Method for aligning and mounting two components on a support member in a positionally accurate manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

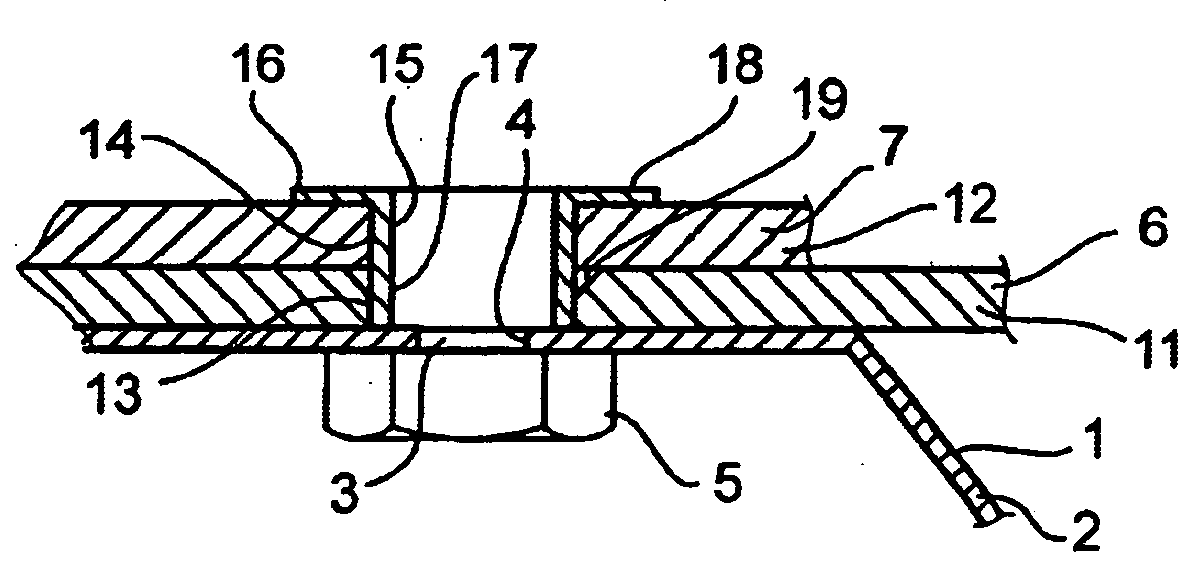

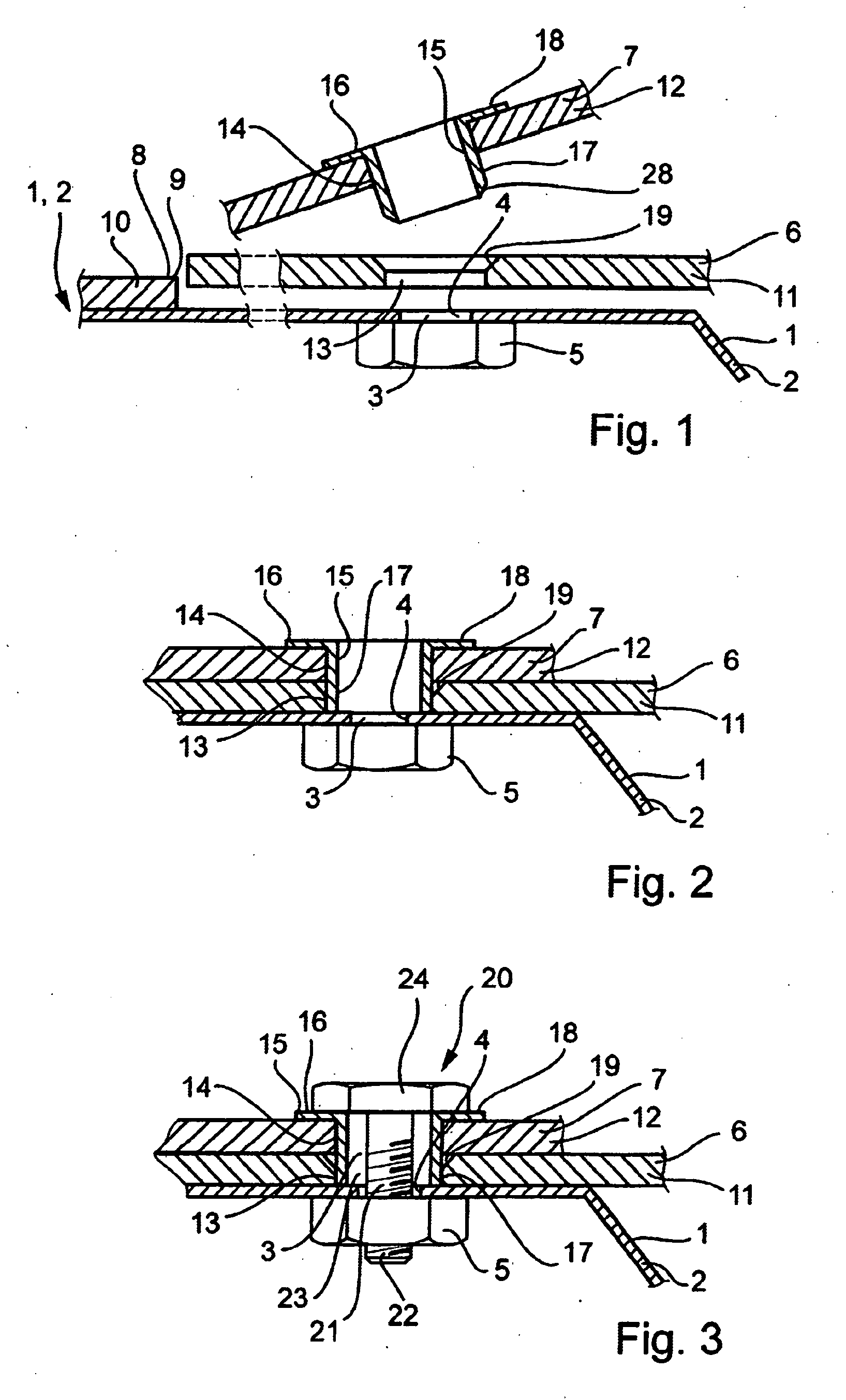

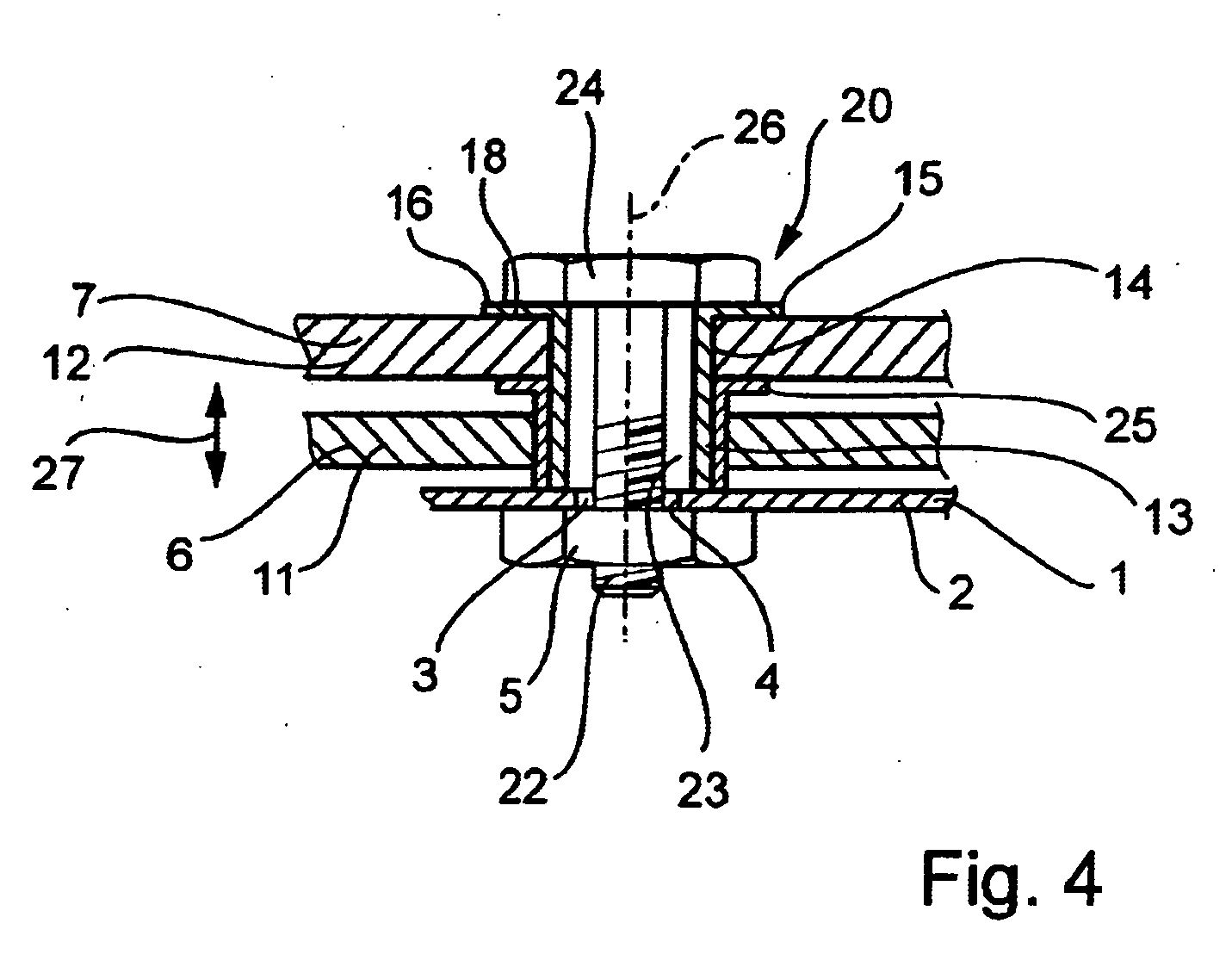

[0024] In FIG. 1, the components to be connected to each other in a positionally accurate manner are represented at the start of implementation of the method according to an example embodiment of the present invention. Illustrated is a support member 1, which may be, e.g., a car-body component 2 of a motor vehicle, to which components of a motor-vehicle front end are to be mounted. Located on support member 1 is an attachment region 3, which is formed, in this exemplary embodiment, by an opening 4 in support member 1 and a nut 5 rigidly connected to support member 1. In this attachment region 3, two other components, a guide part 6 and a follower part 7, shall be attached to support member 1. Support member 1 also has an alignment element 8, which may ensure that the components mounted to support member 1 are aligned. As illustrated in the drawing, this alignment element 8 may be formed, for example, by an edge 9 of an adjacent component 10, from which guide part 6 may assume a spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com