Synchronization unit for shift transmission

A technology of synchronizing unit and transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

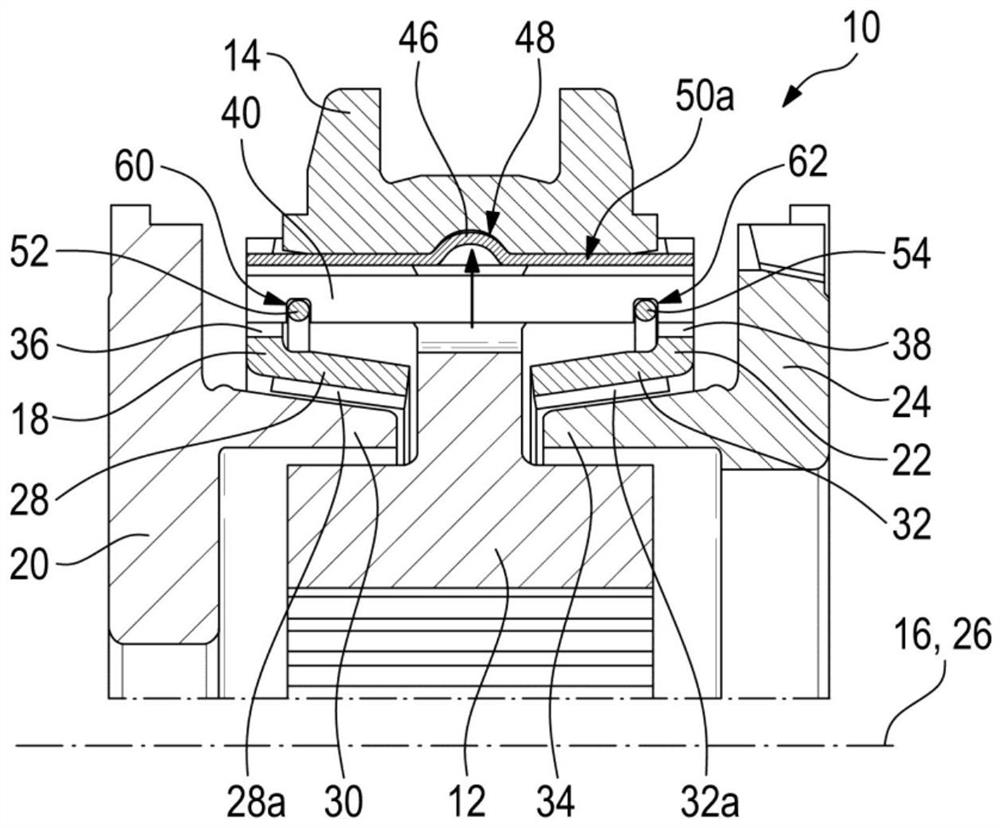

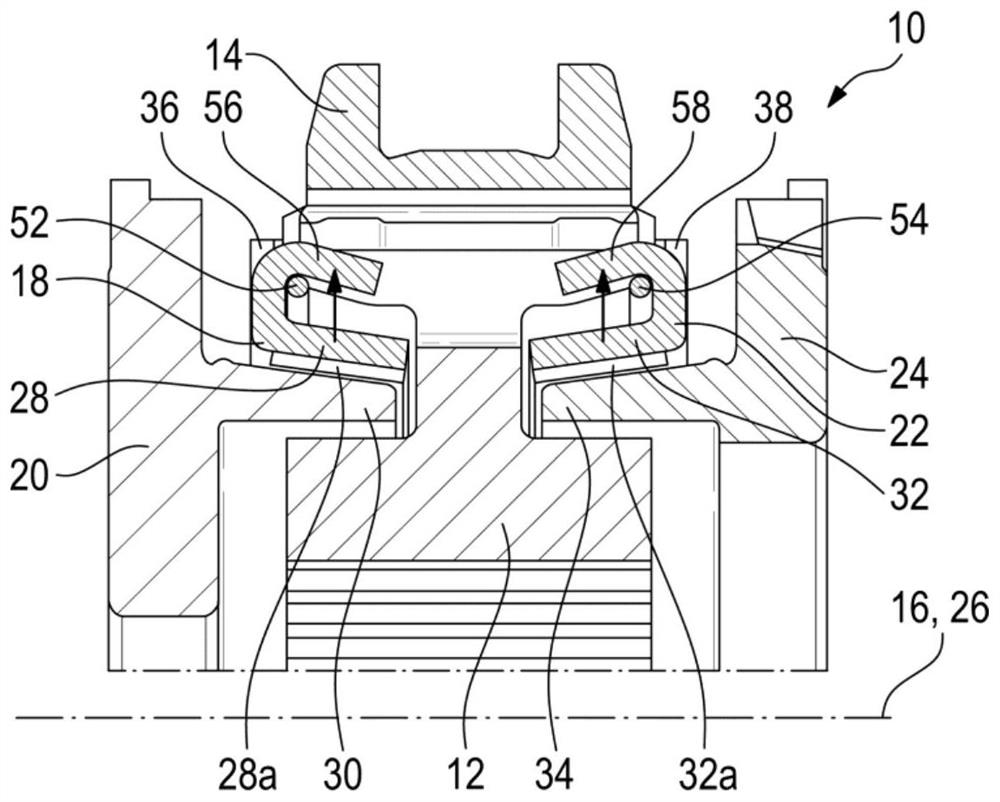

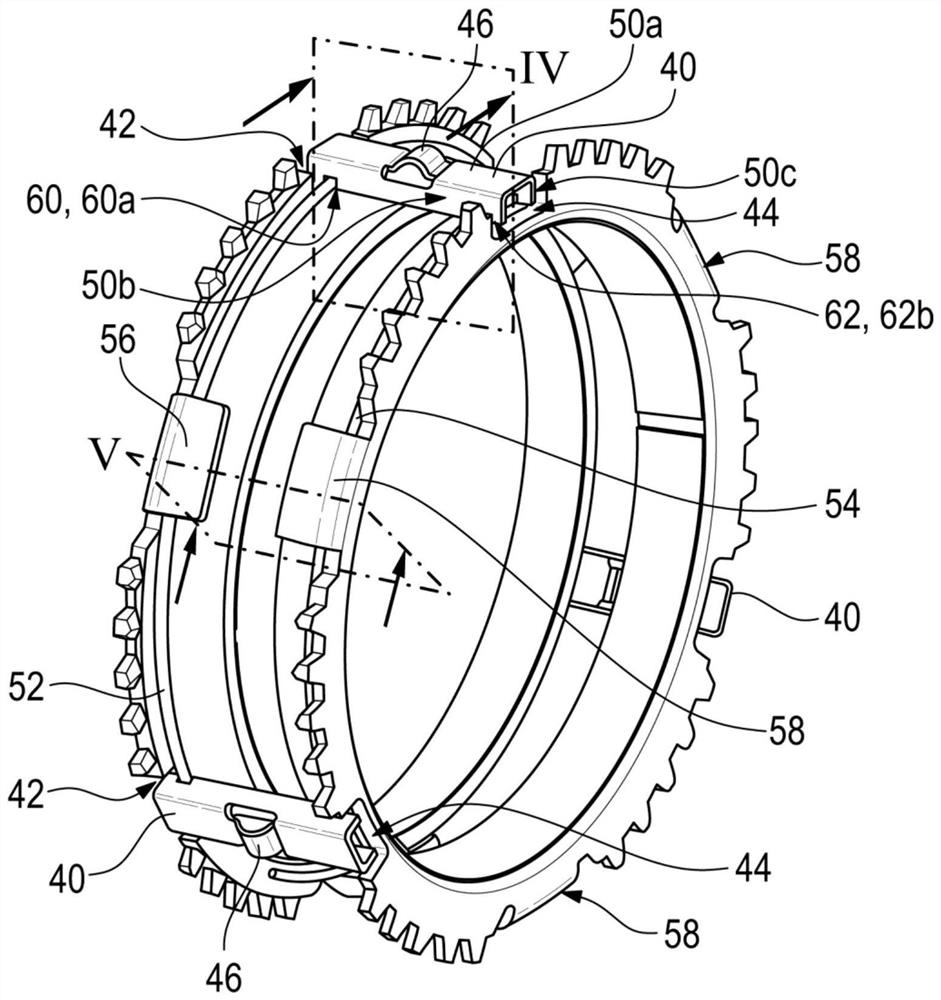

[0060] figure 1 A synchronization unit 10 for a shift transmission of a motor vehicle is shown.

[0061] This synchronization unit includes a hub 12 which can be coupled in a rotationally fixed and axially fixed manner to a transmission shaft, not shown in detail. The sliding sleeve 14 is connected in a known manner to the hub 12 in a non-rotatable, but slidable manner along the central axis 16 of the synchronization unit 10 .

[0062] Furthermore, the synchronization unit 10 comprises a first synchronization ring 18 , by means of which the rotational speed of the hub 12 can be synchronized with the rotational speed of the first clutch body 20 .

[0063] Furthermore, a second synchronizing ring 22 is provided, by means of which the rotational speed of the hub 12 can be synchronized with the rotational speed of the second clutch body 24 .

[0064] The first unison ring 18 and the second unison ring 22 are arranged coaxially and rotatably about a unison ring axis 26 which corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com