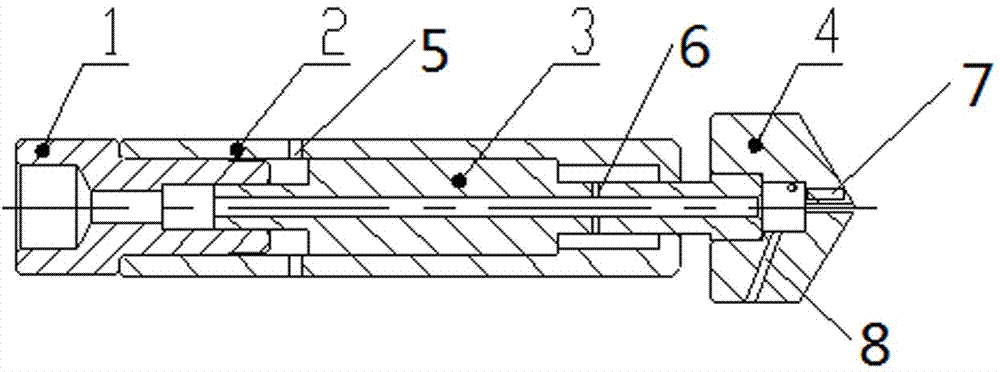

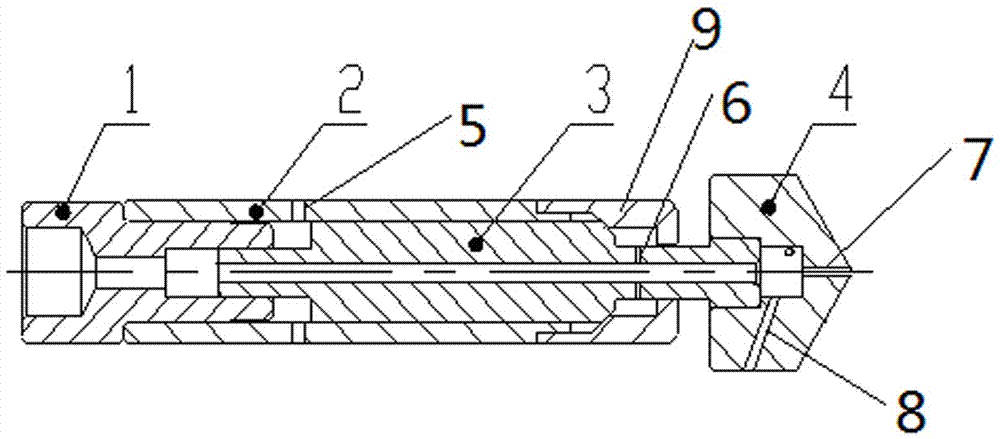

Hydraulically driven intra-casing radial drilling high-pressure rotary grinding head

ActiveCN105507815ASmooth cuttingEliminates reduction in cutting efficiencyEarth drilling toolsDrill bitsEngineeringHigh pressure

The invention discloses a hydraulically driven intra-casing radial drilling high-pressure rotary grinding head, comprising a lower connector, a body, a core and a grinding head. The lower connector is axially provided with an inner cavity, the body is in a tube, and the lower connector is connected with the tail of the body; the core is provided with an axial through hole and is arranged in the body, an enlarged diameter section of the core and the body covering outside are in interference fit, the tail of the core is in axial hermetic sliding fit with a cavity of the lower connector or the body, and an end of the core is connected with the grinding head; an end of the grinding head is conical, the grinding head is provided with jet holes in front and rear directions, and the jet holes are communicated with a cavity in the grinding head; both the body and the core are provided with radially distributed straight holes that are communicated with the inner cavity of the body, and a core straight hole is communicated with a core through hole. When jet drilling is carried out, a pump is started, the grinding head rotates at high speed and generates high-pressure water jets towards a stratum, the grinding head moves forward under the action of self-traction, and operation is complete when a jet bore reaches a design required depth.

Owner:CHINA PETROCHEMICAL CORP +1

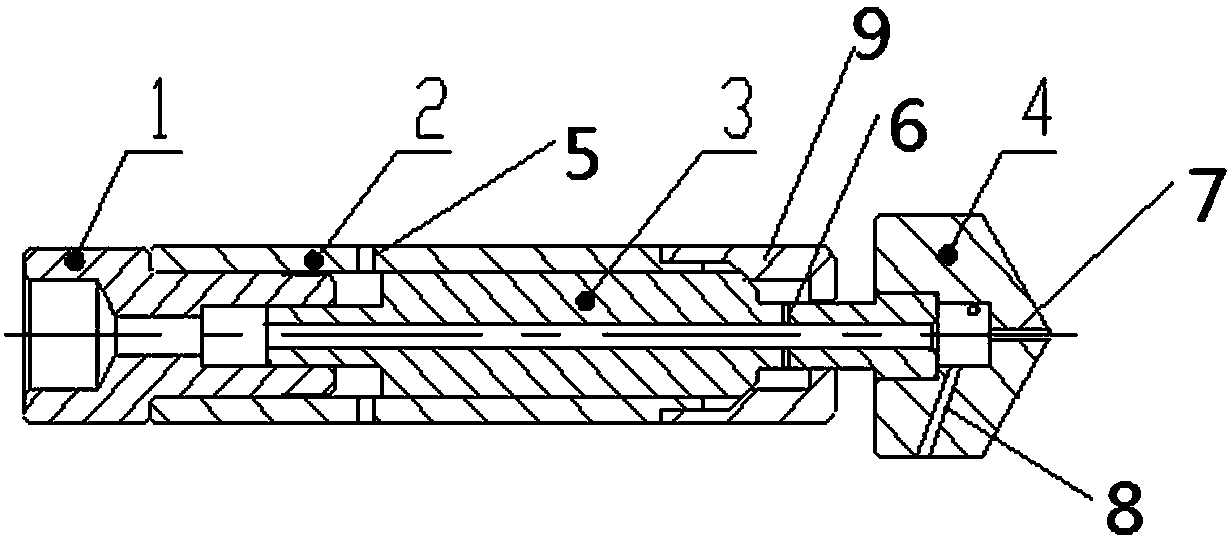

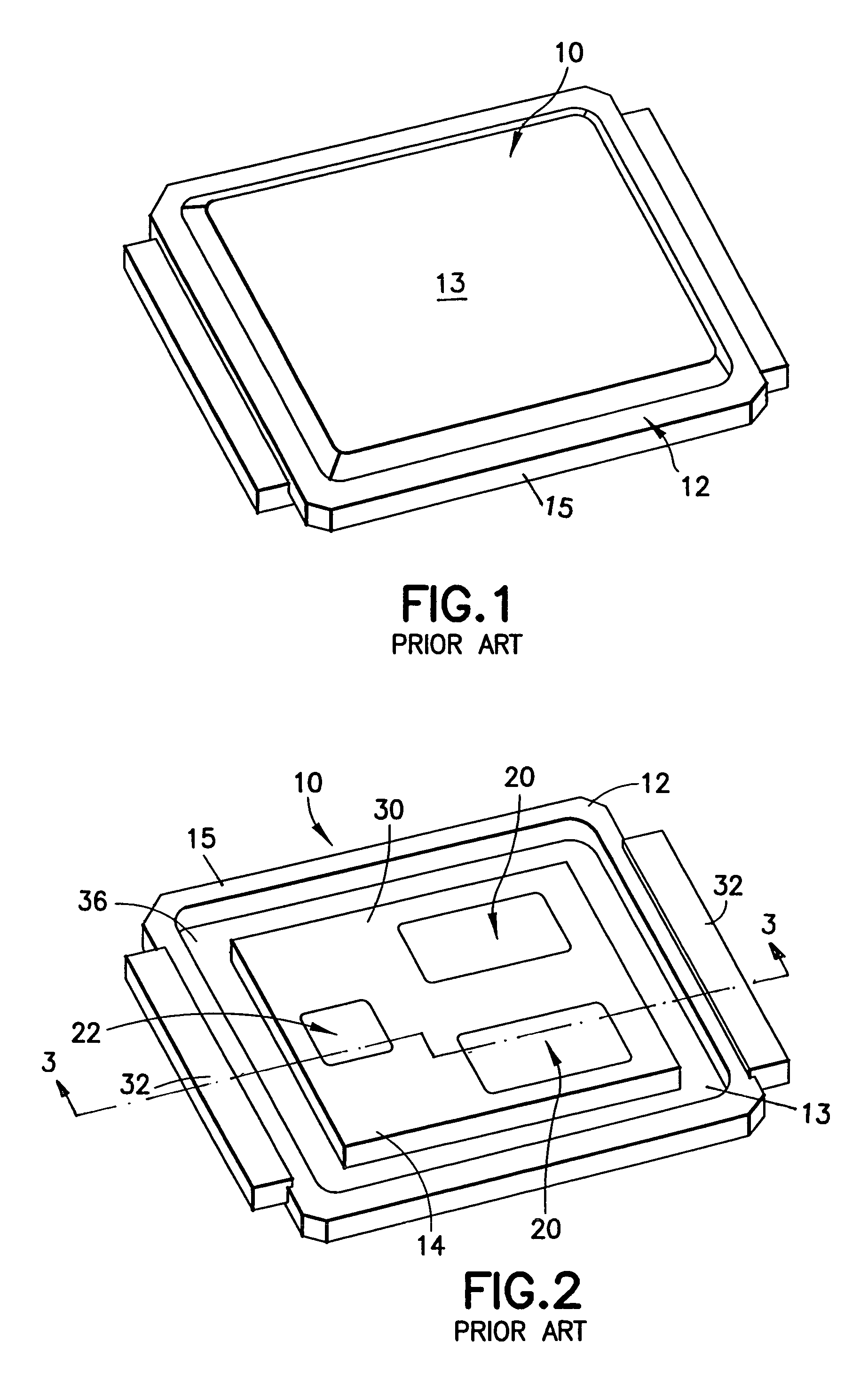

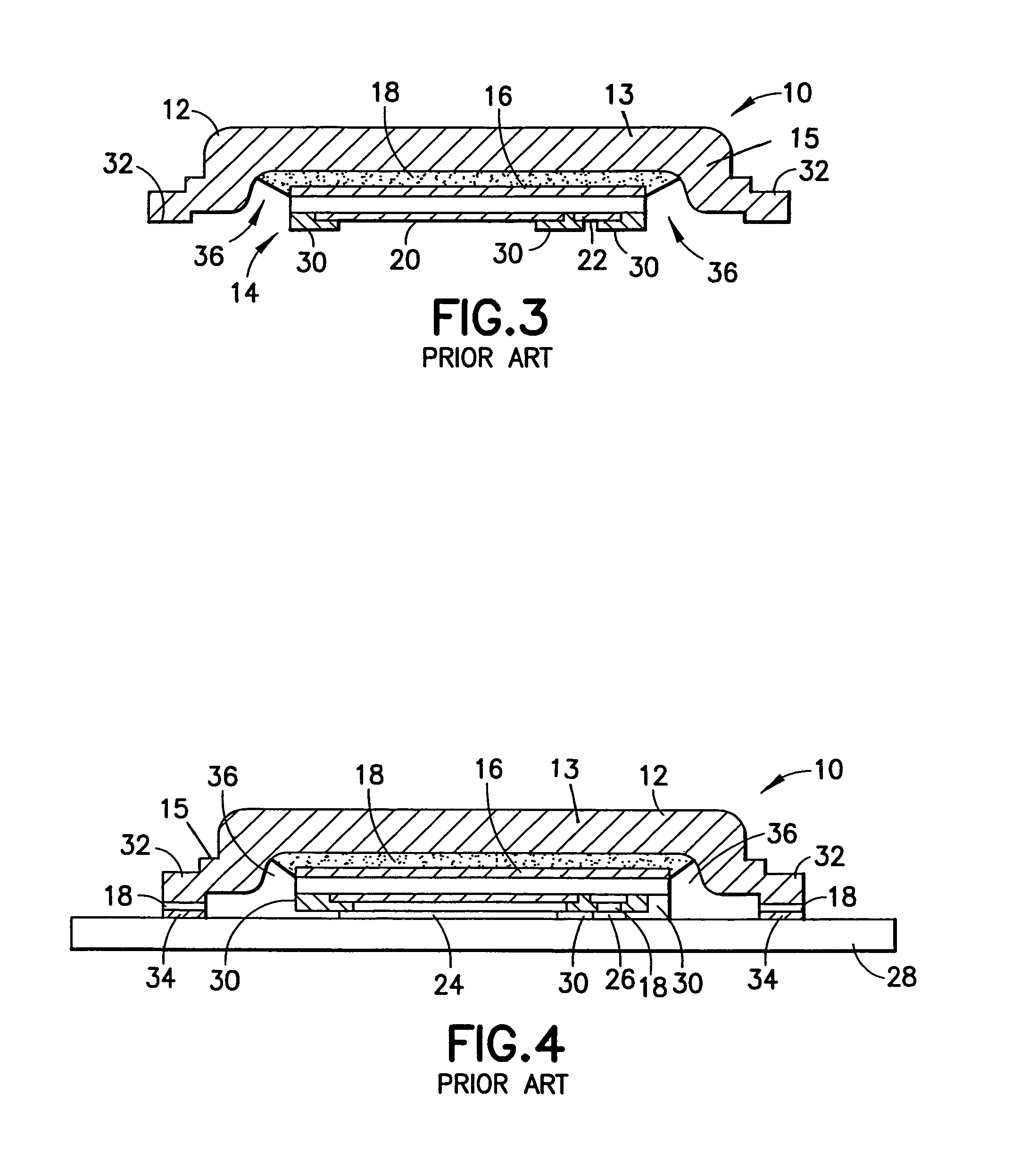

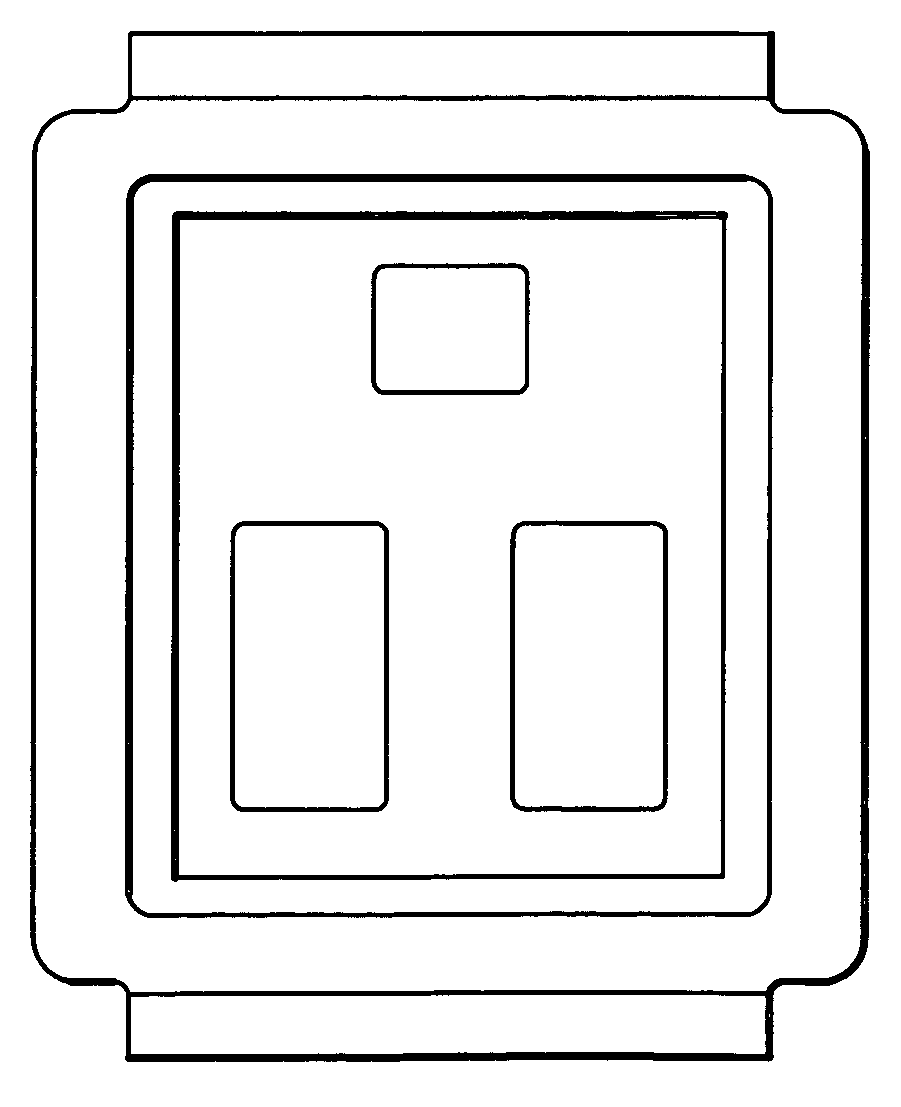

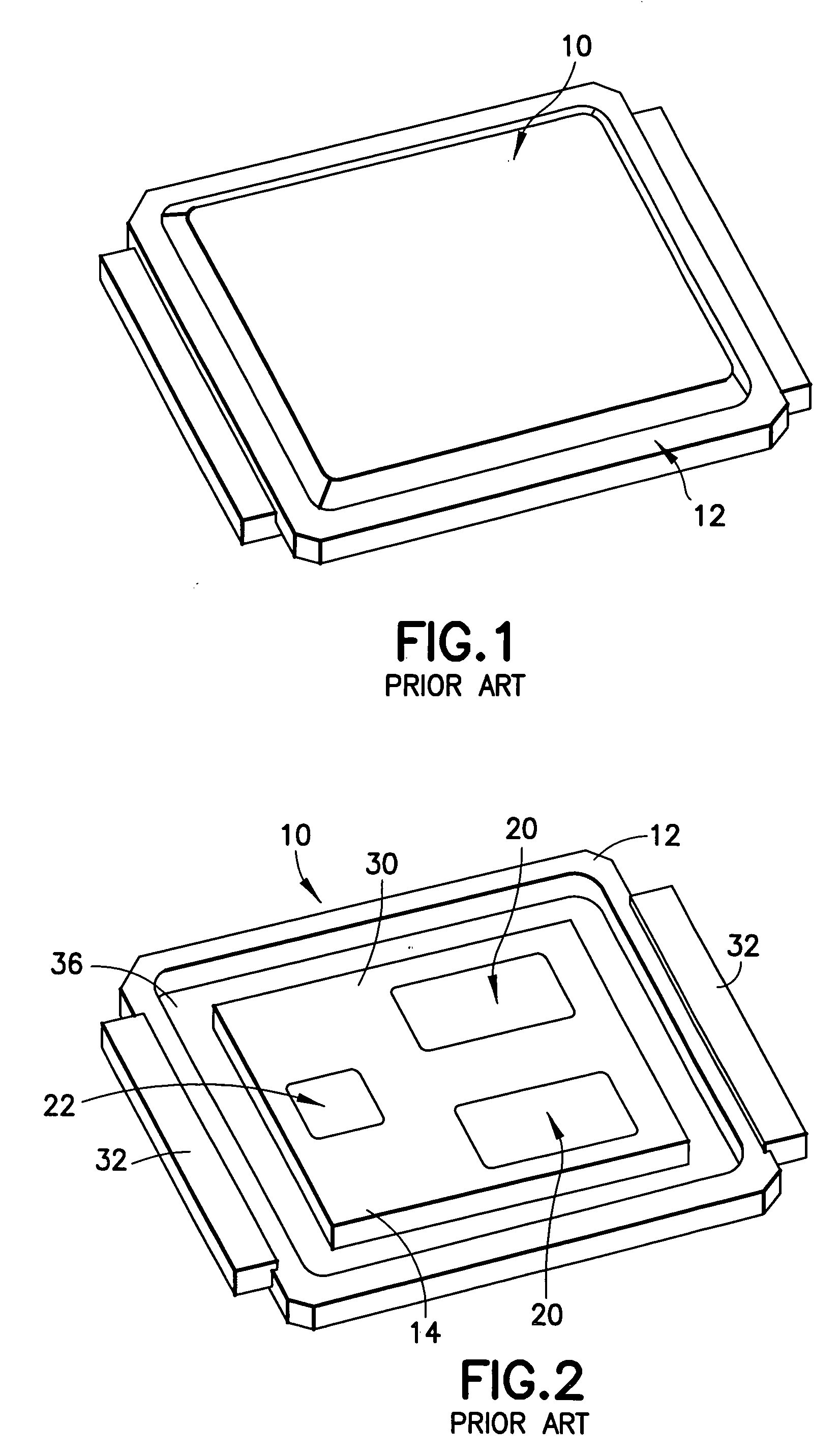

Chip-scale package

InactiveUS7524701B2Improve placement accuracyEffective centeringSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A method for manufacturing a semiconductor package that includes forming a frame inside a conductive can, the frame being unwettable by liquid solder.

Owner:INFINEON TECH AMERICAS CORP

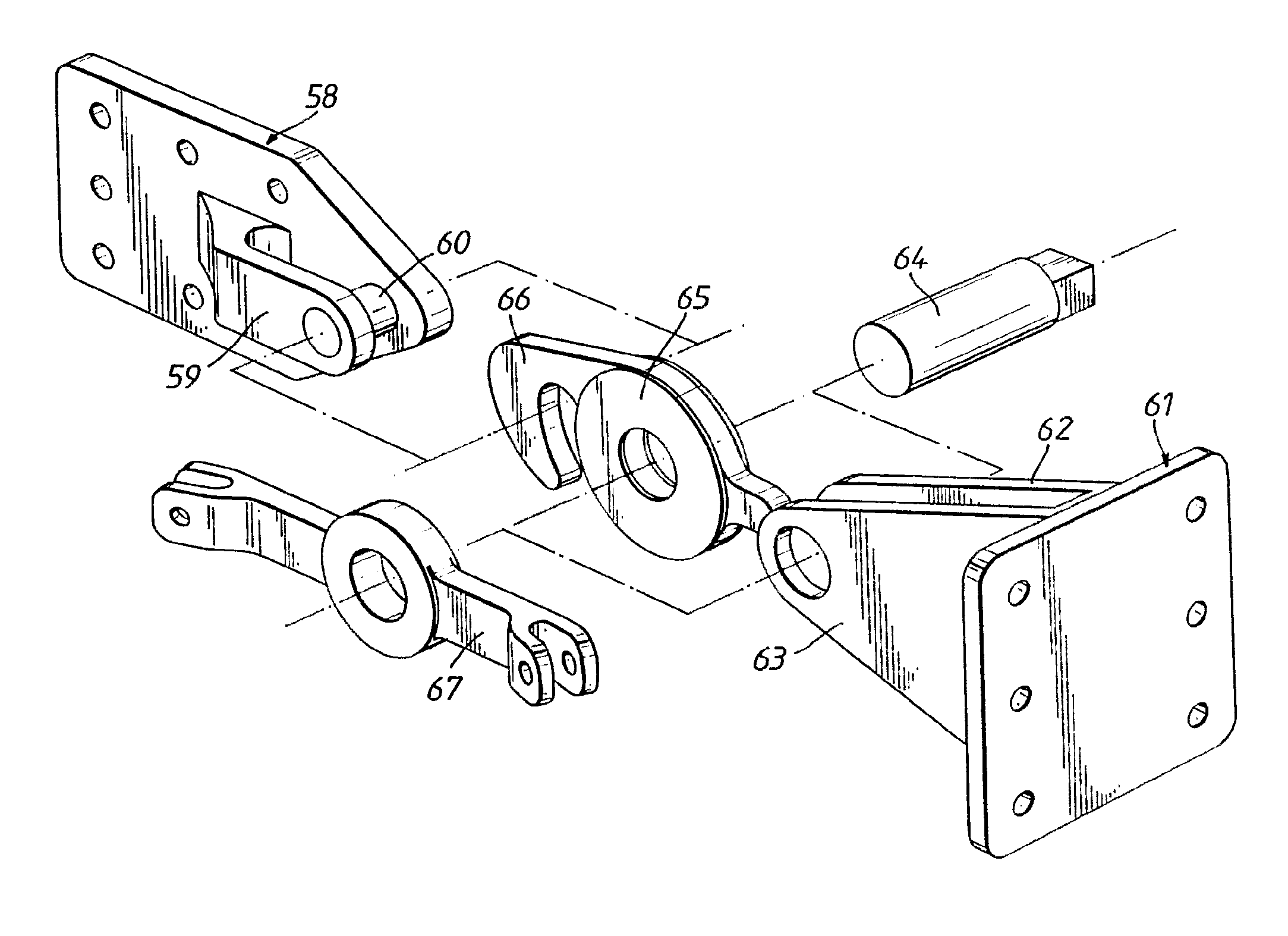

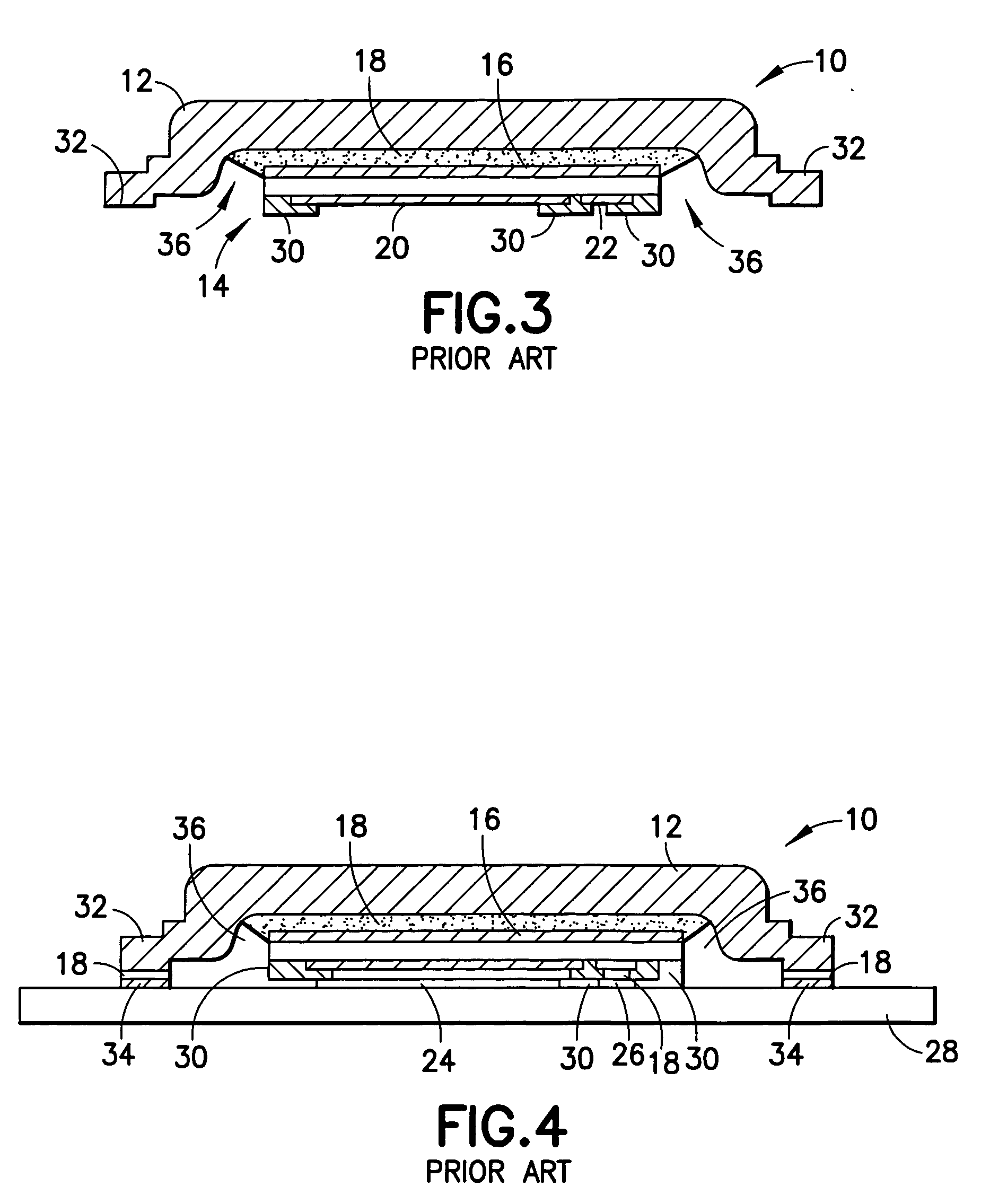

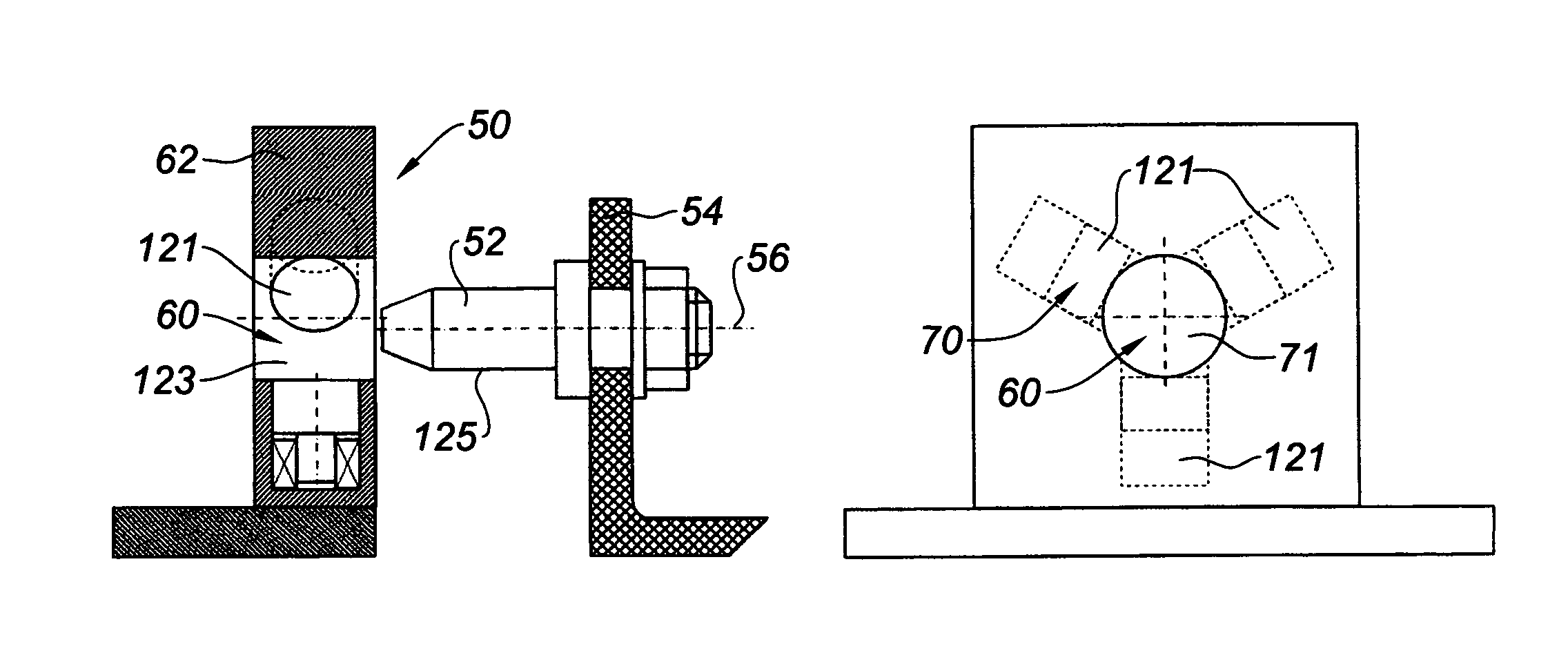

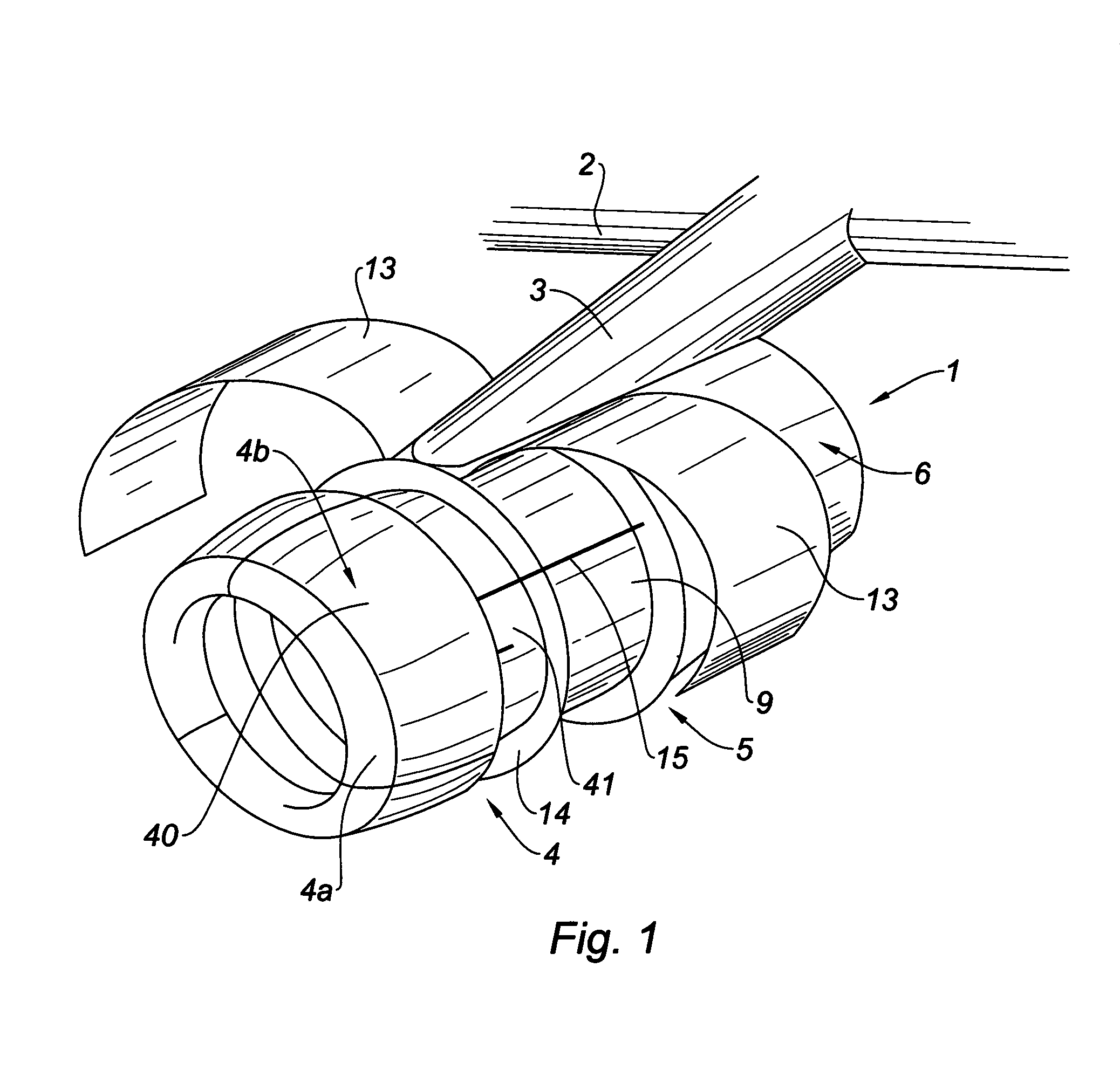

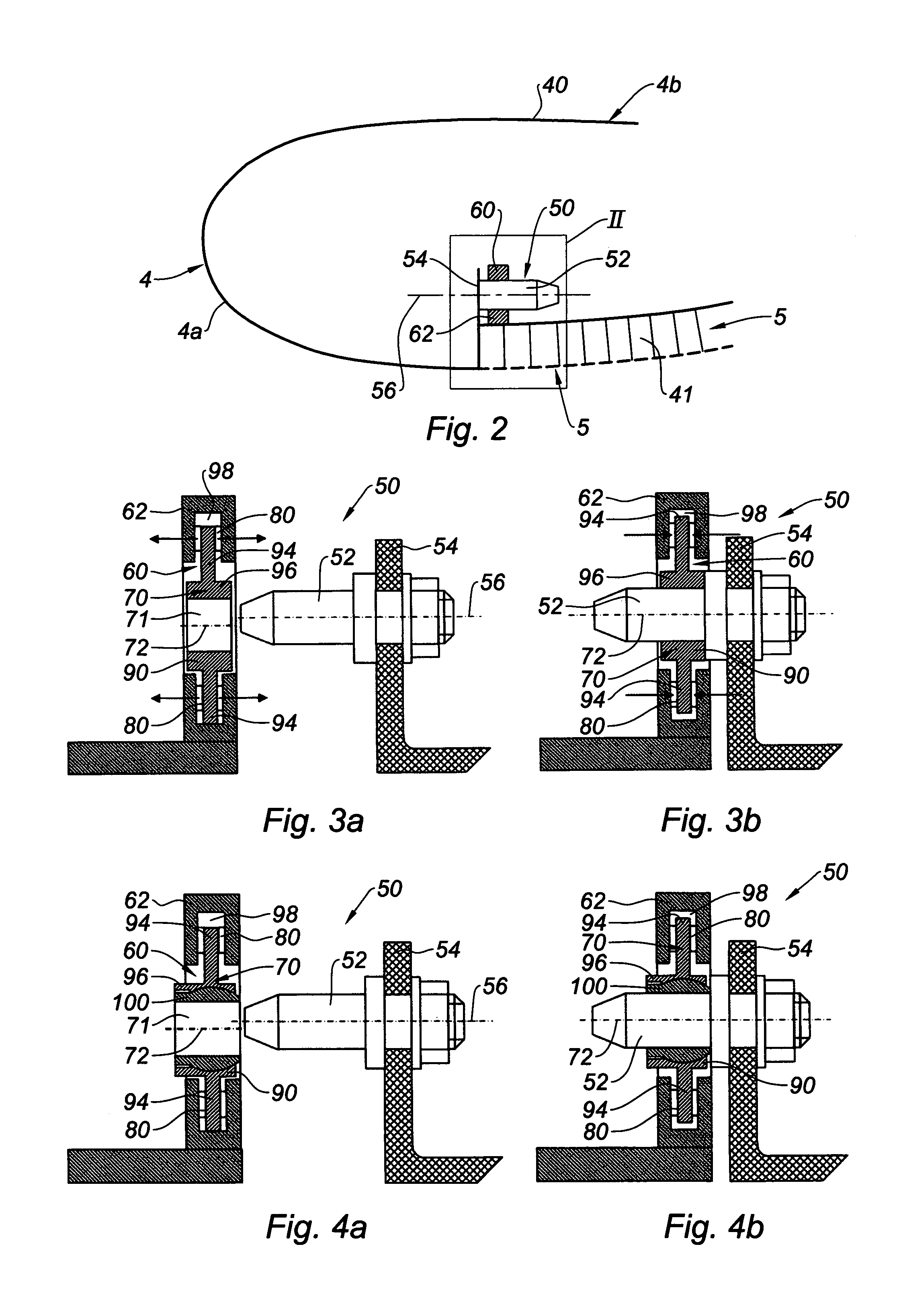

Device for centering an air inlet structure on a central structure of a nacelle

InactiveUS20120096730A1Resistant to jammingEasy to implementMeasurement devicesAircraft power plant componentsNacelleEngineering

The invention relates to a device (50) for centering a movable structure (4) on a stationary structure (5) of a nacelle, comprising: a centering pin (52) mounted on a pin holder (54) attached onto the movable structure (4) or onto the stationary structure (5), the centering pin (52) having a central axis (56) and a receiving bore (60) mounted onto a bore holder (62) attached onto the stationary structure (5) or onto the movable structure (4), said receiving bore (60) being capable of receiving at least the centering pin (52), characterized in that the centering device (50) also comprises a movable interface system, capable of overlapping the central axis (56) of the centering pin (52) and the central axis of said interface system or of the receiving bore (60) and capable of receiving said centering pin (52) in a central opening, and a locking means capable of locking said interface system. The invention also relates to a nacelle including such a device (50).

Owner:SAFRAN NACELLES

Chip scale package

InactiveUS20060240598A1Improve placement accuracyEffective centeringSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageChip-scale package

A method for manufacturing a semiconductor package that includes forming a frame inside a conductive can, the frame being unwettable by liquid solder.

Owner:INFINEON TECH AMERICAS CORP

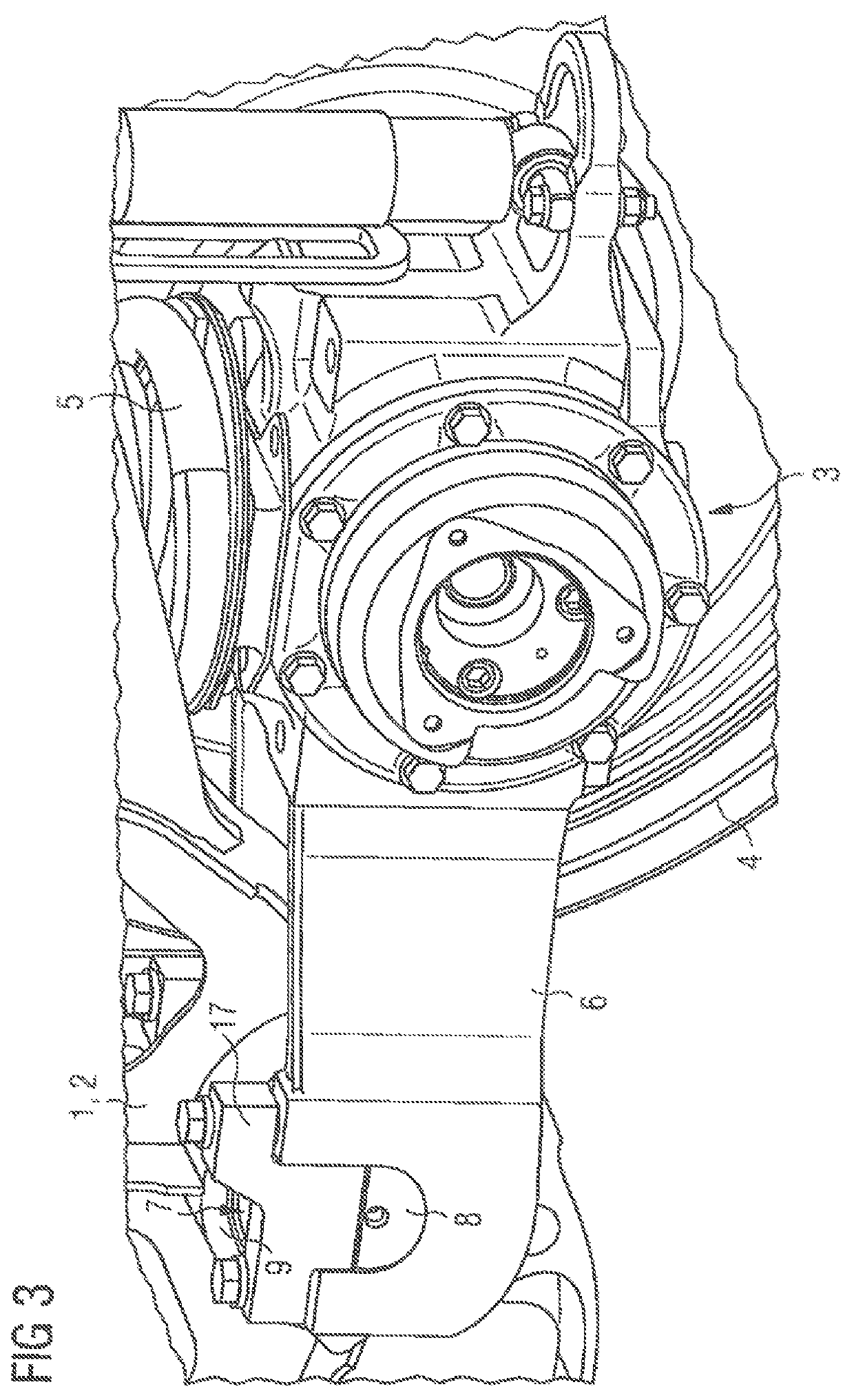

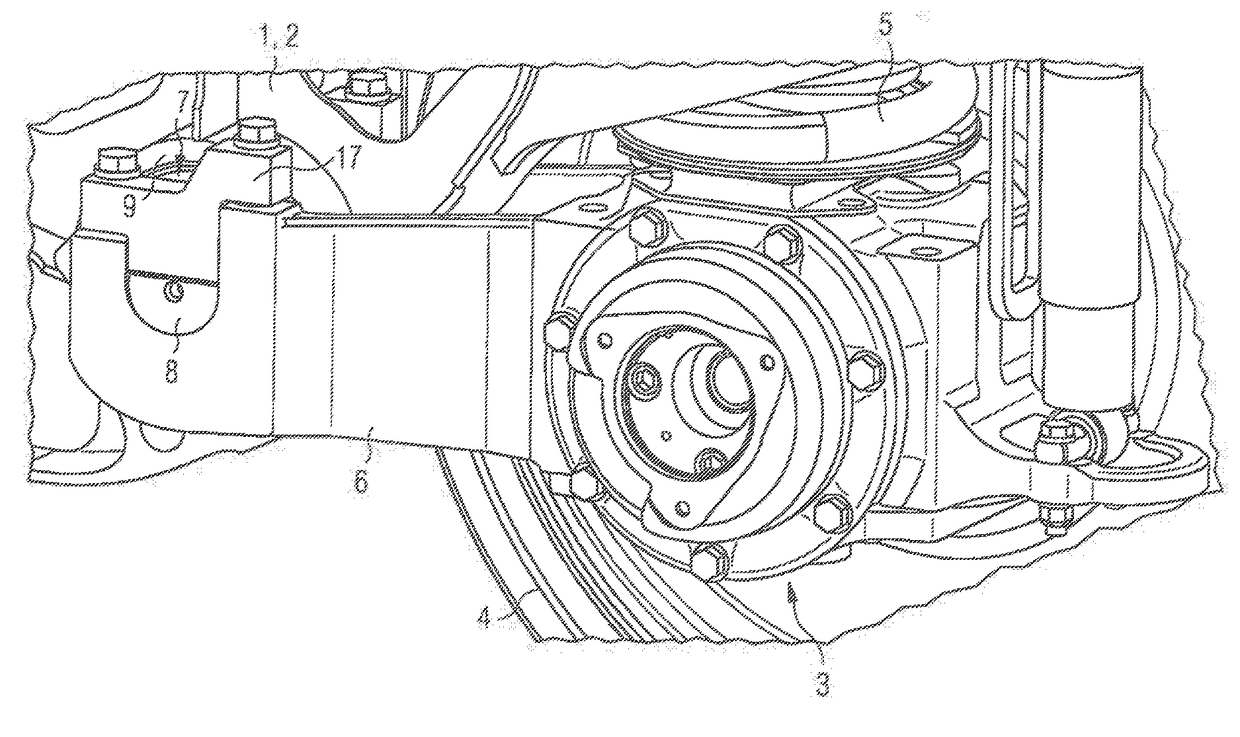

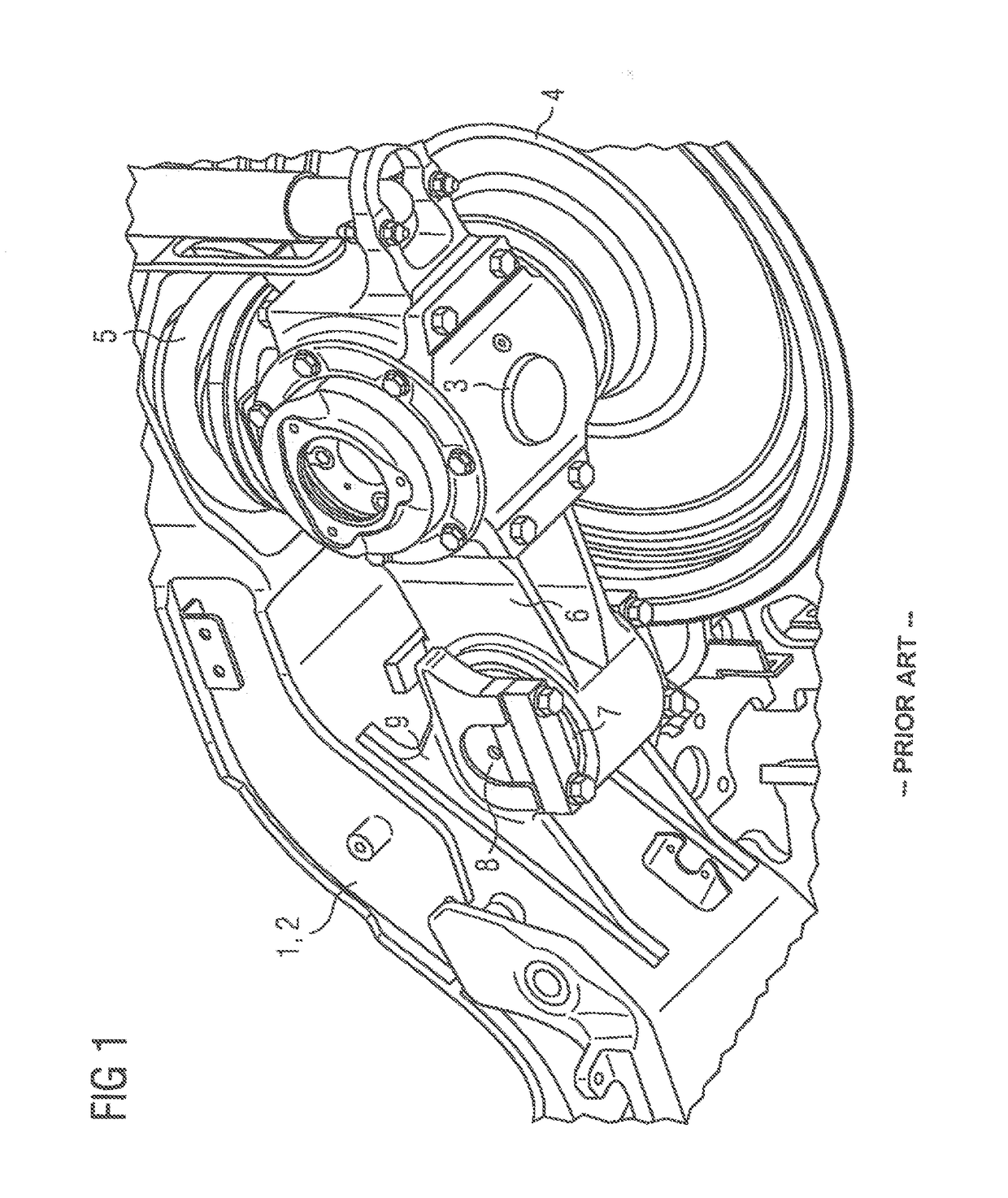

Wheelset guide for a vehicle

A wheelset guide for a rail vehicle, which has a bogie frame, includes at least one longitudinal support, and includes a wheelset bearing for a wheelset of the rail vehicle, wherein the wheelset bearing is connected to the bogie frame and includes a rocker that is pivotably attached to the bogie frame via an elastic rocker bearing, and a pin guided by the rocker bearing, where the bogie frame forms a receptacle for the rocker bearing, which is configured such that the force is introduced into the bogie frame via the rocker bearing itself, and the rocker bearing is positioned in the receptacle in order to improve the strength and stability of the attachment of the rocker to the bogie frame or to the longitudinal support with an open profile.

Owner:SIEMENS MOBILITY AUSTRIA GMBH

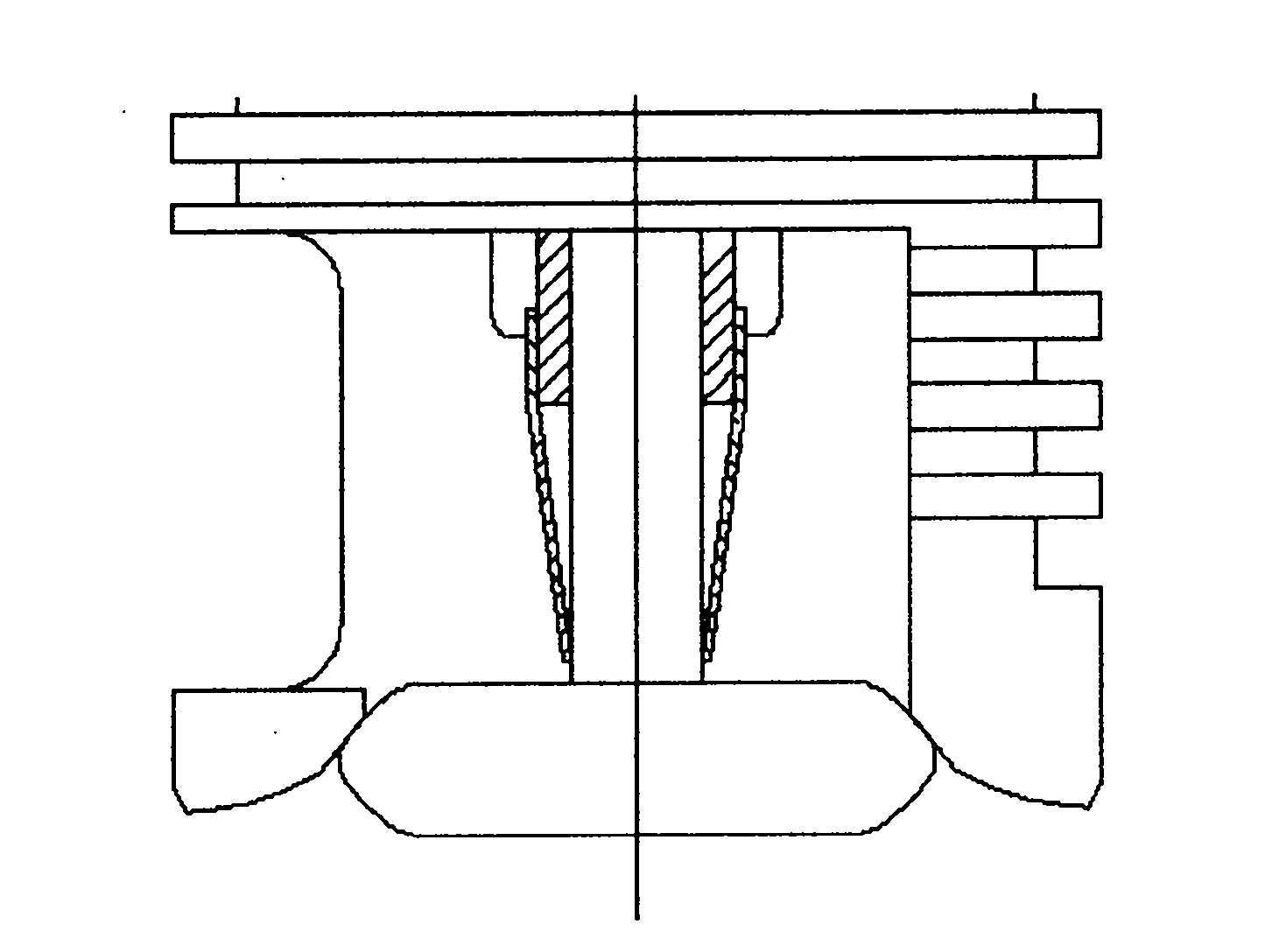

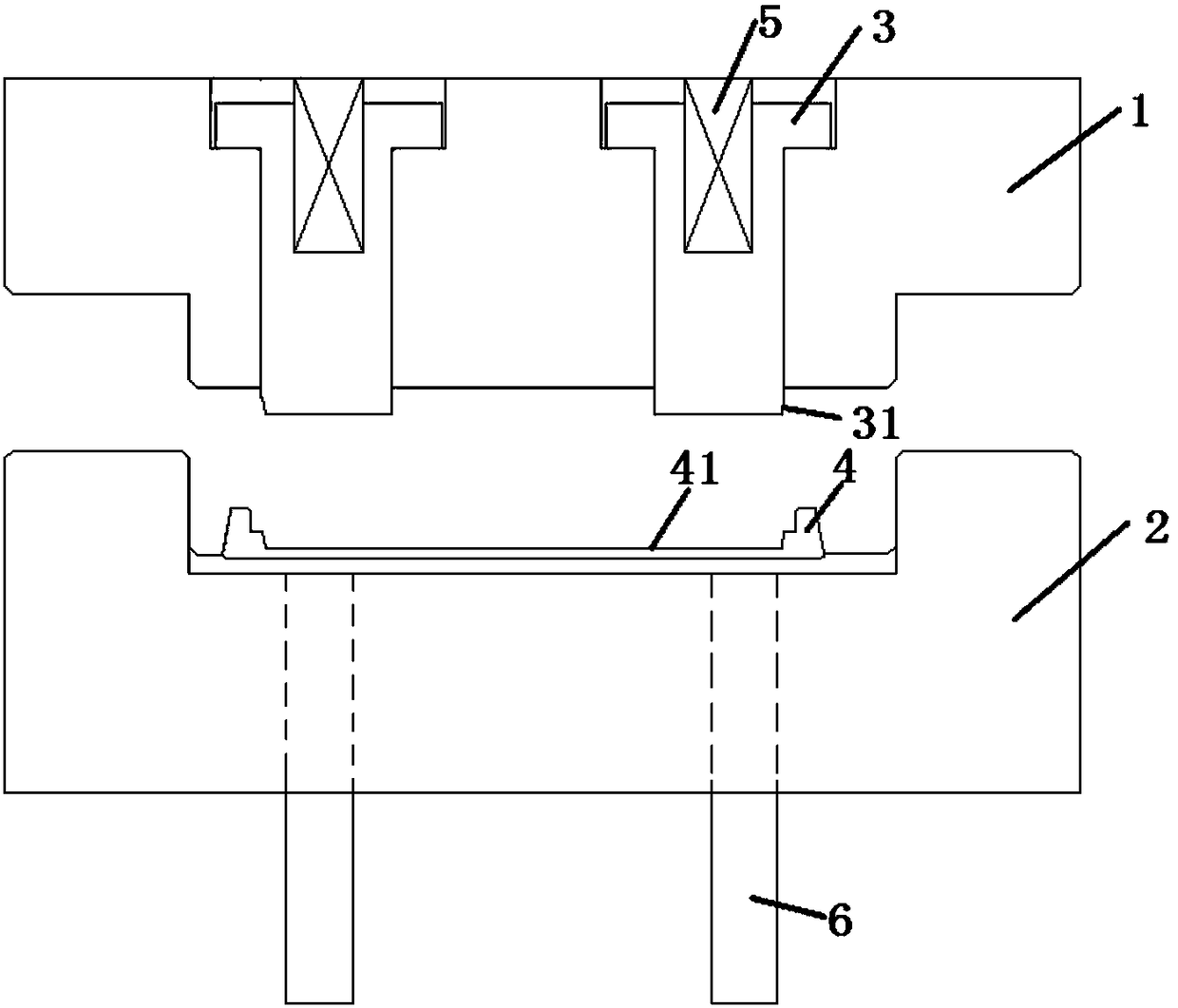

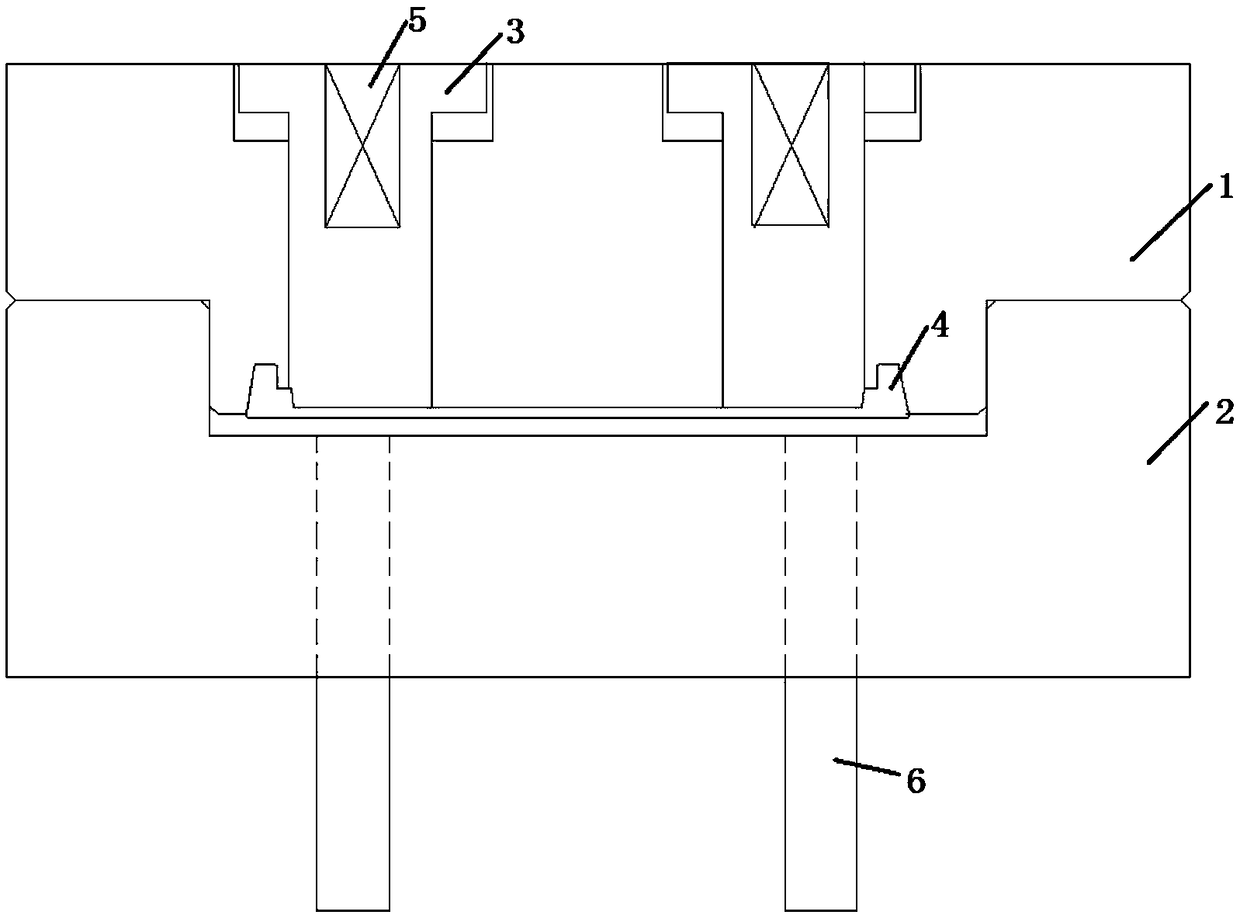

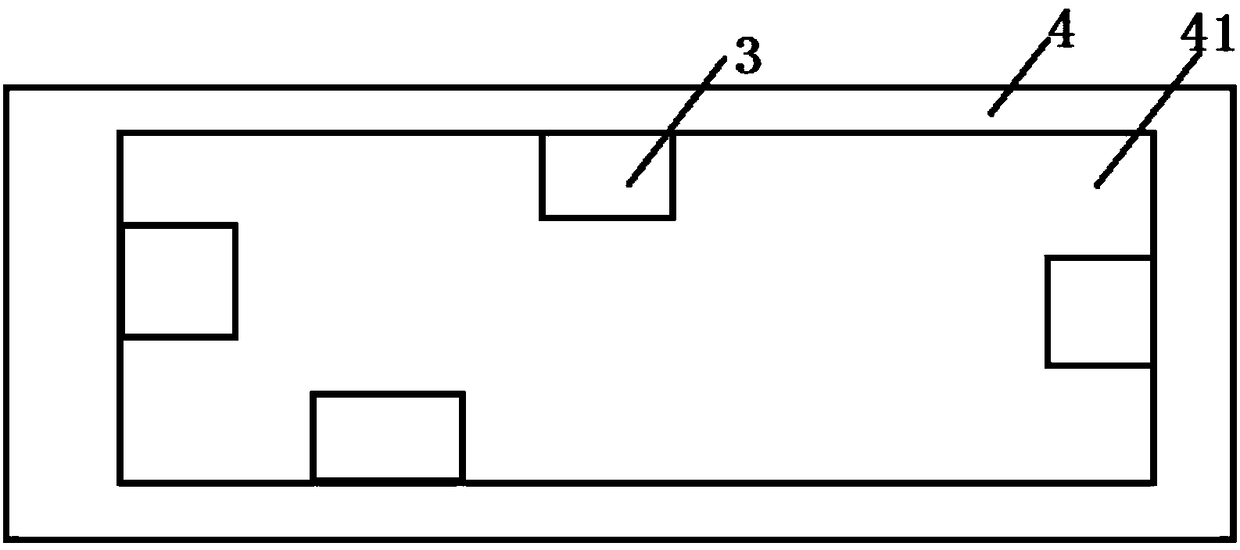

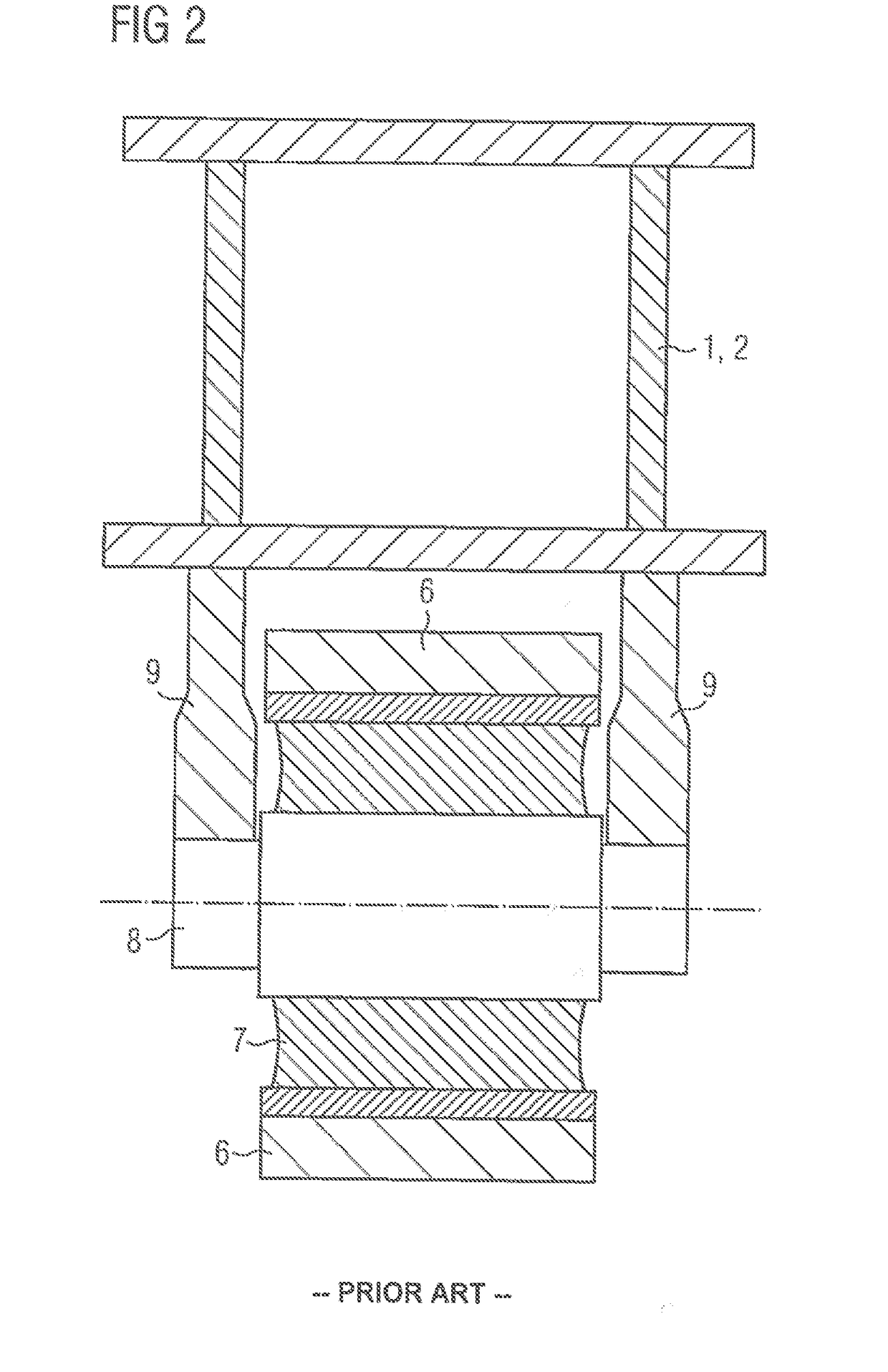

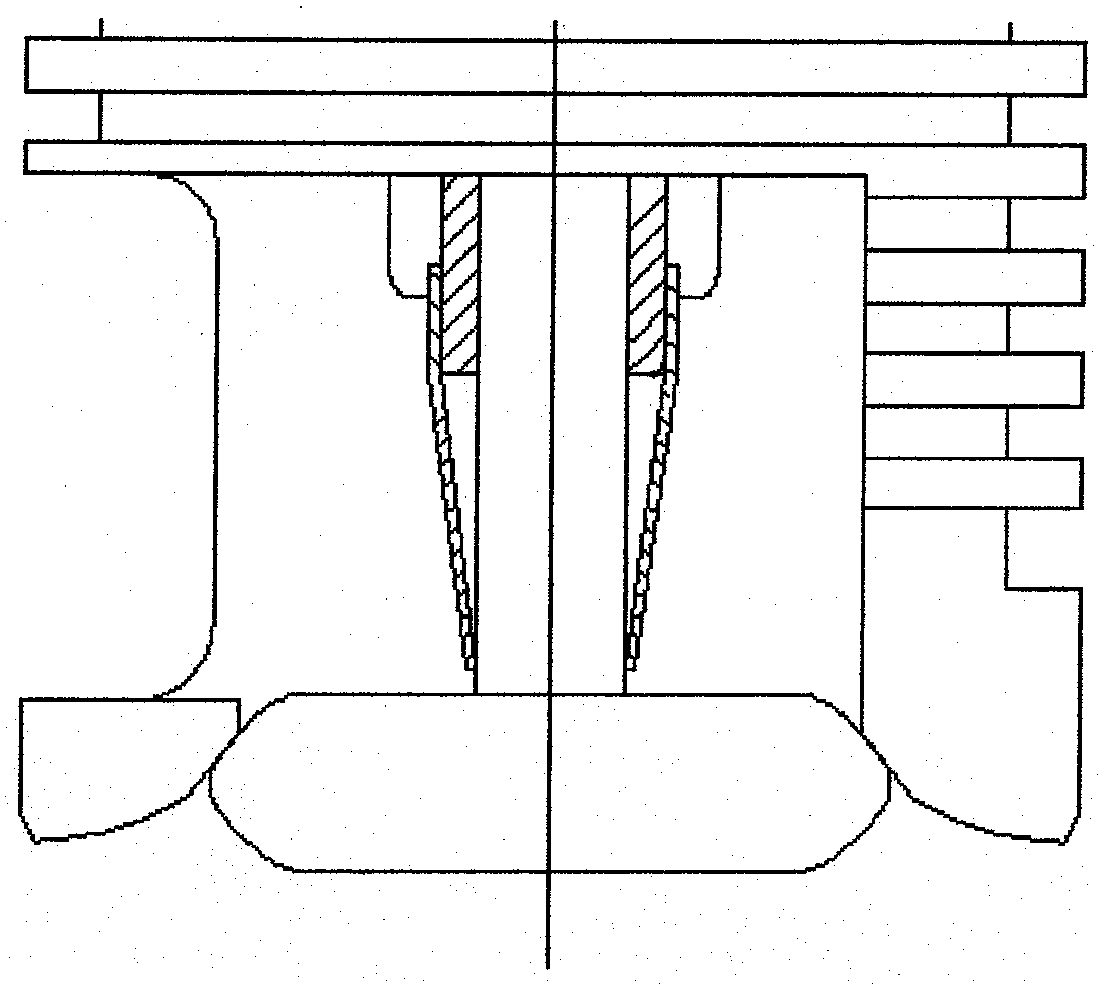

Mold assembly for steel disc injection molding in mold

The invention relates to an injection mold, in particular to a mold assembly for steel disc injection molding in a mold. The mold assembly comprises a male mold and a female mold matched with the malemold. The male mold is a front mold core, the female mold is a rear mold core, and the male mold is arranged above the female mold. The mold assembly for steel disc injection molding in the mold is higher in centering precision and is provided to solve the technical problems that according to an injection mold in the prior art, when a steel disc is put, deviation probably exists due to gaps, thesteel disc is prone to being seriously scratched with the mold, and even the mold is damaged after long-time using.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

Wheelset Guide For A Vehicle

ActiveUS20170341662A1Enhanced attachmentEasy to attachResilient suspensionsBogiesRocker armEngineering

A wheelset guide for a rail vehicle, which has a bogie frame. Includes at least one longitudinal support, and includes a wheelset bearing for a wheelset of the rail vehicle, wherein the wheelset bearing is connected to the bogie frame and includes a rocker that is pivotably attached to the bogie frame via an elastic rocker bearing, and a pin guided by the rocker bearing, where the bogie frame forms a receptacle for the rocker bearing, which is configured such that the force is introduced into the bogie frame via the rocker hearing itself, and the rocker bearing is positioned in the receptacle in order to improve the strength and stability of the attachment of the rocker to the bogie frame or to the longitudinal support with an open profile.

Owner:SIEMENS MOBILITY AUSTRIA GMBH

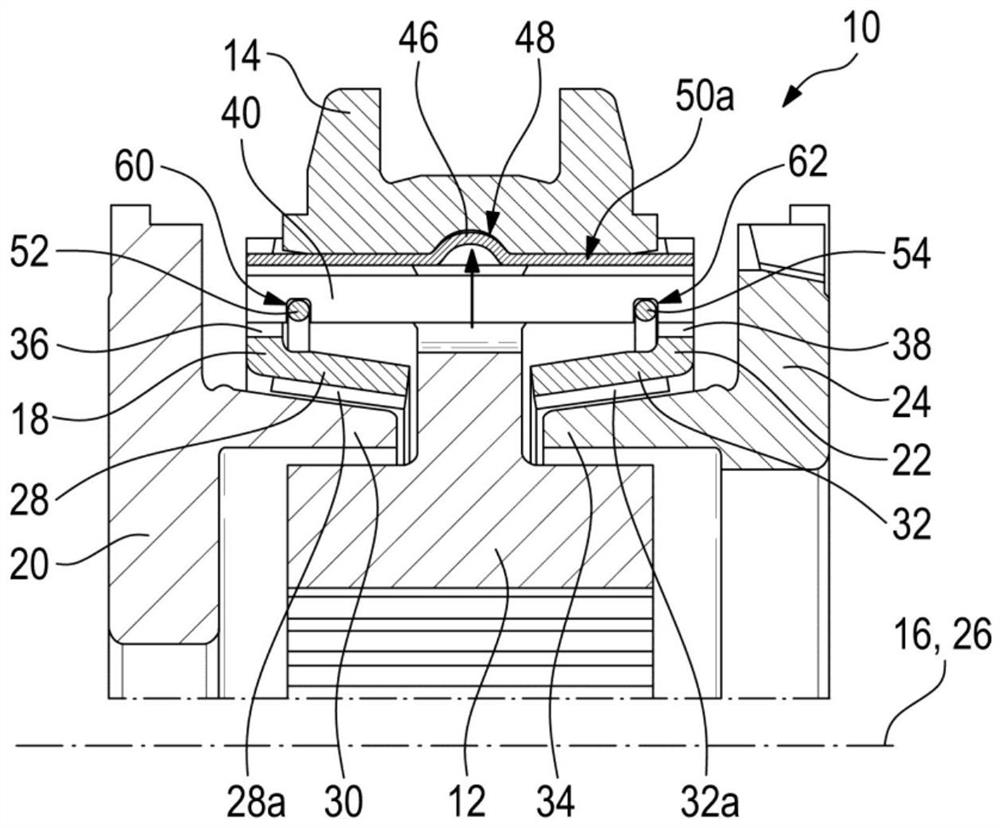

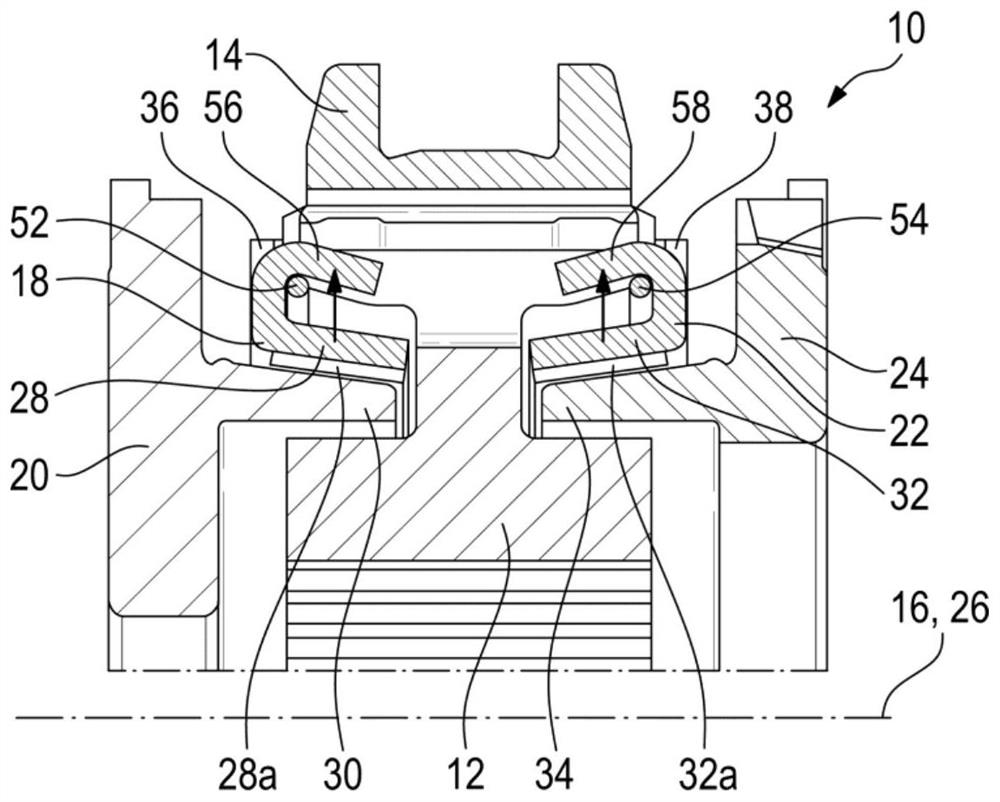

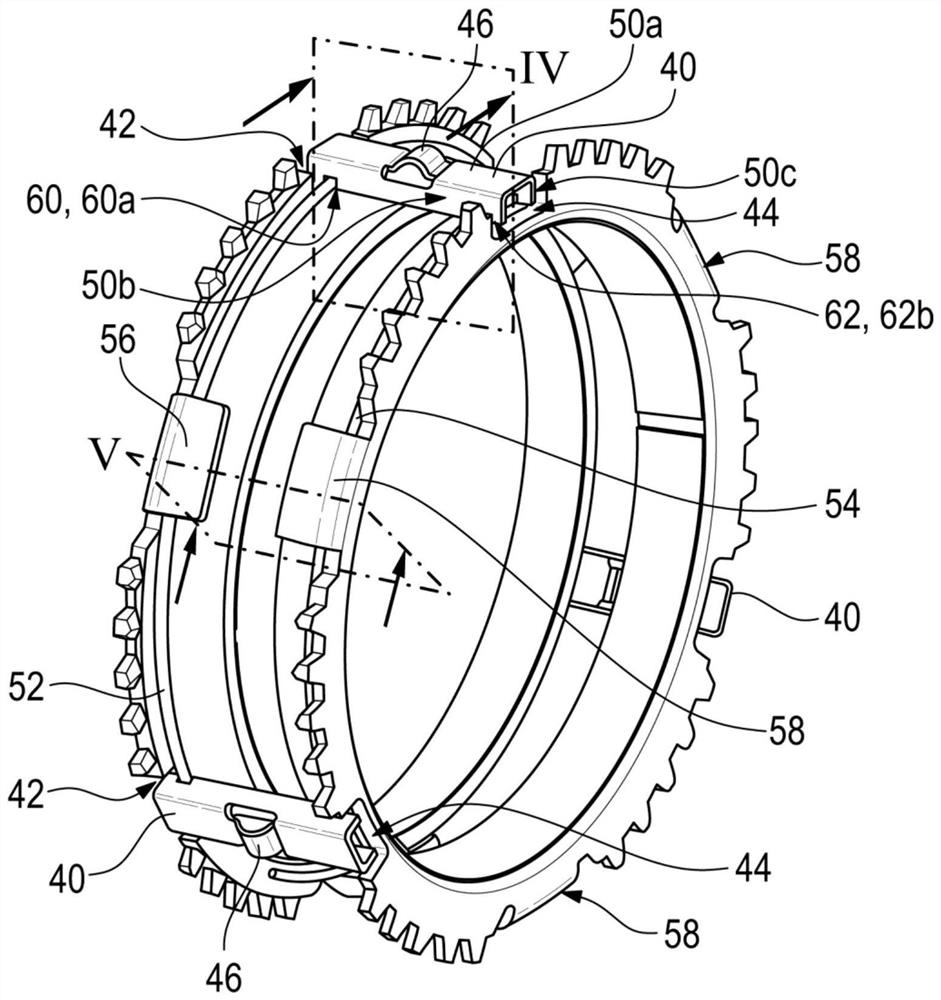

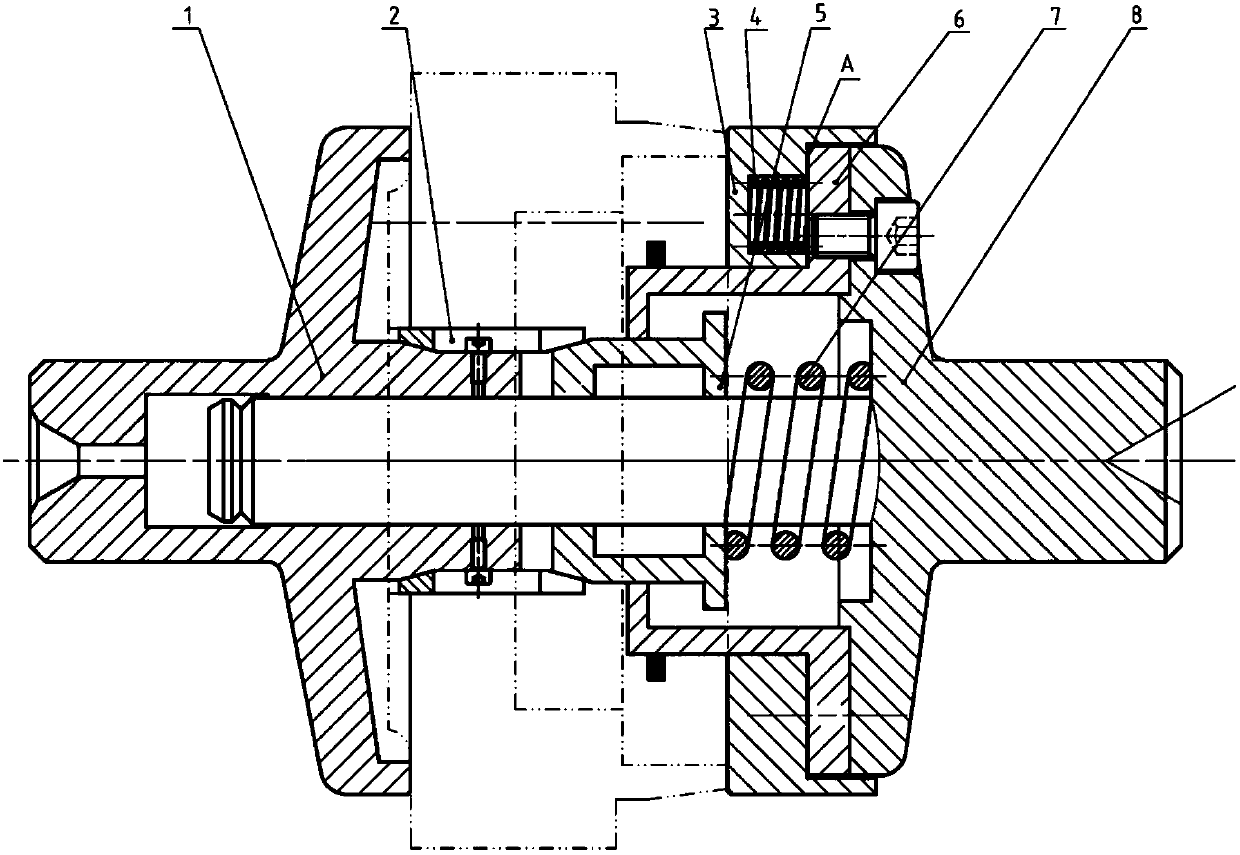

Synchronization unit for shift transmission

InactiveCN112211919AReduce noiseFavorable vibration characteristicsMechanical actuated clutchesVibration suppression adjustmentsEngineeringControl theory

The invention relates to a synchronization unit (10) for a gearshift transmission, comprising a first synchronizing ring (18), a second synchronizing ring (22), at least one carrier plate (40) and twoannular springs (52, 54). The first synchronizing ring (18) and the second synchronizing ring (22) each have a friction cone section (28, 32) and a locking tooth section (36, 38). Here, one of the annular springs (52, 54) is arranged on the radially outer side of the friction cone section (28) of the first synchronizing ring (18) and the other of the annular springs (52, 54) is arranged on the radially outer side of the friction cone section (32) of the second synchronizing ring (22). Furthermore, the two annular springs (52, 54) are coupled in the axial direction by means of a carrier plate(40).

Owner:HOERBIGER ANTRIEBSTECHN HLDG

A hydraulically driven high-pressure rotary grinding head for radial drilling in casing

ActiveCN105507815BImprove efficiencyEffective centeringEarth drilling toolsDrill bitsHigh pressureBody cavity

The invention discloses a hydraulically driven high-pressure rotary grinding head for radial drilling in casing pipes, which includes a lower joint, a body, a core and a grinding head. The tail of the body is connected; the core is provided with an axial through hole, and the core is set in the body, and the expanded diameter section of the core forms a clearance fit with the outer body, and the tail of the core forms an axial cavity with the lower joint or the body. Sealing and sliding fit, the end of the core is connected with the grinding head; the end of the grinding head is conical, and the grinding head is provided with spray holes in the front and rear directions, and the spray holes are connected with the cavity inside the grinding head; the body and the core are both There are radially distributed straight holes, the straight holes of the body communicate with the inner cavity of the body, and the straight holes of the core communicate with the through holes of the core. When the invention performs jet drilling, the pump is turned on, and the grinding head rotates at high speed to generate high-pressure water jets to spray the rock formation. At the same time, the grinding head moves forward under the action of self-traction force. Finish.

Owner:CHINA PETROCHEMICAL CORP +1

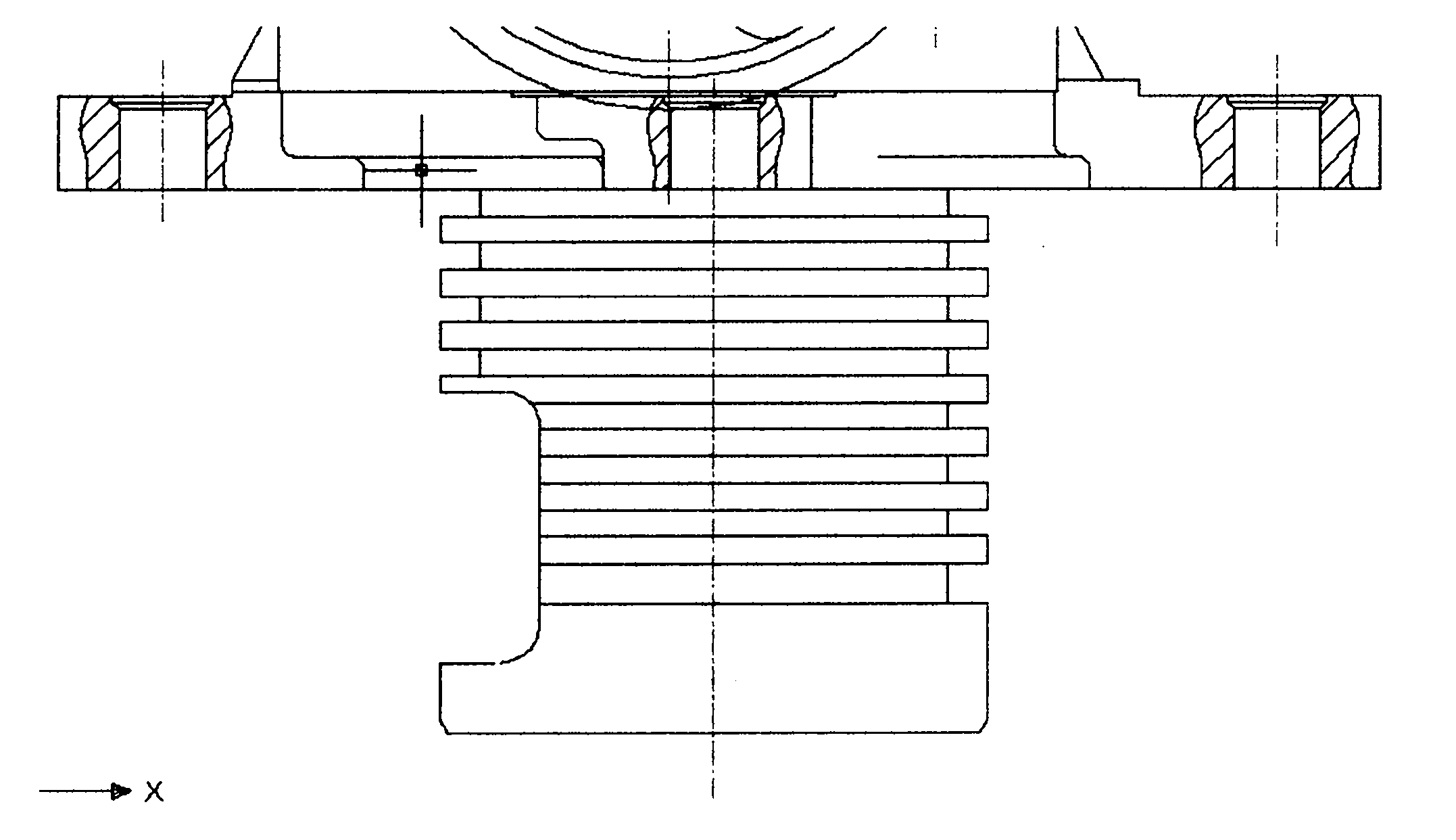

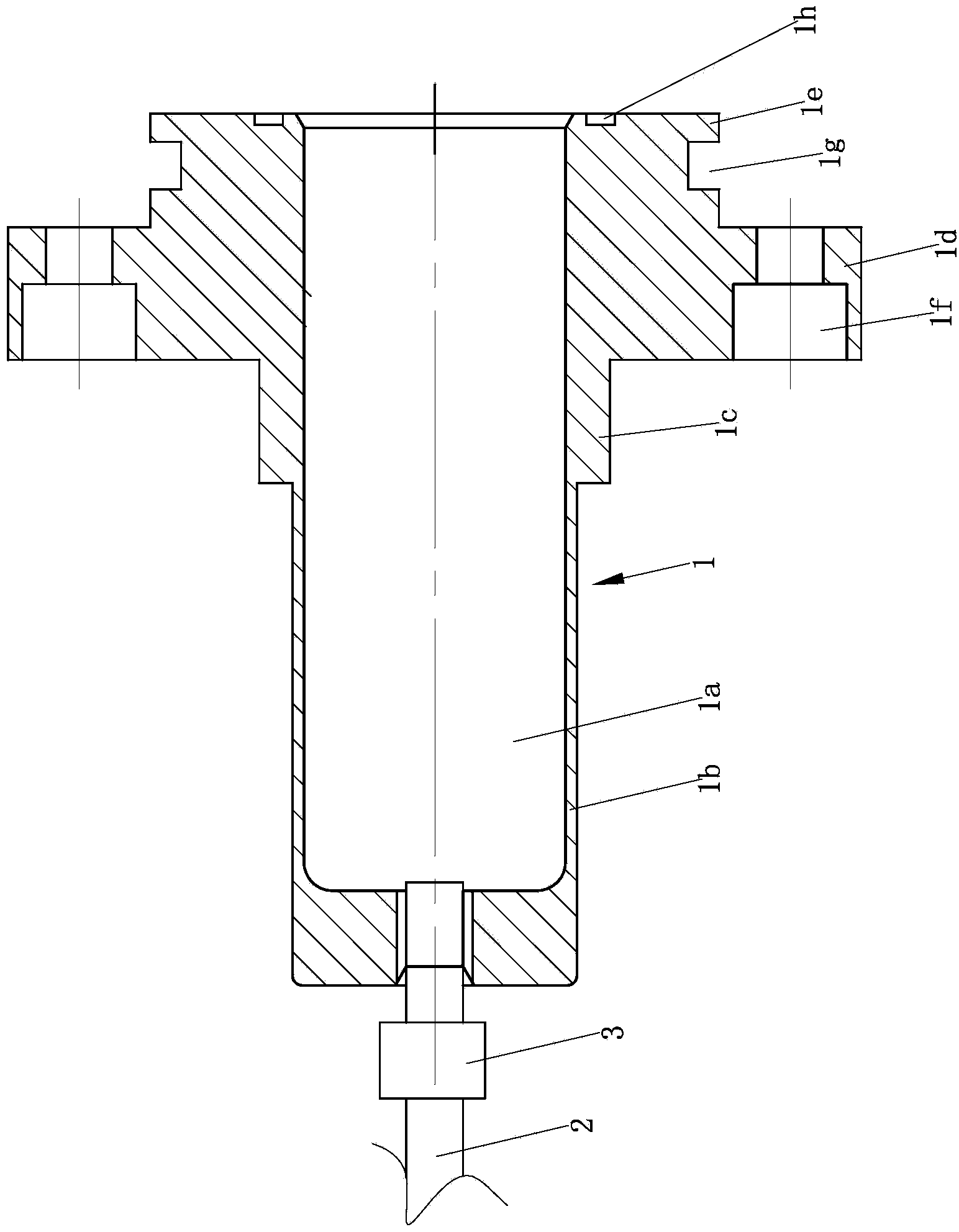

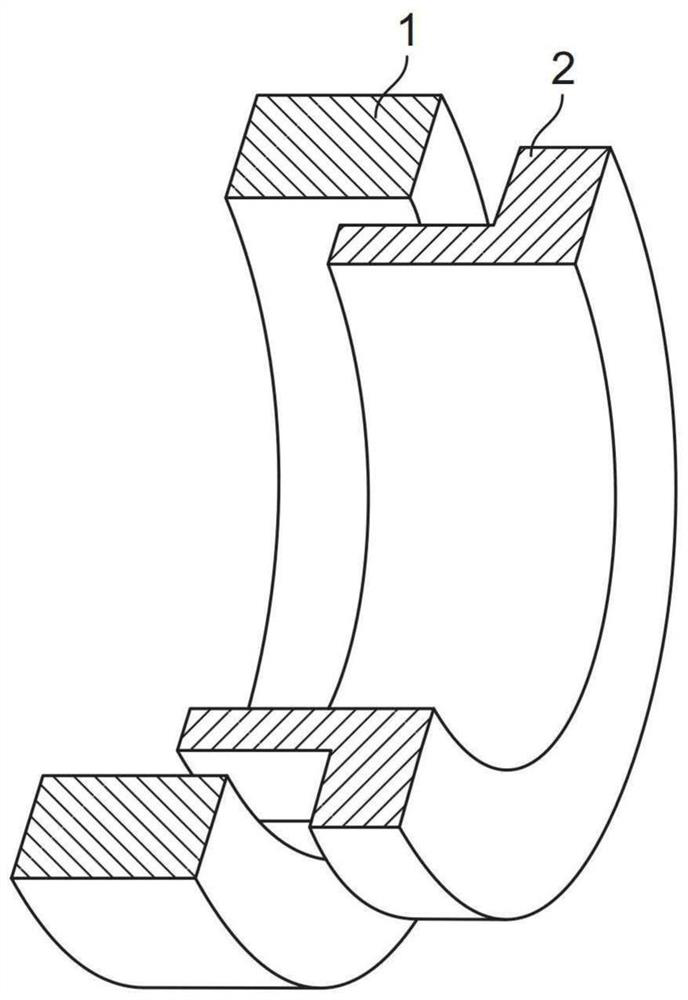

Centering clamp

ActiveCN104289769AEffective centeringHigh centering accuracyPositioning apparatusGear-cutting machinesSpring steelRelief valve

The invention discloses a centering clamp. A clamp body is made of spring steel. A center hole of the clamp body is a two-section-type combining hole and is formed by a thread hole section on the left and an oil injection hole section on the right in a connecting mode. The diameter of the oil injection hole section is larger that the diameter of the thread hole section. An oil inlet end of a pressure relief pipe is connected to the thread hole section of the center hole of the clamp body. A pressure relief valve is arranged on the pressure relief pipe. The clamp body is of a four-section type stepped shaft structure which comprises a first cylinder section, a second cylinder section, a third cylinder section and a fourth cylinder section from left to right in sequence. The length of the first cylinder section is 1 / 2-2 / 3 of the length of the clamp body. The position of the first cylinder section corresponds to the thread hole section of the center hole of the clamp body and the left portion of the oil injection hole section. At least three sinking table holes are evenly distributed in the periphery direction of the third cylinder section of the clamp body and are formed in the axial direction of the clamp body, and the sinking table holes become small from left to right. A workpiece can be subjected to centering effectively, centering accuracy is high, and pressure adjusting is convenient and quick.

Owner:CHONGQING CITY JIANGJIN DISTRICT JINXING MACHINERY

Device for centering an air inlet structure on a central structure of a nacelle

InactiveUS8413346B2Easy to implementReduce riskMeasurement devicesAircraft power plant componentsNacelleEngineering

The invention relates to a device (50) for centering a movable structure (4) on a stationary structure (5) of a nacelle, comprising: a centering pin (52) mounted on a pin holder (54) attached onto the movable structure (4) or onto the stationary structure (5), the centering pin (52) having a central axis (56) and a receiving bore (60) mounted onto a bore holder (62) attached onto the stationary structure (5) or onto the movable structure (4), said receiving bore (60) being capable of receiving at least the centering pin (52), characterized in that the centering device (50) also comprises a movable interface system, capable of overlapping the central axis (56) of the centering pin (52) and the central axis of said interface system or of the receiving bore (60) and capable of receiving said centering pin (52) in a central opening, and a locking means capable of locking said interface system. The invention also relates to a nacelle including such a device (50).

Owner:SAFRAN NACELLES

Cup plug insertion tool

ActiveUS20210323127A1Reduce overall outer diameterSmall inner diameterMetal-working hand toolsStructural engineeringMechanics

A cup plug insertion tool comprises a cylindrical base and a cylindrical collet extending from the base and including at least two longitudinal slots that divide the collet into at least two flexible segments adapted to flex radially inward under force, an annular groove formed adjacent the base, the annular groove adapted to allow the flexible segments to flex radially inward, further wherein, the force necessary to flex the flexible segments radially inward is tunable based on a width and depth of the annular groove, a first section defining a circumferential outer diameter and a circumferential inner diameter, a second section defining a circumferential outer diameter that is larger than the circumferential outer diameter of the first section, a tip positioned at the distal end of the collet, and a chamfer formed between the outer diameter of the first section and the tip.

Owner:GM GLOBAL TECH OPERATIONS LLC

An electronically controlled egr valve that reduces working temperature and improves working reliability

ActiveCN101949340BEffective centeringLower working temperatureInternal combustion piston enginesExhaust gas recirculationDrive shaftWorking temperature

Owner:哈尔滨安龙迪环保科技有限公司

a centering fixture

ActiveCN104289769BEffective centeringHigh centering accuracyPositioning apparatusGear-cutting machinesEngineeringSpring steel

The invention discloses a centering clamp. A clamp body is made of spring steel. A center hole of the clamp body is a two-section-type combining hole and is formed by a thread hole section on the left and an oil injection hole section on the right in a connecting mode. The diameter of the oil injection hole section is larger that the diameter of the thread hole section. An oil inlet end of a pressure relief pipe is connected to the thread hole section of the center hole of the clamp body. A pressure relief valve is arranged on the pressure relief pipe. The clamp body is of a four-section type stepped shaft structure which comprises a first cylinder section, a second cylinder section, a third cylinder section and a fourth cylinder section from left to right in sequence. The length of the first cylinder section is 1 / 2-2 / 3 of the length of the clamp body. The position of the first cylinder section corresponds to the thread hole section of the center hole of the clamp body and the left portion of the oil injection hole section. At least three sinking table holes are evenly distributed in the periphery direction of the third cylinder section of the clamp body and are formed in the axial direction of the clamp body, and the sinking table holes become small from left to right. A workpiece can be subjected to centering effectively, centering accuracy is high, and pressure adjusting is convenient and quick.

Owner:CHONGQING CITY JIANGJIN DISTRICT JINXING MACHINERY

Cup plug insertion tool

ActiveUS11253985B2Raise the possibilityTightly grabblingMetal-working hand toolsStructural engineeringMechanics

A cup plug insertion tool comprises a cylindrical base and a cylindrical collet extending from the base and including at least two longitudinal slots that divide the collet into at least two flexible segments adapted to flex radially inward under force, an annular groove formed adjacent the base, the annular groove adapted to allow the flexible segments to flex radially inward, further wherein, the force necessary to flex the flexible segments radially inward is tunable based on a width and depth of the annular groove, a first section defining a circumferential outer diameter and a circumferential inner diameter, a second section defining a circumferential outer diameter that is larger than the circumferential outer diameter of the first section, a tip positioned at the distal end of the collet, and a chamfer formed between the outer diameter of the first section and the tip.

Owner:GM GLOBAL TECH OPERATIONS LLC

A centering fixture for external cone grinding

ActiveCN104308734BEffective centeringHigh centering accuracyGrinding work supportsEngineeringSpring steel

The invention discloses an outer cone grinding centering fixture. The outer cone grinding centering fixture is characterized in that a fixture body is made of spring steel, a center hole of the fixture body is a double-section combination hole, and a left threaded hole section and a right oil injection hole section are connected with each other to form the center hole; a plug is arranged at the threaded hole section of the center hole of the fixture body, and the right portion of the plug extends into the oil injection hole section of the center hole; the fixture body is of a four-section stepped shaft structure and sequentially comprises a first cylinder section, a second cylinder section, a third cylinder section and a fourth cylinder section from the left to the right, the diameters of the first cylinder section, the second cylinder section and the third cylinder section are gradually increased, and the diameter of the fourth cylinder section ranges from the diameter of the second cylinder section to the diameter of the third cylinder section; at least three counter-bored holes are peripherally uniformly formed in the third cylinder section of the fixture body, a radial hole is further formed in the third cylinder section, an oil return pipe is connected to an outer orifice of the radial hole by screws, and the inner end of the radial hole is communicated with the middle of the oil injection hole section of the center hole of the fixture body. The outer cone grinding centering fixture has the advantages that workpieces can be effectively centered by the aid of the outer cone grinding centering fixture, and the outer cone grinding centering fixture is high in centering precision.

Owner:CHONGQING WINSTAR PRECISE MACHINERY

A hand-held expansion sleeve centering shaving fixture

ActiveCN105665845BEffective centeringImplement automatic recoveryGear-cutting machinesGear teethHand heldEngineering

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

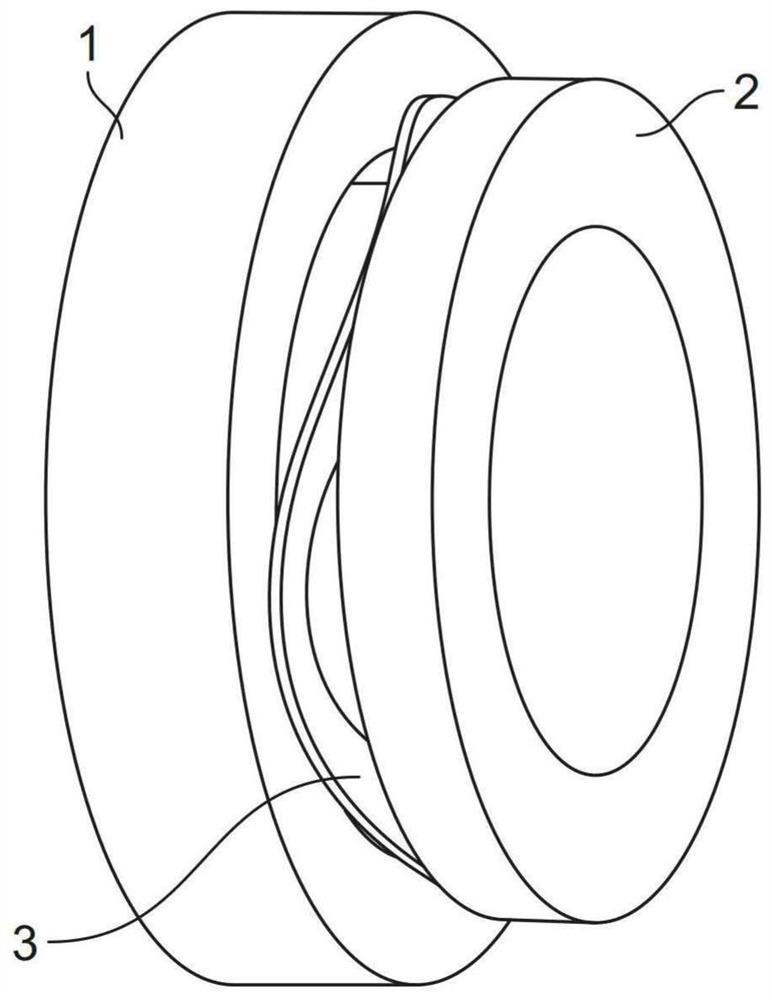

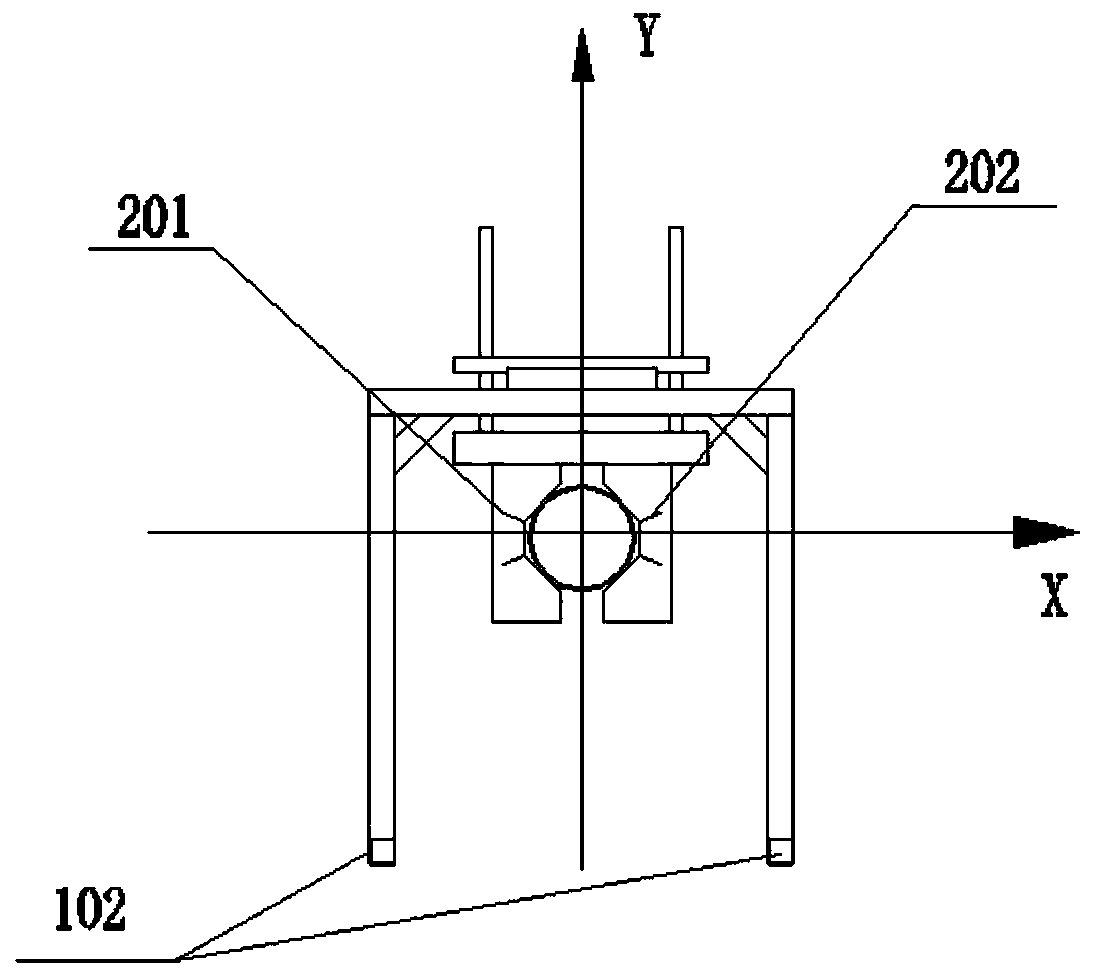

Contact ring and contact system

PendingCN113594742AEffective centeringAvoid relative motionCoupling contact membersConnection contact member materialClassical mechanicsEngineering

The present invention relates to a contact ring (10, 100) for connecting at least a first and a second electrically conductive contact element (1, 2), the contact ring (10, 100, 1000) comprising: a strip (12) comprising electrically conductive material, wherein the strip (12) comprises a plurality of projections (14, 104, 1004) on at least one longitudinal side, wherein the projections (14, 104) are configured such that they contact the electrically conductive materials of the contact elements (1, 2) and establish an electrically conductive connection therebetween. The present invention further relates to a contact system composed of a contact ring (100), a ground cylinder (200), and a shielding cylinder (300) with centering projections, where the contact ring is disposed between the two cylinders and where the ground cylinder (200) and the shielding cylinder (300) are connected to one another by a press-fit.

Owner:TE CONNECTIVITY GERMANY GMBH

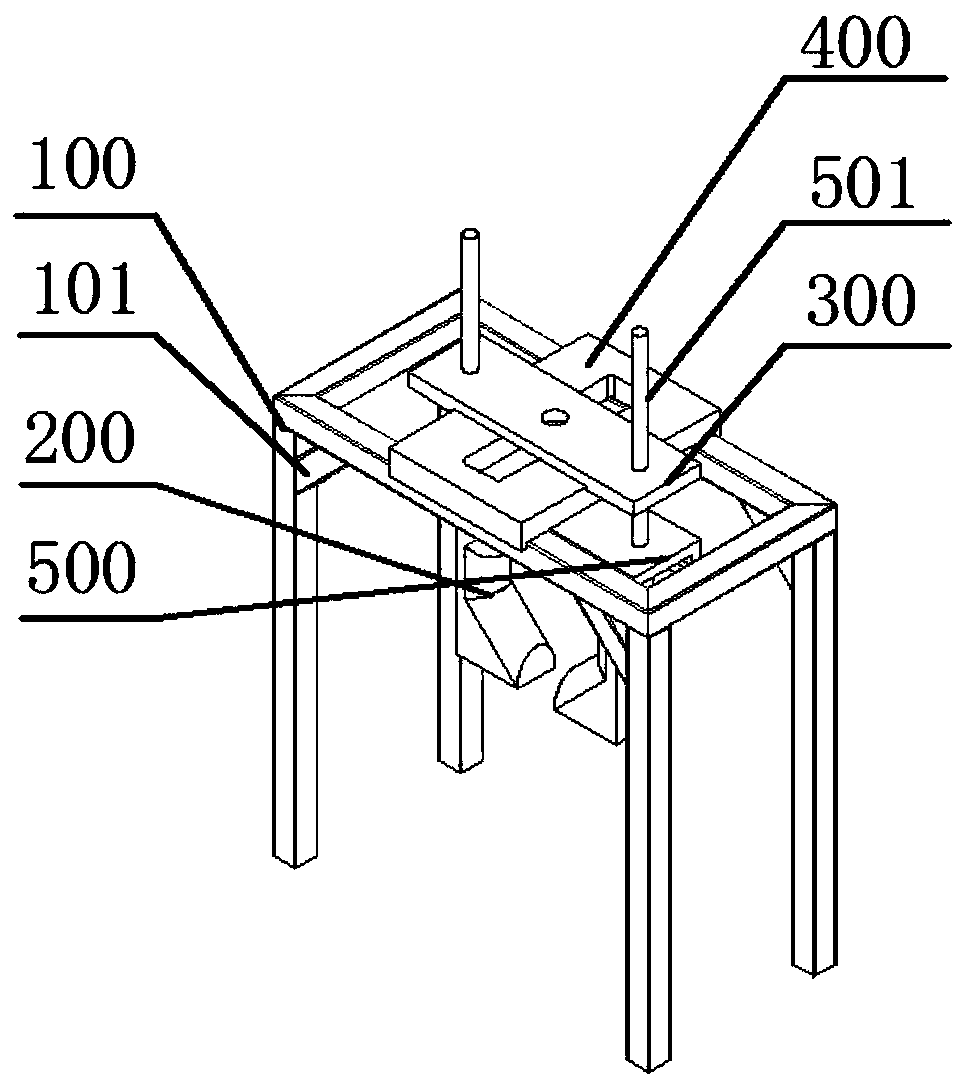

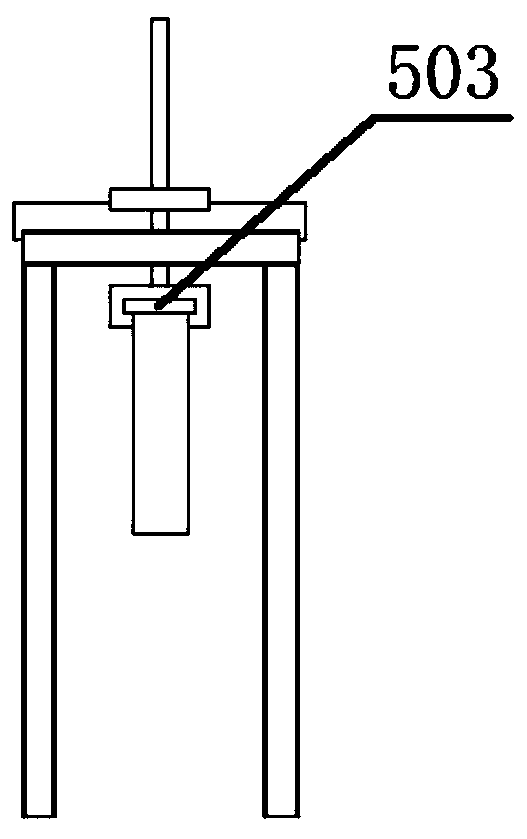

A pipeline alignment method

ActiveCN108247280BQuick alignmentEffective centeringWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention discloses a pipeline centring method. The pipeline centring method comprises the steps that centring devices are jointed; initial values are set; the coordinates on a first pipeline aredetermined; the axis equation of the first pipeline is determined; the coordinates on a second pipeline are guided out; displacement is determined; and centring is carried out according to the displacement. Meanwhile, the centring devices with clamping mechanisms are adopted. The centring method is provided, the centring devices which are provided with the clamping mechanisms and can move in the Xdirection, the Y direction and the Z direction are adopted, the coordinates of the first pipeline are adopted as the datum, the second pipeline is adjusted through the displacement, and therefore fast, effective and convenient pipeline centring is achieved.

Owner:BEIHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com