Mold assembly for steel disc injection molding in mold

An in-mold injection and steel sheet technology, applied in the direction of coating, etc., can solve problems such as mold damage, scratches between steel sheets and molds, and deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

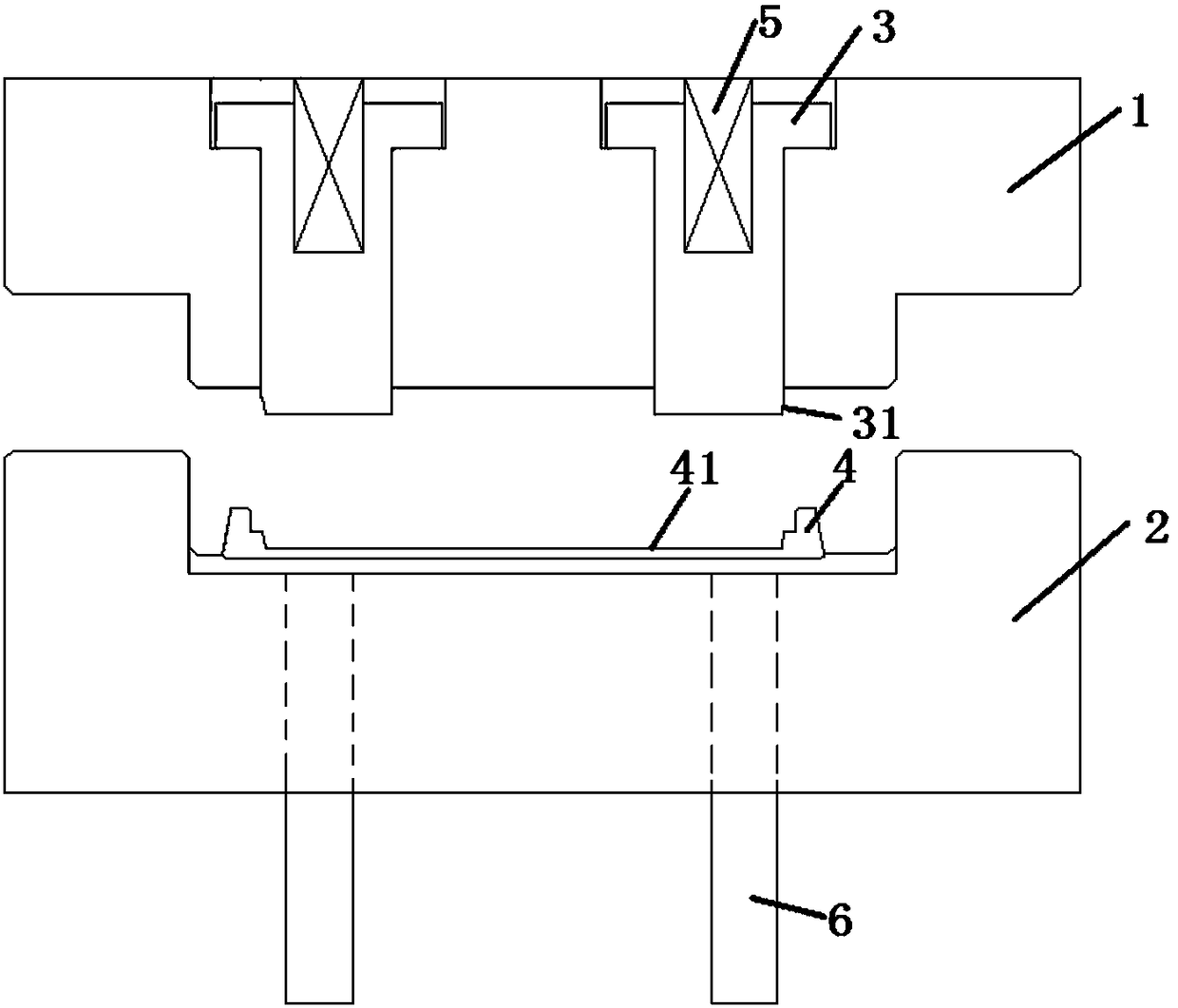

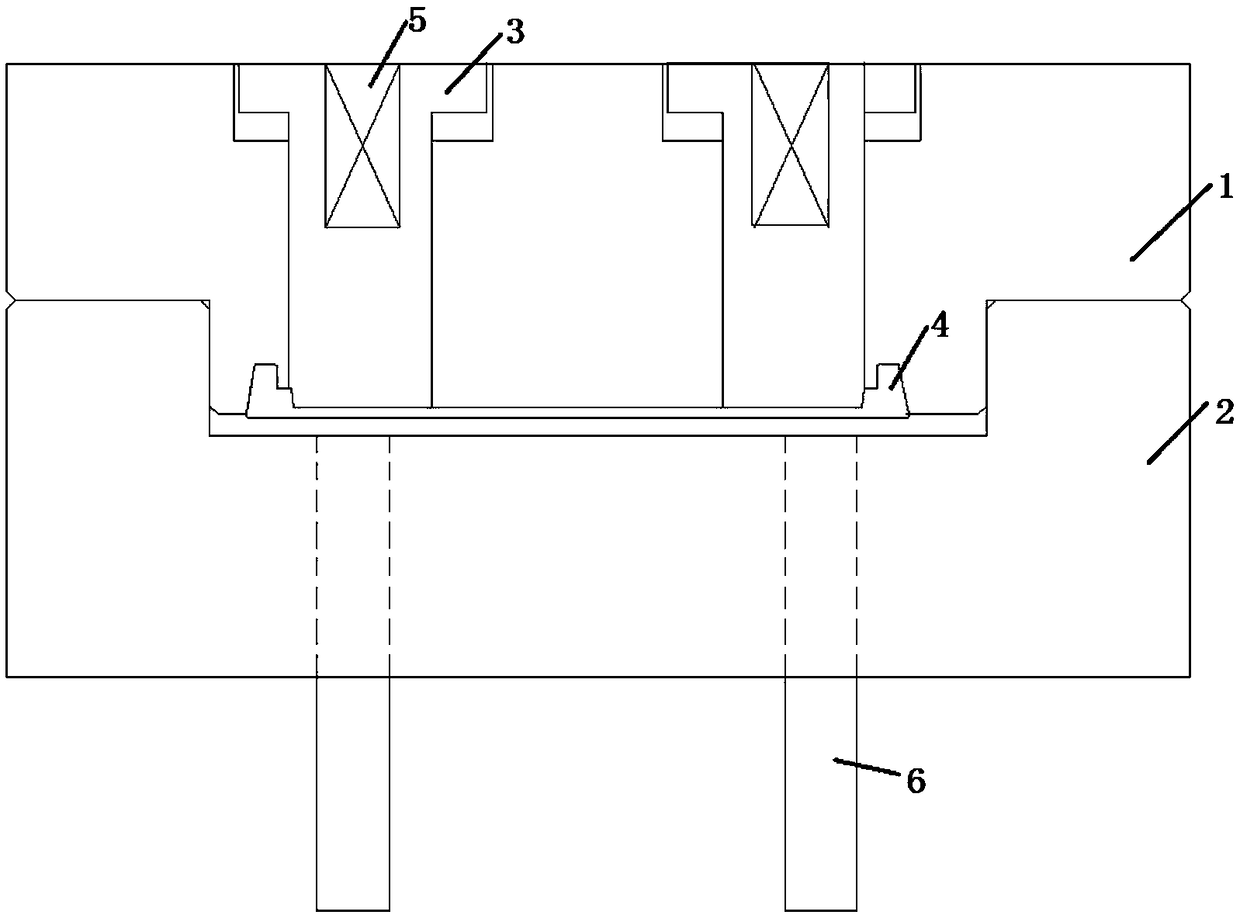

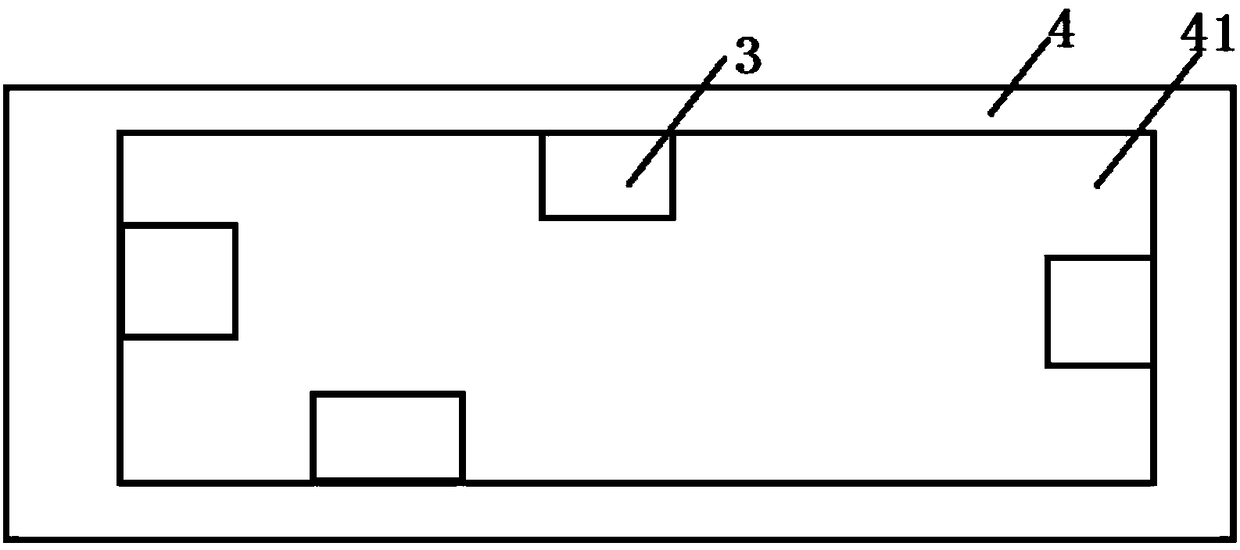

[0019] A mold assembly for in-mold injection molding of steel sheets, comprising a punch 1 and a die 2 adapted to the punch 1, the punch 1 in this embodiment is a front mold core, and the die 2 is the rear die core, and the male die 1 is arranged above the female die 2 . Of course, the positions of the male die 1 and the female die 2 can also be reversed, that is, the female die 2 is arranged above. An injection-molded steel sheet 4 is arranged in the die 2, and a square cavity 41 is formed on the injection-molded steel sheet 4. A plurality of square inserts 3 are arranged on the punch 1, and the square inserts 3 face toward the The concave mold 2 extends out from the punch 1, and the square inserts 3 have at least four sides in the square inserts 3 before the punch 1 and the concave mold 2 are closed. The four side walls of the concave cavity 41 are against each other. In this embodiment, the respective two sides of the two square inserts 3 are respectively against the four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com