Supply device and method for long reinforcing steel bars in four-side-ribbed high-speed-rail reinforcing steel bar meshes

A technology of four-sided rib high-speed iron and steel mesh, which is applied in the field of cold-rolled steel bars, can solve the problems of losing parallelism, affecting the straightness of steel bars, and affecting the production of mesh sheets, and achieves the effects of reducing impact and preventing bending deformation of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following description, the steel bar feeding side is regarded as the front of the equipment, and the welding side is described as the rear.

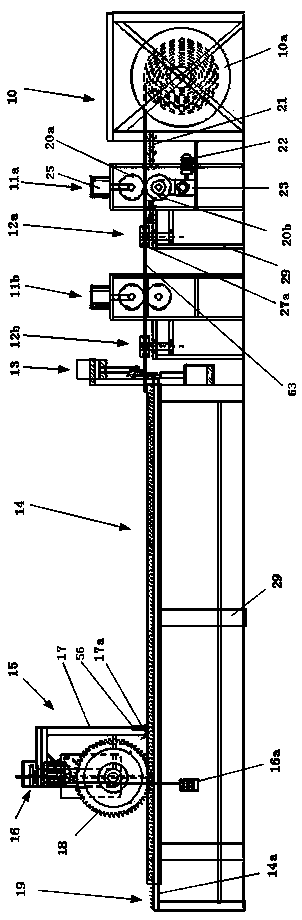

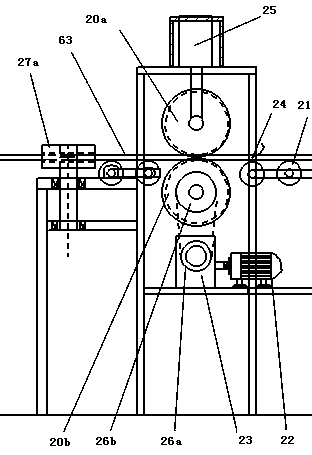

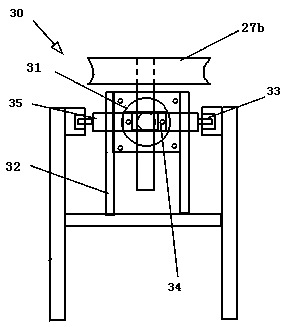

[0034] The supply device for the long steel bar 60 in the four-sided rib high-speed iron steel mesh sheet, figure 1 A schematic diagram of the side structure of the upper long steel bar 60 sent to the supply device. Including an unfolding device, the middle and long steel bar 60 is a longitudinally long steel bar in the mesh, and the supply device for the long steel bar 60 includes a steel bar roll unfolding device 10, a steel bar straightening roller device, and one or more hydraulic steel bar shearing devices 13 arranged in sequence. 1. The reinforcement frame platform 14 of the reinforcing steel mesh welding device and rolling on it are provided with a mobile frame 15, and the mobile frame 15 is provided with a long steel bar 60 fixed-length baffle plate 17 corresponding to each long steel bar 60 ends, and the hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com