Sampling system suitable for multi-channel terminal reflection type optical fiber SPR sensor and using method thereof

A sampling system and terminal reflection technology, applied in the field of sampling systems, can solve the problems of difficulty in detecting multiple samples at one time, low detection efficiency, etc., and achieve the effects of avoiding abnormal detection data, small dead volume, and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

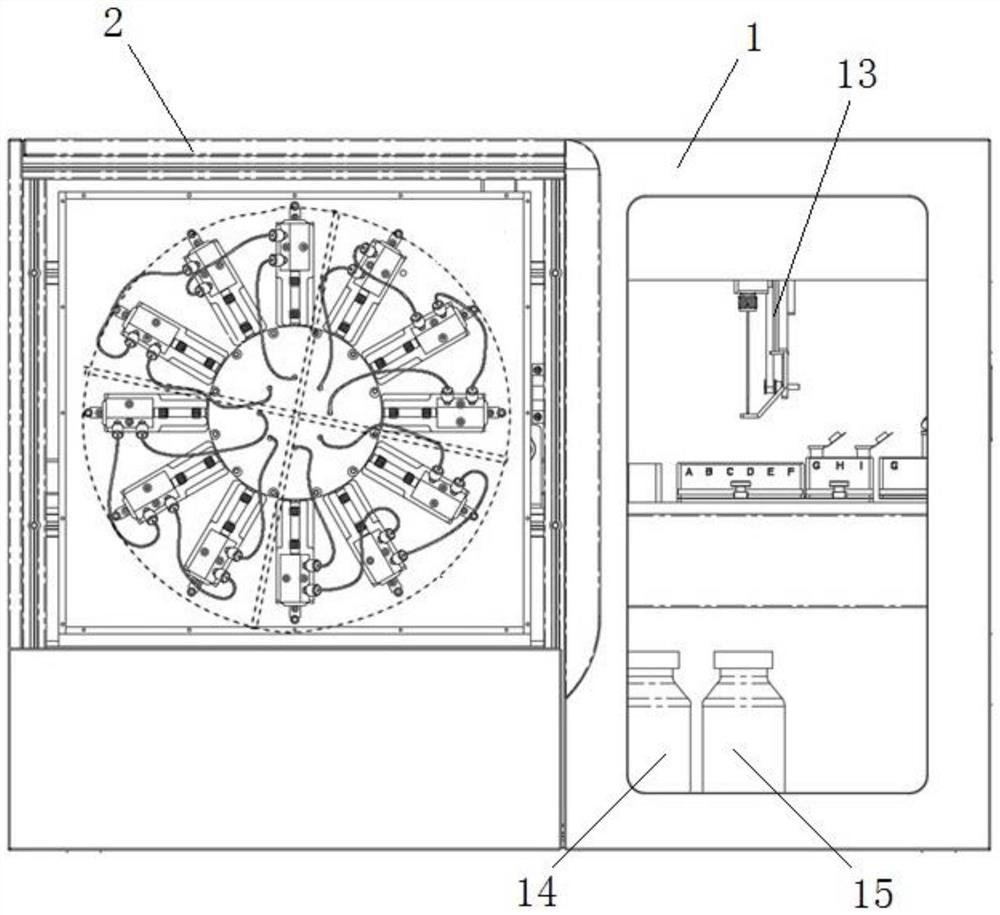

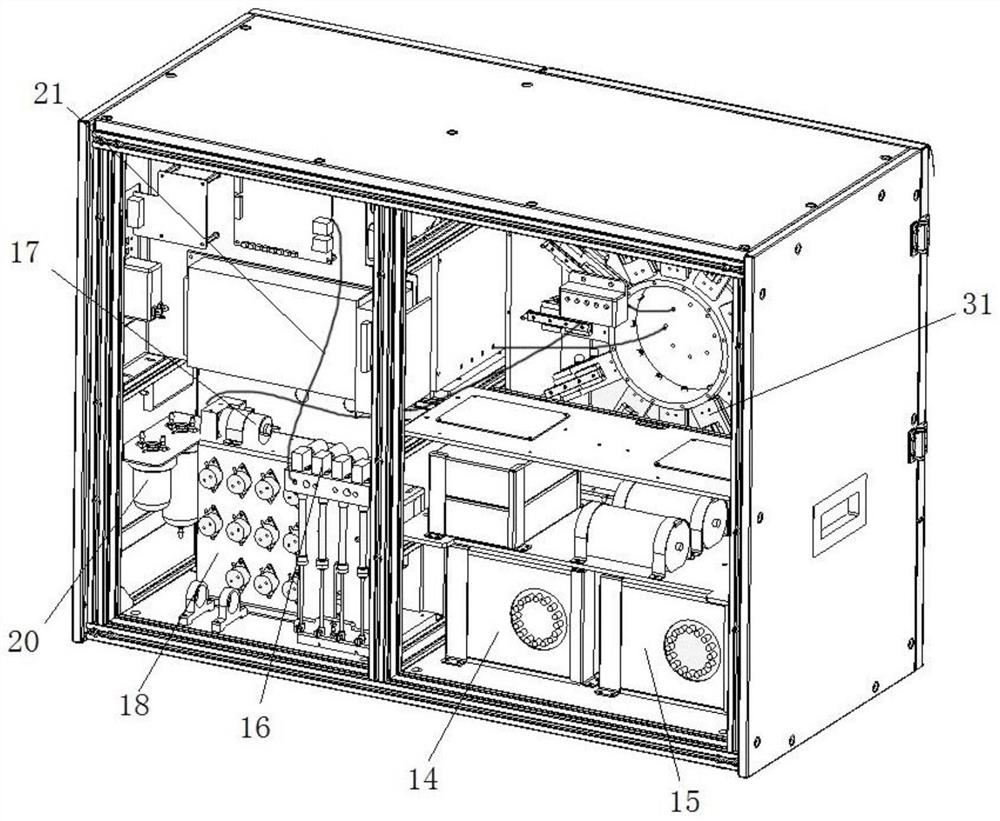

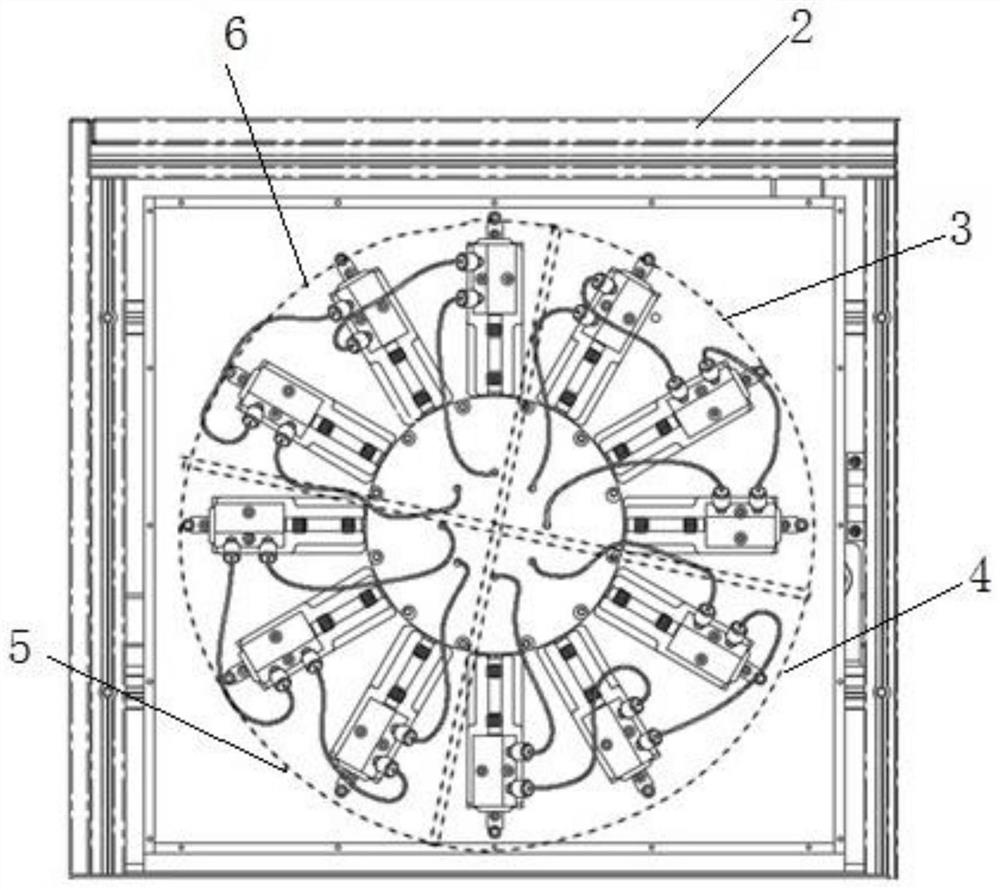

[0052] As shown in the figure, a sampling system applicable to a multi-channel terminal reflection optical fiber SPR sensor of the present invention includes: a housing, a sampling mechanism installed in the housing for collecting and transporting the sample to be tested, for The optical fiber SPR detection mechanism located at the terminal reflective optical fiber SPR detection end for detecting the sample to be tested and the liquid discharge mechanism 13 for self-cleaning and discharging the detection waste liquid, the sampling mechanism is set at the front sampling end of the optical fiber SPR detection mechanism , the liquid discharge mechanism 13 is arranged at the rear side sample outlet end of the optical fiber SPR detection mechanism, and the sample feeding mechanism, the optical fiber SPR detection mechanism and the liquid discharge mechanism 13 are communicated through a capillary 21;

[0053] The sampling mechanism includes a sample tube 12 for containing the sample...

Embodiment 2

[0078] On the basis of Embodiment 1, the sampling needle is installed on the housing through a driving mechanism, and the driving mechanism includes a horizontally moving stepper motor and a vertically moving stepping motor for controlling the position movement of the sampling needle, so that the sampling needle Move to the required sample tube 12 to collect the sample to be tested.

[0079] Furthermore, a horizontal deep hole 30 is formed in the connection base 25 , and a sleeve 29 is inserted into the deep hole 30 , and the optical fiber is embedded in the sleeve 29 .

[0080] Furthermore, the inner diameter of the sleeve 29 is adjusted according to the outer diameter of the optical fiber, so as to match various optical fibers with different outer diameter specifications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com