Contact ring and contact system

A technology of contact system and contact ring, applied in the direction of contact parts, connection contact materials, connections, etc., can solve the problems of non-conductive connection, low efficiency of electromagnetic shielding, poor electrothermal performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following will refer to Figures 2A to 13D Embodiments of the present invention are described in detail.

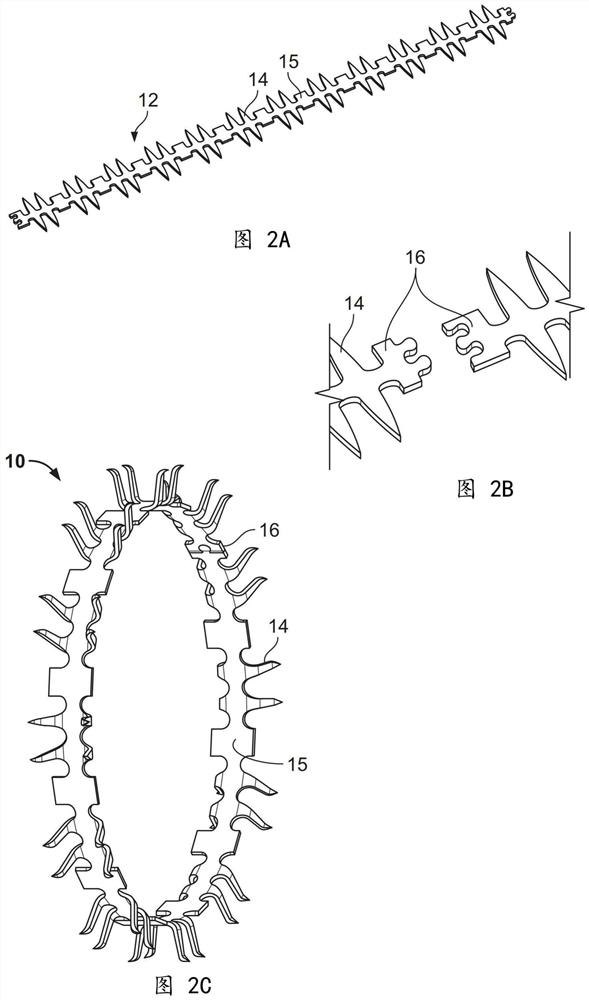

[0054] Figures 2A to 2C A contact ring 10 according to a first embodiment of the invention is shown. like Figure 2A As shown, the contact ring 10 comprises a strip 12 of electrically conductive material. The strip 12 is provided with protrusions 14 on at least one longitudinal side. The protrusion 14 tapers and forms a point at its end. Figure 2B It is shown that the strip 12 may be equipped with closures 16 at the ends, which allow the strip 12 to be closed to form an annular cylindrically arranged structure, as in Figure 2C can be seen in . This construction allows simple and inexpensive production of the contact ring 10 by punching and bending. like Figure 2C As shown, the protrusions 14 are curved outwards and have an S-shaped cross-section.

[0055] A helical spring (not shown) may optionally surround the contact ring 10 concentrically, makin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com