An electronically controlled egr valve that reduces working temperature and improves working reliability

A technology of EGR valve and working temperature, applied in charging system, combustion engine, machine/engine, etc., can solve the problems of device complexity and increase cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

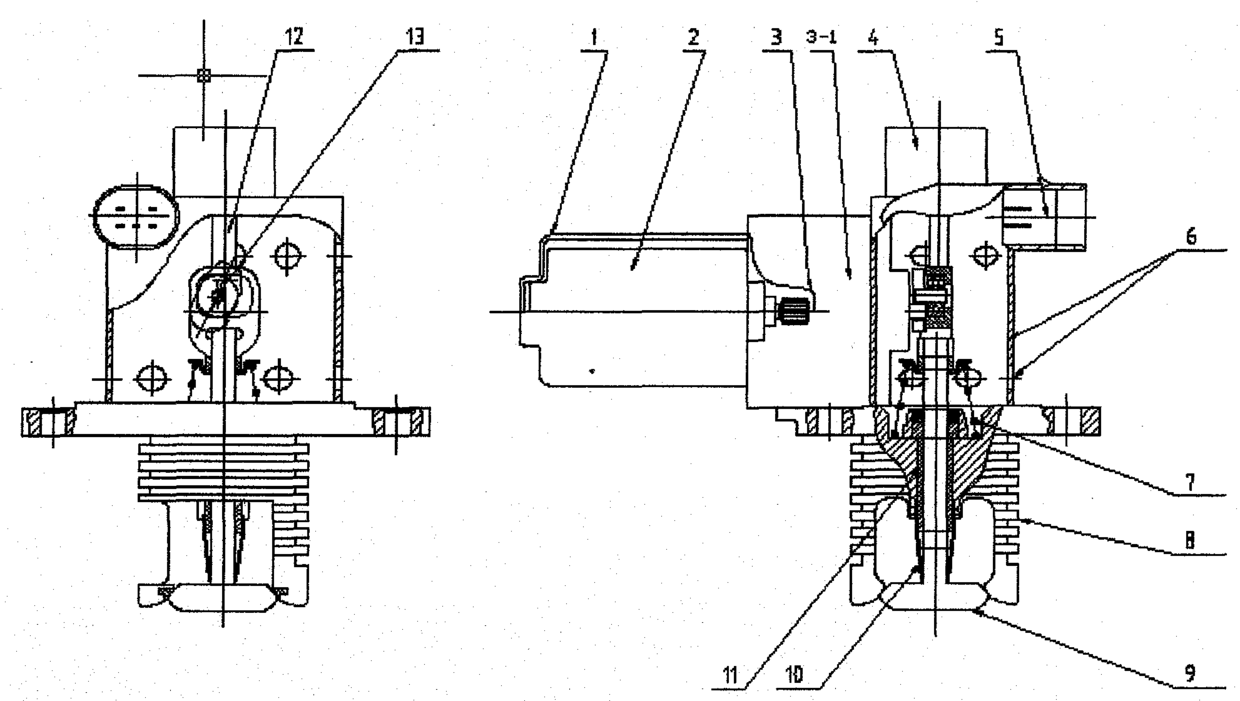

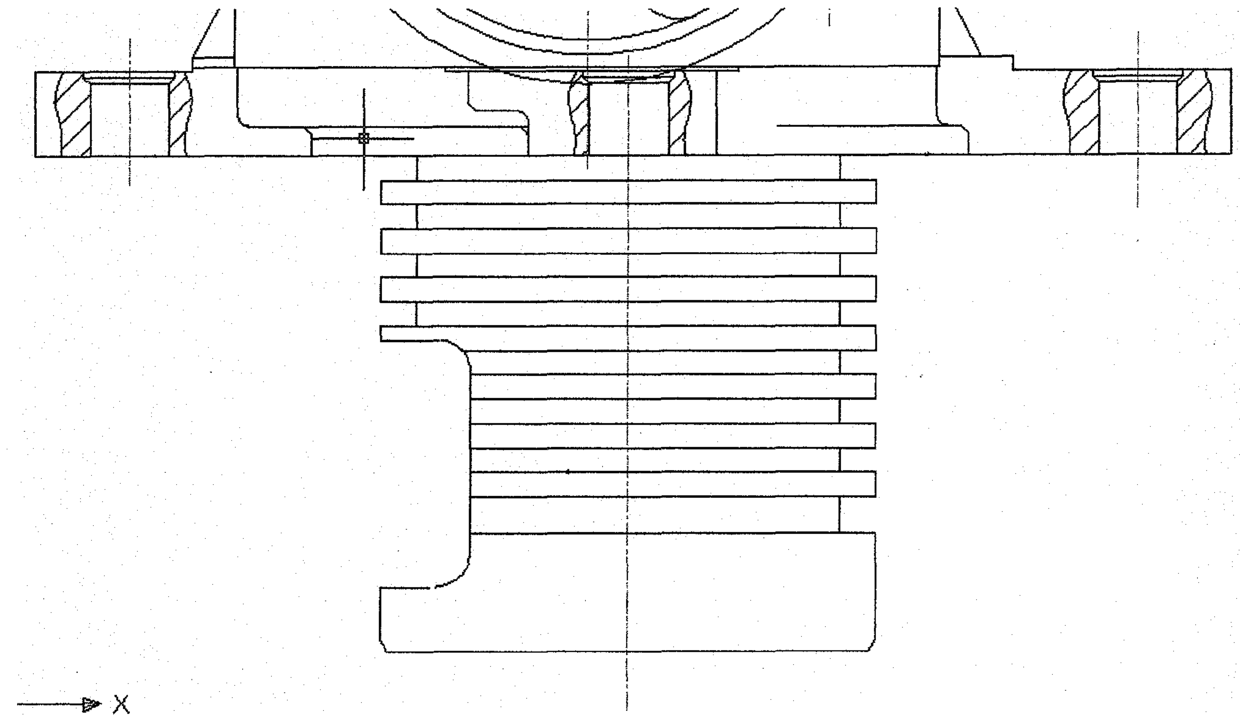

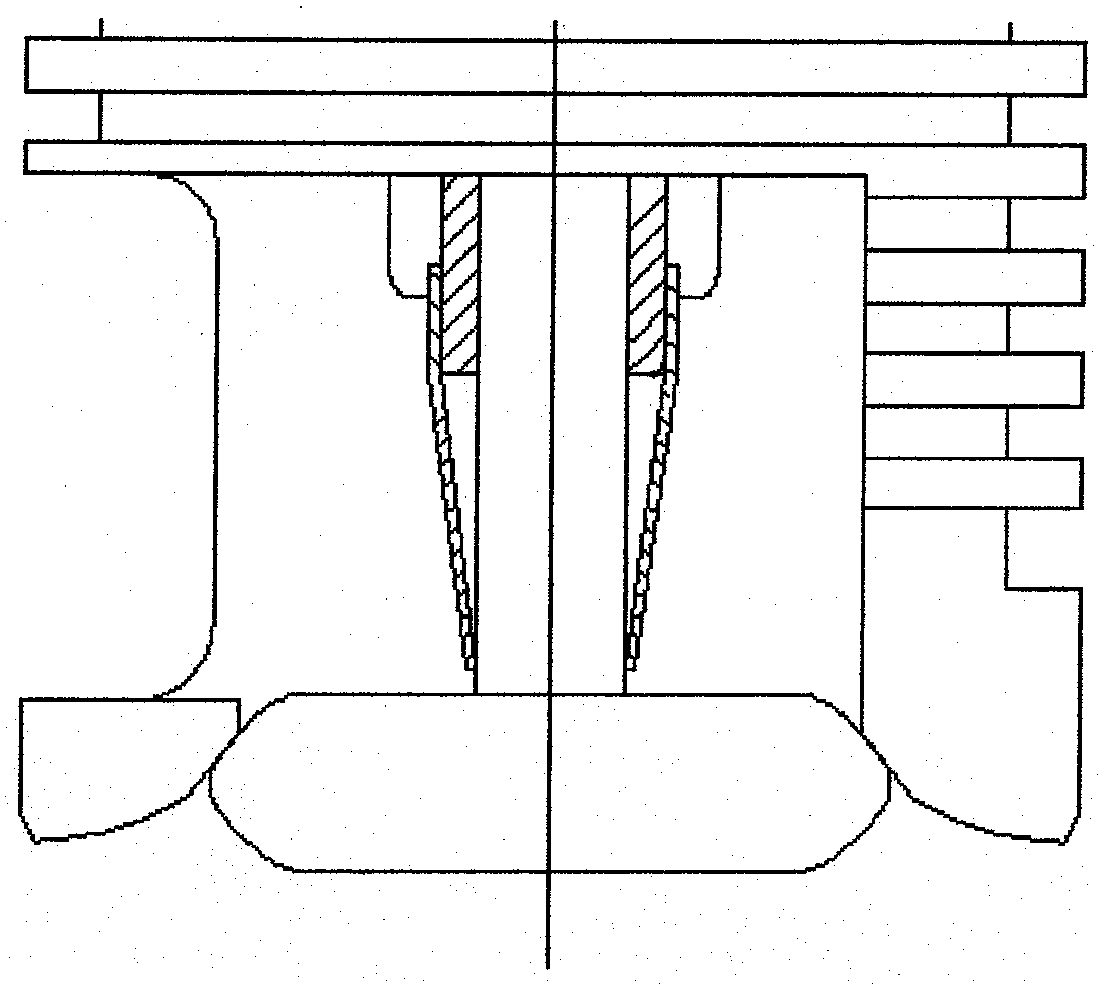

[0012] The technical solution of the present invention is: the servo motor 2 controlled by the ECU is sealed in the casting cylinder 1 connected with the valve seat, which effectively shields external electromagnetic interference and forms a reliable protection to prevent foreign objects from colliding with Dust pollution; the shaft end of the servo motor is connected with the star reducer 3-1 with the cycloid gear 3, and the reducer is sealed in the reducer casing. Because all the gear trains are made of polycarbonate material without lubrication; at the output end of the reducer, the crank arm mechanism 13 converts the decelerated circumferential motion of the servo motor into axial motion; the above parts are all in a dustproof box 6 in the low-temperature car body; centering in the copper sleeve 11, the valve rod connected to the spherical valve 9 is compressed by the return spring 7 so that the valve is in a closed state.

[0013] Its working procedure is: drive the servo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com