Separated bottom bed structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

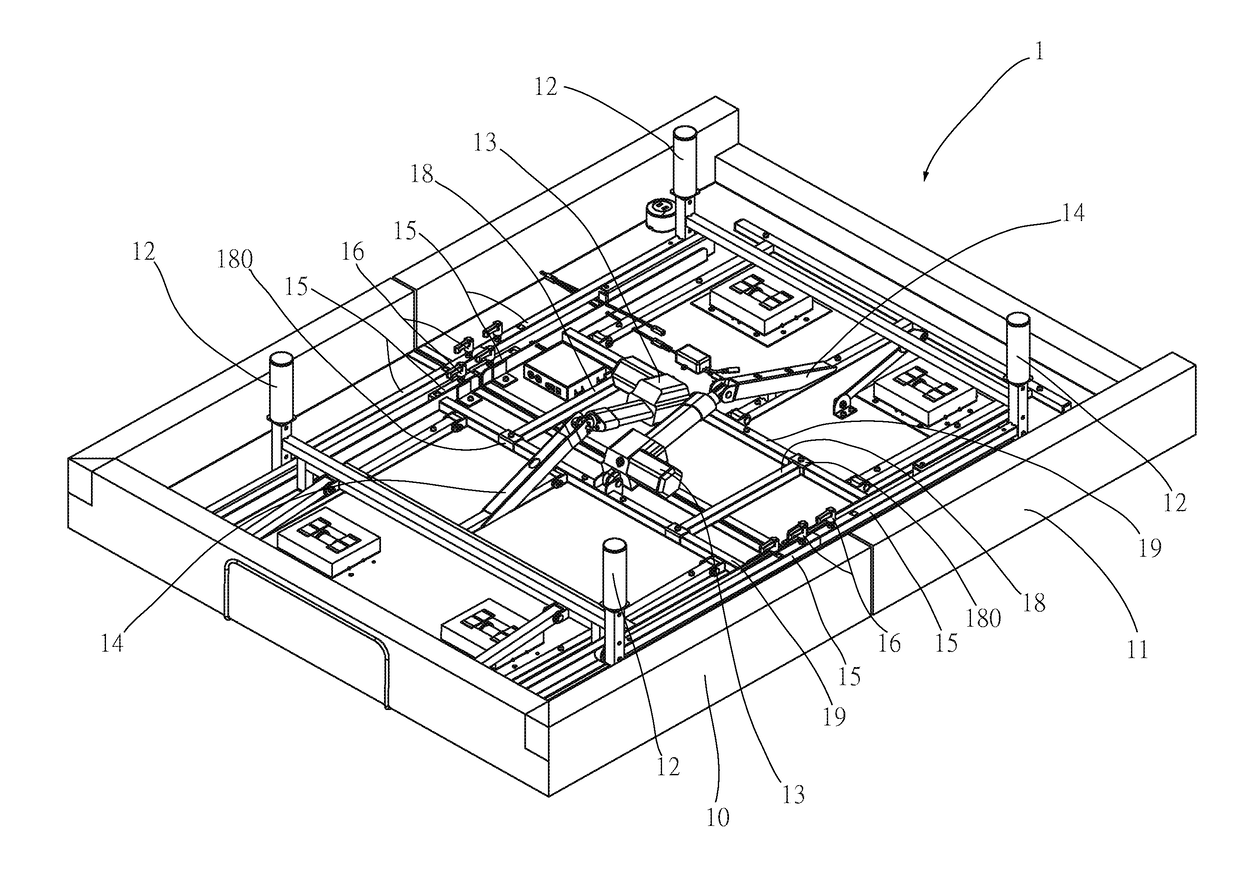

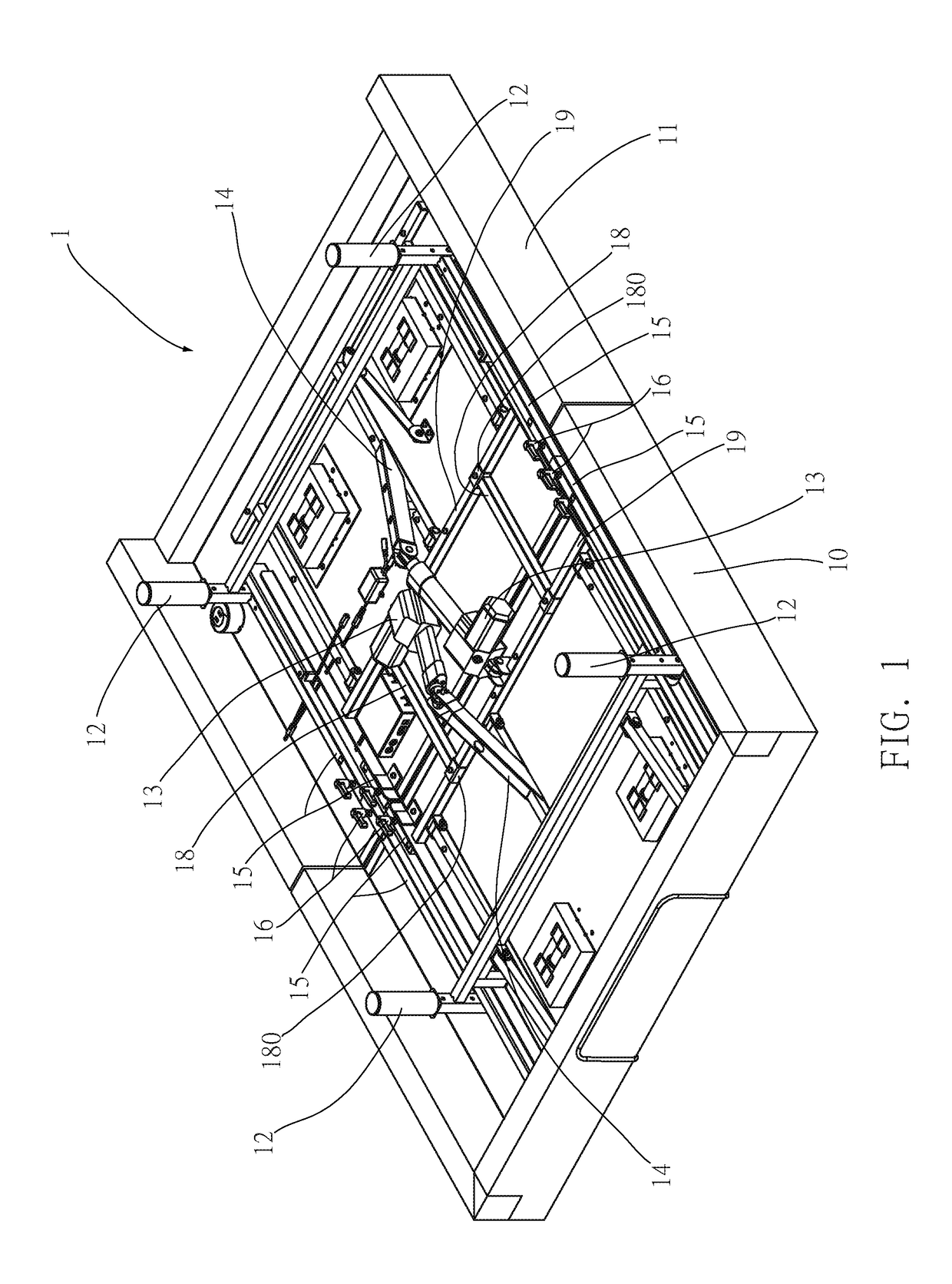

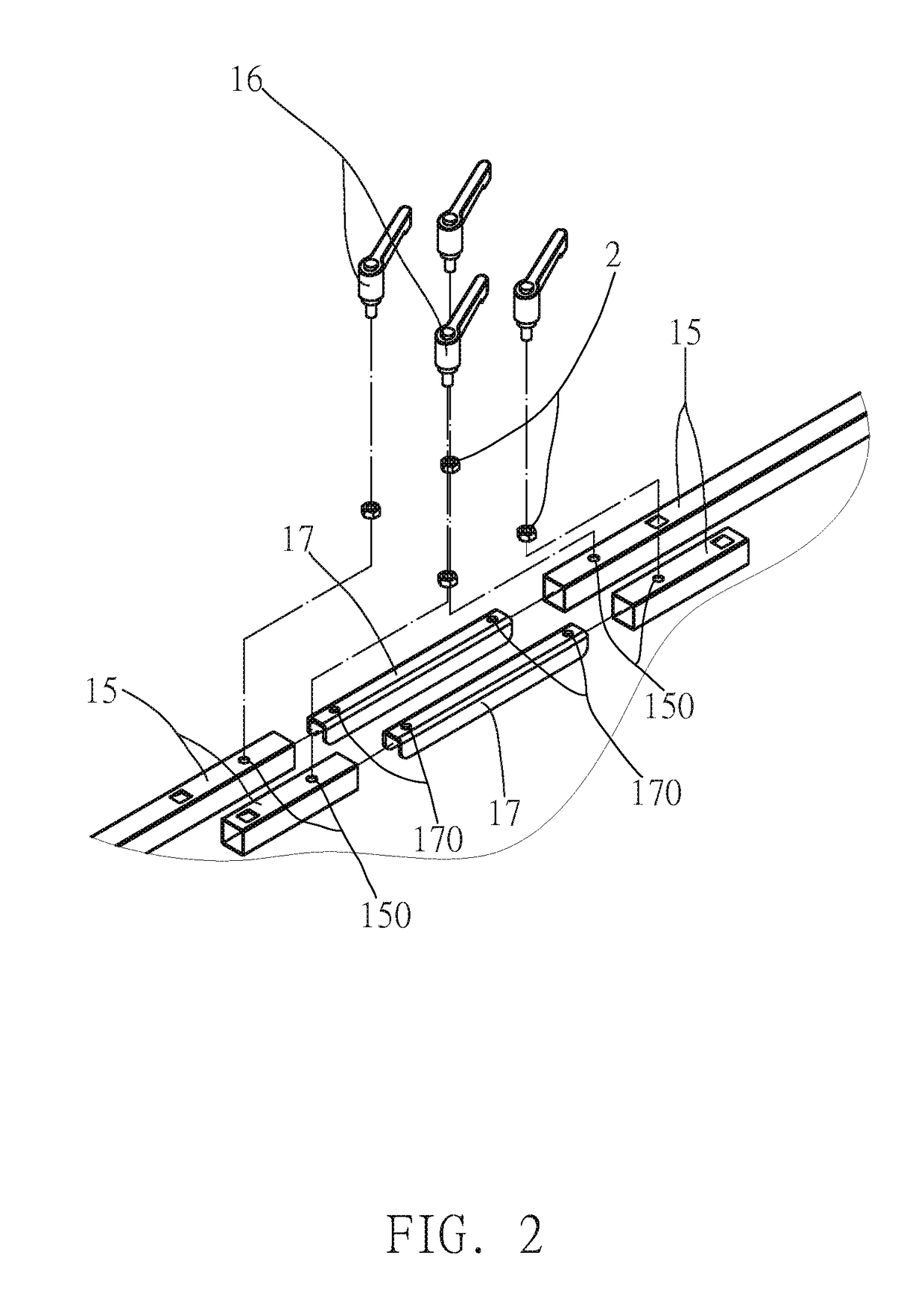

[0018]First, referring to FIG. 1, which is a perspective view of the present invention, a general separable bottom bed set 1 is configured with a front bottom bedplate 10, a rear bottom bedplate 11, supports 12, electric cylinders 13 and linkages 14. One design focus of the present invention is in that: more than one set of hollow frames 15 and screw handles 16 are respectively configured on the left and right corresponding ends of the central connection of the front bottom bedplate 10 and rear bottom bedplate 11, and a inverted U-shaped frame 17 is installed between each set of left and right corresponding hollow frames 15 as FIG. 2 shows, where the corresponding ends of the hollow frame 15 and inverted U-shaped frame 17 are respectively opened with a hole 150, 170. Furthermore, a screw handle 16 is passed through each two corresponding holes 150, 170, and a nut 2 is then engaged therewith to lock the hollow frame 15 and inverted U-shaped frame 17 together as FIG. 3 shows, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com