PCR full-automatic fibre curtain cloth cutting splicer

A jointing machine, fully automatic technology, applied in the cutting of non-woven fabrics, textile materials, textiles and papermaking, etc., can solve problems such as uneven joint strength, unstable joint length, and inconsistent alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

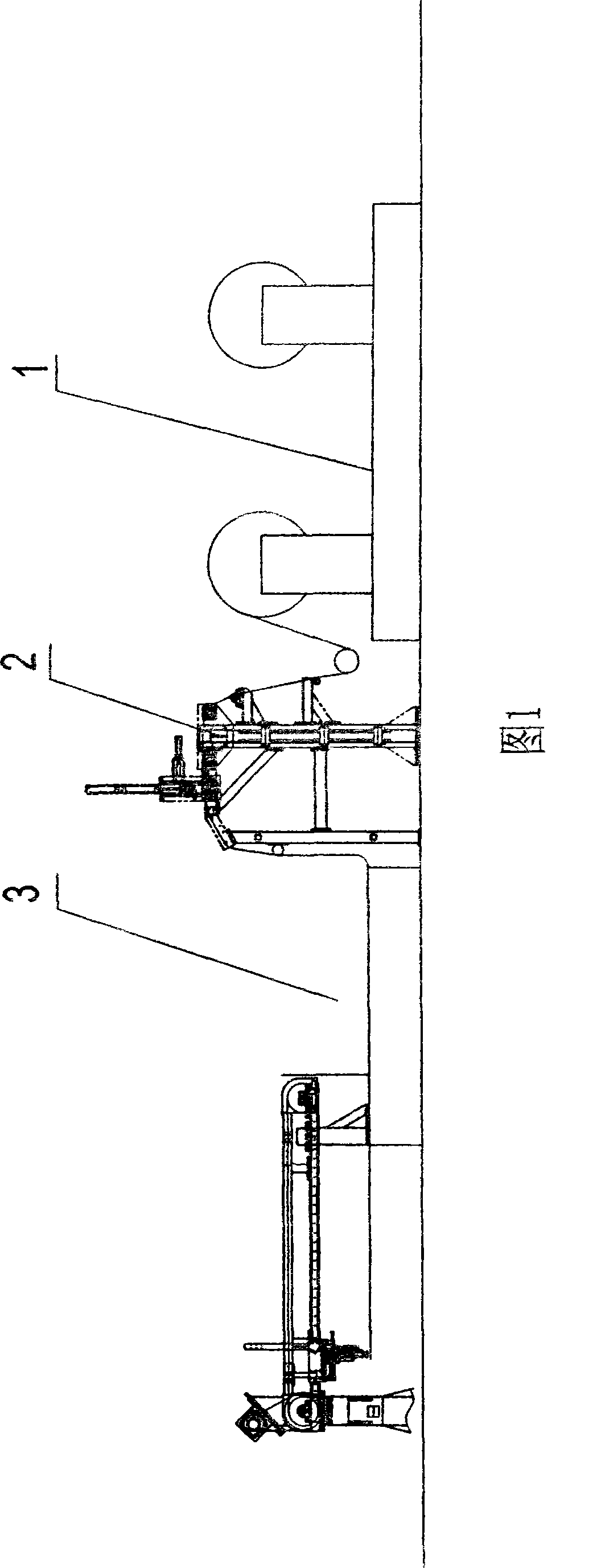

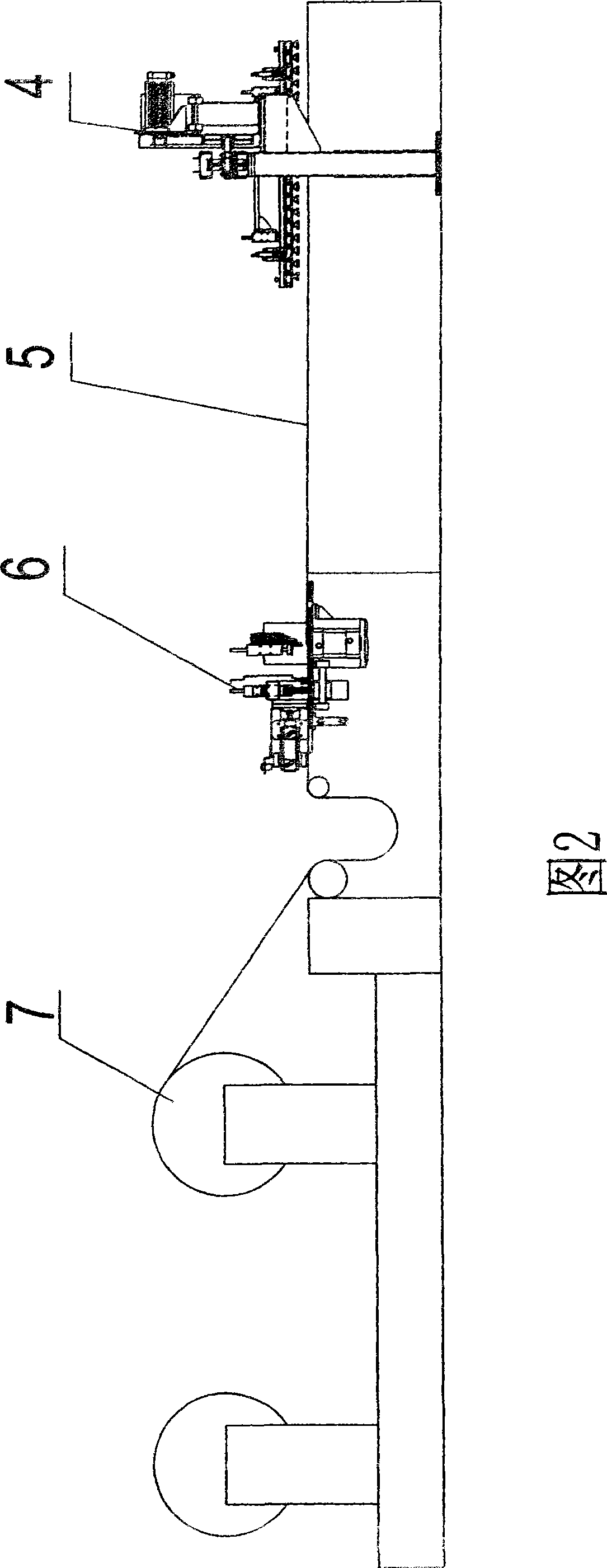

[0022] As shown in Fig. 1 and Fig. 2, the present invention is a PCR automatic fiber cord cutting and jointing machine, which includes a guiding and conveying device 1, an electric heating piercing device 2, a cord conveying and cutting device 3, an automatic cord transfer device 4, a cord The conveying device 5, the cord automatic jointing device 6, and the automatic deviation correcting coiling device 7 are connected.

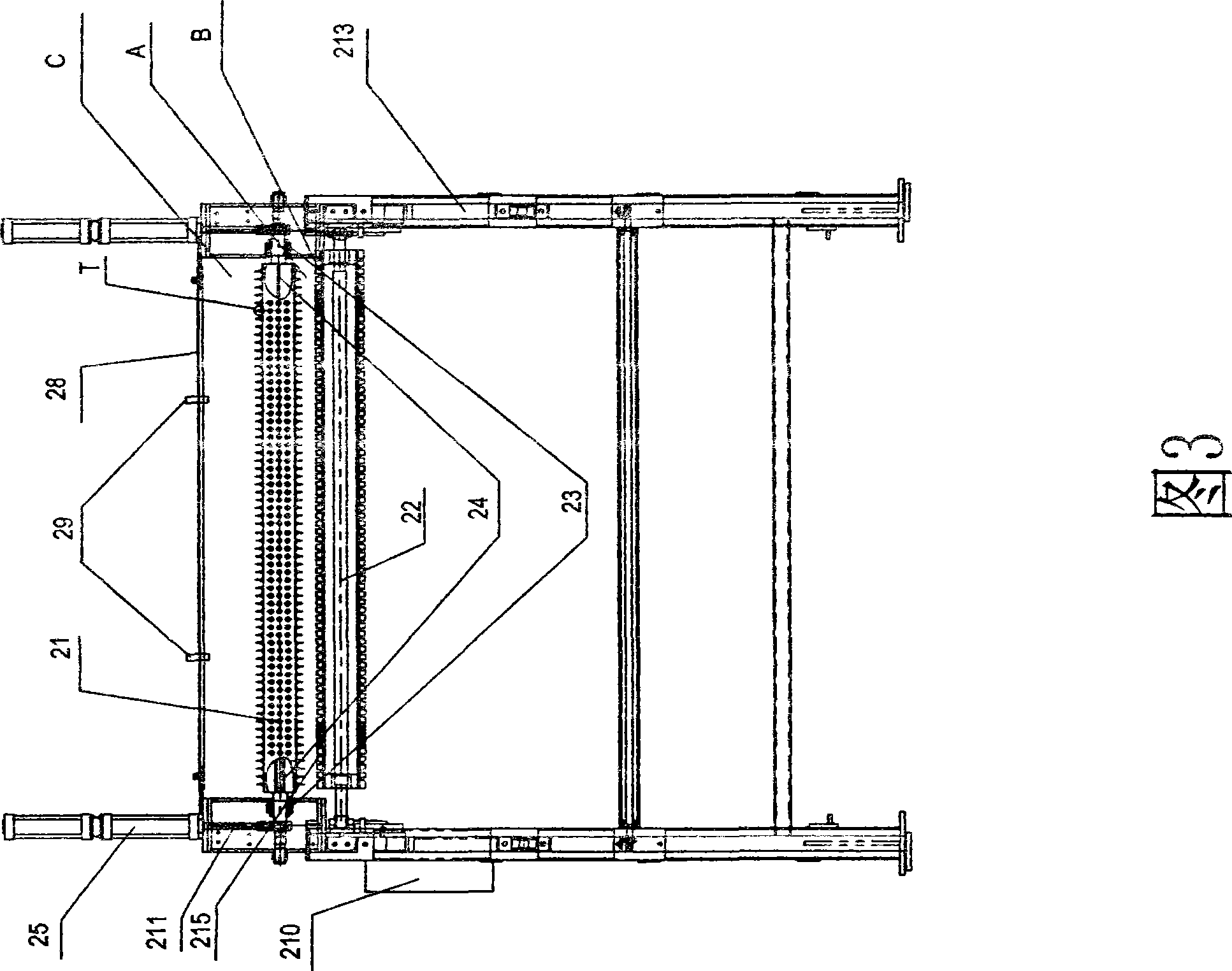

[0023] The whole roll of calendered cord and a layer of anti-adhesive pad cloth are rolled on a roller, and placed on the guide conveying device 1, and the guide conveying device 1 separates the cord from the pad cloth, so that the pad cloth rolls On the other roller, the cord is transported to be pierced; the electric heating piercing device 2 is equipped with an electric heating licker-in roller 21 and a polyurethane roller 22, which is used to puncture the cord, and is displayed by temperature control The instrument 210 and the infrared temperature sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com