A hydraulically driven high-pressure rotary grinding head for radial drilling in casing

A radial drilling and hydraulic drive technology, applied in drill bits, drilling tools, drilling equipment, etc., can solve problems such as easy stoppage and fracture, low milling efficiency, and difficulty in intuitively judging whether the casing window is successful or not. , to eliminate the reduction of cutting efficiency, not easy to wear, and to achieve good reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

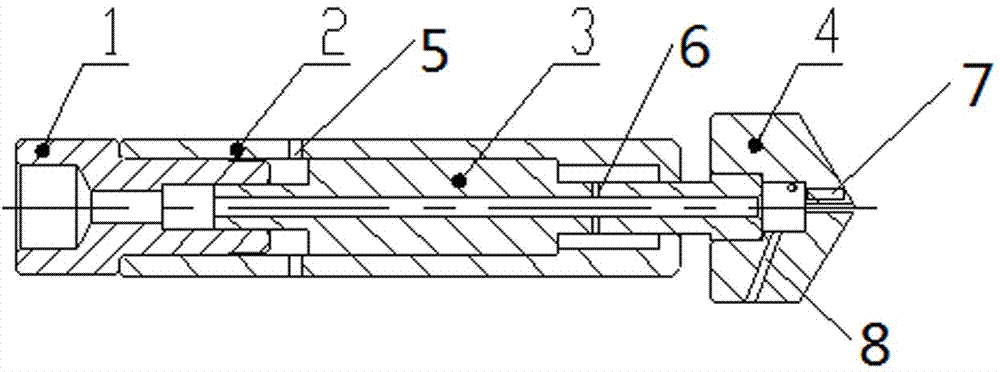

[0018] Such as figure 1 Shown is a hydraulically driven high-pressure rotary grinding head for radial drilling in the casing, which includes four parts: a lower joint 1 , a body 2 , a core 3 and a grinding head 4 . The inner cavity of the main body 2 can accommodate the core part 3, and the surface of the main body 2 has radially distributed straight holes 5 communicating with the inner cavity of the main body 2. The lower joint 1 and the main body 2 are connected together by threads, and there is a cavity inside the lower joint 1, which can Hold the tail of the core 3, the core 3 can move in this cavity, the middle part of the core 3 is cylindrical, the surface is smooth, and matches the inner cavity of the body 2, the core 3 has through holes inside, and the surface has radial distribution The straight hole 6 communicates with the internal through hole, and the front part is connected with the grinding head 4 through threads. The two can move relative to the lower joint 1 th...

Embodiment 2

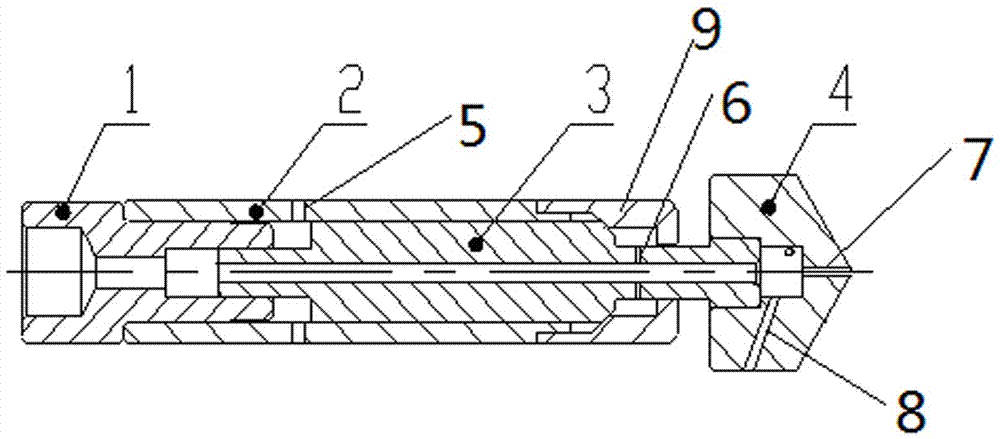

[0020] Such as figure 2 Shown is another hydraulically driven high-pressure rotary grinding head for radial drilling in the casing, including four parts: the lower joint 1 , the body 2 , the core 3 and the grinding head 4 . The body 2 is composed of a cylinder body and a front block 9 of the body. The two parts are connected together by threads, and a groove is formed at the junction of the two parts. The inner cavity of the body 2 can accommodate the core 3. The surface of the body 2 has a vertical straight The hole 5 communicates with the inner cavity of the body 2, and the lower joint 1 and the main body 2 are connected together by threads. There is a cavity inside the lower joint 1, which can accommodate the tail of the core 3, and the core 3 can move in this cavity. The middle part of part 3 is cylindrical, with a smooth surface, matching with the inner cavity of the body 2, with a slope on the front end of the cylinder, matching with the inclined surface of the inner ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com