Patents

Literature

31results about How to "Equal width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

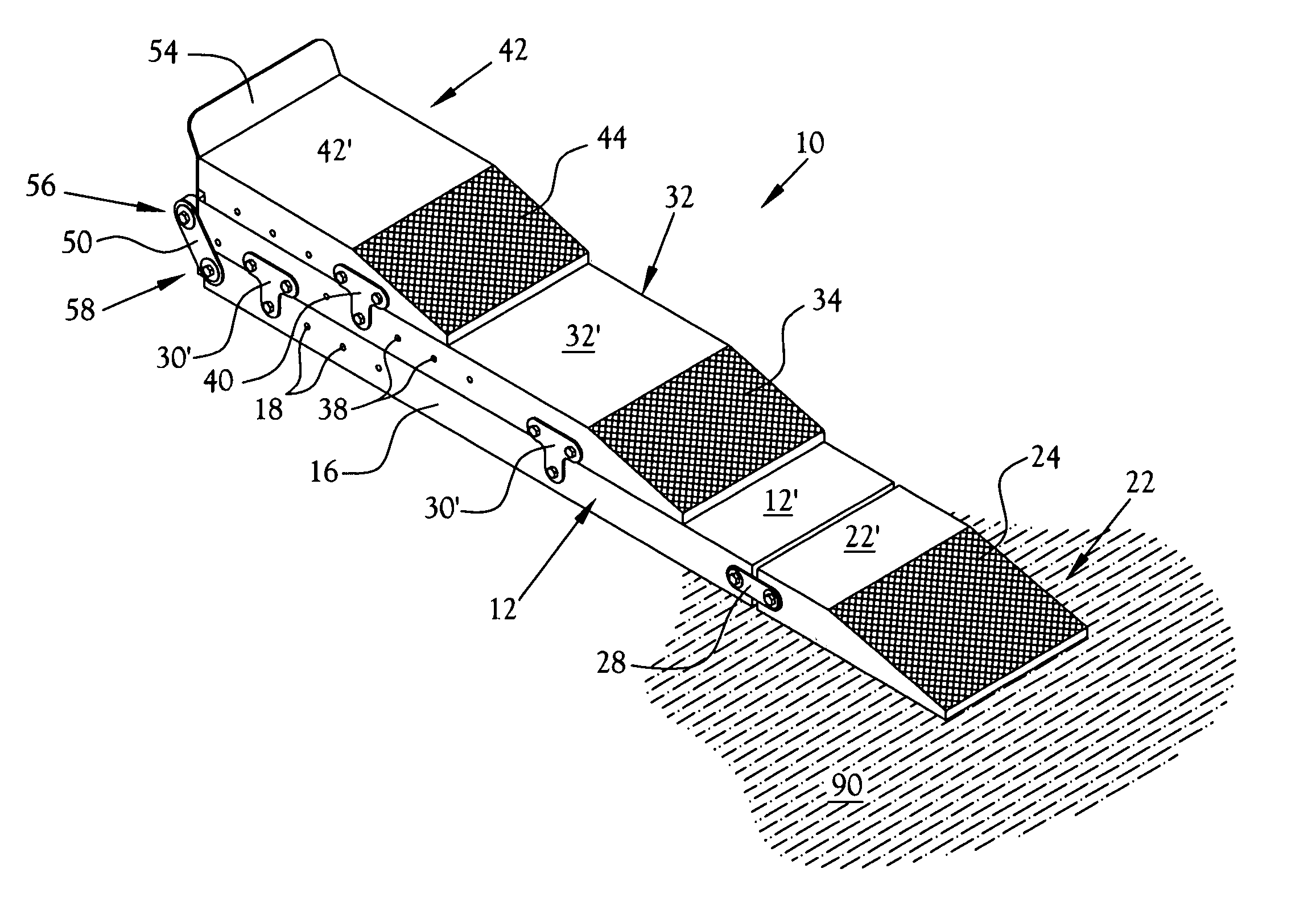

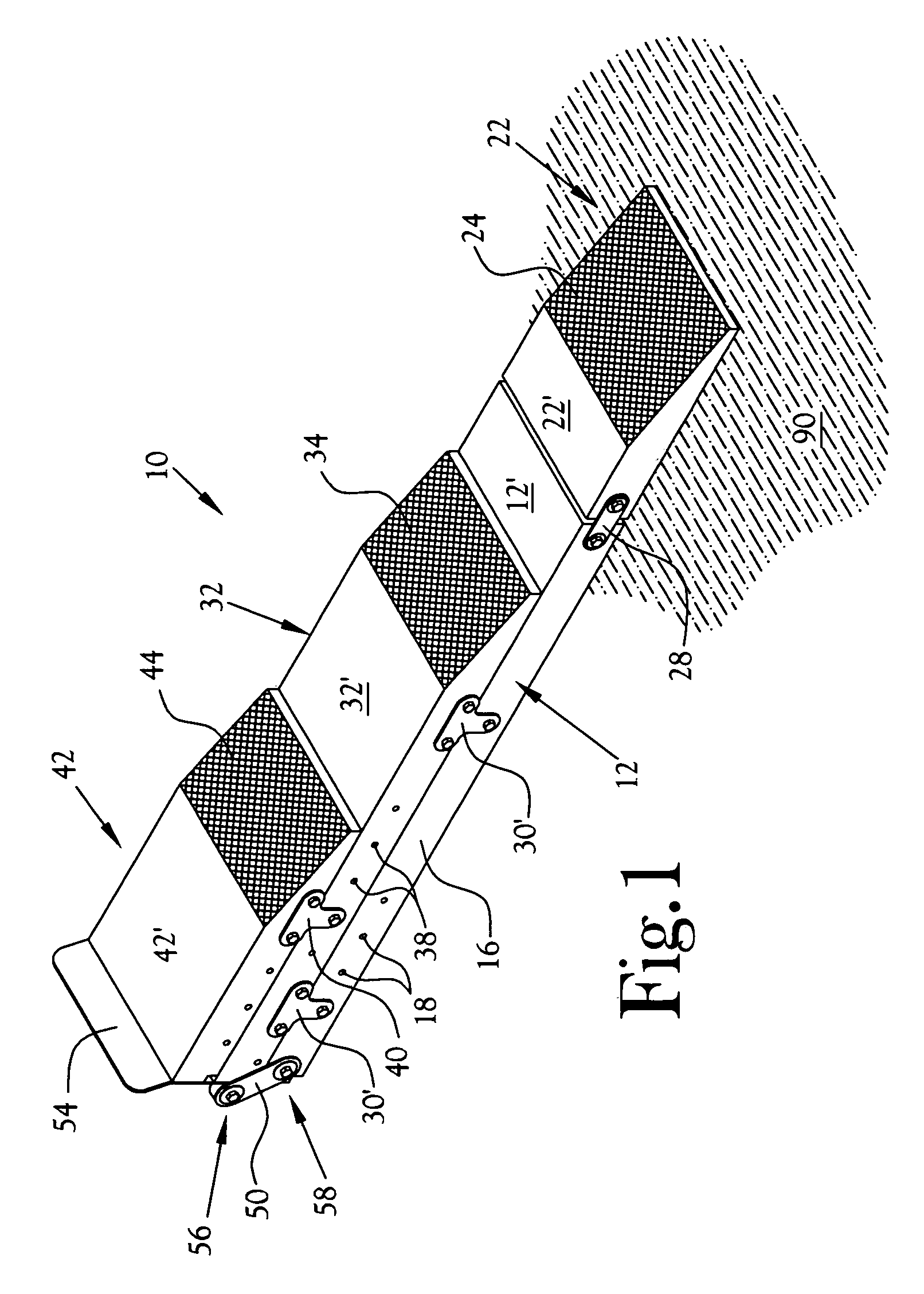

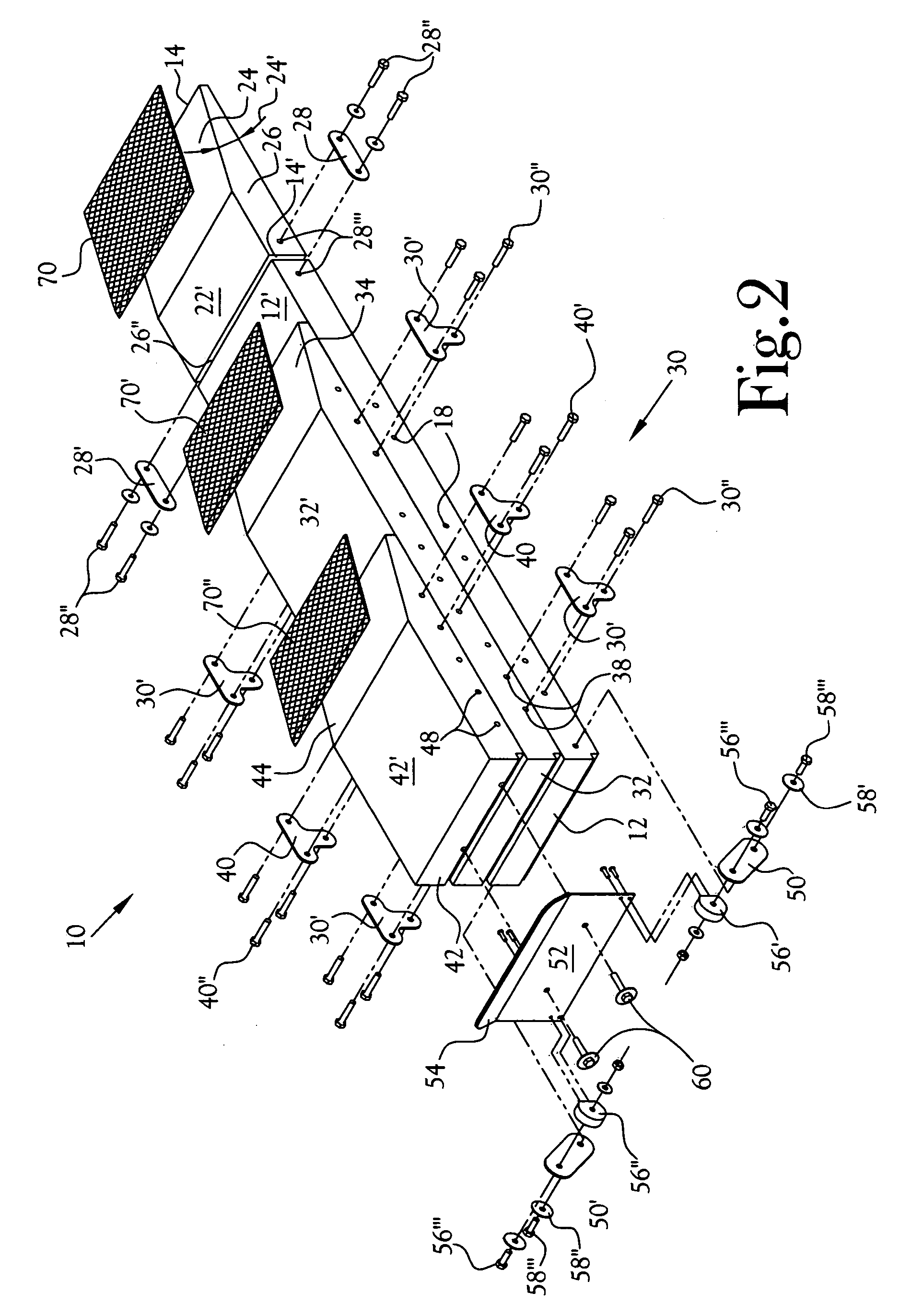

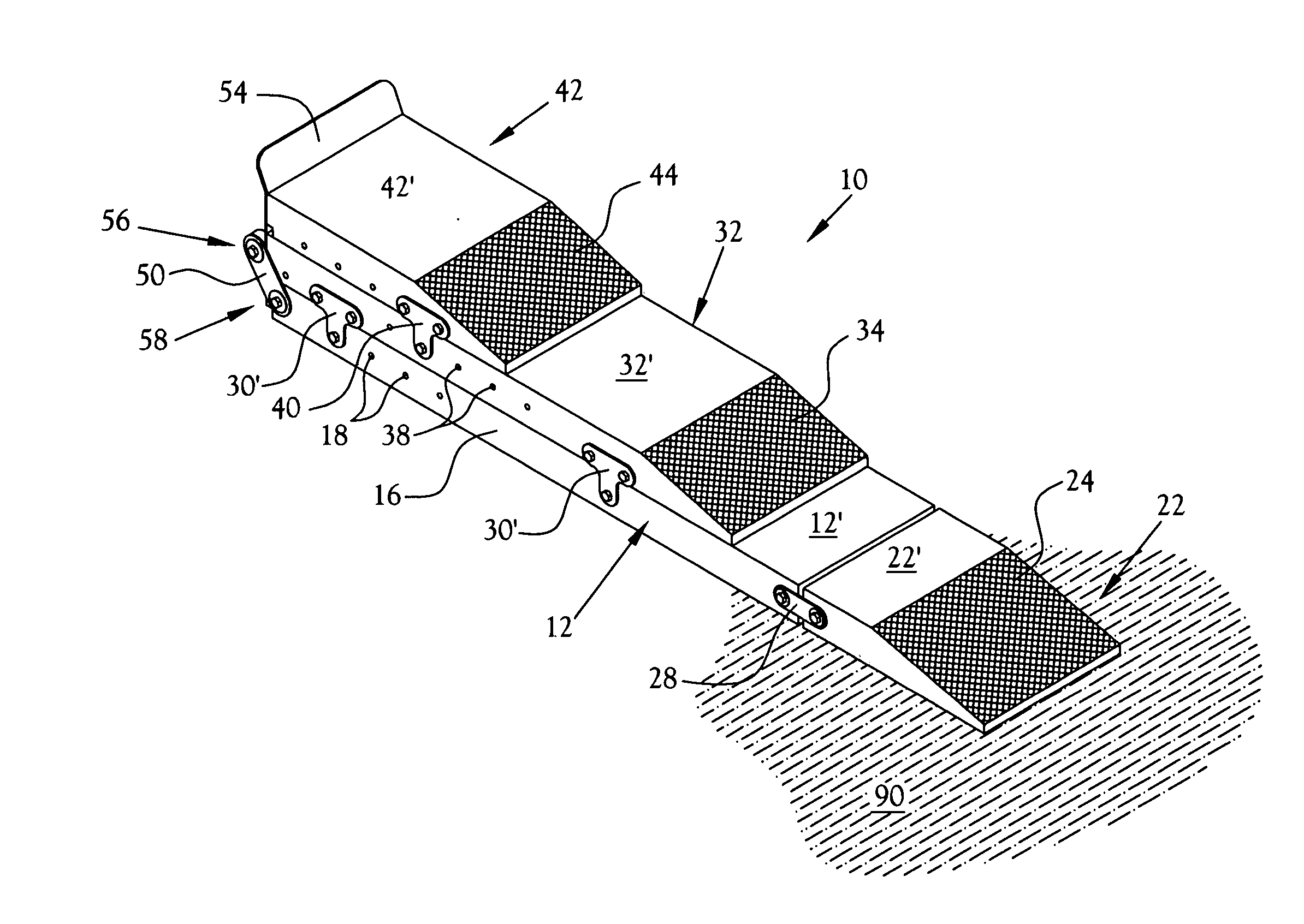

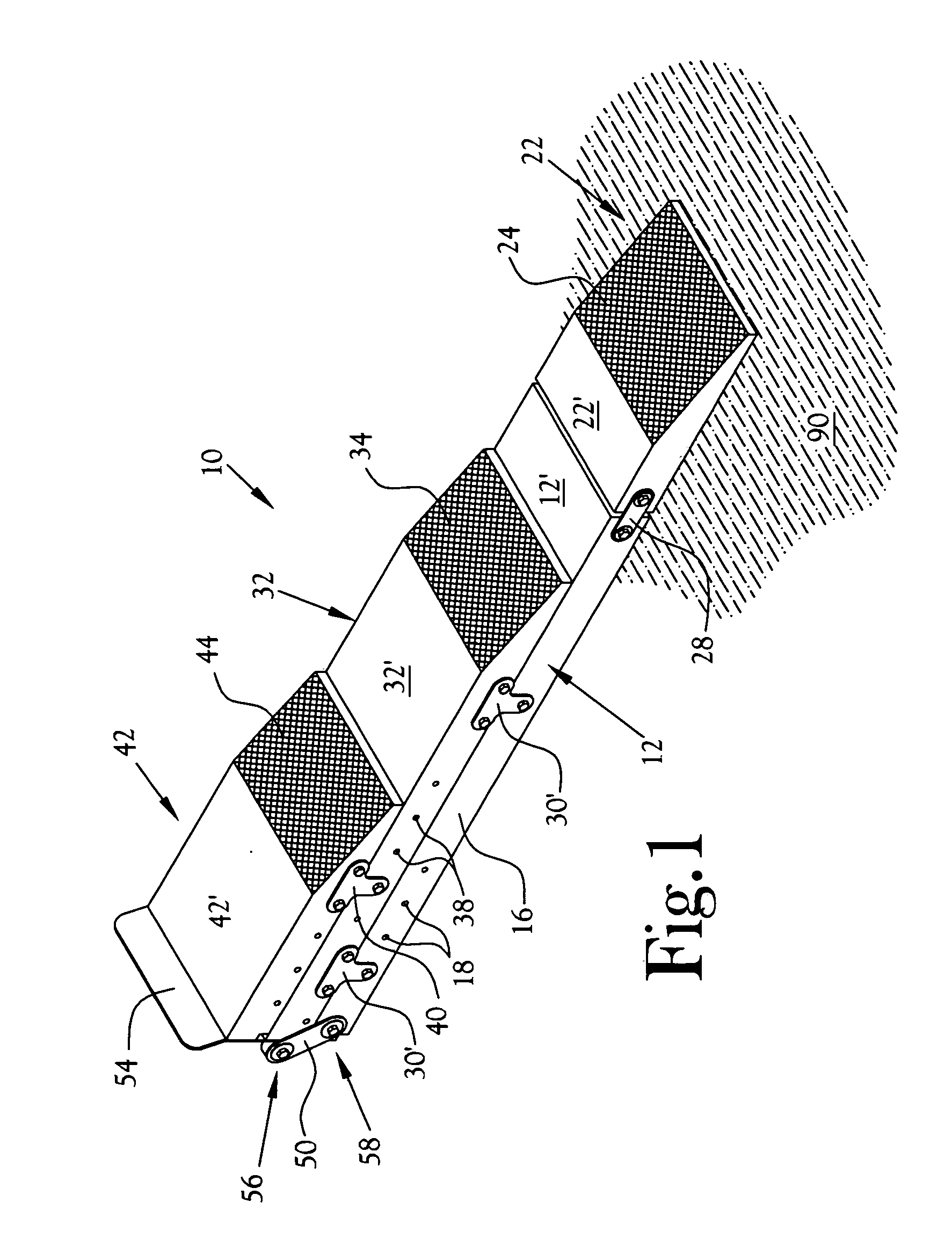

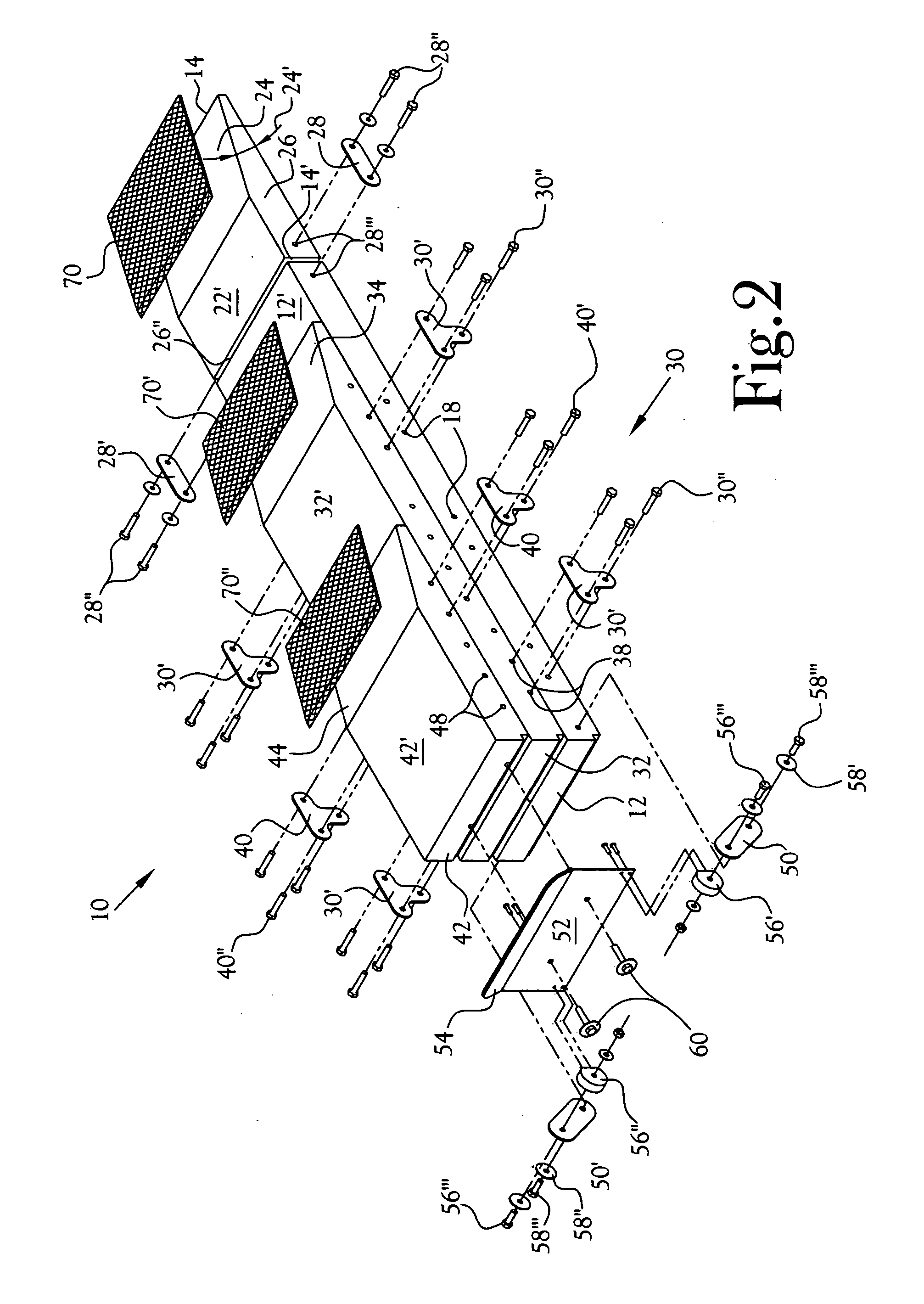

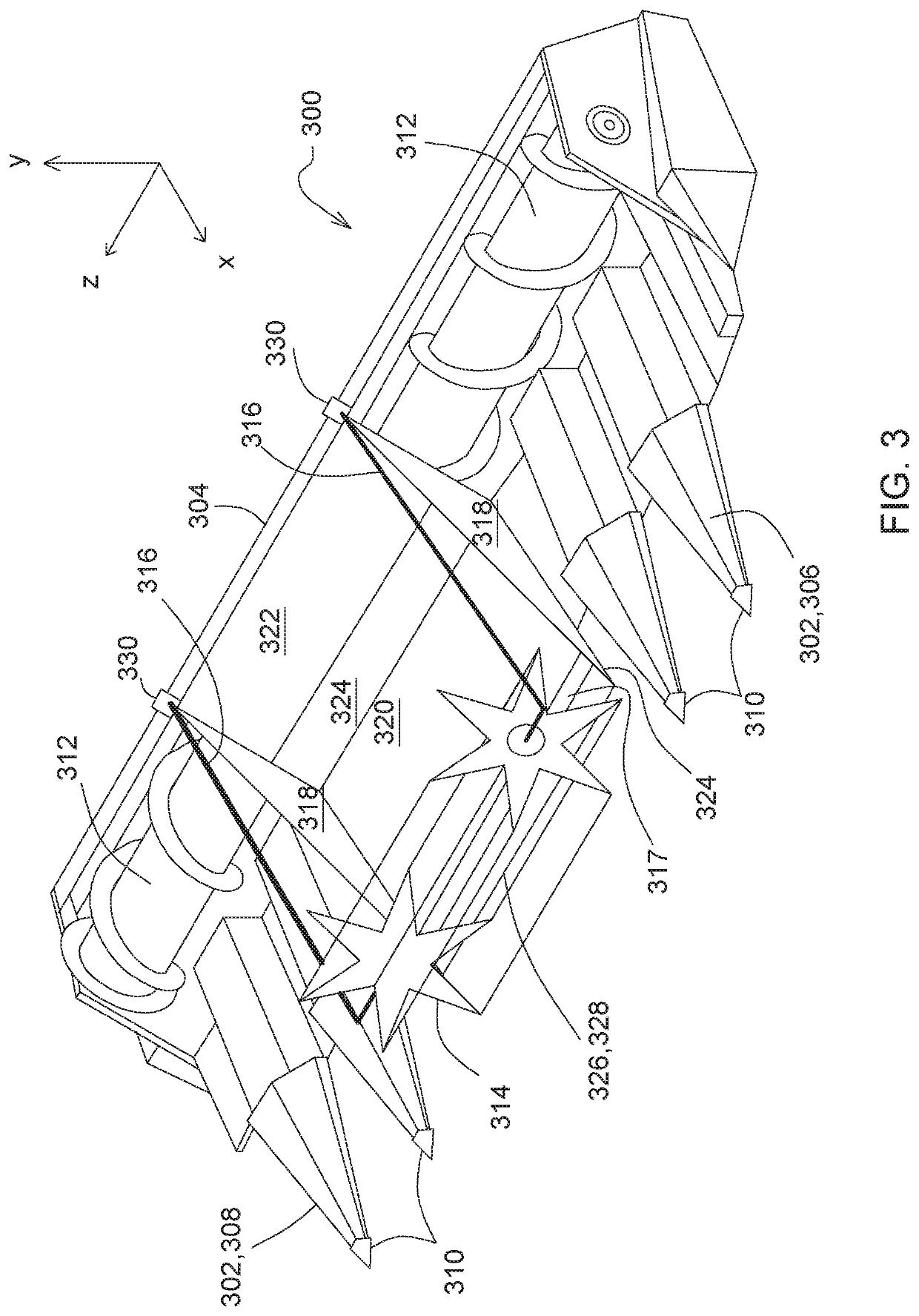

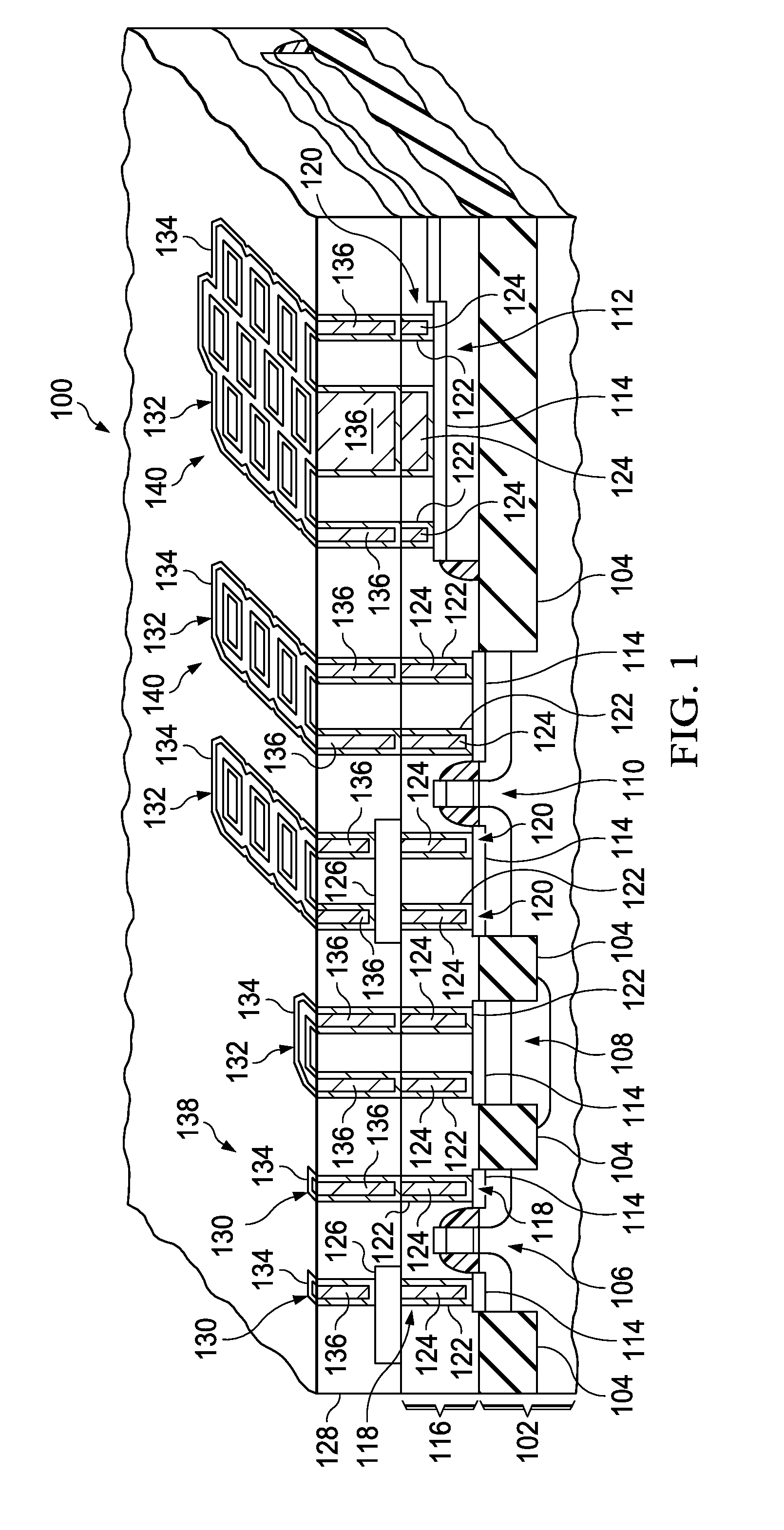

Portable modular wheel lift

InactiveUS7073777B2Easy to stackLess lengthInclined ship-liftingLifting framesEngineeringShort length

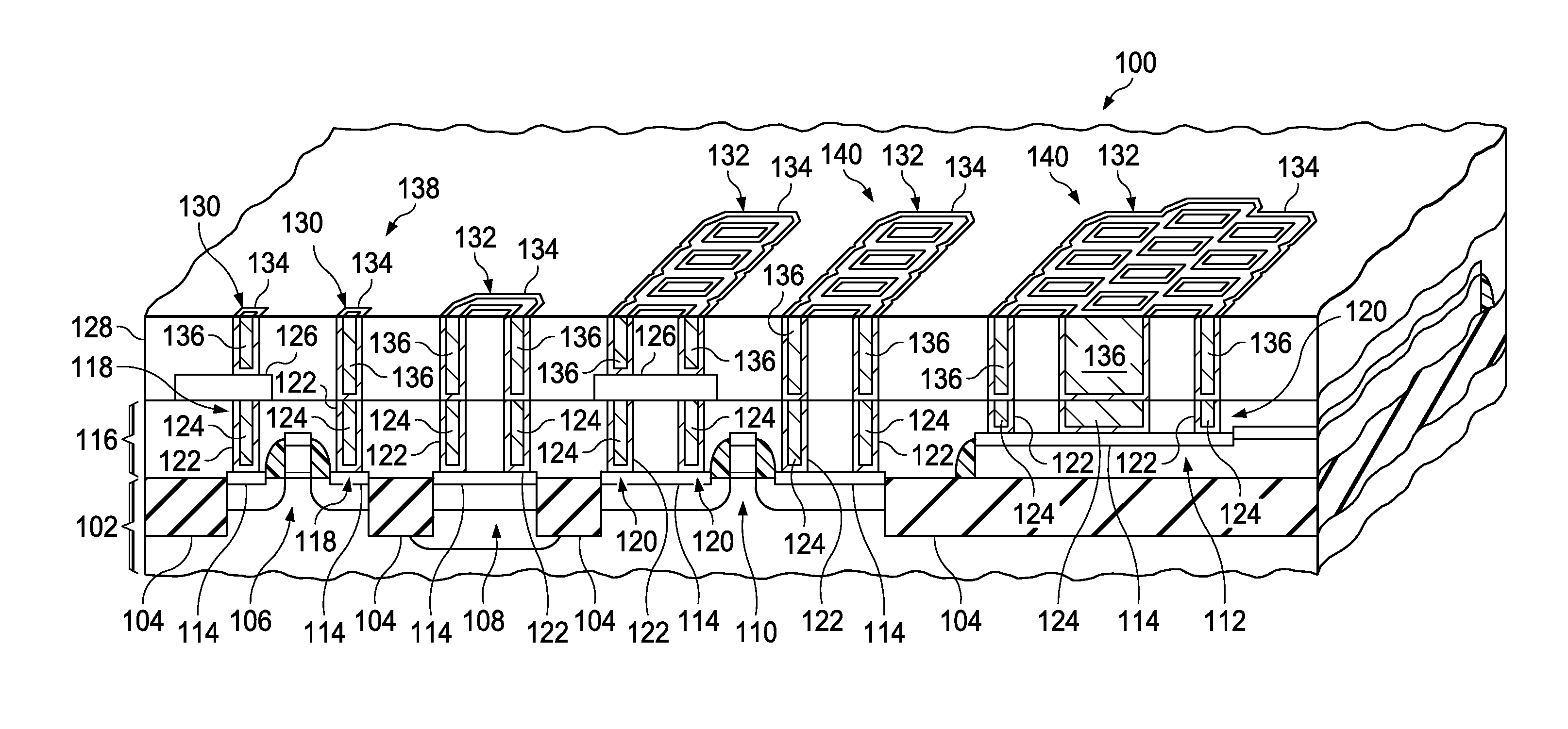

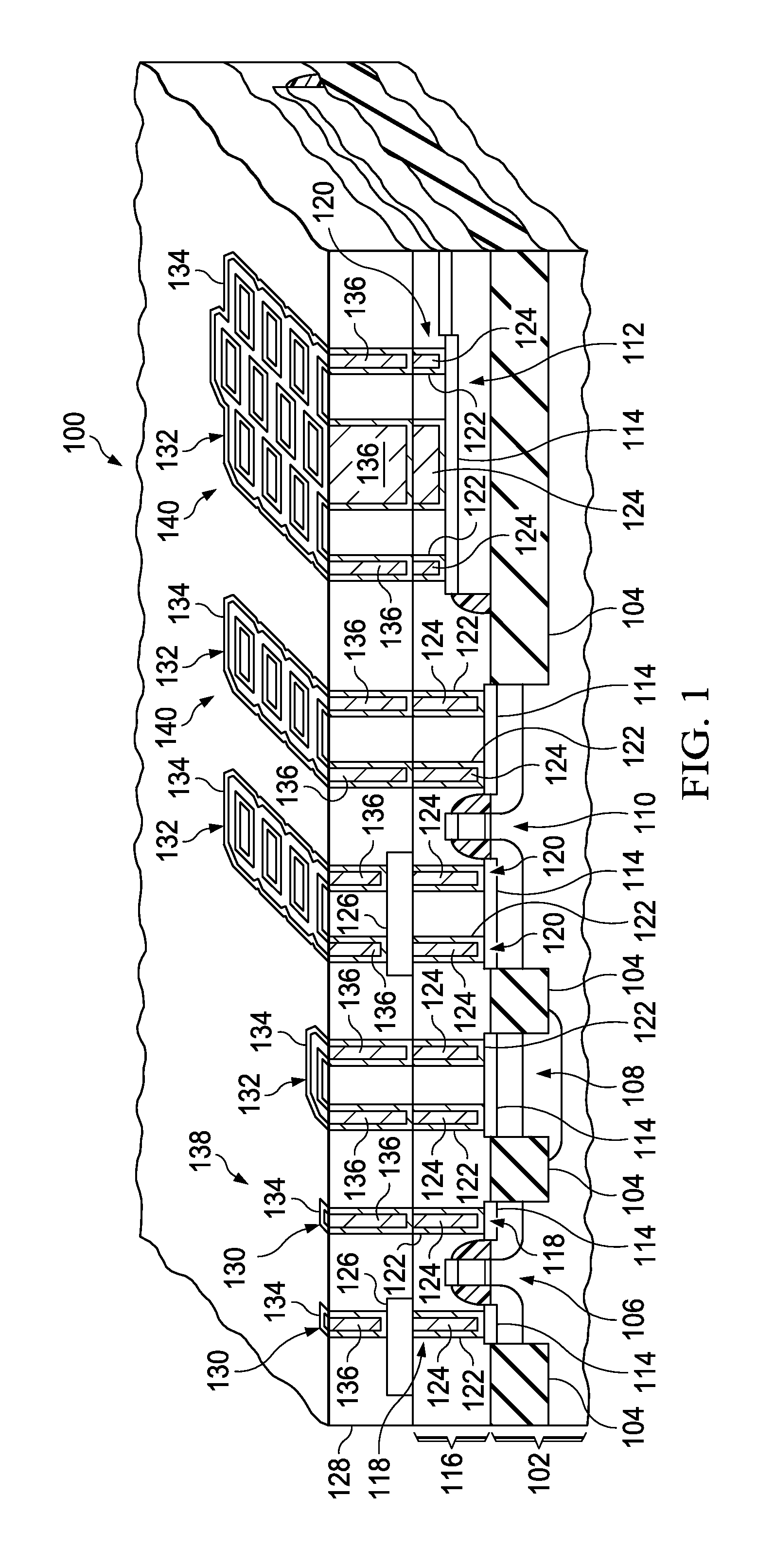

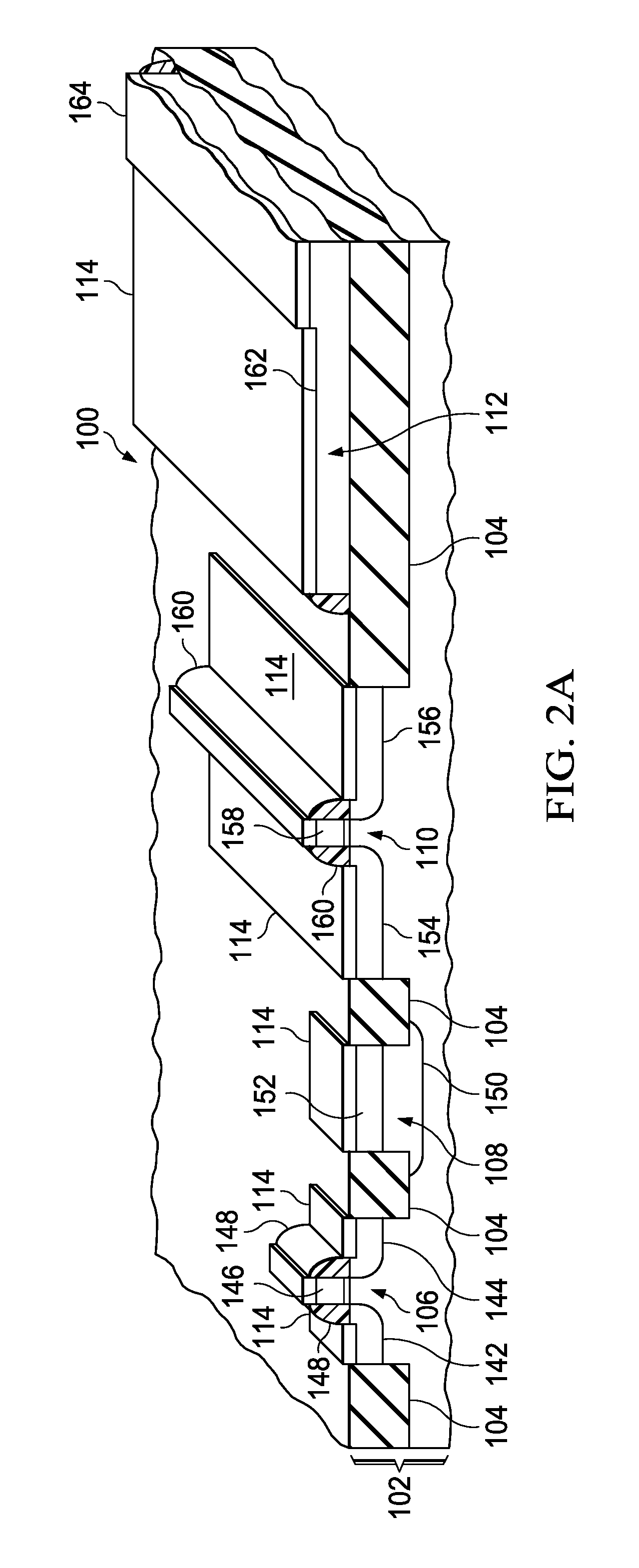

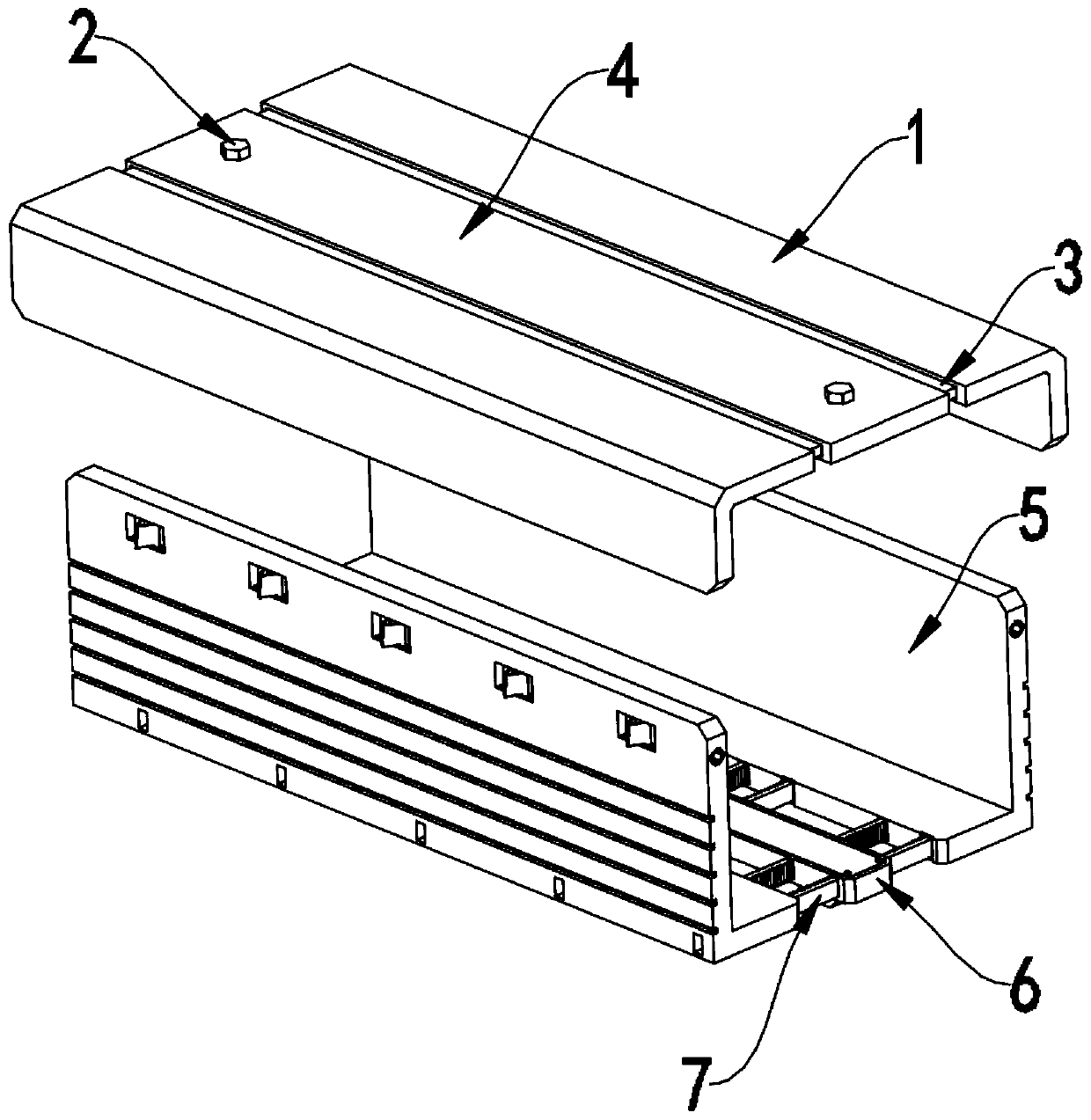

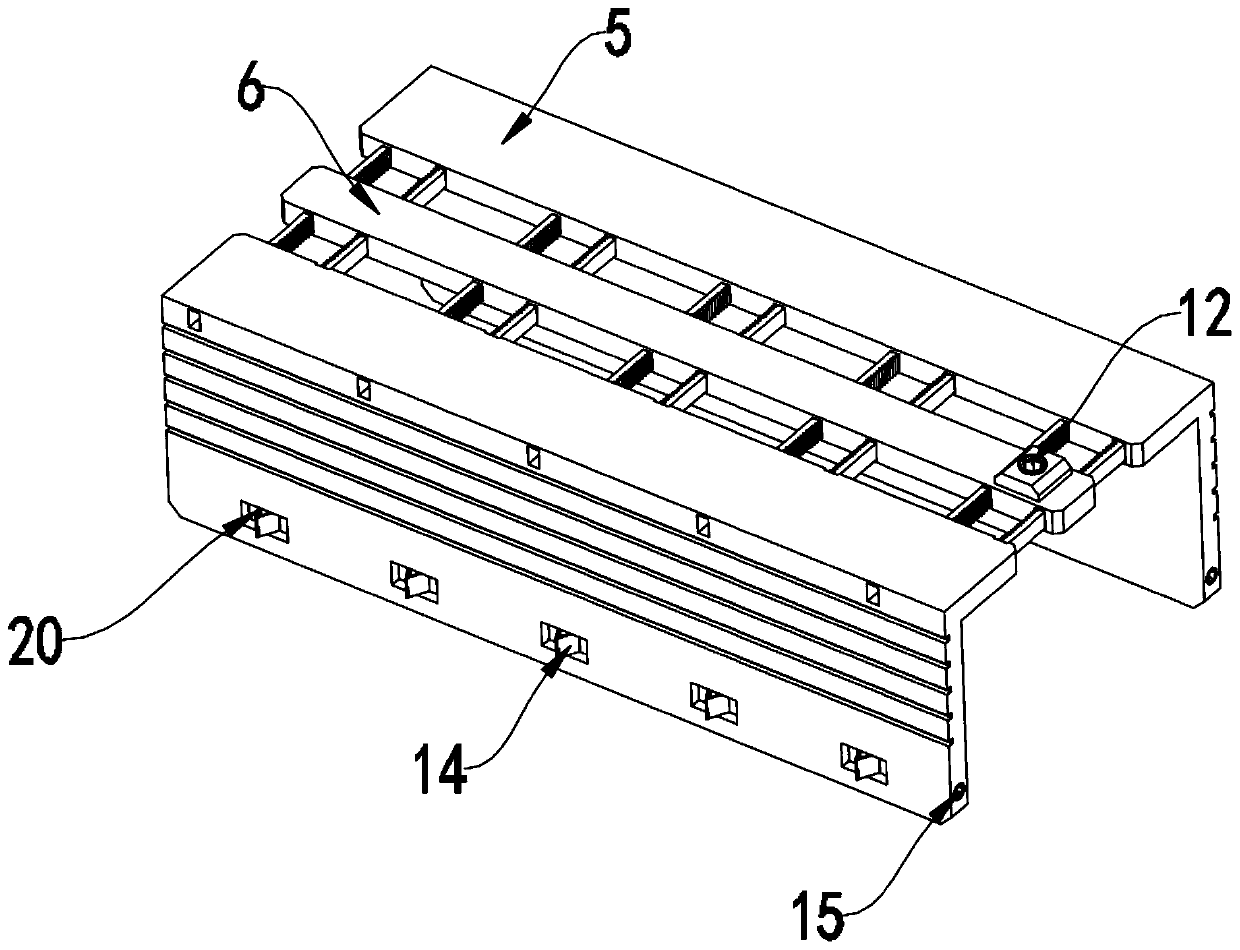

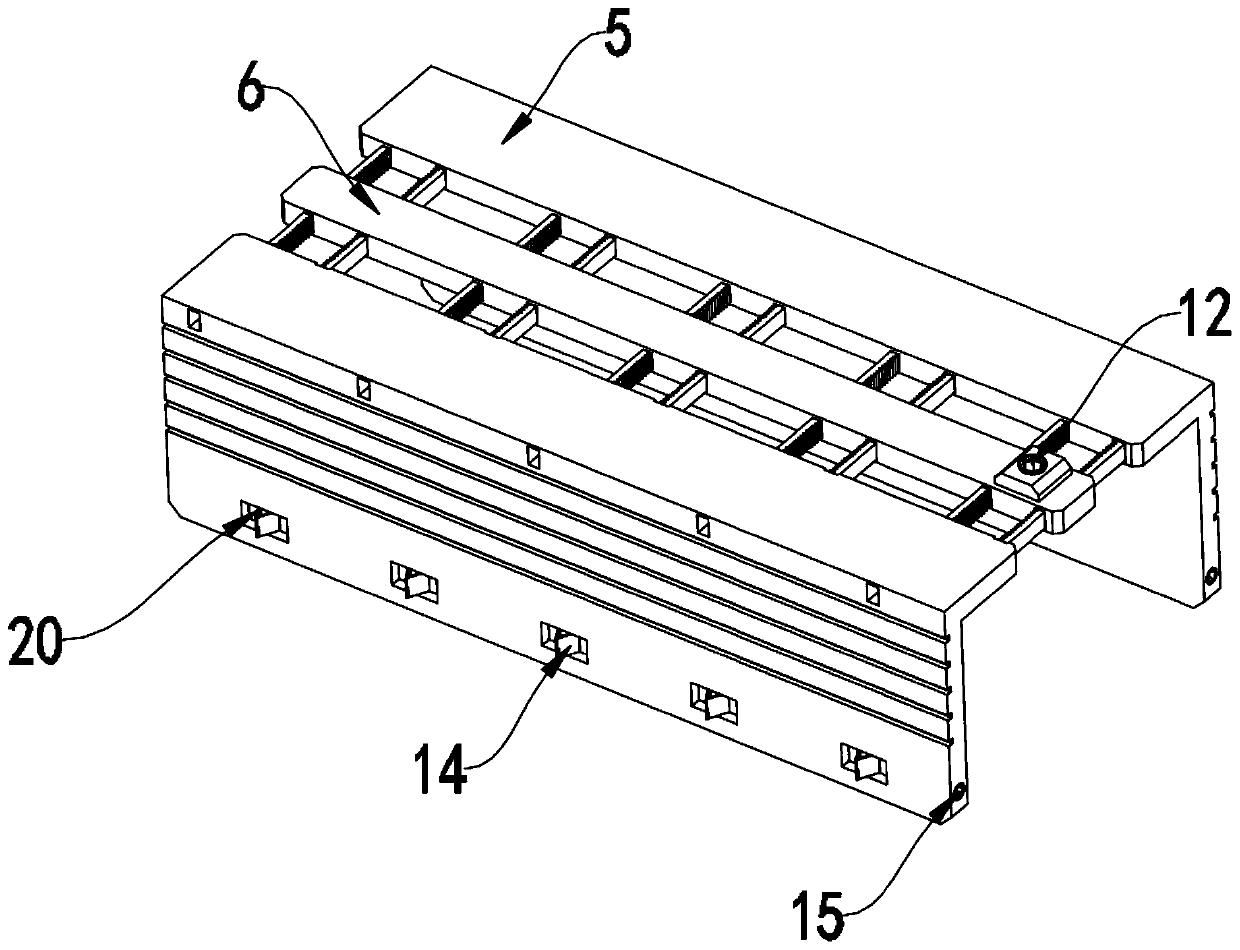

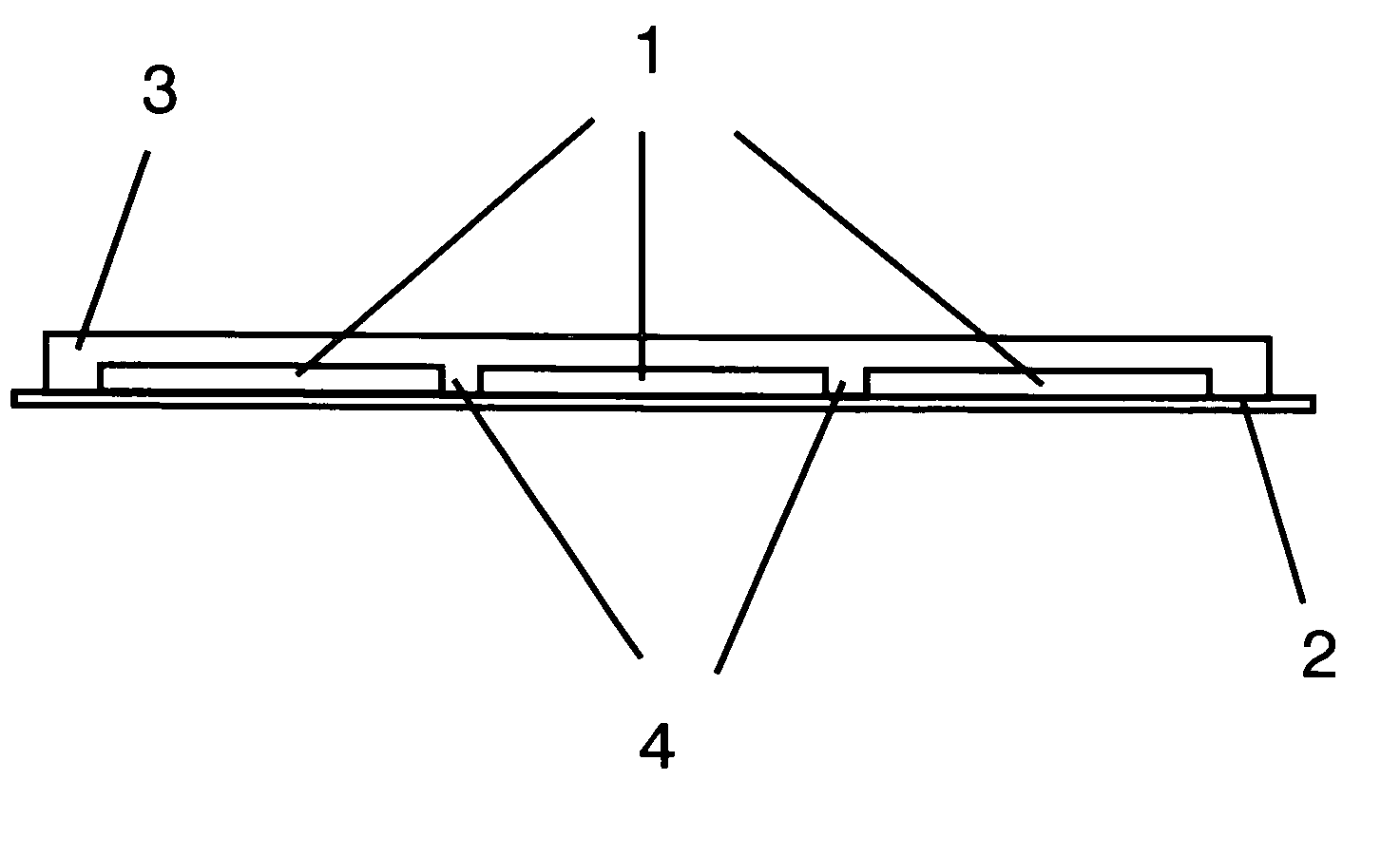

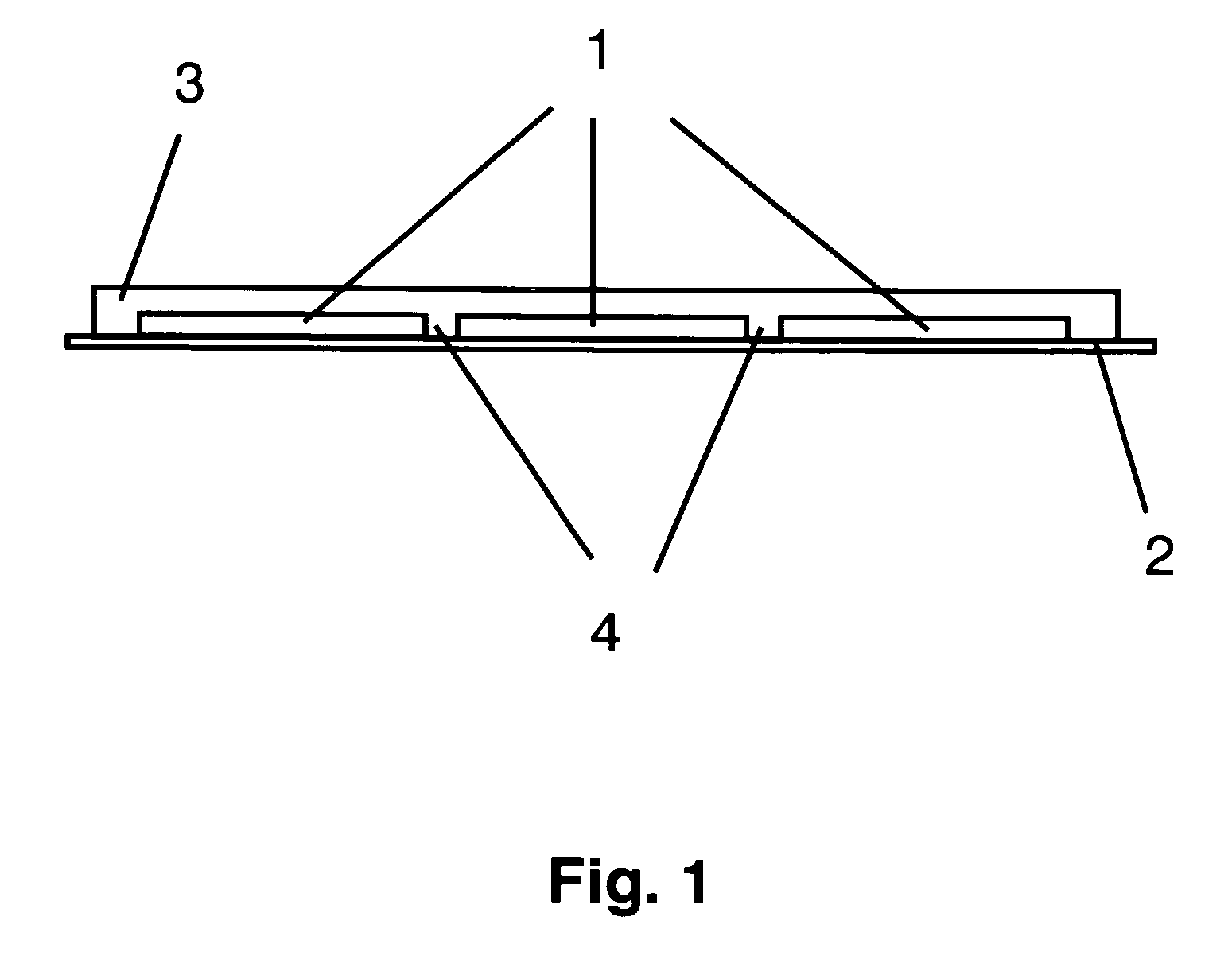

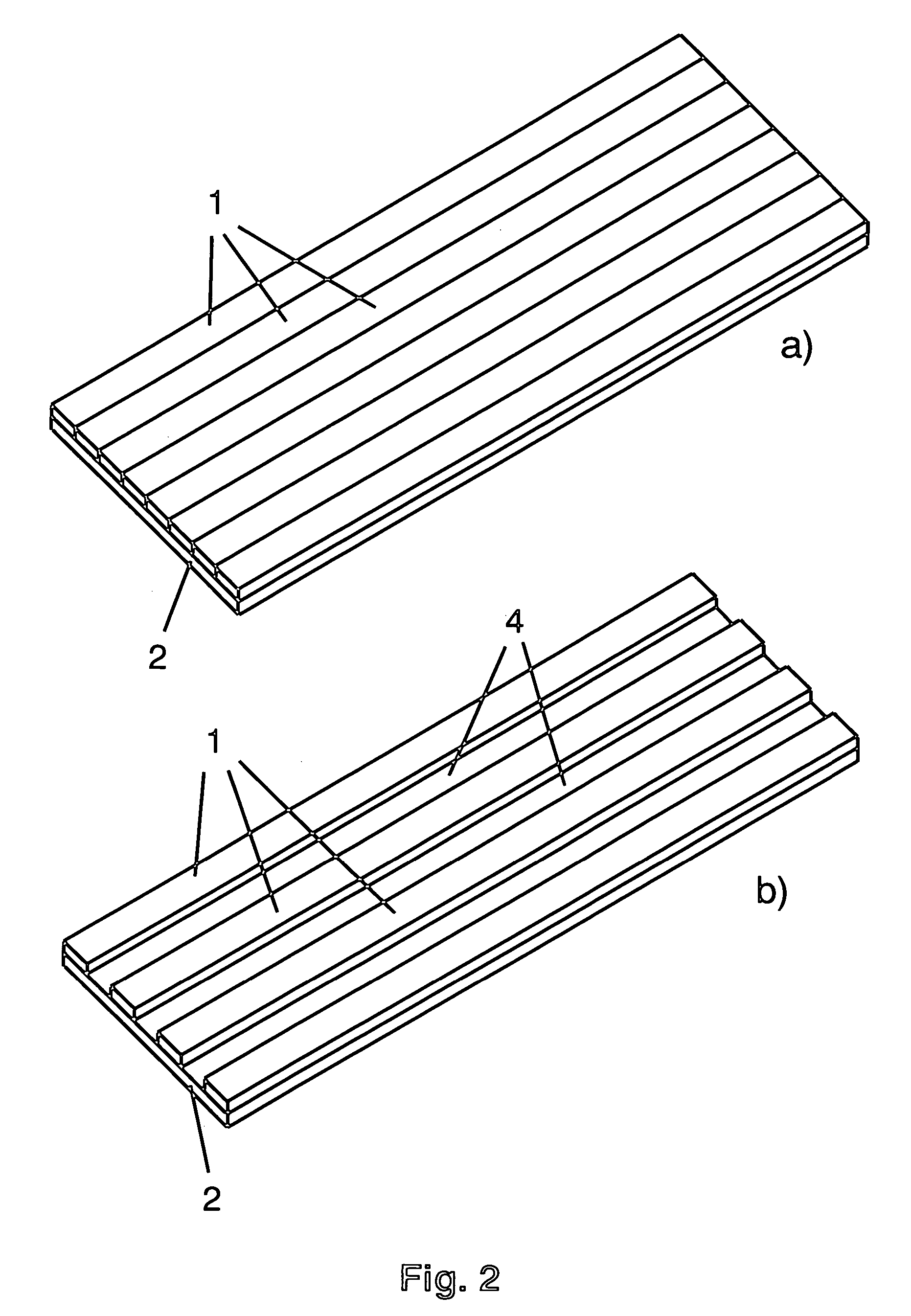

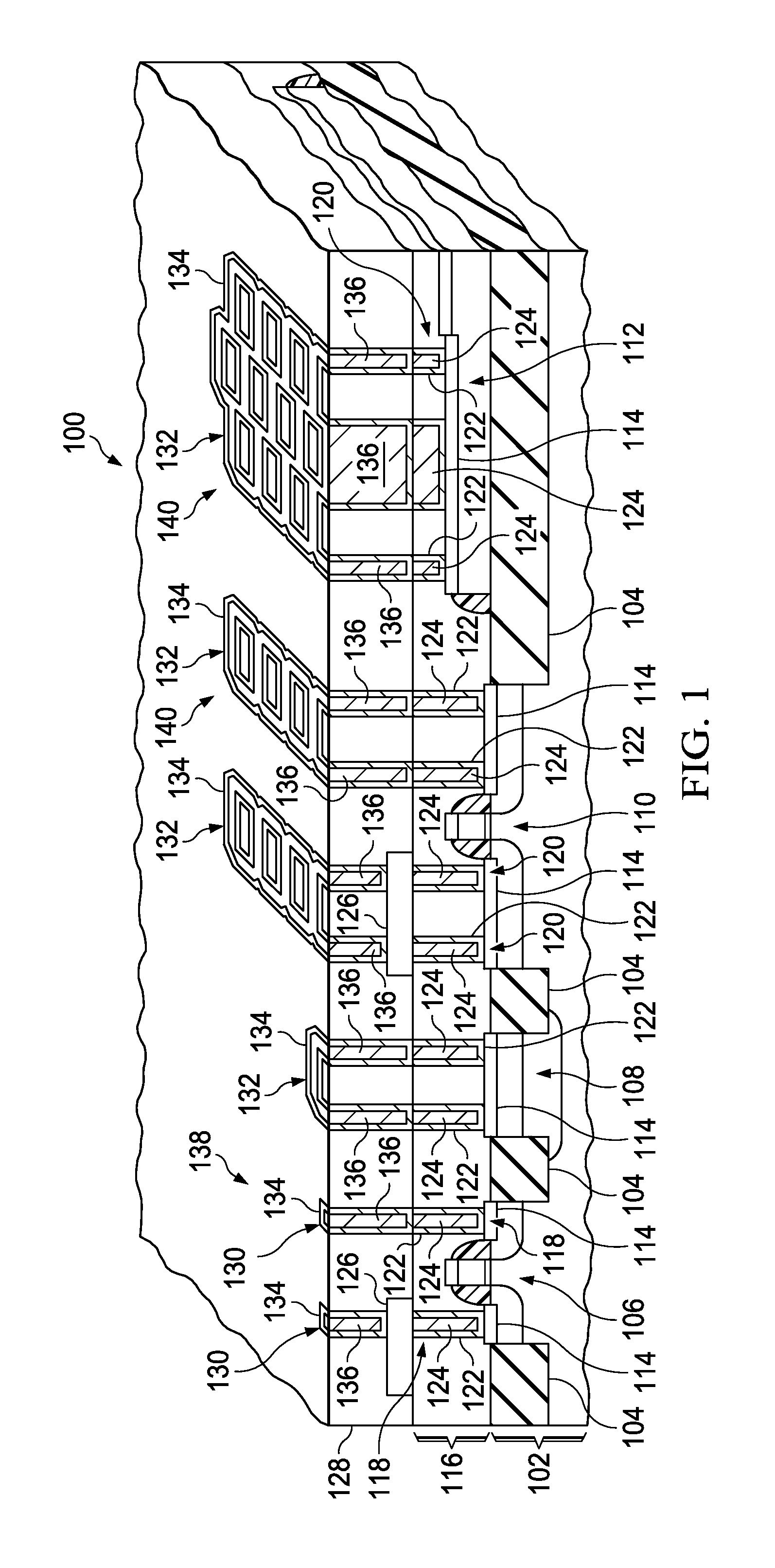

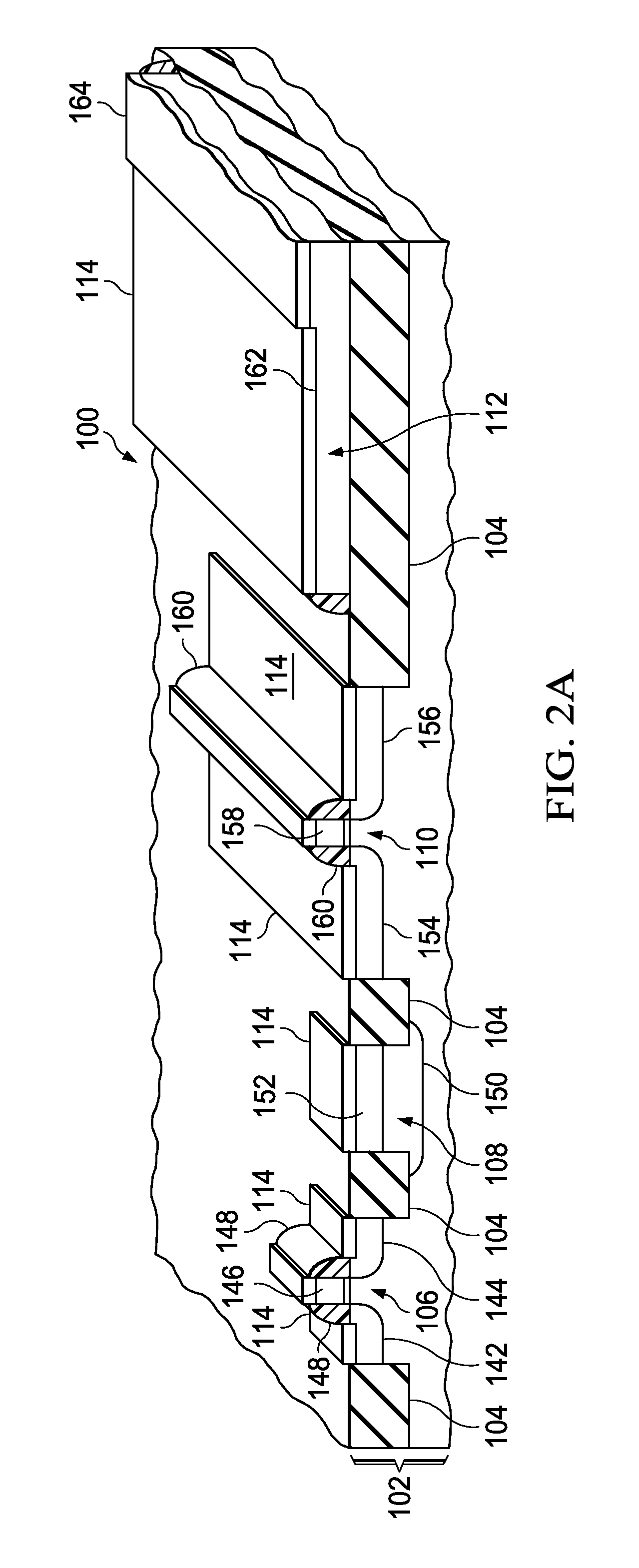

A modular wheel lift provides elevation of a vehicle wheel enclosed by body portions of a low height above the ground. A base lift unit includes a lift surface height selected to be less than the body portions height. A ramp unit is aligned and hingedly attached to one end of the base lift unit, to allow rotational movement of a wheel to the base lift surface. Additional lift units having ramp ends and progressively decreasing lengths are laterally positioned and stacked on the base lift surface. Side brackets are releasably positioned along either side surface to secure the stacked additional lift units to allow rotational movement of the vehicle wheel to an uppermost lift surface. A method of assembly and elevating includes laterally positioning and stacking a plurality of lift units having progressively shorter lengths to provide lifting of a vehicle wheel without disruption of the vehicle body portions.

Owner:BRANSTETTER ANN

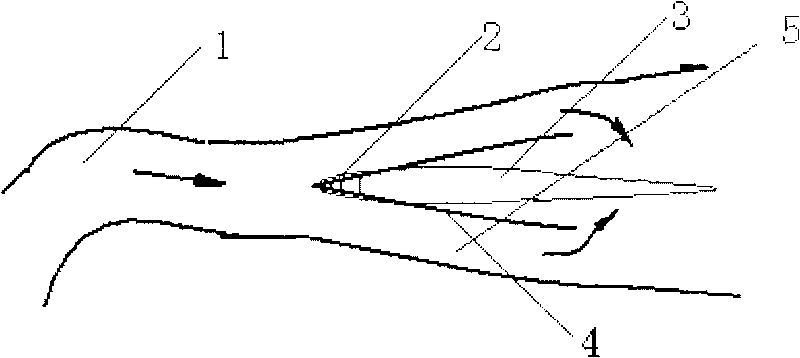

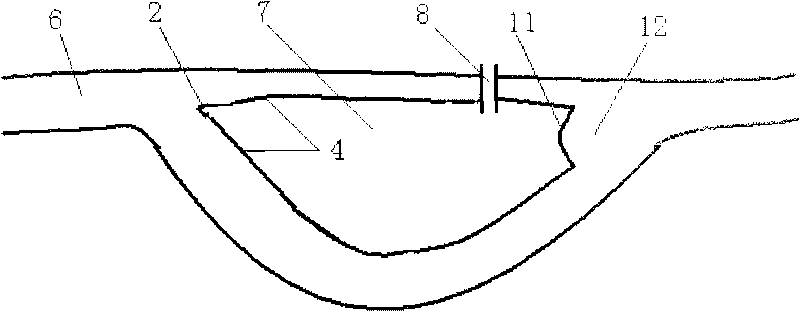

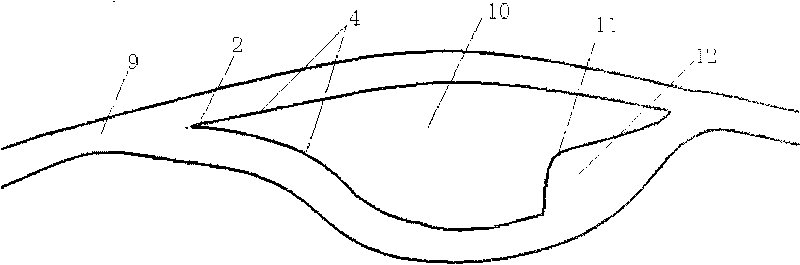

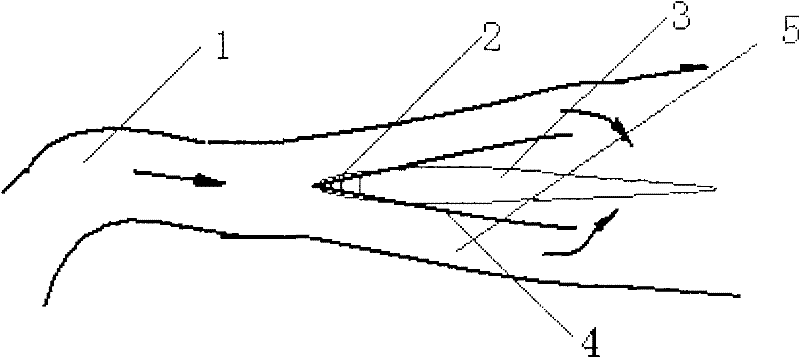

Method for river dredging and management and ait construction

InactiveCN101736717AEmbankment stabilityNot erodedStream regulationSystem constructionRiver management

The invention relates to a method for dredging and management and ait construction, which belongs to the techniques of environment protection and hydraulic engineering. The method comprises the following steps of: protecting dikes along both shores of a river by a light and hard shell dike method; arranging a nose dike in the middle position of the gradually-wide section of the river along the upstream end of a longitudinally ridged sand sill; according to the shape of the sand sill, hard shell sheet piles gradually extending to the downstream along both sides of the nose dike to form an aequilate river surface; inserting sheet piles, connecting the sheet piles into a whole, throwing the dredged mud into a range surrounded by the hard shell sheet piles, and then gradually forming a man-made island; marking a helix-shaped man-made bay on the downstream of the gradually-narrow section of the river to form a fixing sand point on the sudden-widen river; and then planting and fixing sand on the man-made island. The invention aims to satisfy the functions of flood discharge, tide suppressing, irrigation, water storage and navigation, and also can establish stable man-made islands and marsh parks. The invention has the advantages of dike stabilization, reduction of sand accretion, utilization of natural energy, and increase of earth resources, and is suitable for various types of river management.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

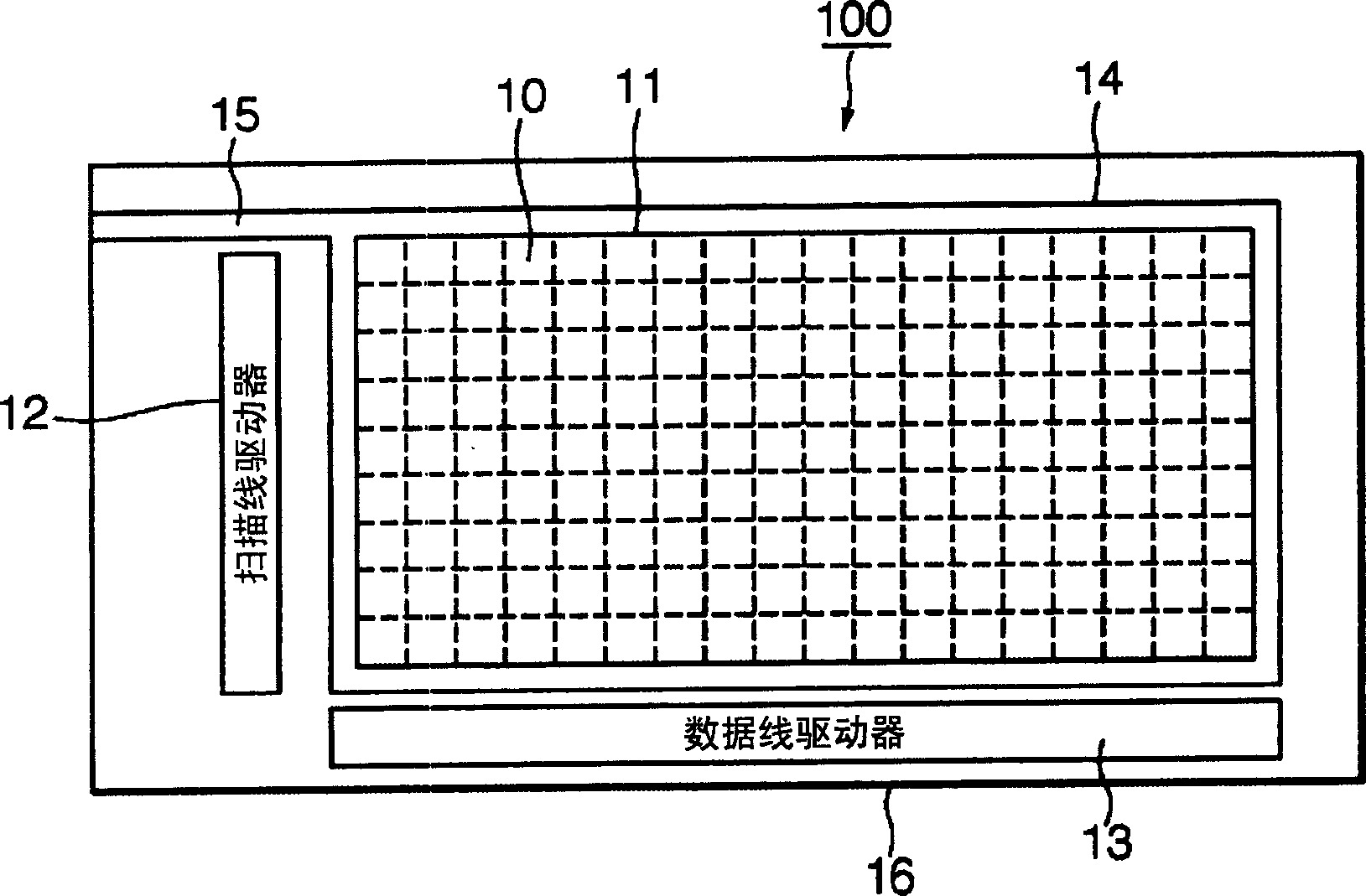

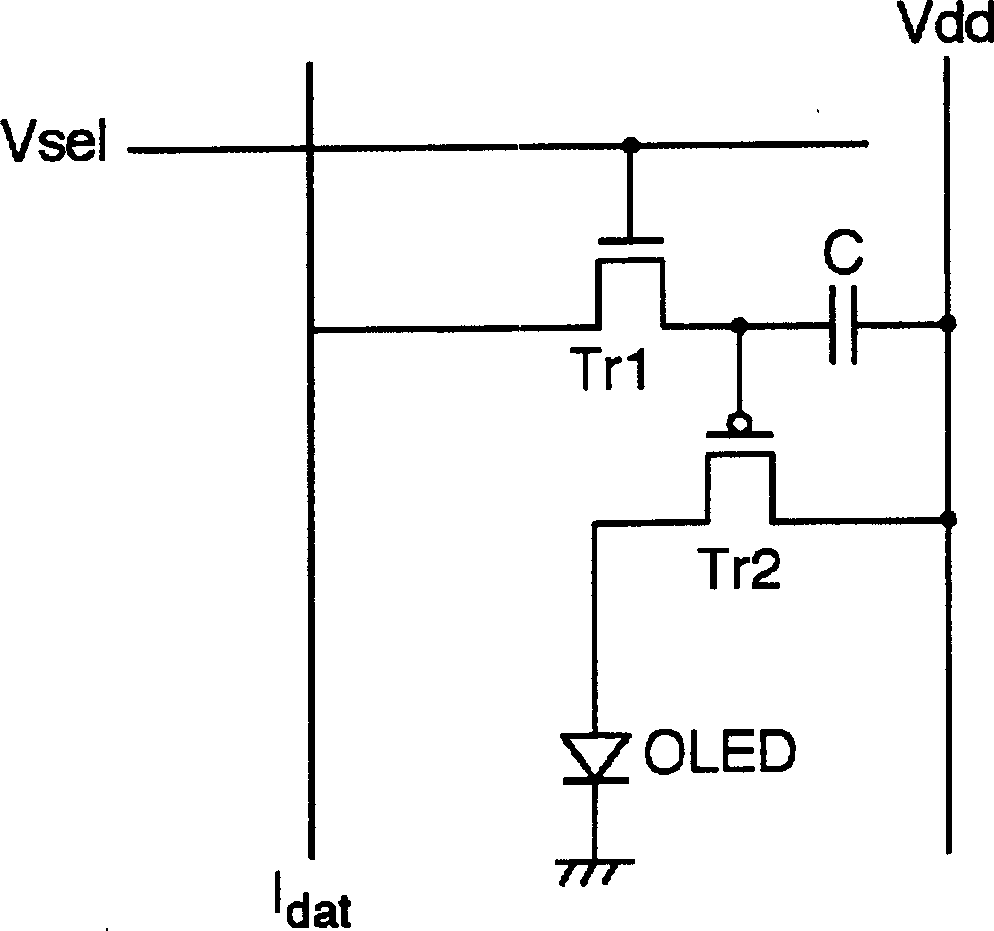

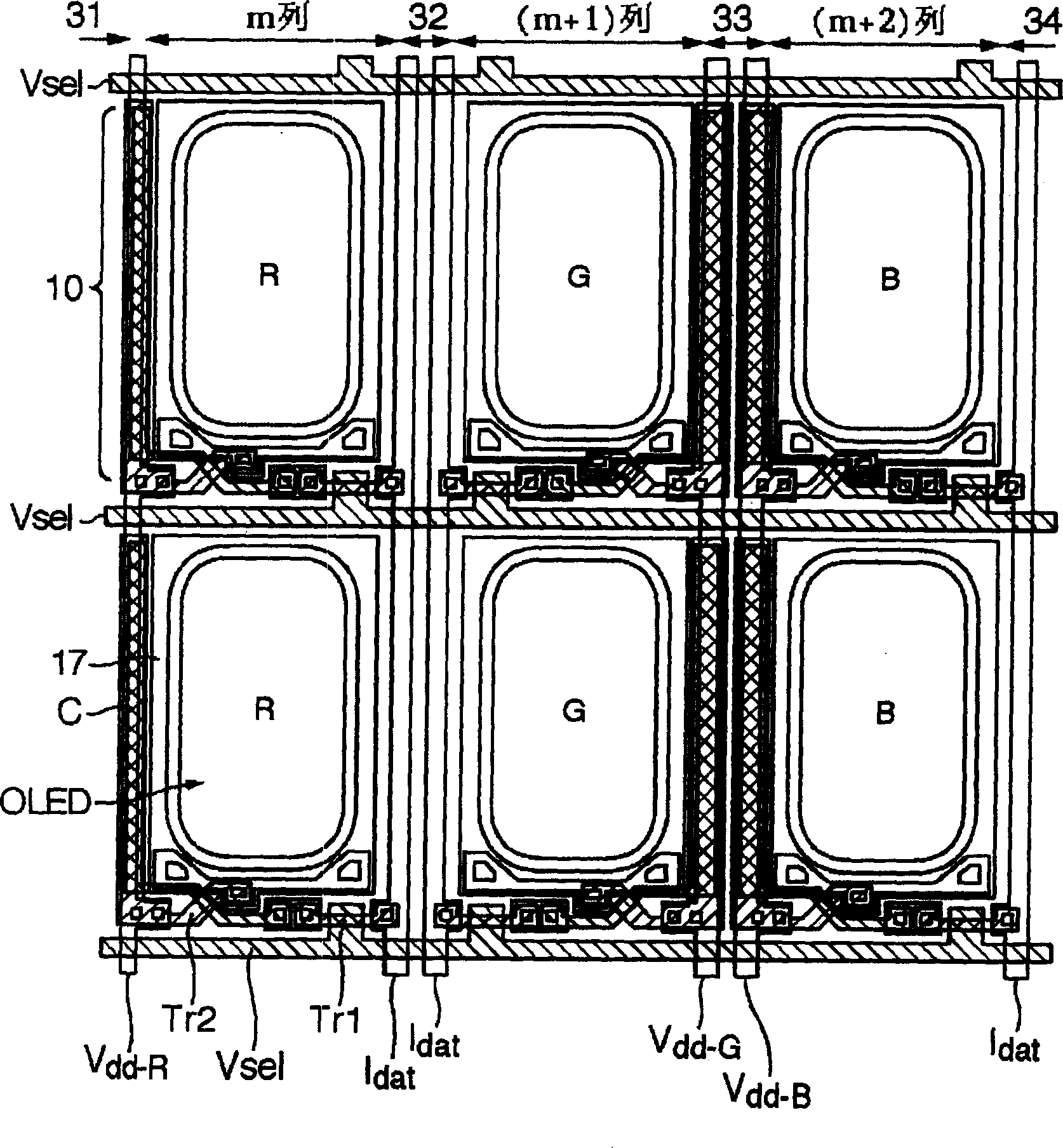

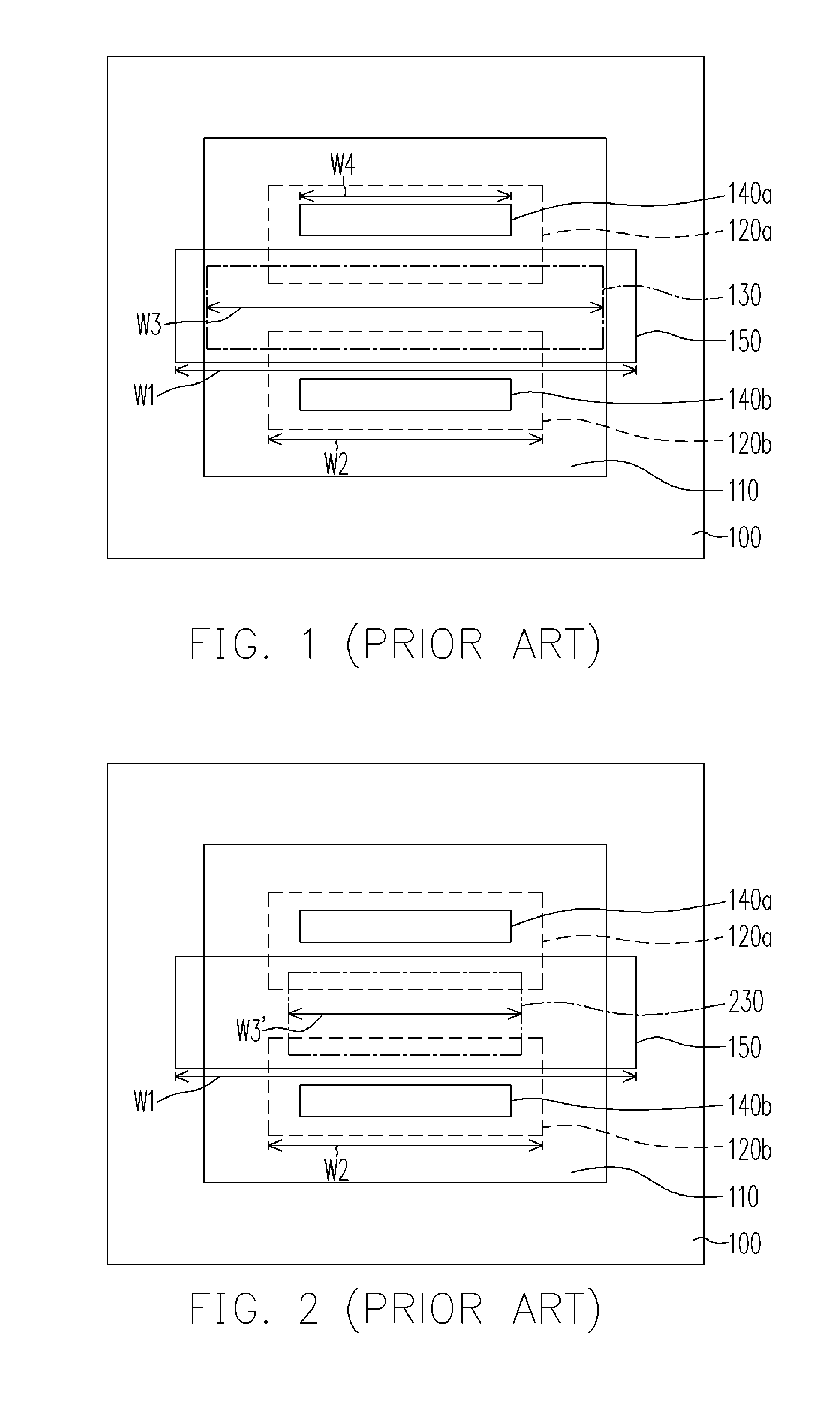

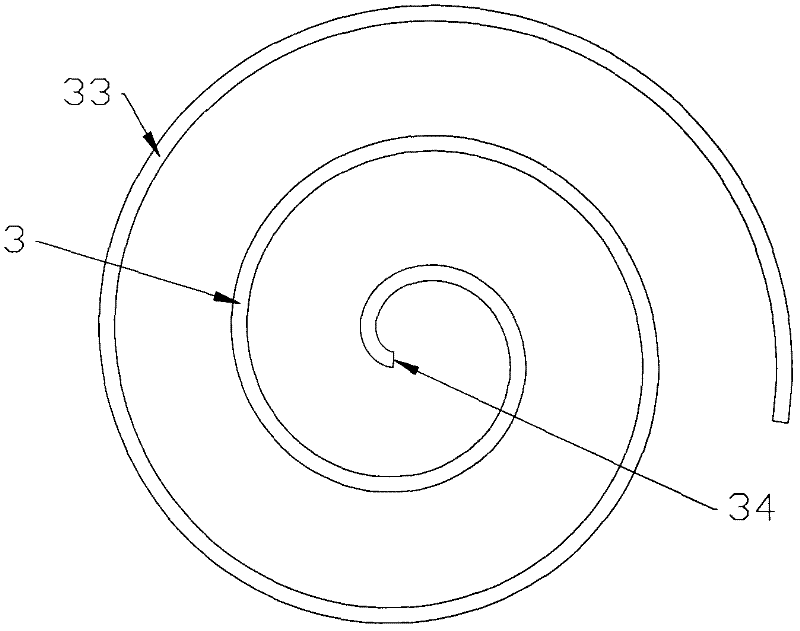

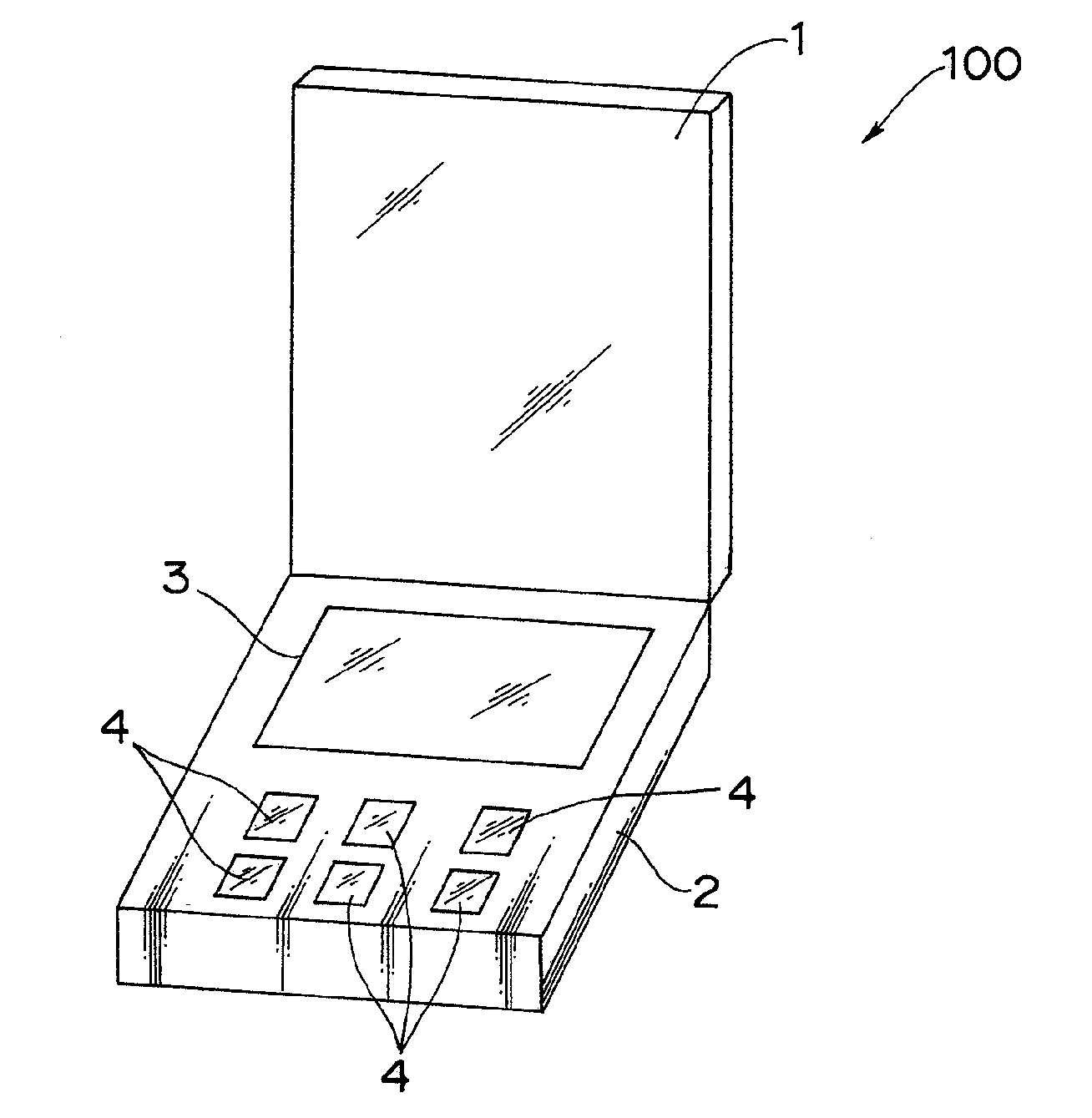

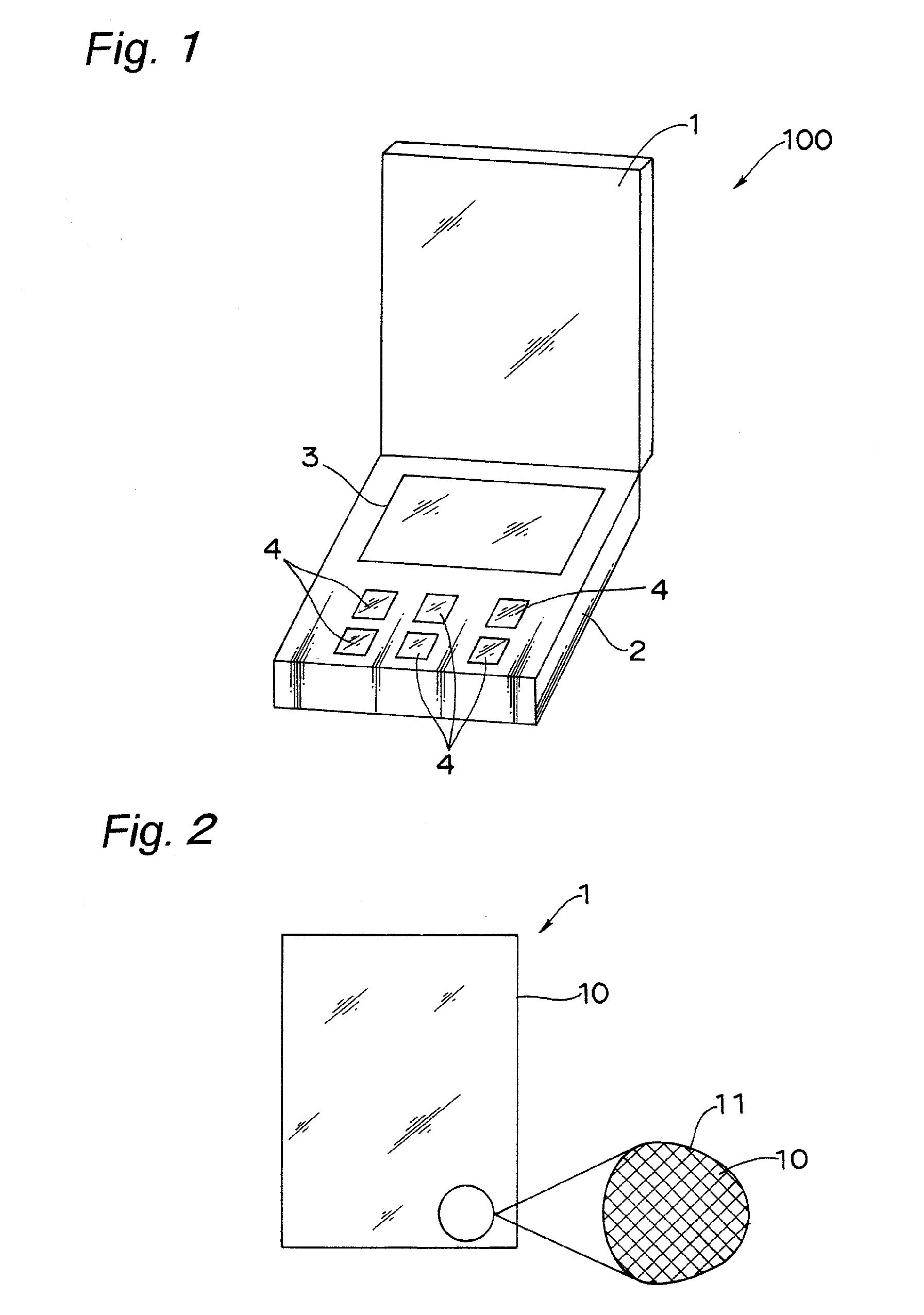

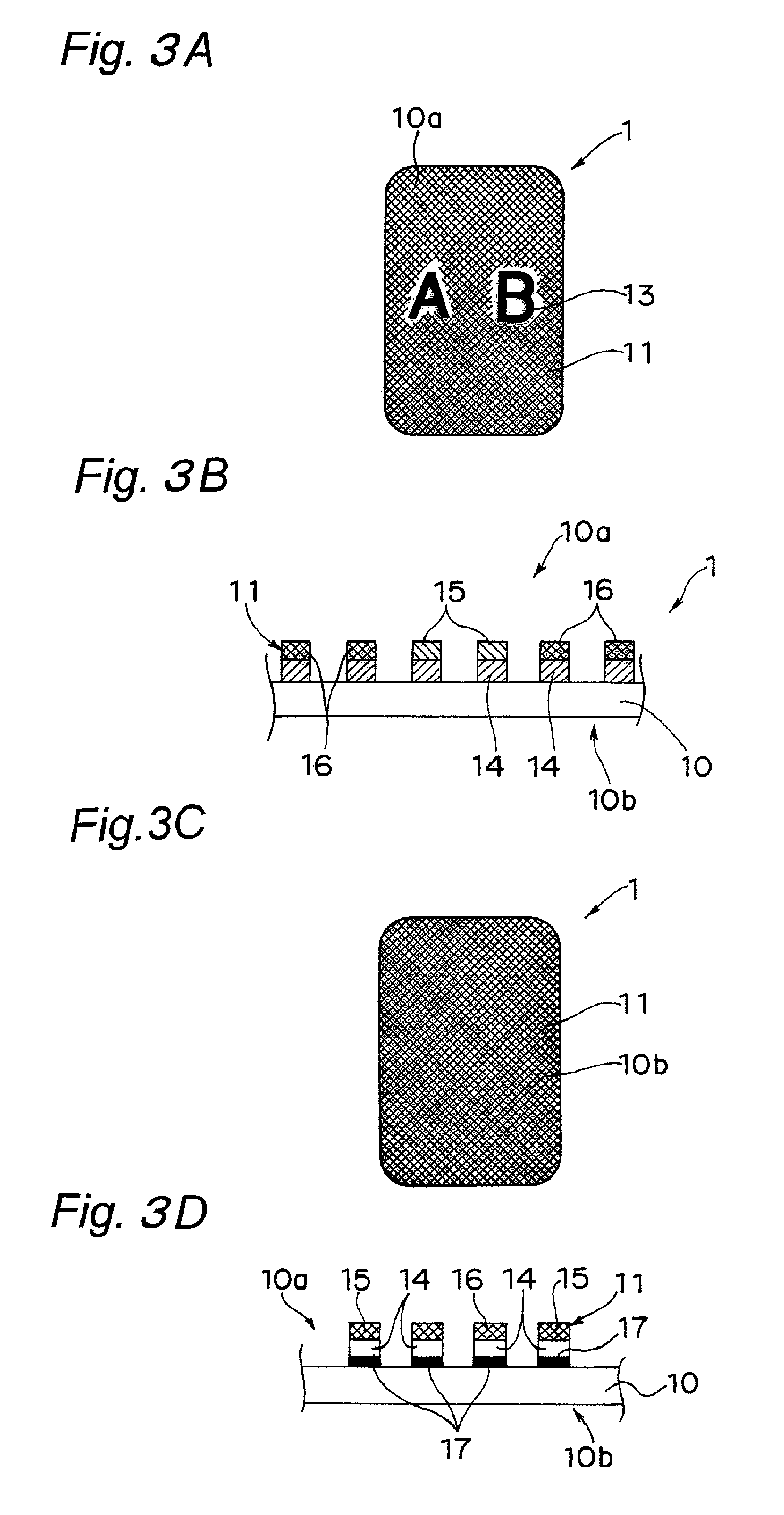

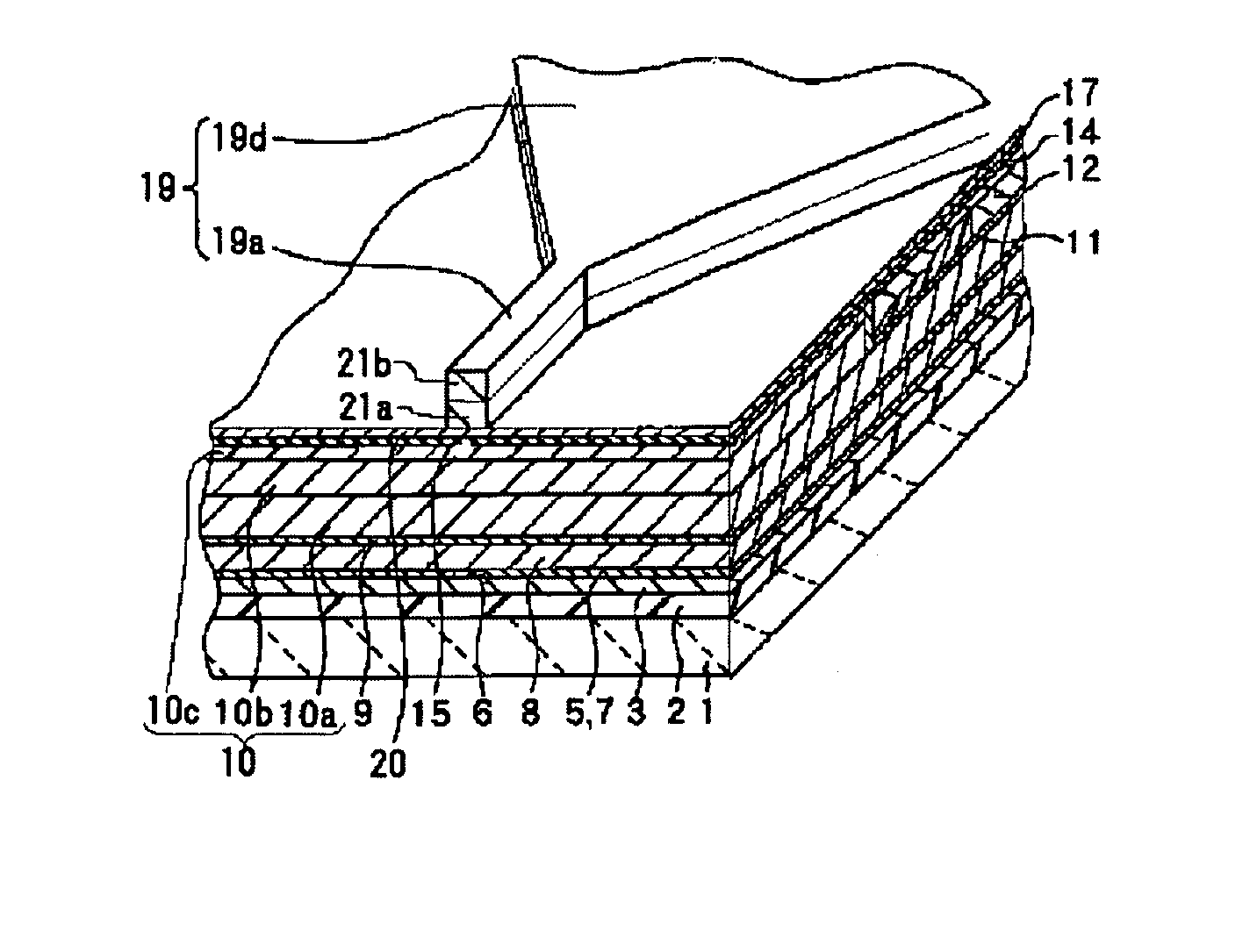

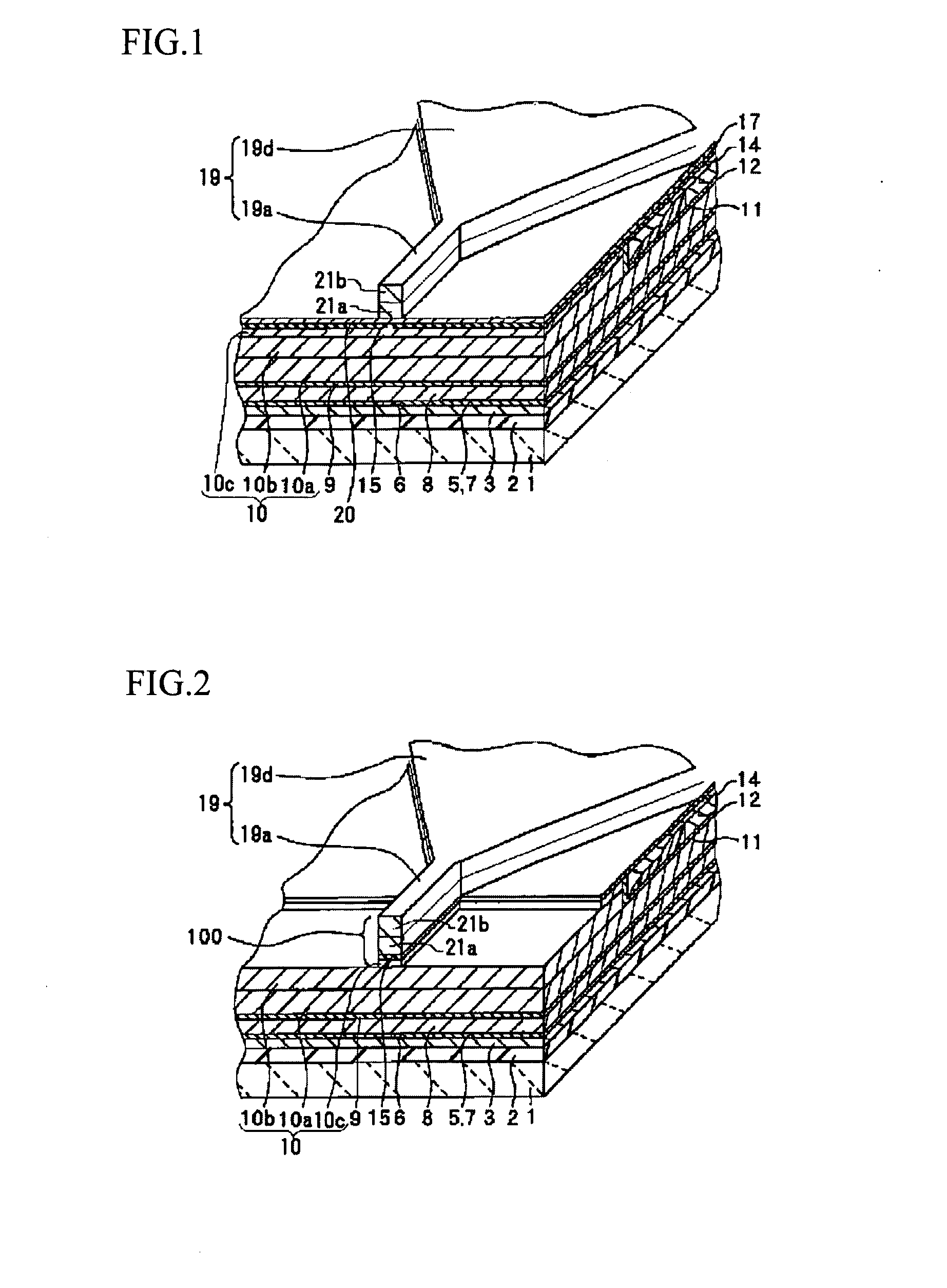

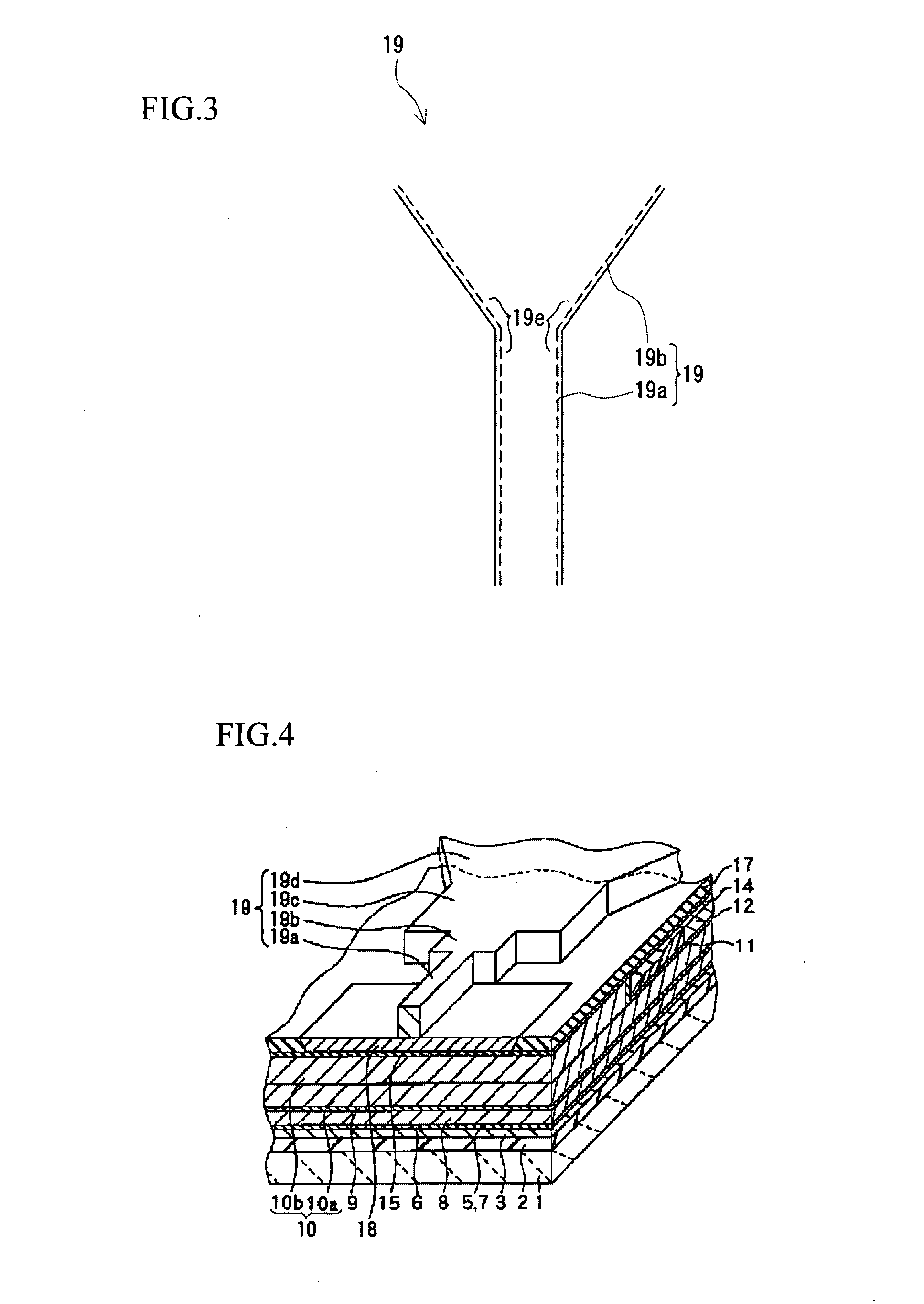

Electro-optical deivce, matrix base plate and electronic machine

InactiveCN1497513AIncrease opening ratioEqual widthElectroluminescent light sourcesSolid-state devicesElectric power systemAperture ratio

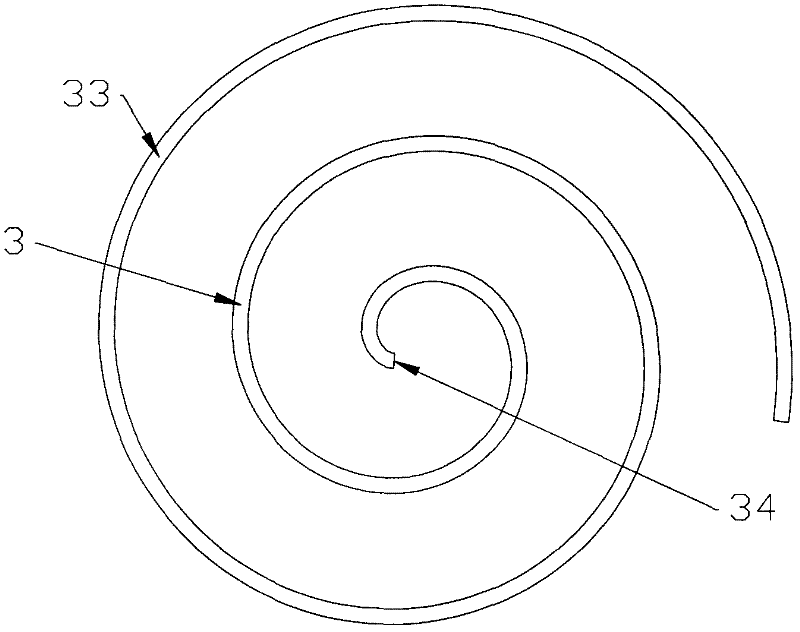

Provided is a wiring layout of electric power lines, which improves the aperture ratio of the pixel while forming pixels with the same pixel pitch. An electric-optical apparatus according to the present invention comprises multiple pixels (10) arranged in matrix including electro-optical devices driven by receiving electric power from an electric power supply circuit, wherein the aforementioned multiple pixels (10) make up multiple pixel groups formed of a series of pixels arrayed in at least one direction of the row direction and the column direction, and any of line forming regions (31, 32, 33, 34) is disposed between adjacent pixel groups of the aforementioned pixel groups, wherein the aforementioned line forming regions (31, 32, 33, 34) are formed with generally the same width.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

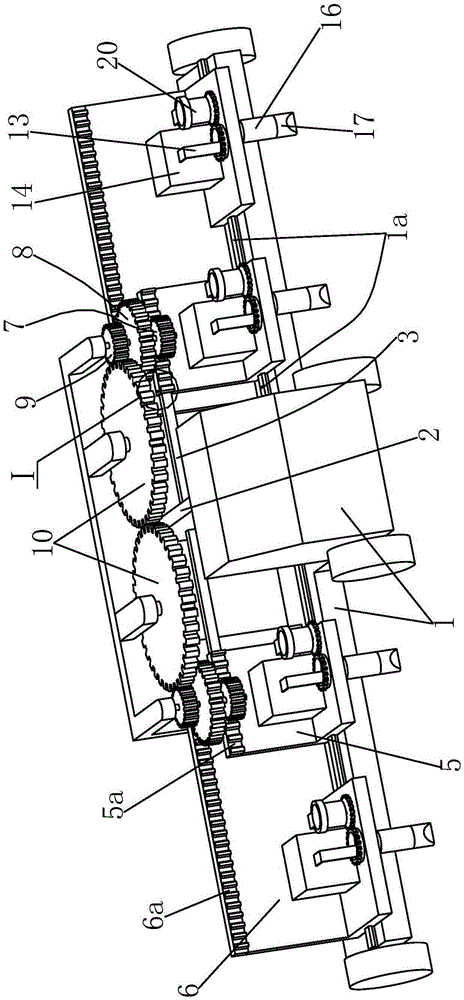

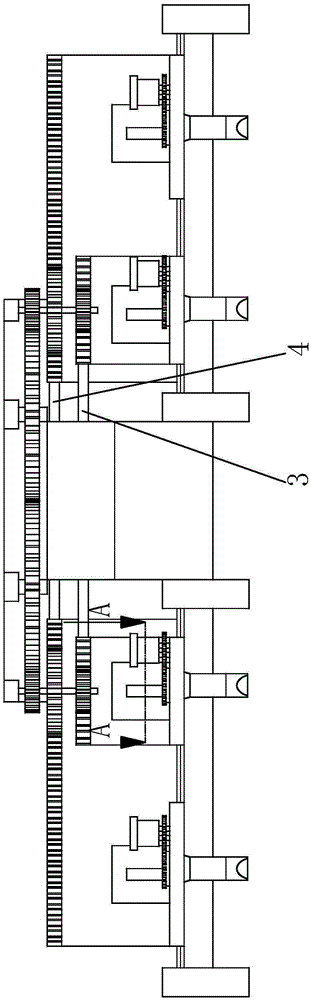

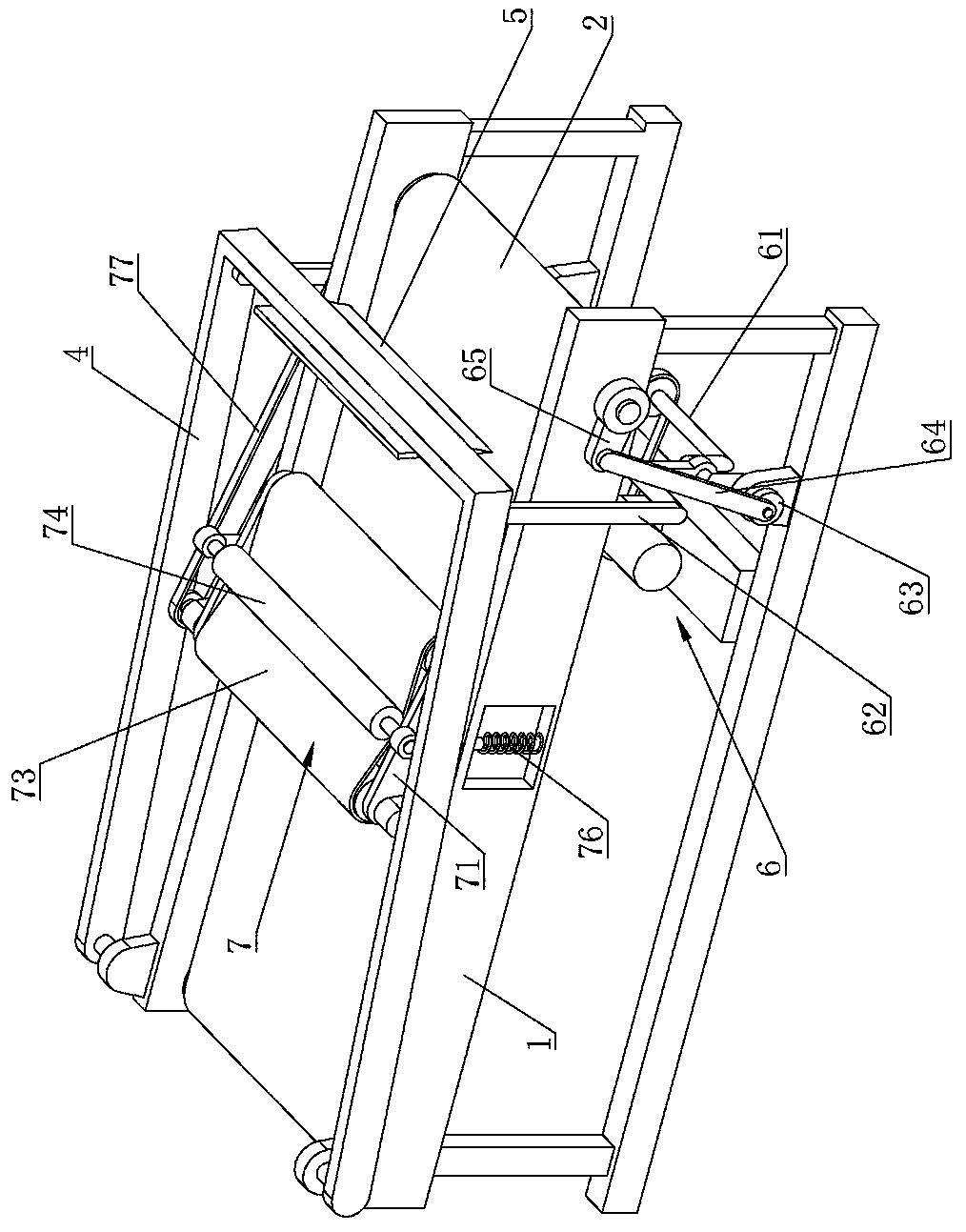

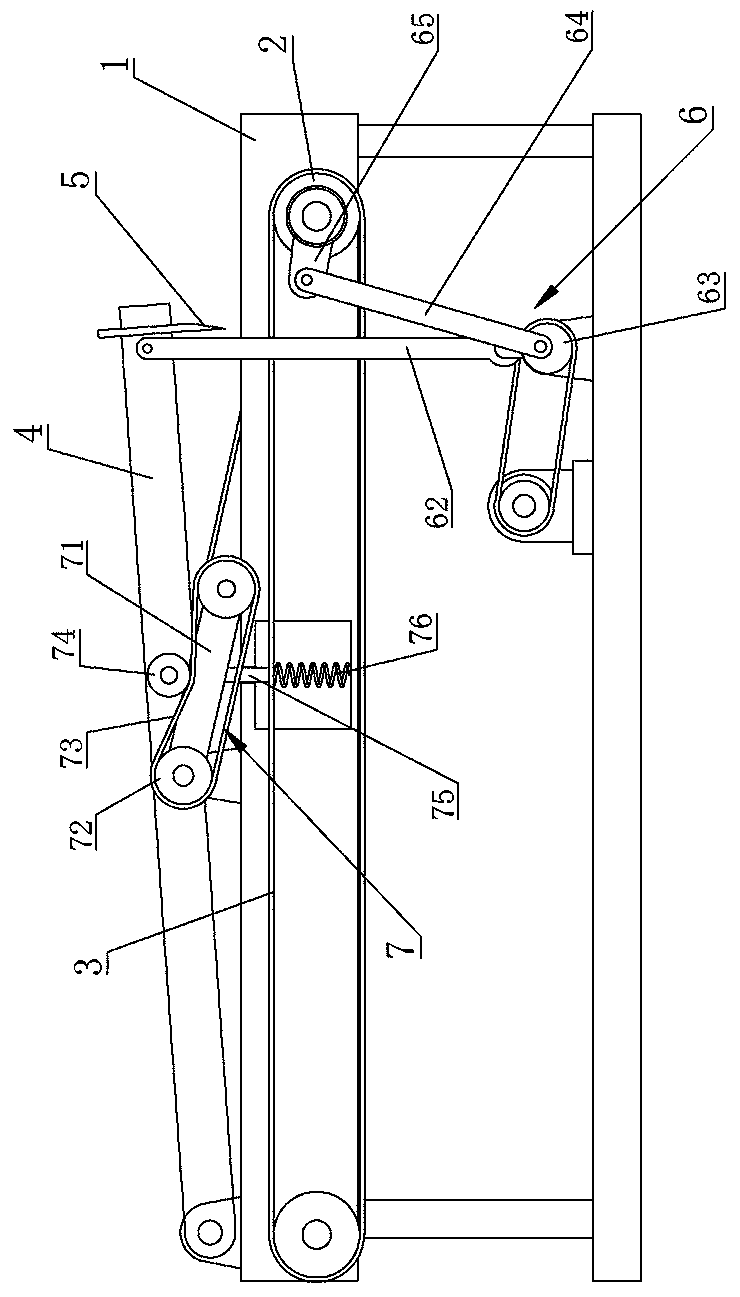

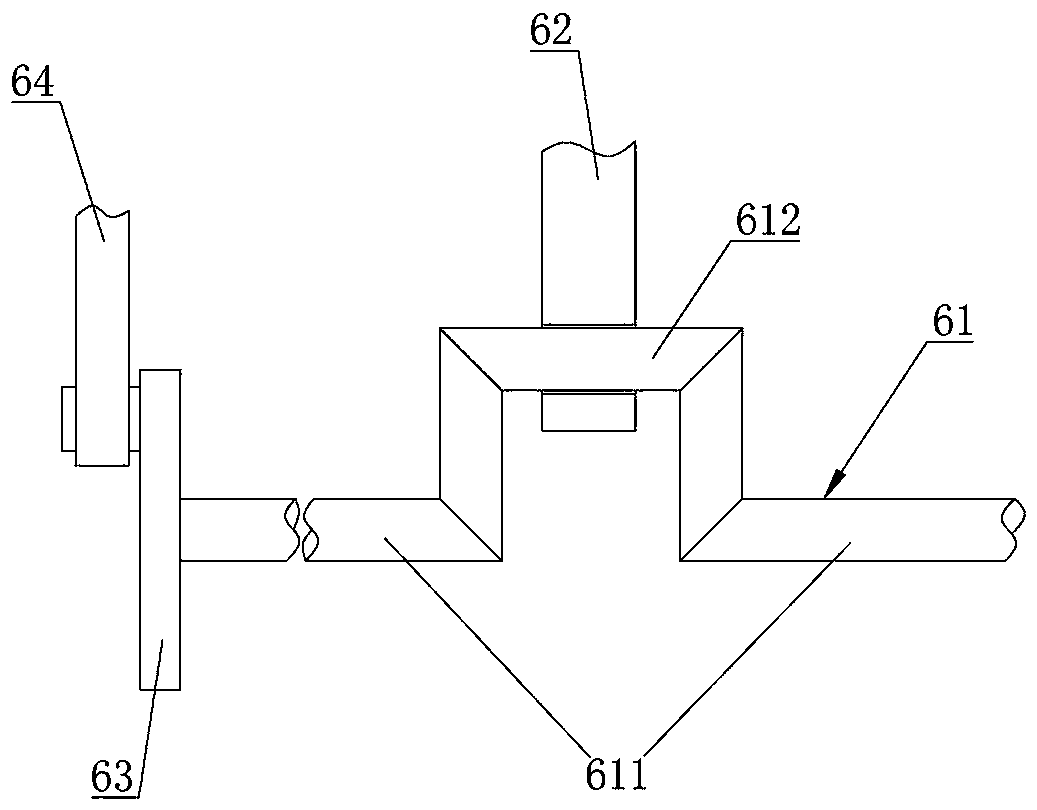

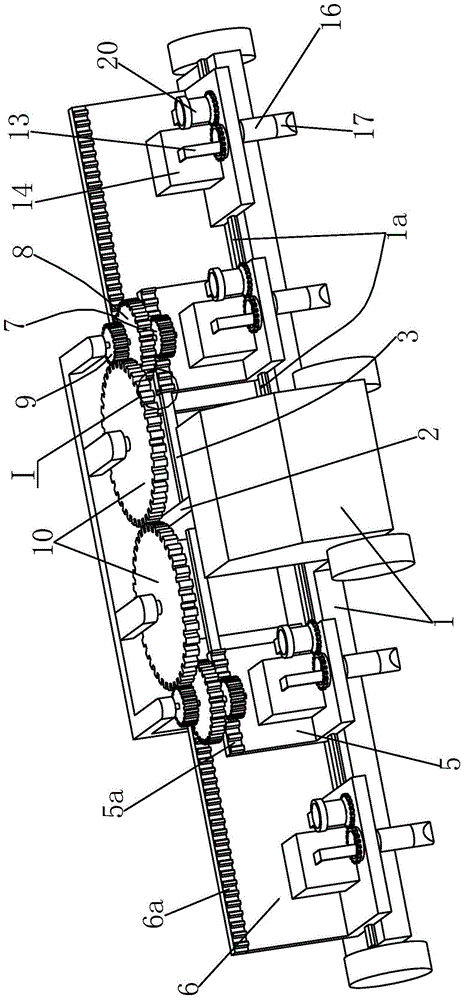

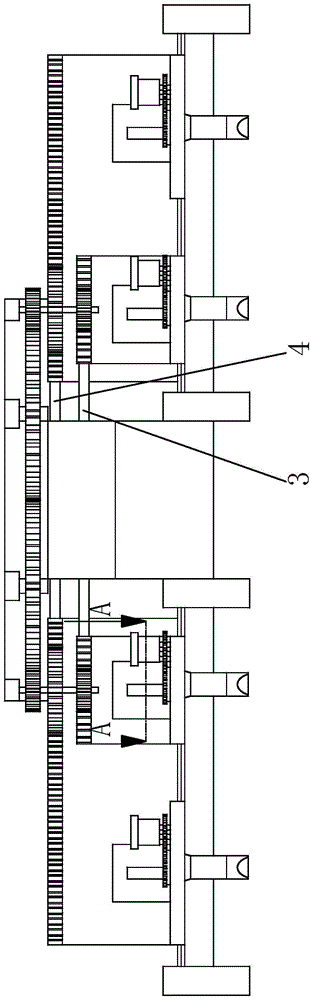

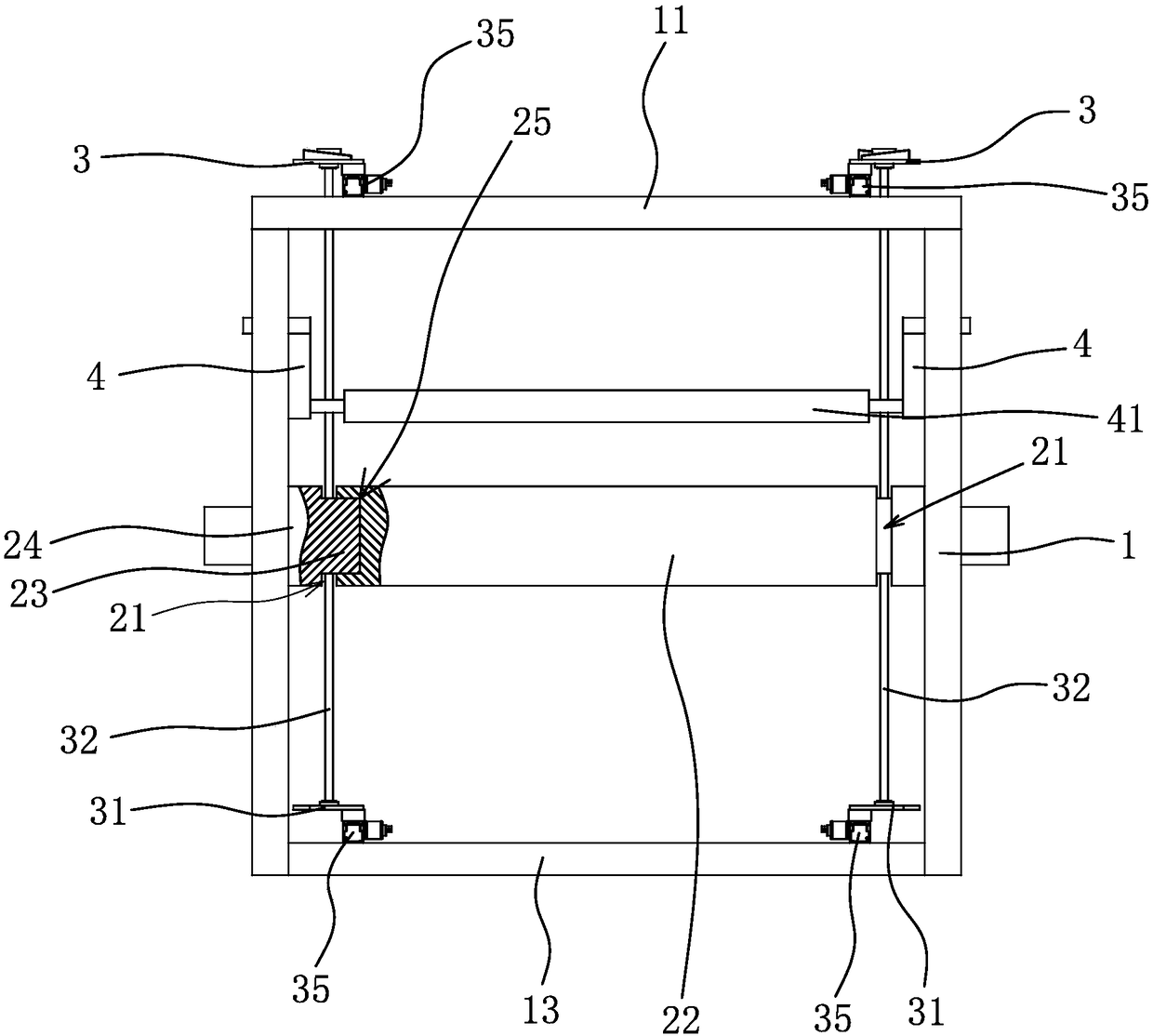

Marking vehicle used for three-lane road

ActiveCN105350439AEasy to operateEasy to controlRoads maintainenceMechanical engineeringRaw material

The invention relates to a marking vehicle used for a three-lane road. The marking vehicle mainly comprises a vehicle body. A central frame is arranged on the vehicle body. A No.1 sliding holder and a No.2 sliding holder are installed on the central frame. The No.1 sliding holder and the No.2 sliding holder are in sliding connection with a No.1 bearing holder and a No.2 bearing holder respectively. A No.1 rack is installed on the No.1 bearing holder and a No.2 rack is installed on the No.2 bearing holder. The No.1 rack is engaged to a No.1 gear. The No.1 gear is connected with a No.2 gear and transmission gears. The No.2 gear is engaged to the No.2 rack. Two idle gears are arranged between the two transmission gears. Plugging covers are arranged at the lower end of the No.1 bearing holder and the lower end of the No.2 bearing holder respectively. An opening is arranged beside each plugging cover. The upper end of each plugging cover is pressed against a bar-shaped pipe. The bar-shaped pipe is connected with a raw material storage box. Annular teeth are arranged at the circumferential outer end of each plugging cover. The annular teeth are engaged to an auxiliary gear. The marking vehicle has functions of ensuring marking length and marking interval constant and marking of roads with different lane widths.

Owner:广州市公路实业发展有限公司

Portable modular wheel lift

InactiveUS20060043350A1Easy to stackLess lengthInclined ship-liftingLifting framesShort lengthLateral positioning

A modular wheel lift provides elevation of a vehicle wheel enclosed by body portions of a low height above the ground. A base lift unit includes a lift surface height selected to be less than the body portions height. A ramp unit is aligned and hingedly attached to one end of the base lift unit, to allow rotational movement of a wheel to the base lift surface. Additional lift units having ramp ends and progressively decreasing lengths are laterally positioned and stacked on the base lift surface. Side brackets are releasably positioned along either side surface to secure the stacked additional lift units to allow rotational movement of the vehicle wheel to an uppermost lift surface. A method of assembly and elevating includes laterally positioning and stacking a plurality of lift units having progressively shorter lengths to provide lifting of a vehicle wheel without disruption of the vehicle body portions.

Owner:BRANSTETTER ANN

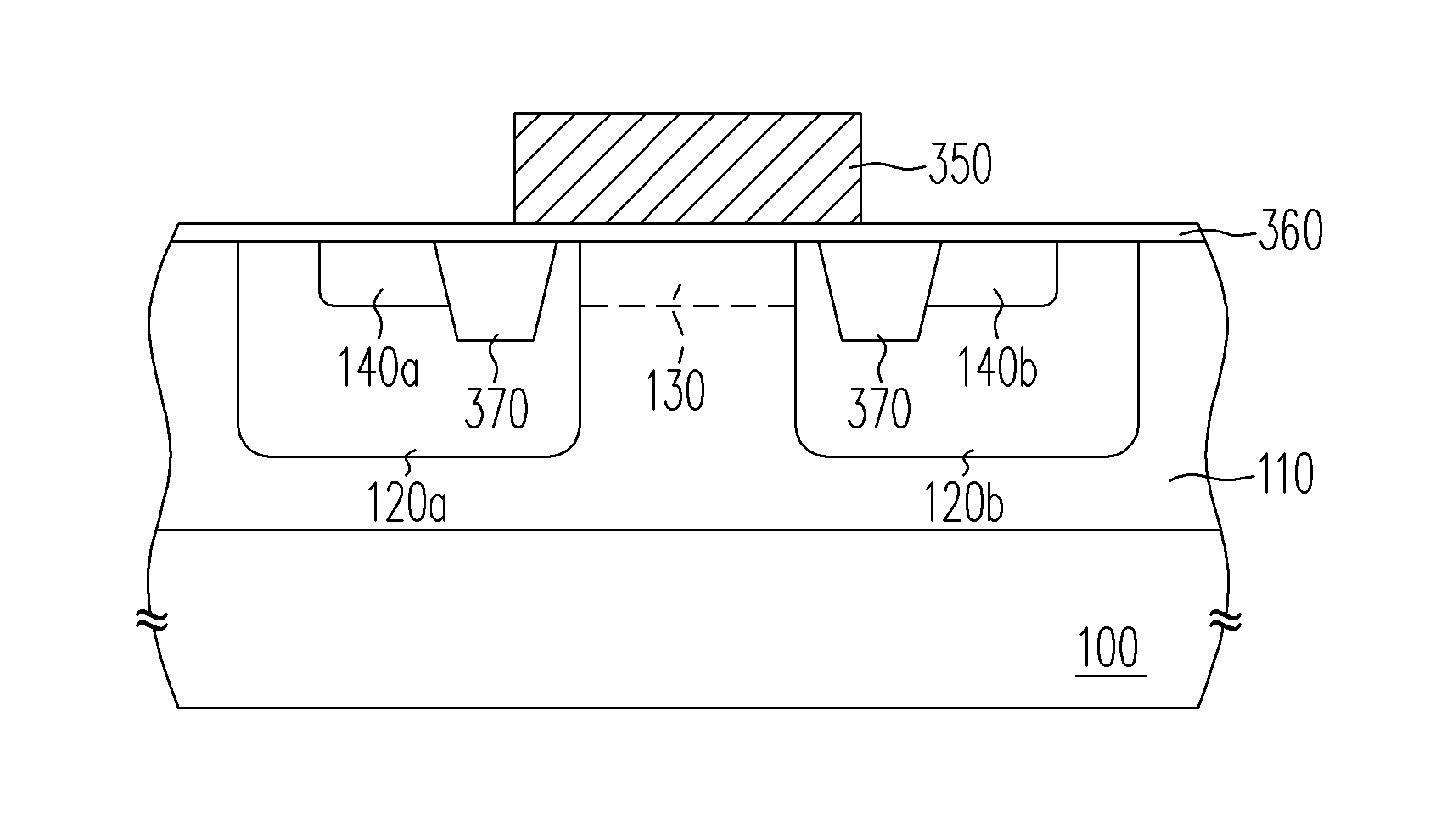

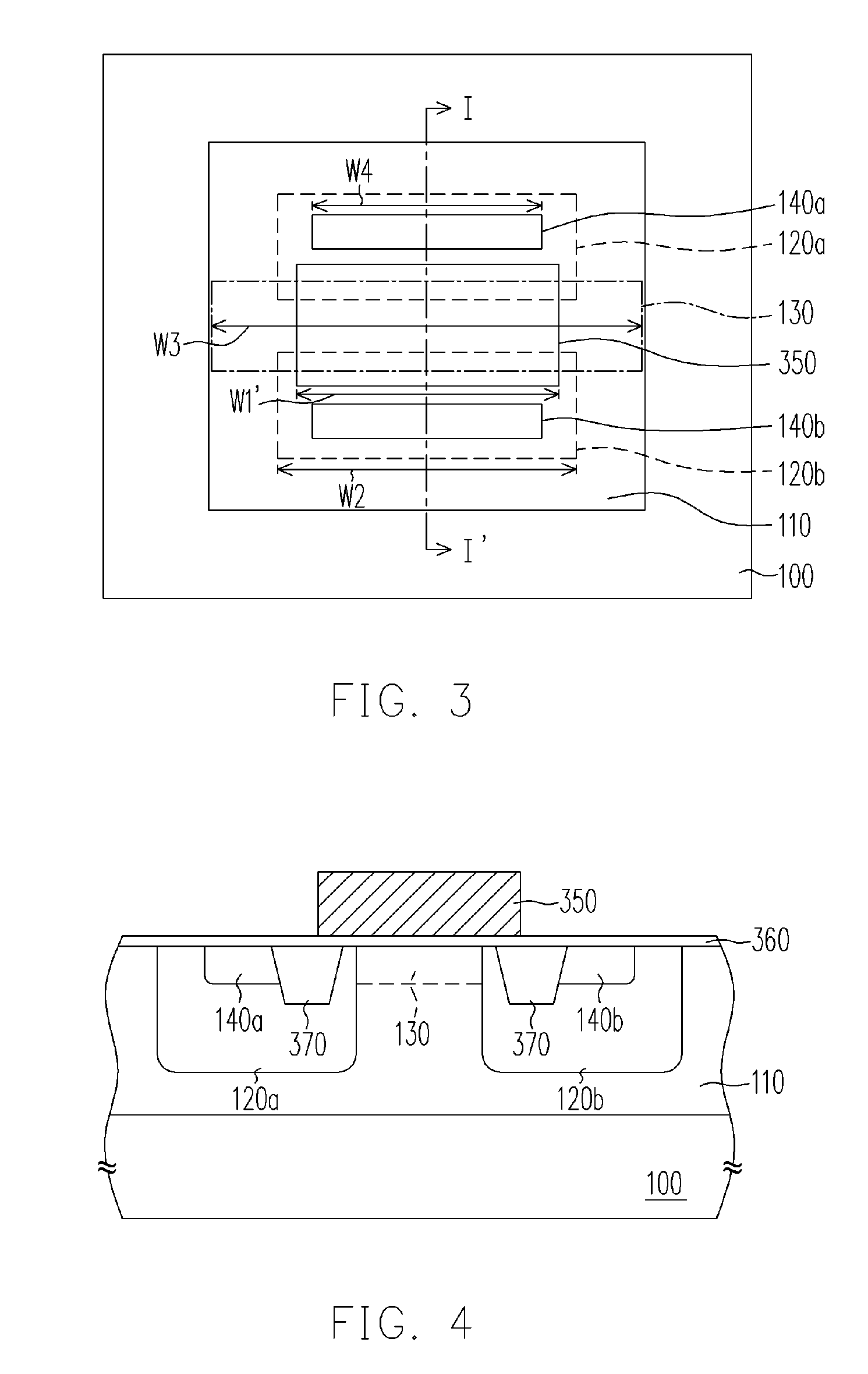

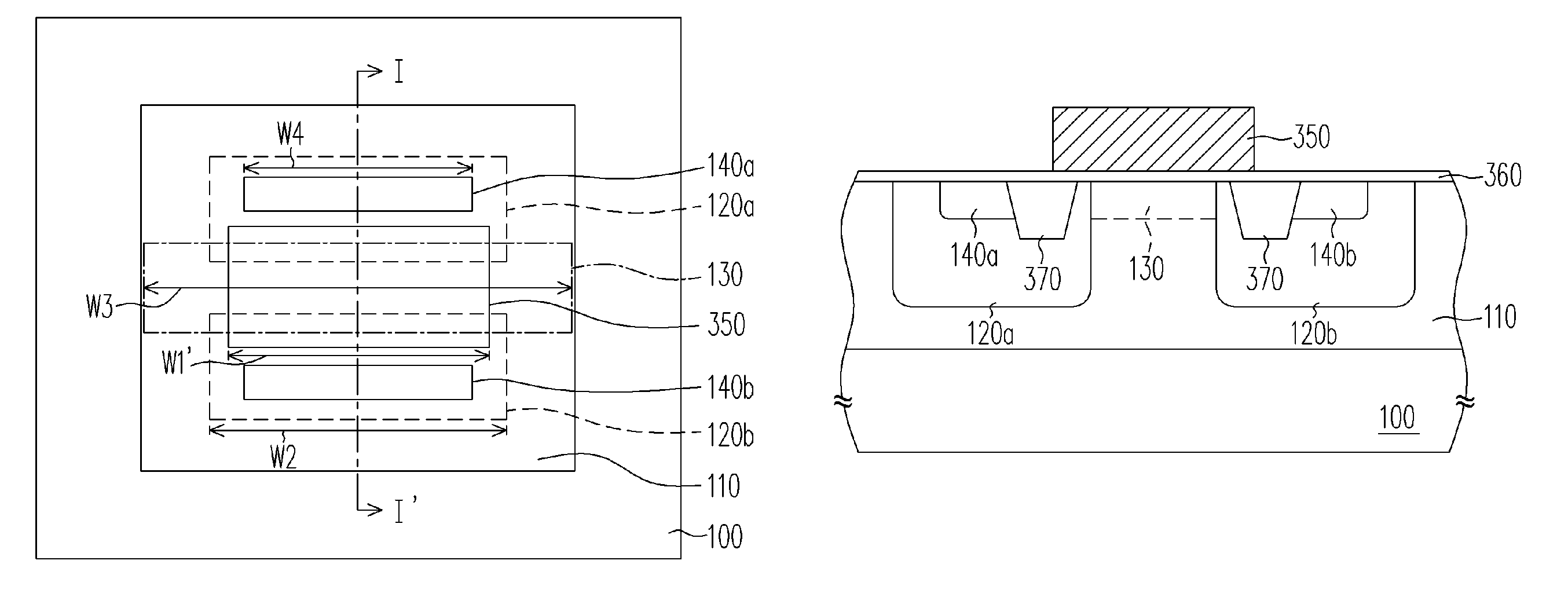

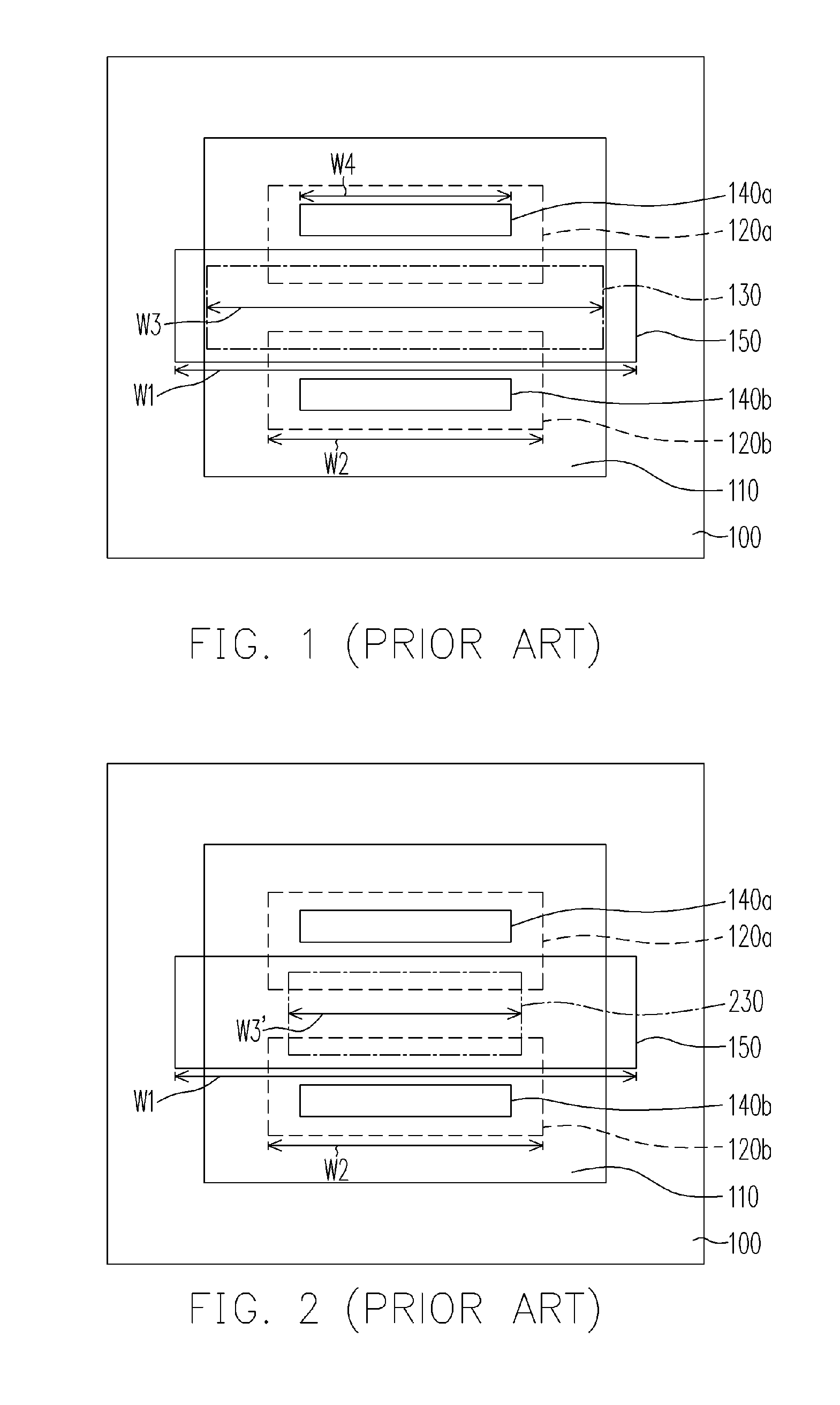

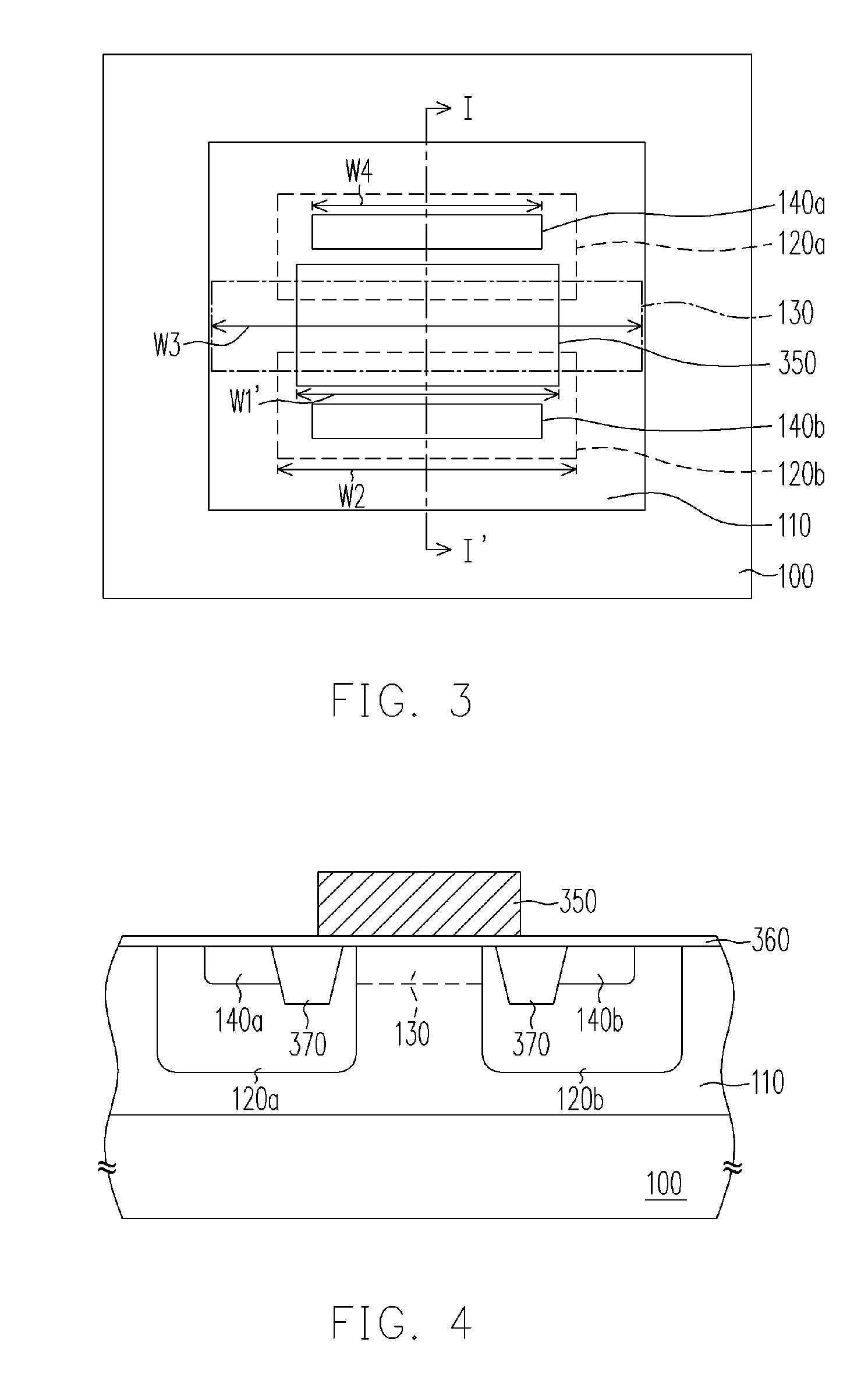

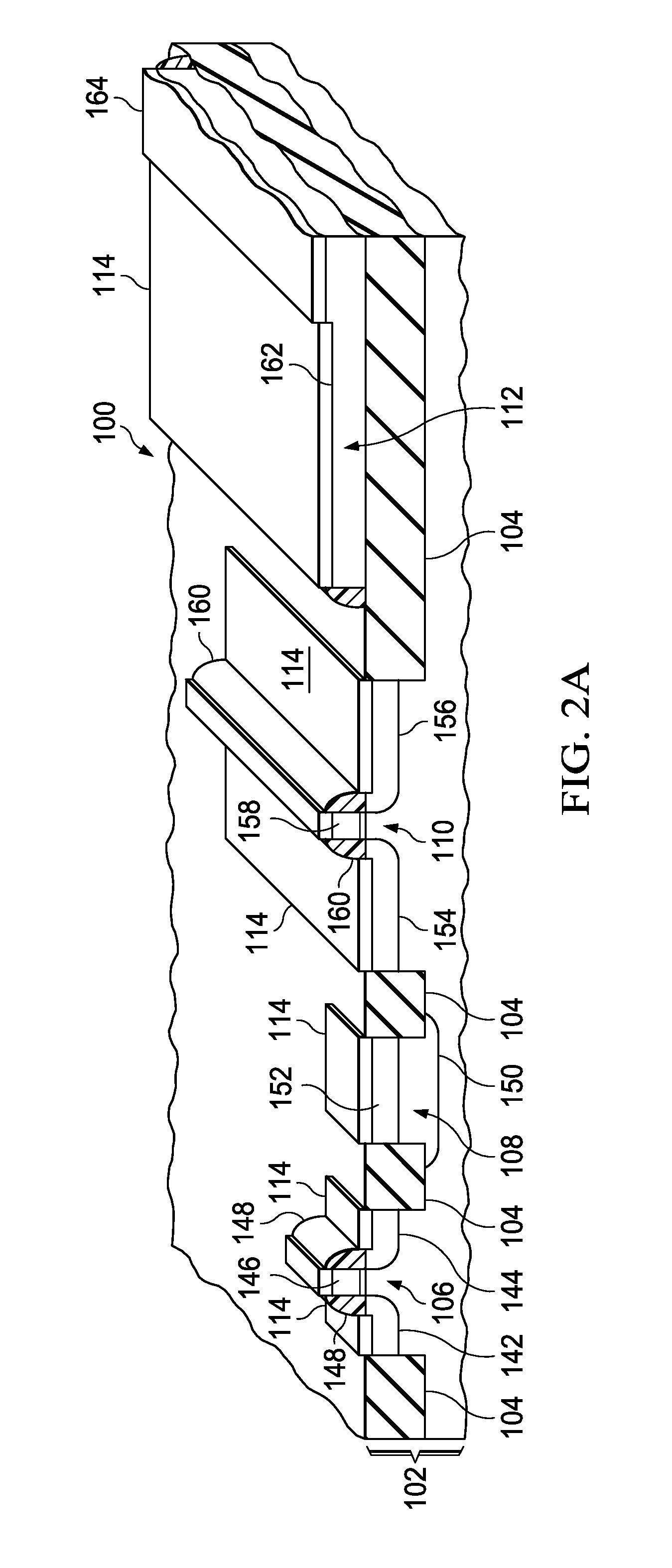

High voltage metal oxide semiconductor transistor and fabricating method thereof

ActiveUS20070045675A1AvoidingLowering sub-threshold currentTransistorSolid-state devicesInsulation layerHigh pressure

A high voltage MOS transistor including a substrate, a well, a gate insulation layer, a gate, two drift regions, a channel region, a source / drain region and an isolation structure is provided. The well is disposed in the substrate and the gate insulation layer is disposed over the substrate. The gate is disposed over the gate insulation layer. The two drift regions are in the well at two sides of the gate and the width of the gate is greater than or equal to that of the drift regions. The channel region is disposed between the drift regions and the width of the channel region is greater than that of the drift regions. The source / drain regions are formed within the drift regions. The isolation structure is disposed inside the drift regions between the source / drain region and the channel region. The drift regions enclose the source / drain regions and the isolation structure.

Owner:UNITED MICROELECTRONICS CORP

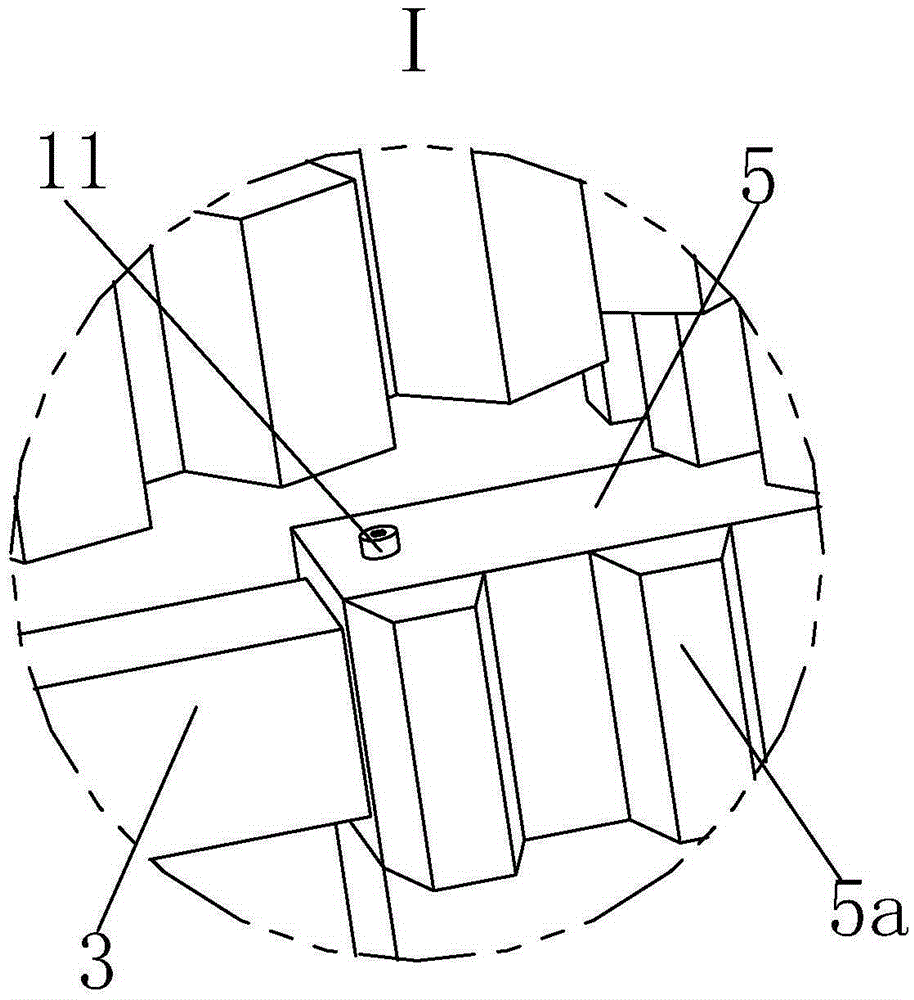

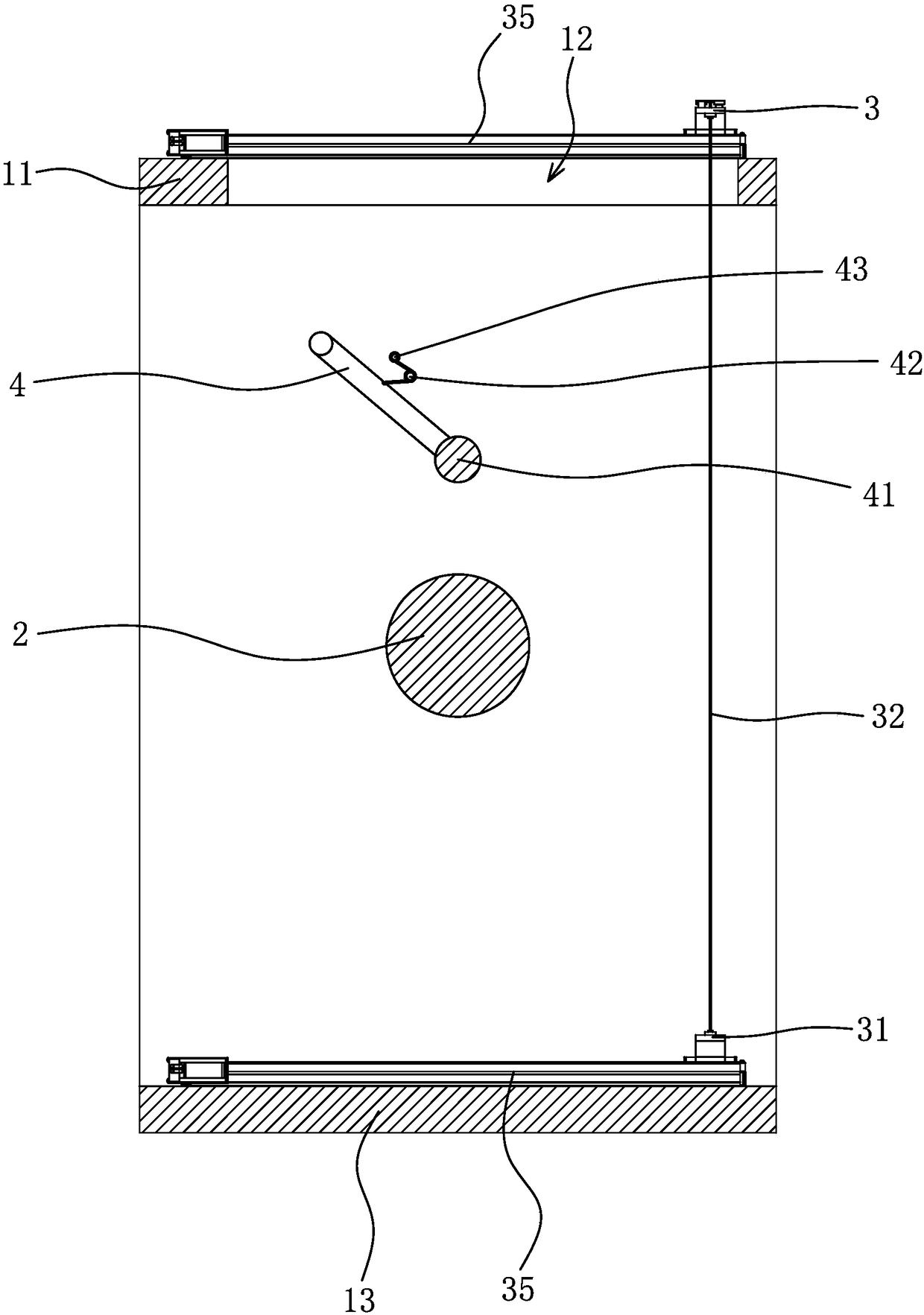

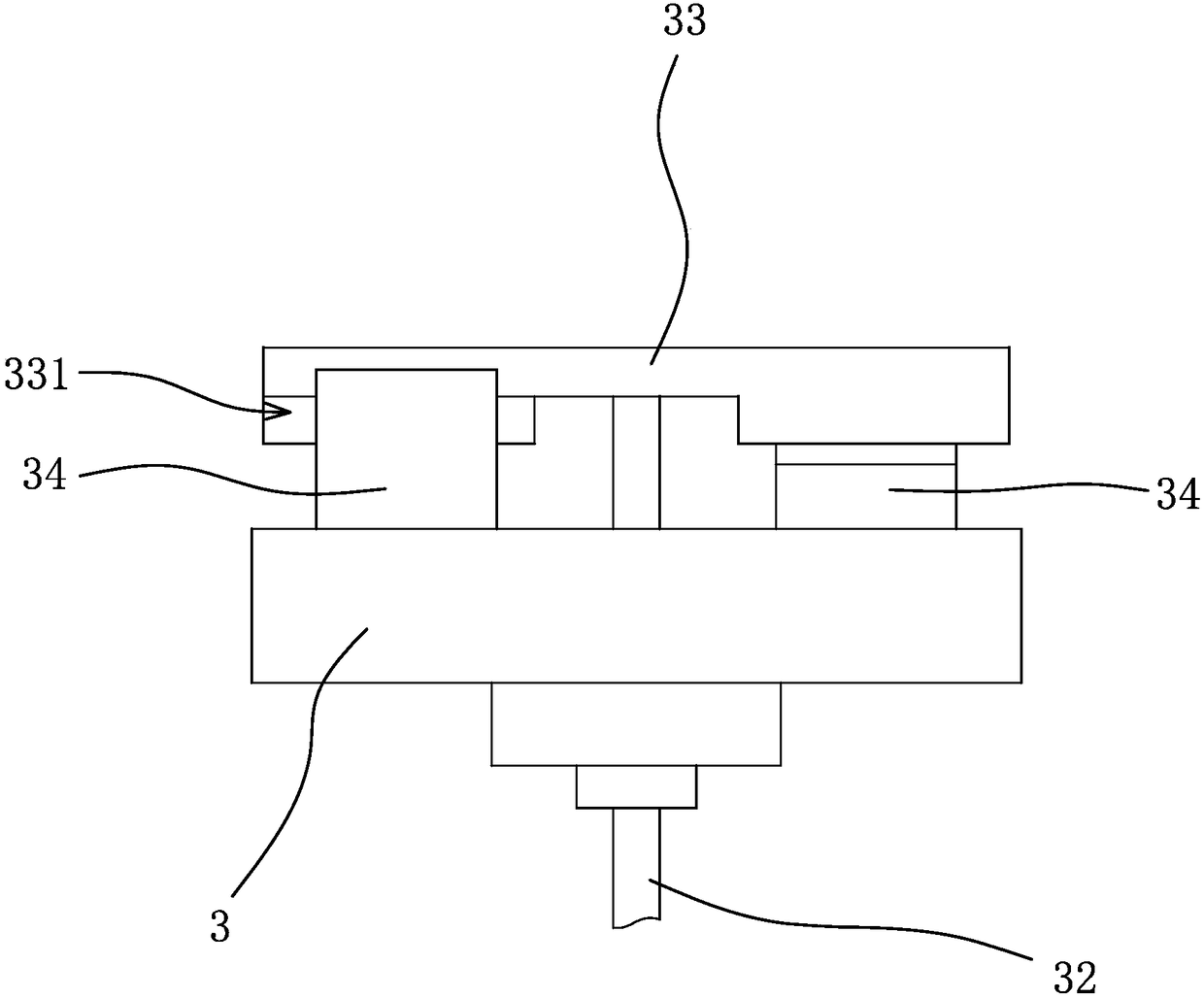

Laminaria japonica cutting equipment

PendingCN109109068AAvoid damageGuaranteed cutting qualityMetal working apparatusLaminaria japonicaEngineering

The invention relates to laminaria japonica cutting equipment. The equipment comprises a rack, conveying rollers, a conveying belt, a cutting tool and a driving mechanism. The driving mechanism at least comprises a main shaft. A supporting frame driving the cutting tool to move up and down is connected between the main shaft and the cutting tool. The lower end of the supporting frame is hinged tothe eccentric position of the main shaft. The conveying rollers rotate in an intermittent mode and drive the conveying belt to move forwards in an intermittent mode. An intermittent transmission mechanism used for controlling the conveying belt to stop or move when the cutting tool is located in a cutting position or a non-cutting position is connected between the main shaft and the conveying rollers. According to the laminaria japonica cutting equipment provided by the invention, the conveying belt moves in the intermittent mode, both laminaria japonica and the conveying belt are kept in a stationary state when the cutting tool cuts downwards, damage of the cutting tool to the conveying belt is reduced, and the laminaria japonica cutting quality is guaranteed; the cutting tool and the conveying rollers are driven by the same driving mechanism and are high in moving synchronism, and the equipment operating stability is high; and a pressing device can be used for stretching the laminaria japonica to be flat, it is guaranteed that the cutting width of the laminaria japonica each time is the same, and the cutting quality is improved.

Owner:福建省天源水产集团有限公司

High voltage metal oxide semiconductor transistor and fabricating method thereof

ActiveUS7485925B2Lowering sub-threshold currentAvoid leakage currentTransistorSolid-state devicesInsulation layerHigh pressure

A high voltage MOS transistor including a substrate, a well, a gate insulation layer, a gate, two drift regions, a channel region, a source / drain region and an isolation structure is provided. The well is disposed in the substrate and the gate insulation layer is disposed over the substrate. The gate is disposed over the gate insulation layer. The two drift regions are in the well at two sides of the gate and the width of the gate is smaller than or equal to that of the drift regions. The channel region is disposed between the drift regions and the width of the channel region is greater than that of the drift regions. The source / drain regions are formed within the drift regions. The isolation structure is disposed inside the drift regions between the source / drain region and the channel region. The drift regions enclose the source / drain regions and the isolation structure.

Owner:UNITED MICROELECTRONICS CORP

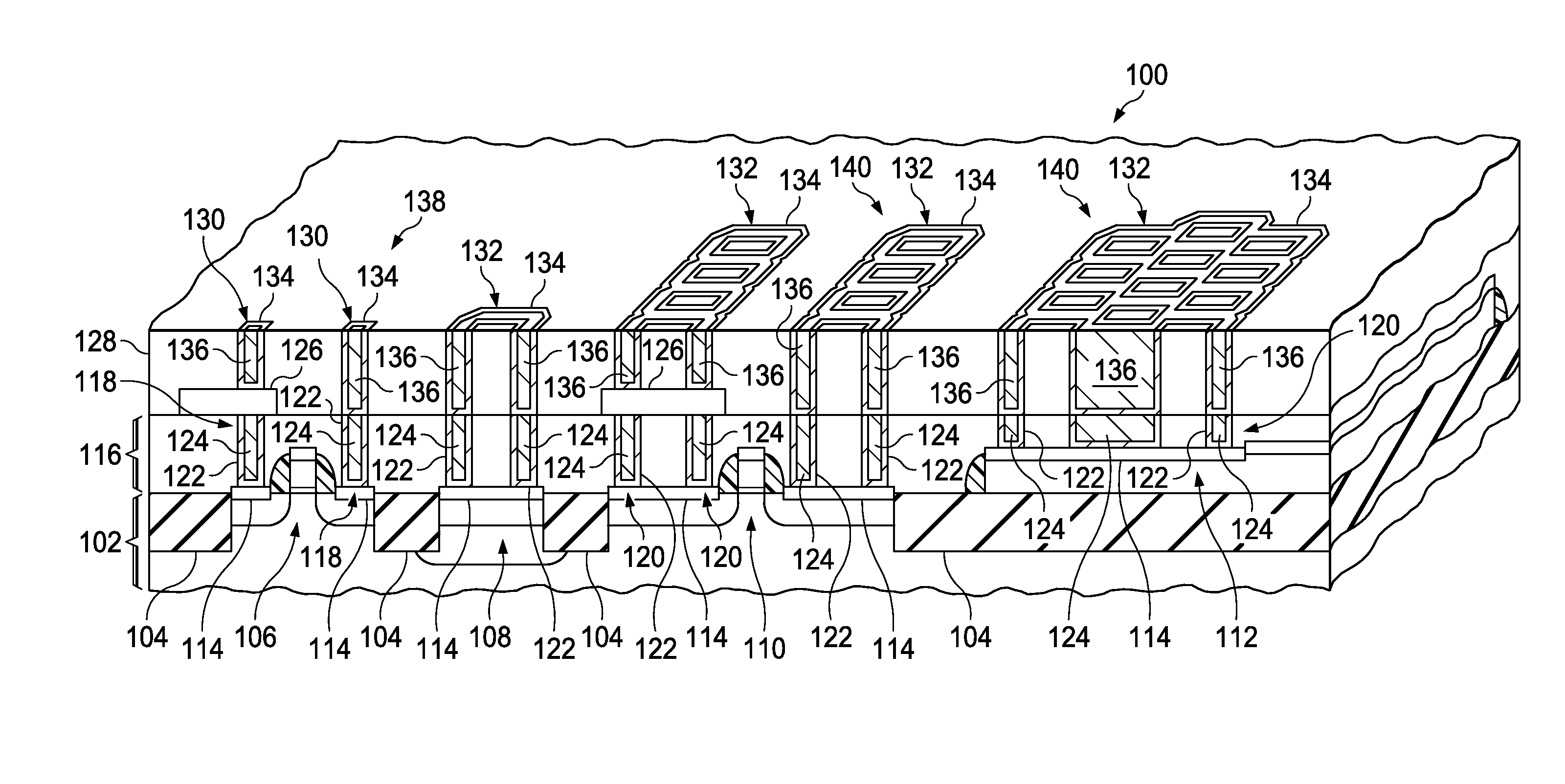

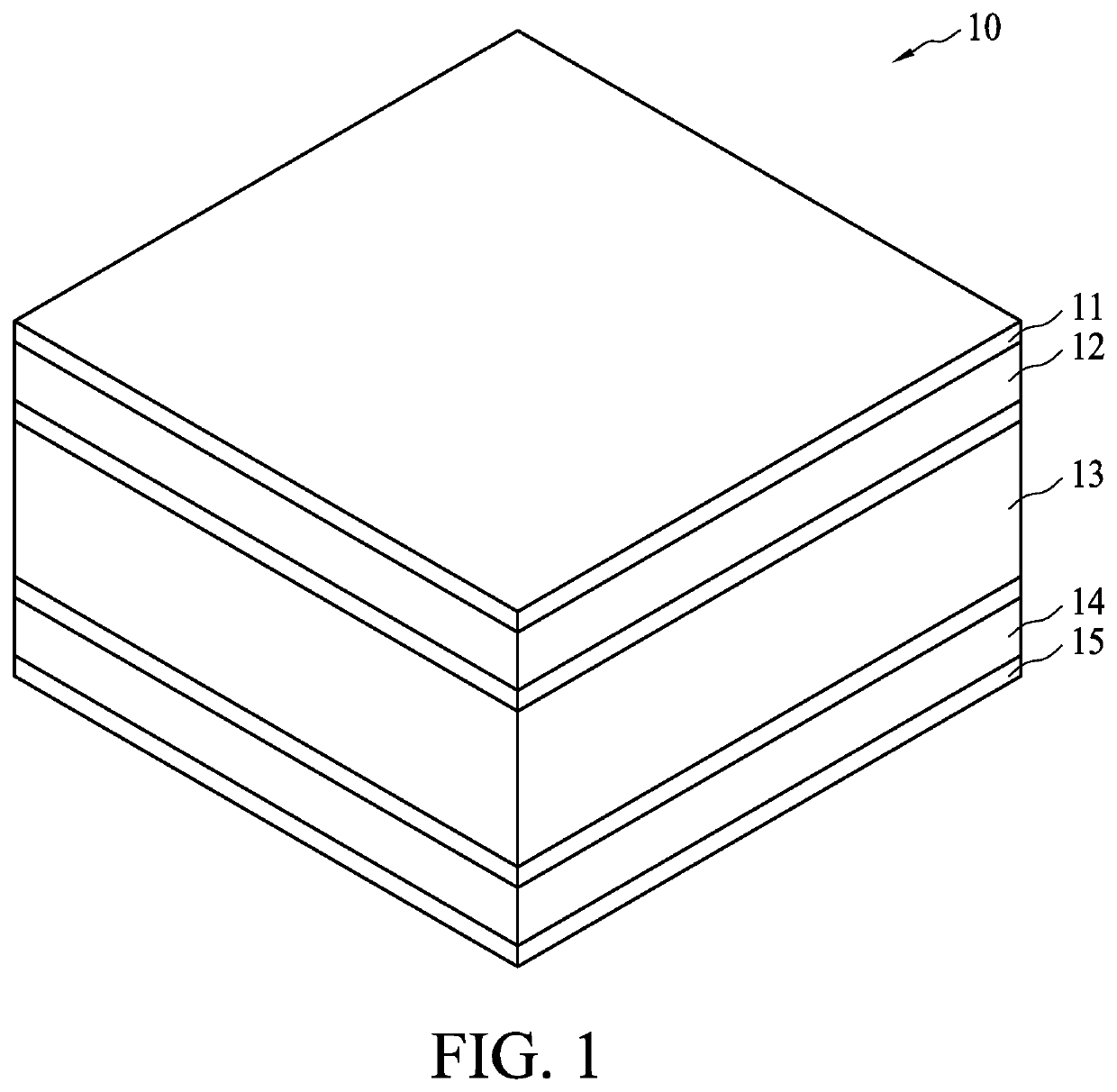

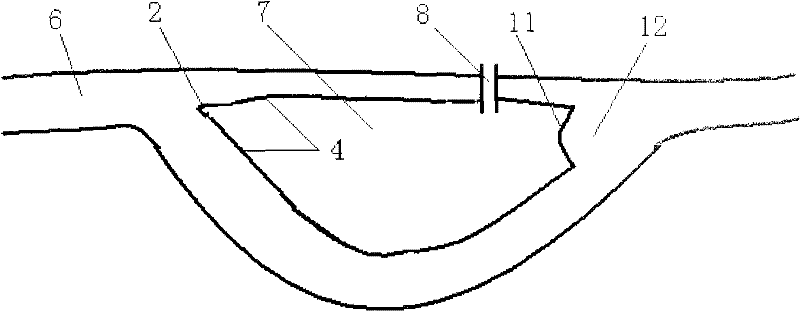

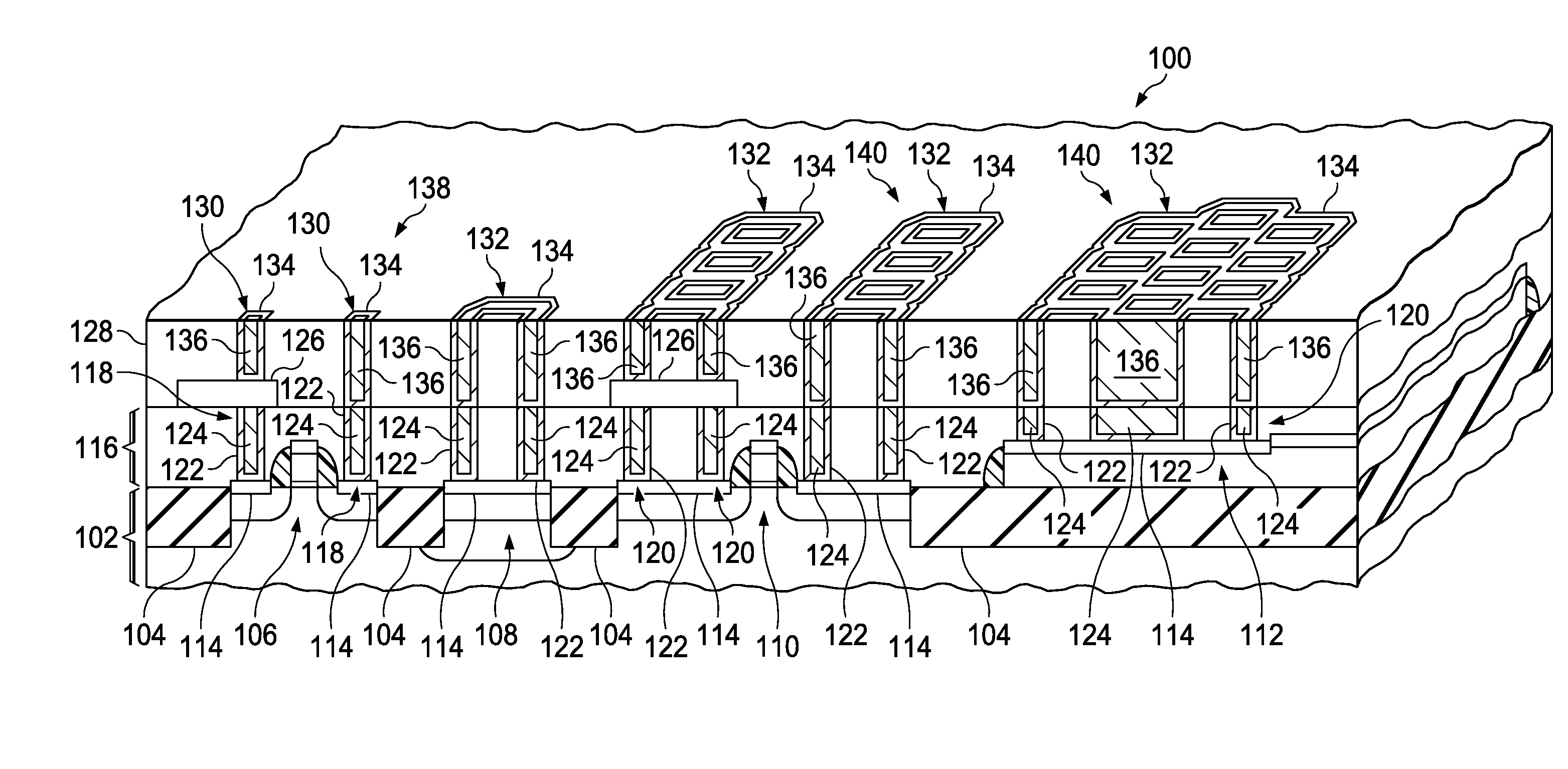

Low resistance stacked annular contact

ActiveUS20130082314A1Equal lengthEqual widthTransistorSemiconductor/solid-state device detailsMetal interconnectEngineering

An integrated circuit contains lower components in the substrate, a PMD layer, upper components over the PMD layer, lower contacts in the PMD layer connecting some upper components to some lower components, an ILD layer over the upper components, metal interconnect lines over the ILD layer, and upper contacts connecting some upper components to some metal interconnect lines, and also includes annular stacked contacts of lower annular contacts aligned with upper annular contacts. The lower contacts and upper contacts each have a metal liner and a contact metal on the liner. The lower annular contacts have at least one ring of liner metal and contact metal surrounding a pillar of PMD material, and the upper contacts have at least one ring of liner metal and contact metal surrounding a pillar of ILD material. The annular stacked contacts connect the metal interconnects to the lower components.

Owner:MIDWEST COMMUNITY DEV FUND IV +1

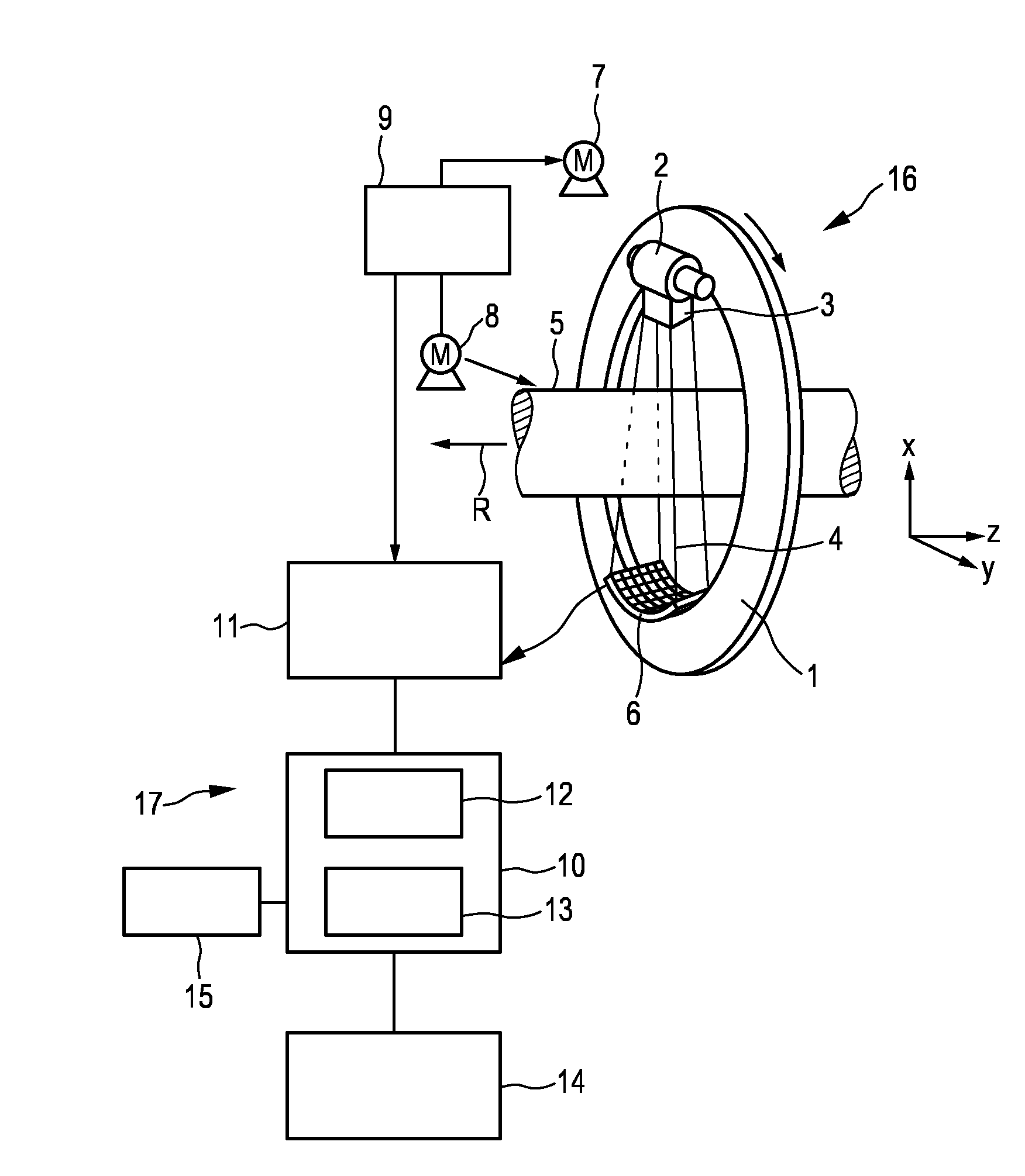

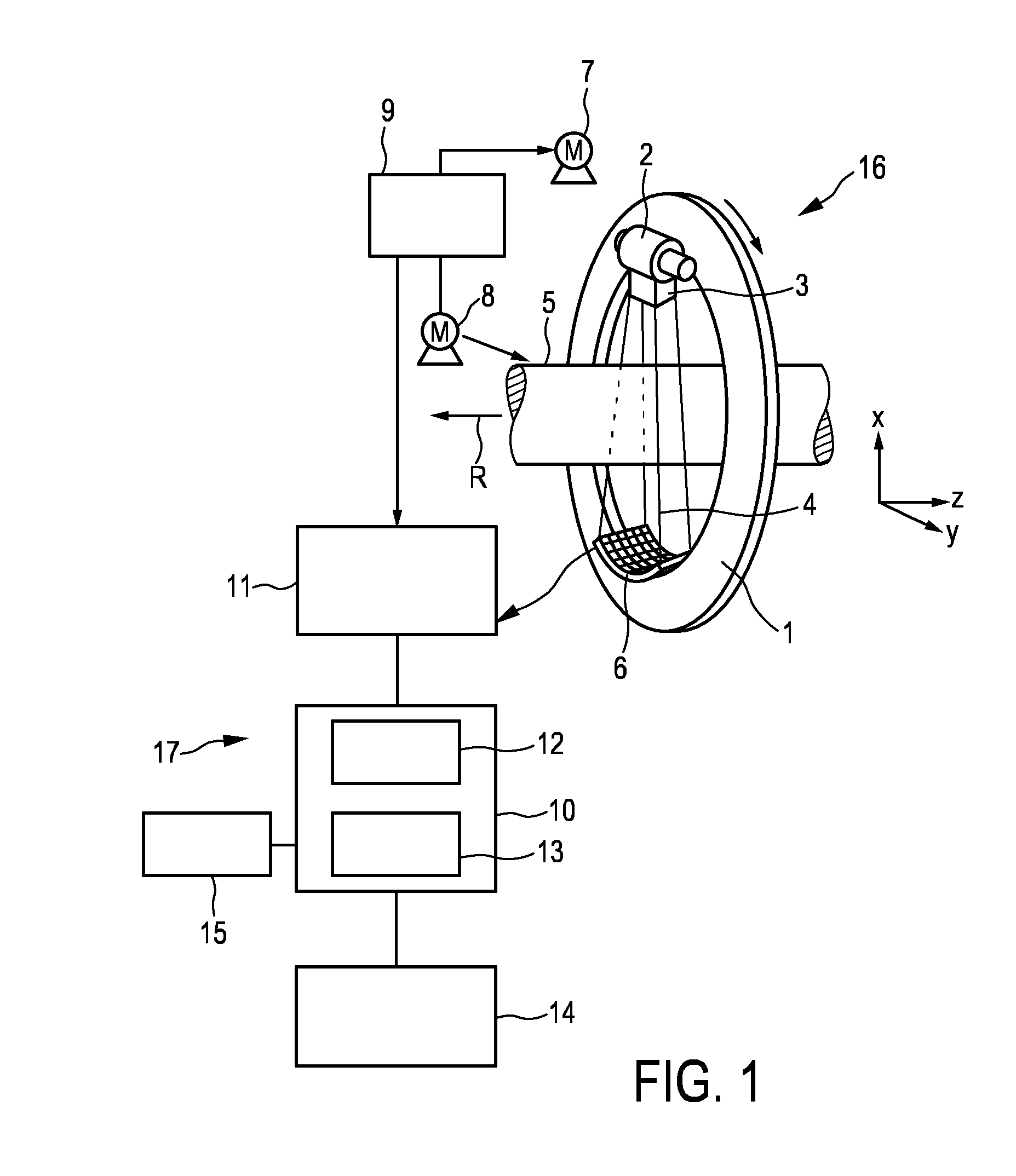

Image generation apparatus

ActiveUS20140153809A1Improved noise appearanceGood lookingImage enhancementReconstruction from projectionNoise levelDisplay device

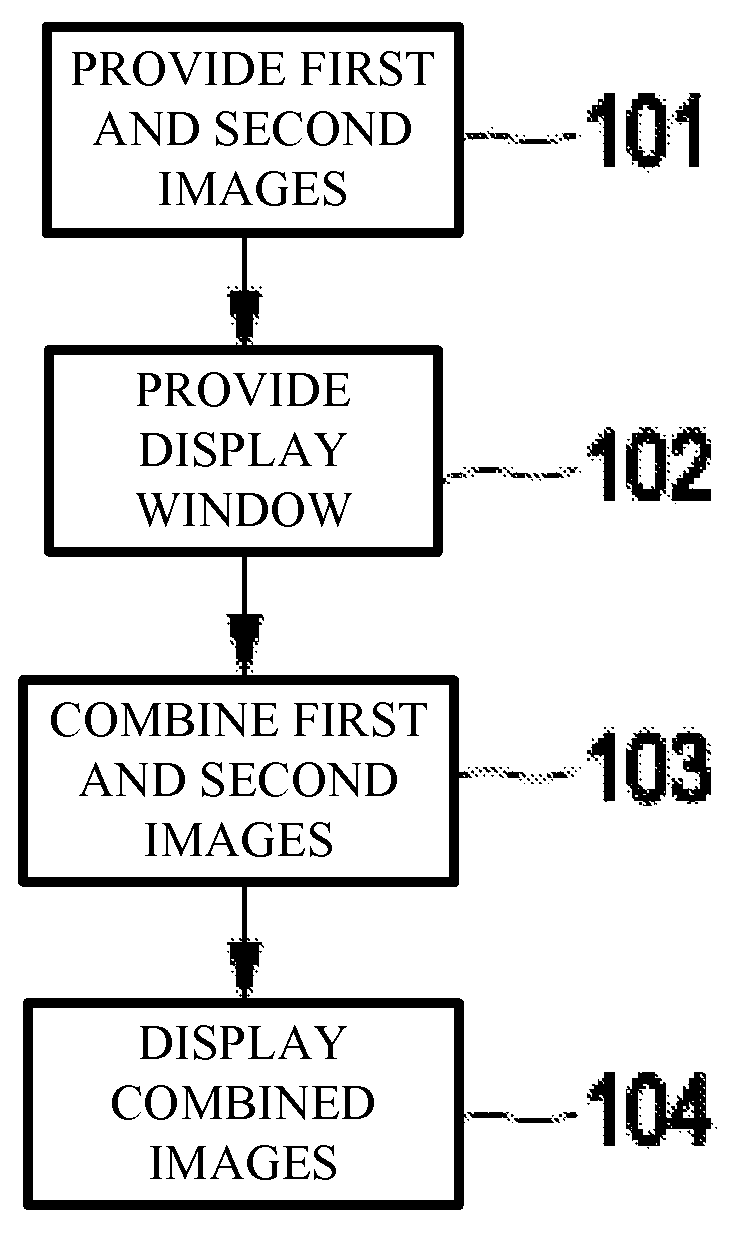

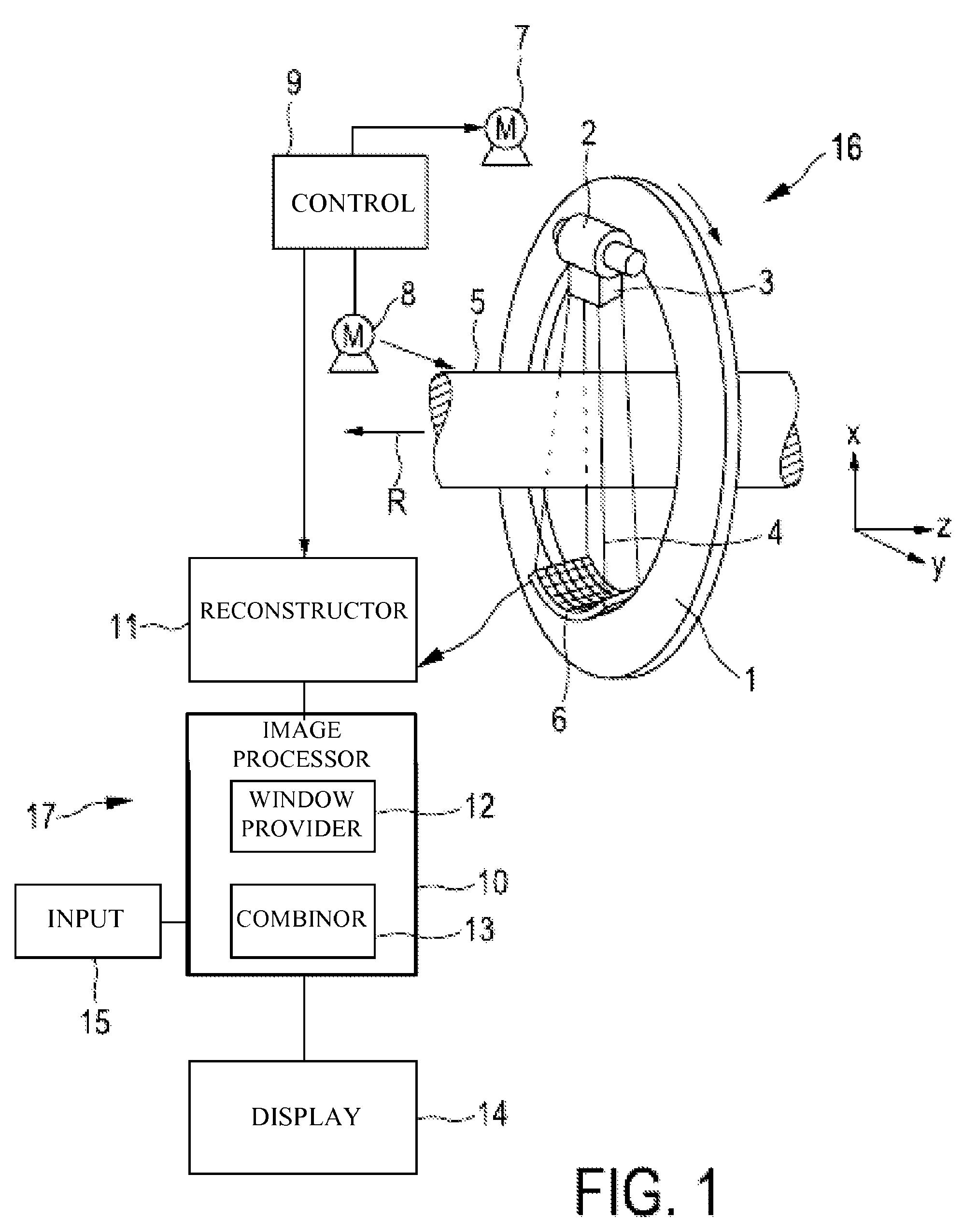

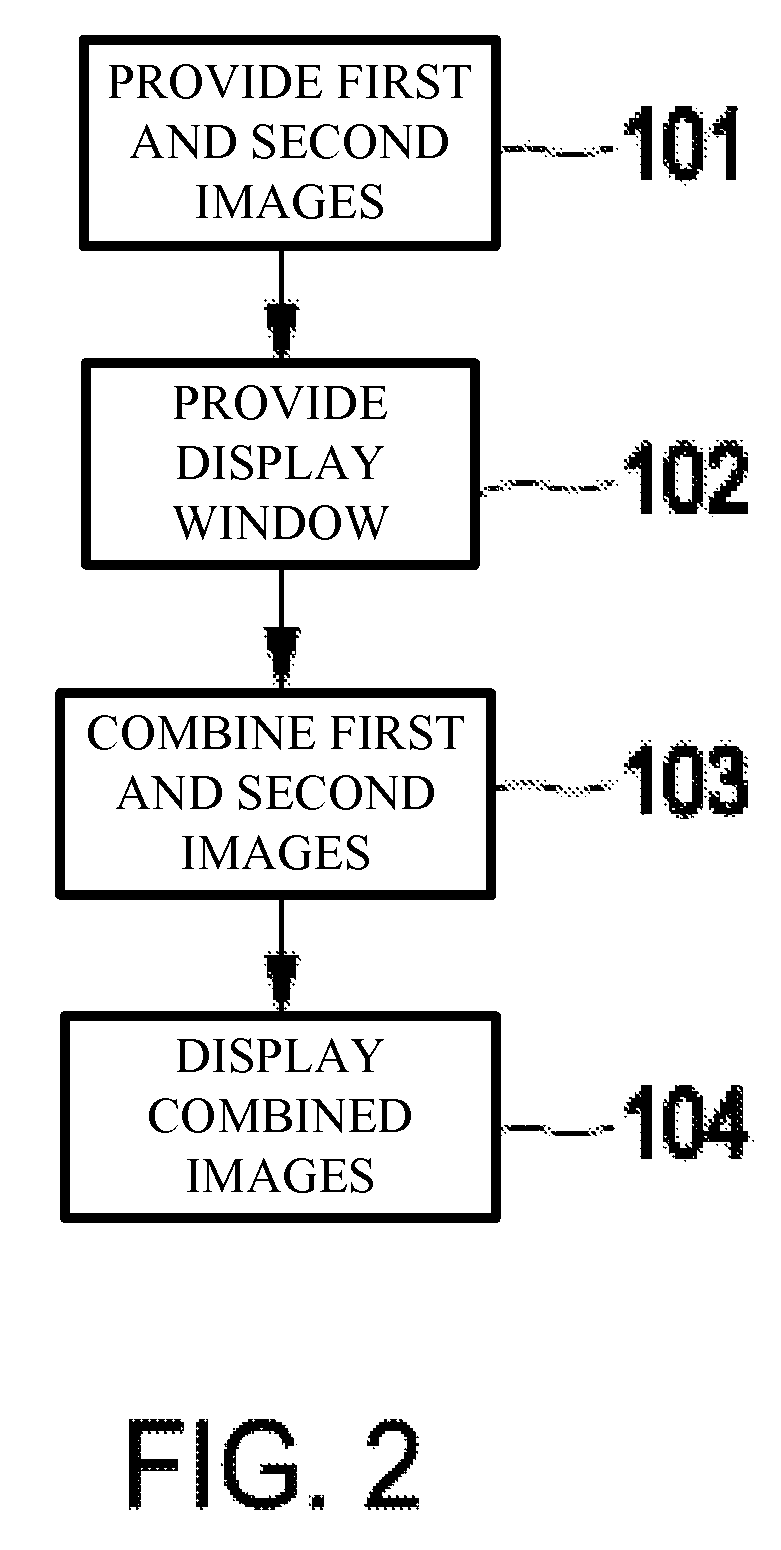

The invention relates to an image generation apparatus for generating an image of an object. An image providing unit (11, 16) provides a first image of the object and a second image of the object, wherein the first image has a smaller noise level than the second image. A display window providing unit (12) provides a display window being indicative of the range of image values shown on a display (14), and a combining unit (13) generates a combination image by combining the first image and the second image depending on the window width of the provided display window. This allows considering the influence of the display window on the noise appearance. Thus, by taking into account the first image and the second image having different noise levels and the provided display window, a combined image can be generated, which has an improved noise appearance.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

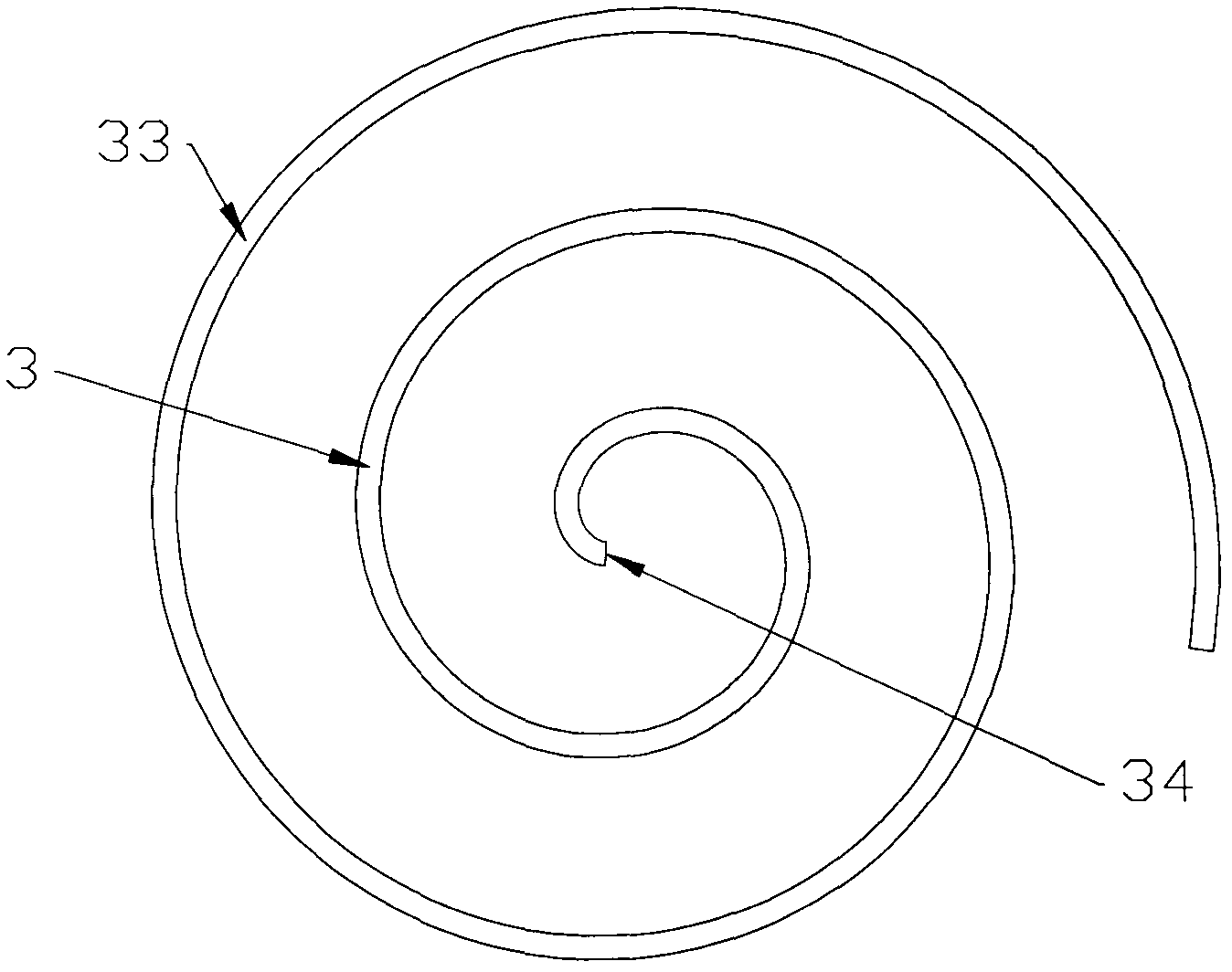

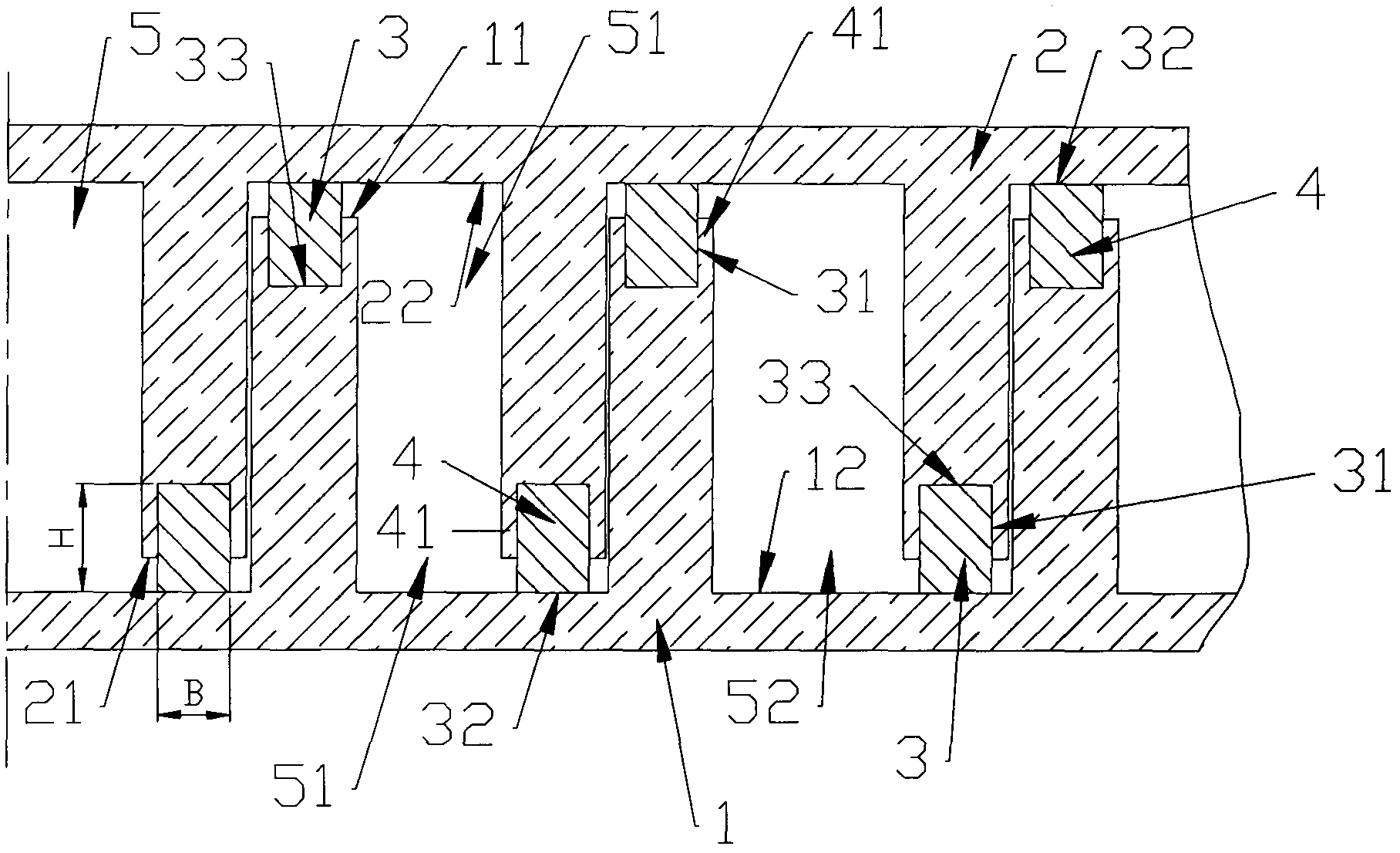

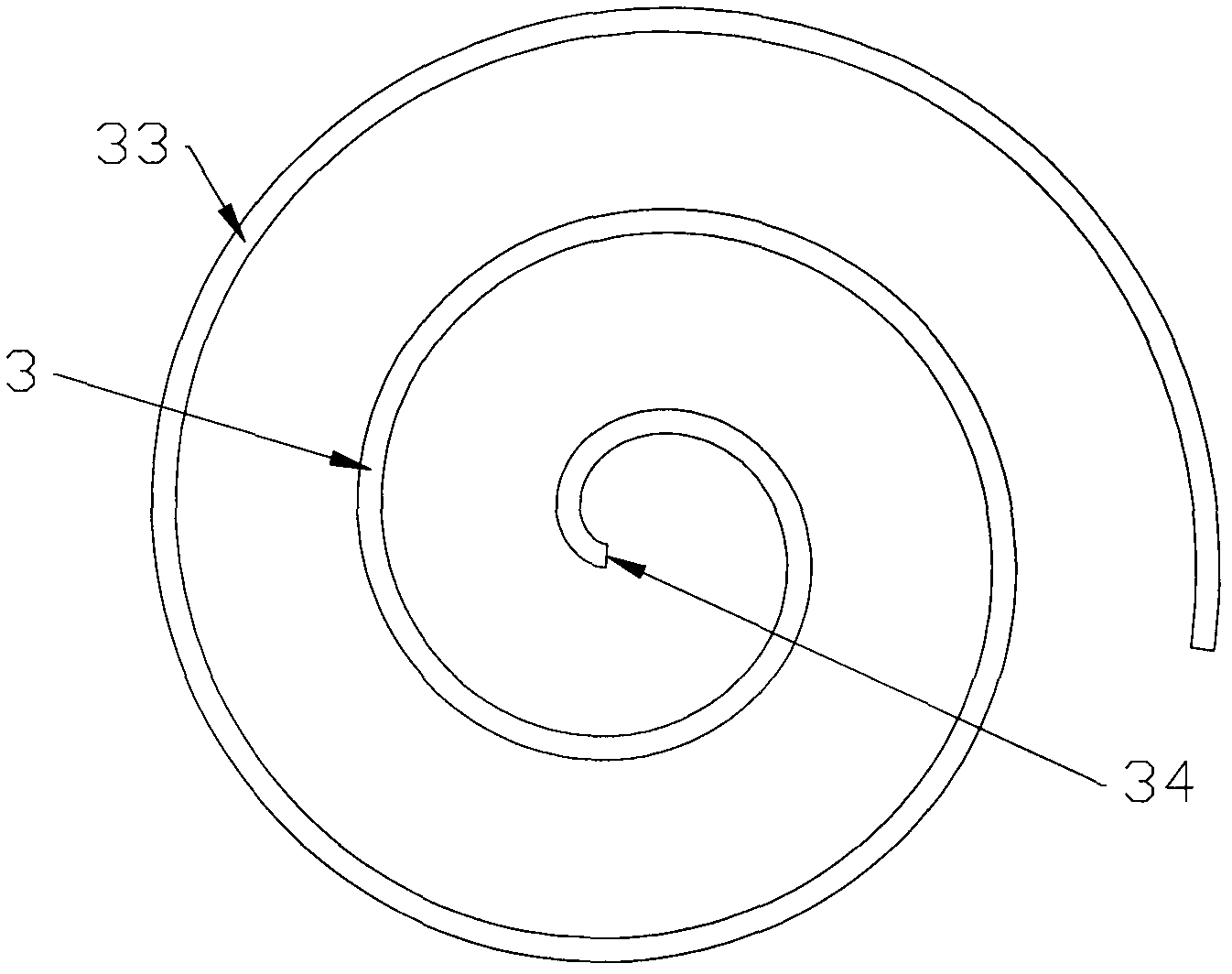

Method for preparing sealing strip of scroll compressor

ActiveCN102585436AImprove mechanical propertiesImprove insulation performanceSealing arrangement for pumpsMachines/enginesFiberThermal expansion

The invention provides a method for preparing a sealing strip of a scroll compressor. The sealing strip prepared by using the method has high strength, a small thermal expansion coefficient, a small abrasion rate and long service life. The preparation method comprises the following step of mixing the following components in parts by weight: 20-30 parts of polybenzimidazole, 40-50 parts PEEK (Polyether-Ether-Ketone), 5-10 parts of carbon fiber and 3-5 parts of molybdenum disulfide, and carrying out hot-press forming.

Owner:NANJING COMPTECH COMPOSITES CORP

Image generation apparatus

ActiveUS9299172B2Improved noise appearanceGood lookingImage enhancementReconstruction from projectionNoise levelDisplay device

The invention relates to an image generation apparatus for generating an image of an object. An image providing unit (11, 16) provides a first image of the object and a second image of the object, wherein the first image has a smaller noise level than the second image. A display window providing unit (12) provides a display window being indicative of the range of image values shown on a display (14), and a combining unit (13) generates a combination image by combining the first image and the second image depending on the window width of the provided display window. This allows considering the influence of the display window on the noise appearance. Thus, by taking into account the first image and the second image having different noise levels and the provided display window, a combined image can be generated, which has an improved noise appearance.

Owner:KONINK PHILIPS ELECTRONICS NV

Bridge structure and assembly method thereof

PendingCN111600253AEasy to assemble and disassembleEasy to assembleElectrical apparatusMetal working apparatusGear wheelEngineering

The invention discloses a bridge structure and an assembly method thereof, relates to the technical field of bridges, and solves the problems that the installation width cannot be adjusted according to a cable with a larger diameter and the assembly is inconvenient. The invention discloses a bridge structure and an assembly method thereof. Connecting plate, two connecting sleeves are mounted at each of the two ends of the inner side of the connecting plate; an adjusting rod is mounted on the inner side of the connecting sleeve; ten limiting holes are formed in the inner side of the adjusting rod; a fixed column is mounted on the inner side of one of the limiting holes; a driven plate is mounted at the upper end of the fixed column; a rotary knob is installed at the upper end of a driven plate, an adjusting plate is installed on one side of an adjusting rod, a sealing plate is installed on one side of the adjusting plate, five limiting grooves are formed in one side of the lower end ofthe sealing plate, placing plates are installed on the two sides of the lower end of a connecting plate, and driving gears are installed at one ends of the inner sides of the placing plates. The installation width can be adjusted according to a cable with a large diameter, and assembling is convenient.

Owner:JIANGSU YONGXING ELECTRIC ENERGY EQUIP TECH CO LTD

Tear propagation resistant film-backed adhesive tape

InactiveUS20070079918A1Improve tear resistanceLower resistanceFilm/foil adhesivesAdhesive articlesAdhesiveEngineering

Adhesive tape with a backing of a polymer material and with an adhesive, wherein the backing material is composed of a multiplicity of strips which are oriented in machine direction and aligned in machine direction, the multiplicity of strips being fixed to one another by means of an auxiliary backing film.

Owner:TESA SE

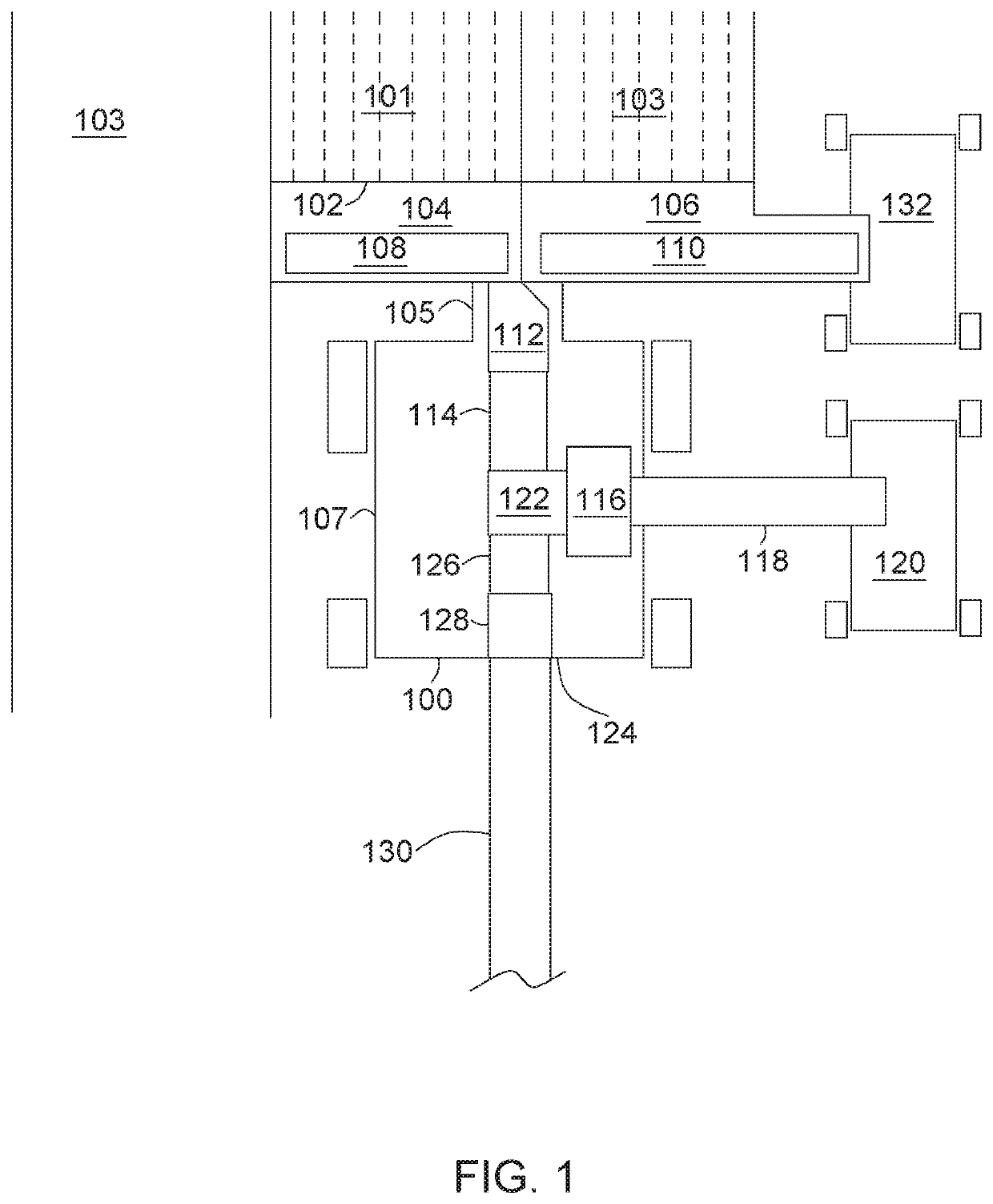

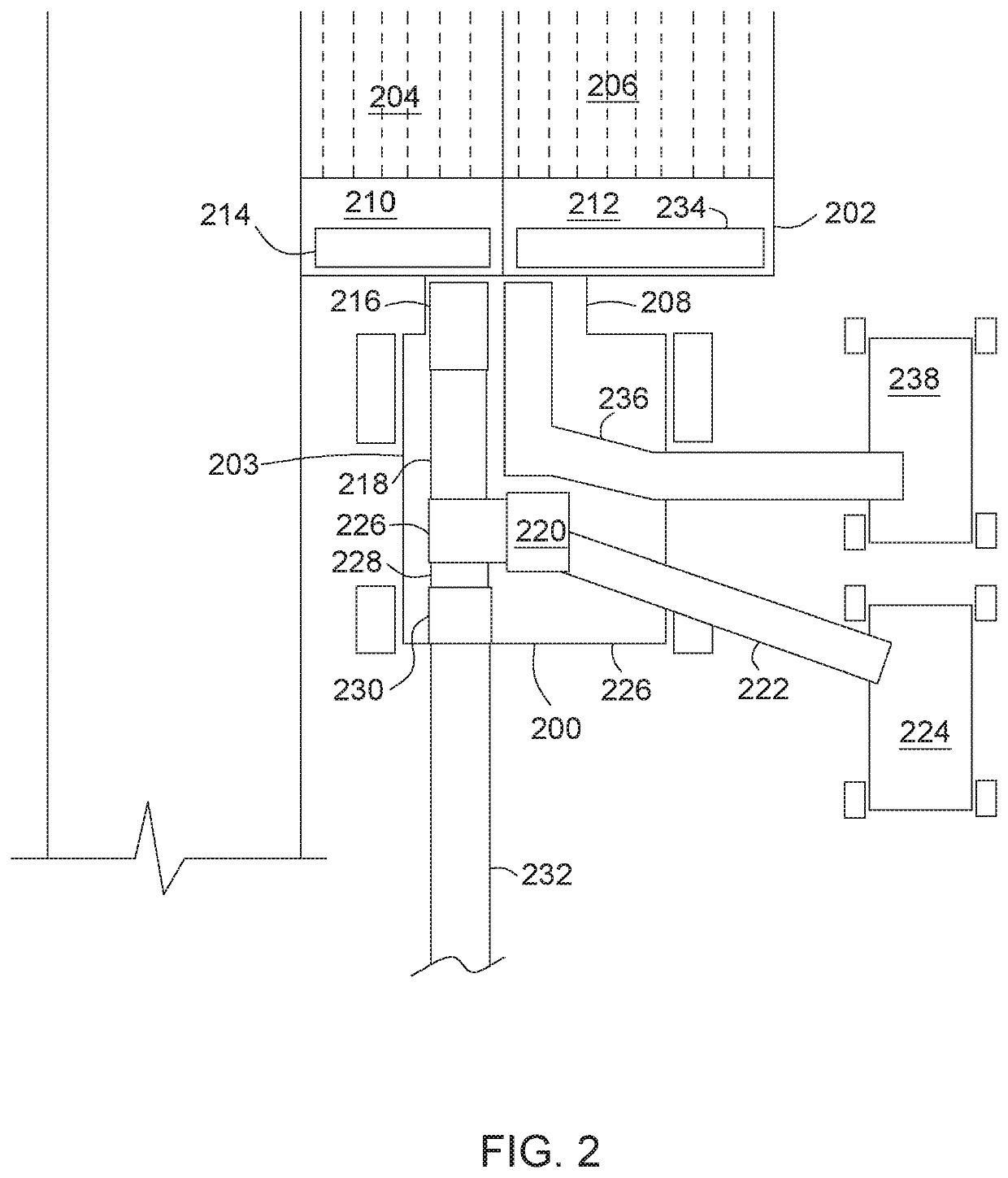

Multicrop harvesting

Compound headers and combine harvesters that include compound headers are disclosed. The compound headers may include two or more crop harvester types that are operable to harvest different crops simultaneously, such as different crops grown in the same field in an intercropped relationship. The simultaneously harvested crops may be separated into individual crop flows that are handled separately from each other.

Owner:DEERE & CO

Transparent thin plate

InactiveUS8692130B2Easy to identifyEqual widthConductive layers on insulating-supportsMagnetic/electric field screeningThin slabTransmittance

A transparent thin plate including a transparent substrate in a sheet form, a mesh layer formed on a surface of the transparent substrate and made of an opaque material having a structure wherein an outline of meshes is made of bands that are very thin and have a substantially equal width, and having a light transmittance of 50% or more. The transparent thin plate also includes a colored layer that is arranged in a state in which the colored layer is laminated in a partial area of the mesh layer and on the surface of the mesh layer, and has a color different from that of the opaque material constituting the mesh layer.

Owner:NISSHA PRINTING COMPANY

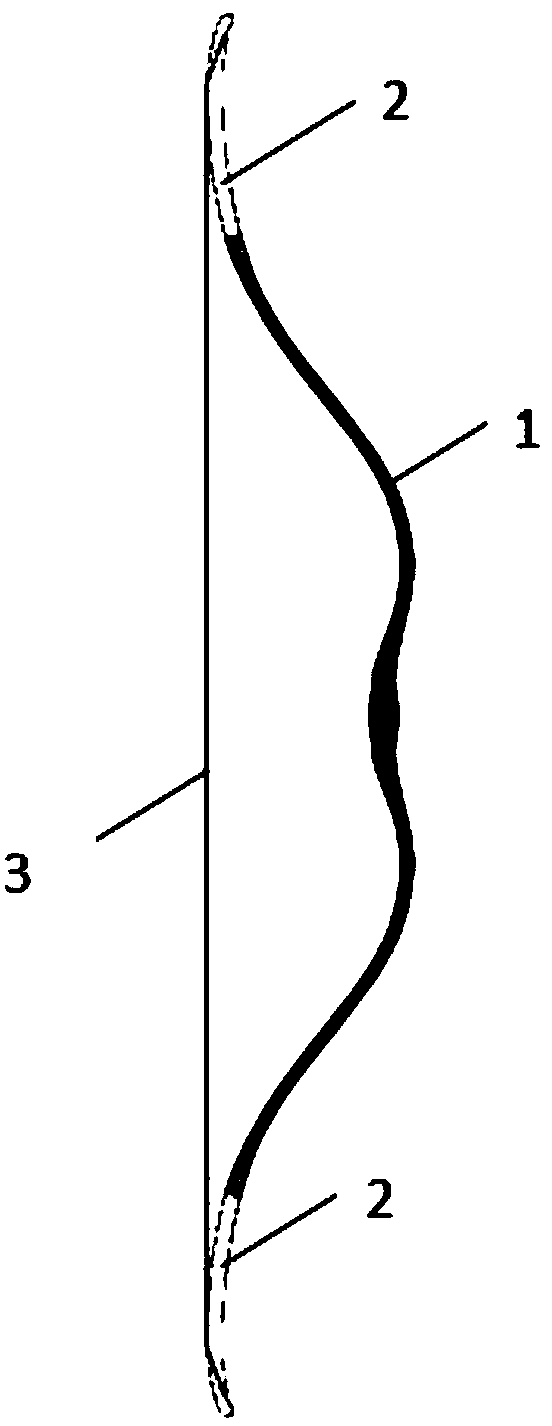

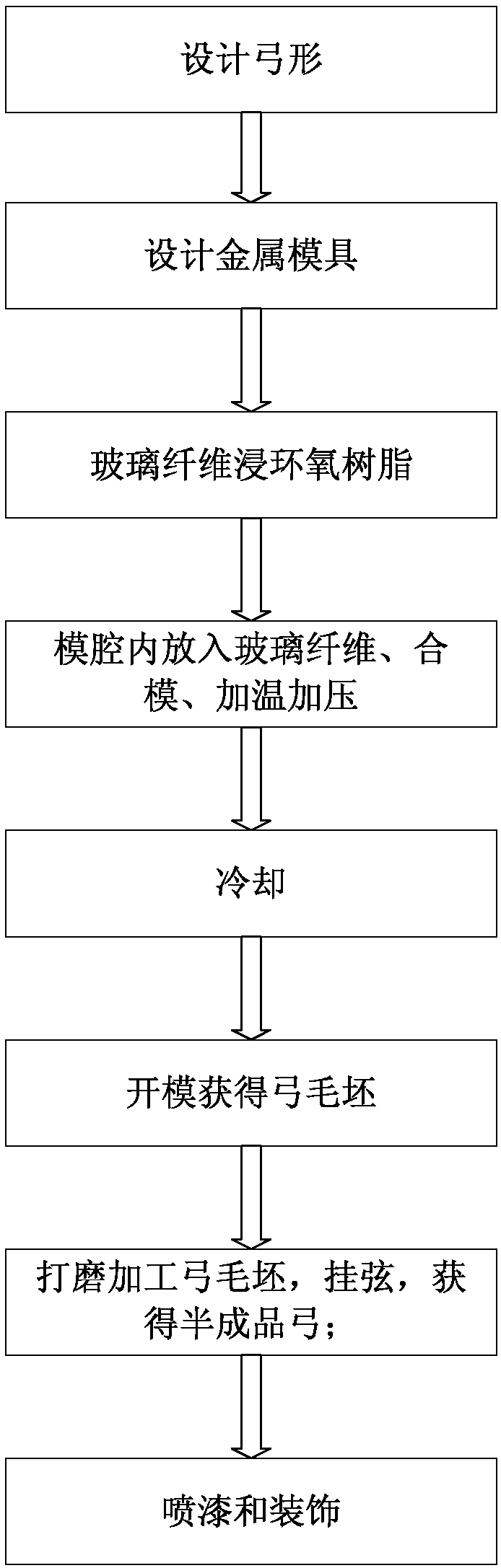

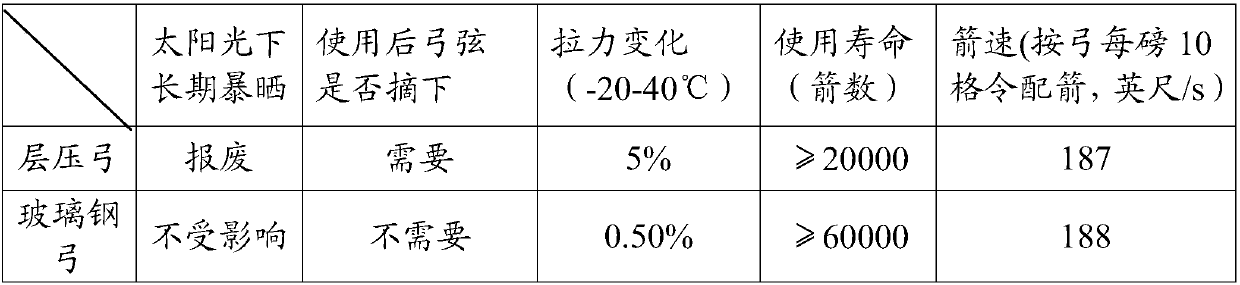

Glass fiber reinforced plastics bow and machining method thereof

PendingCN108120341AGood weather resistanceExtended service lifeBows/crossbowsGlass fiberWeather resistance

The invention relates to a glass fiber reinforced plastics bow comprising a bow arm made of glass fiber, two bow tips symmetrically disposed at two ends of the bow arm, a bow string connected with thetwo bow tips and a grip attached to the bow arm. The bow tips are made of a wood material or glass fiber. The invention also provides a glass fiber reinforced plastics bow machining method. A glass fiber reinforced plastics forming process is applied to the machining of a traditional bow; the bow arm is made of glass fiber reinforced plastics by an integrated hot-pressing process, the glass fiberreinforced plastics are not affected by the external environment and temperature and mechanical properties of the glass fiber reinforced plastics bow are not affected by ambient temperature and humidity changes when the glass fiber reinforced plastics are stored or used, so that the glass fiber reinforced plastics bow not only improves environmental weather resistance, but also prolongs service life, and meets the use requirements of bow enthusiasts.

Owner:梁志

Low resistance stacked annular contact

ActiveUS8652855B2Equal lengthEqual widthTransistorSemiconductor/solid-state device detailsMetal interconnectEngineering

An integrated circuit contains lower components in the substrate, a PMD layer, upper components over the PMD layer, lower contacts in the PMD layer connecting some upper components to some lower components, an ILD layer over the upper components, metal interconnect lines over the ILD layer, and upper contacts connecting some upper components to some metal interconnect lines, and also includes annular stacked contacts of lower annular contacts aligned with upper annular contacts. The lower contacts and upper contacts each have a metal liner and a contact metal on the liner. The lower annular contacts have at least one ring of liner metal and contact metal surrounding a pillar of PMD material, and the upper contacts have at least one ring of liner metal and contact metal surrounding a pillar of ILD material. The annular stacked contacts connect the metal interconnects to the lower components.

Owner:MIDWEST COMMUNITY DEV FUND IV +1

A marking vehicle for three-lane roads

The invention relates to a marking vehicle used for a three-lane road. The marking vehicle mainly comprises a vehicle body. A central frame is arranged on the vehicle body. A No.1 sliding holder and a No.2 sliding holder are installed on the central frame. The No.1 sliding holder and the No.2 sliding holder are in sliding connection with a No.1 bearing holder and a No.2 bearing holder respectively. A No.1 rack is installed on the No.1 bearing holder and a No.2 rack is installed on the No.2 bearing holder. The No.1 rack is engaged to a No.1 gear. The No.1 gear is connected with a No.2 gear and transmission gears. The No.2 gear is engaged to the No.2 rack. Two idle gears are arranged between the two transmission gears. Plugging covers are arranged at the lower end of the No.1 bearing holder and the lower end of the No.2 bearing holder respectively. An opening is arranged beside each plugging cover. The upper end of each plugging cover is pressed against a bar-shaped pipe. The bar-shaped pipe is connected with a raw material storage box. Annular teeth are arranged at the circumferential outer end of each plugging cover. The annular teeth are engaged to an auxiliary gear. The marking vehicle has functions of ensuring marking length and marking interval constant and marking of roads with different lane widths.

Owner:广州市公路实业发展有限公司

Method of manufacturing thin film magnetic head

InactiveUS20080169198A1Suppress fluctuationsSuppress nonuniformityNanomagnetismHeads using thin filmsDivergence angleMagnetic poles

A method of manufacturing a thin film magnetic head can suppress dulling of a magnetic pole tip portion of a write magnetic pole during ion milling carried out when forming the write magnetic pole, and can also suppress fluctuation and nonuniformity in the write core width of the write magnetic pole. The method includes a laminating process of successively laminating a lower magnetic pole layer, a gap layer on the lower magnetic pole layer, and an upper magnetic pole layer on the gap layer to produce a laminated film and an ion milling process of irradiating the laminated film produced by successively laminating the lower magnetic pole layer, the gap layer, and the upper magnetic pole layer from above with an ion beam to trim the laminated film to a narrow width and thereby form the lower magnetic pole layer, the gap layer, and the upper magnetic pole layer into a write magnetic pole. During the ion milling process, trimming is carried out using an ion beam with a first divergence angle and then trimming is carried out using an ion beam with a second divergence angle that differs to the first divergence angle.

Owner:FUJITSU LTD

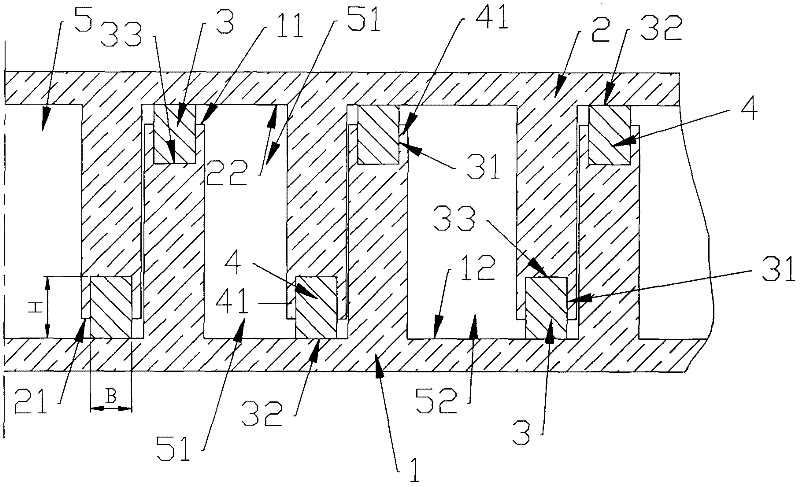

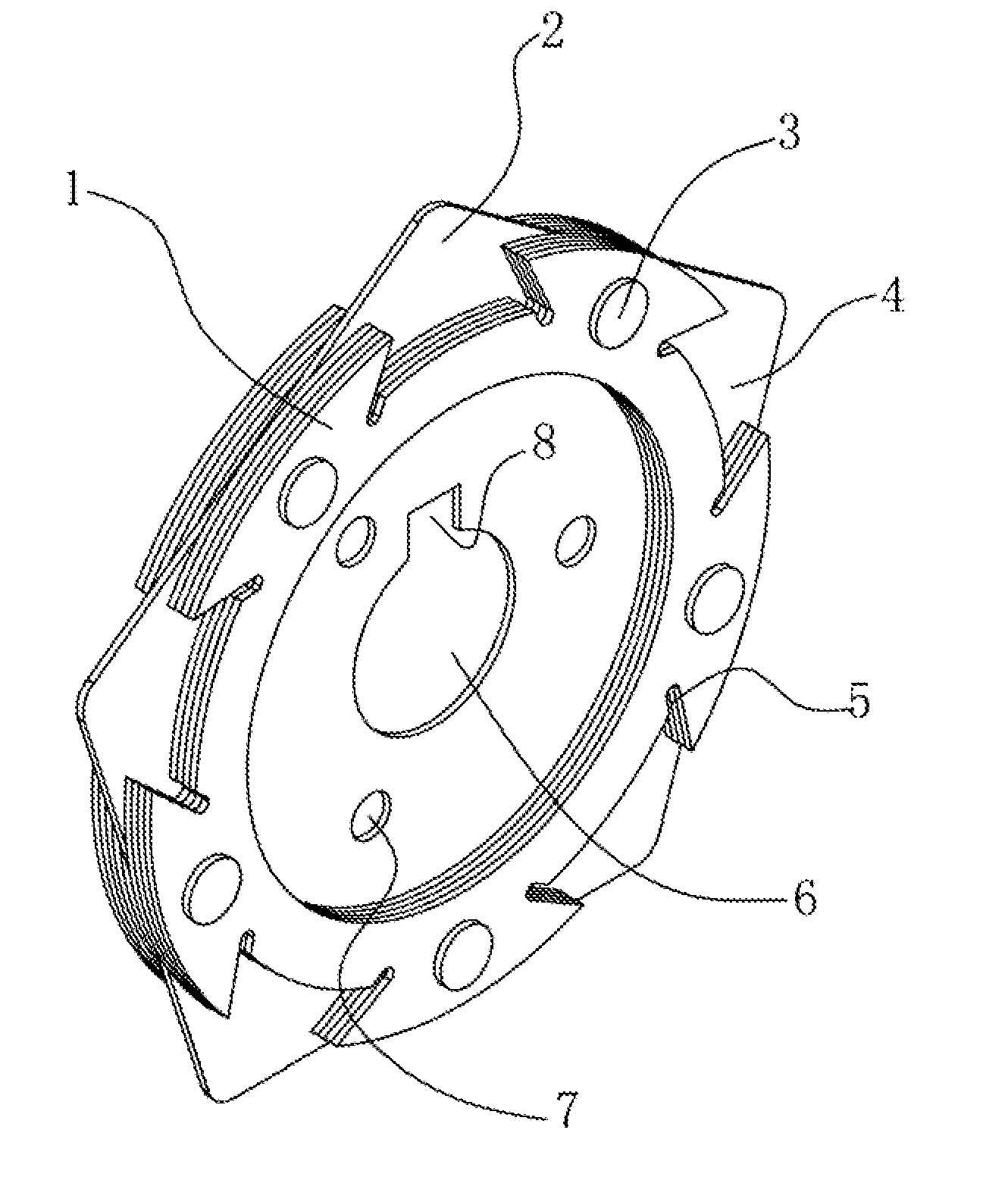

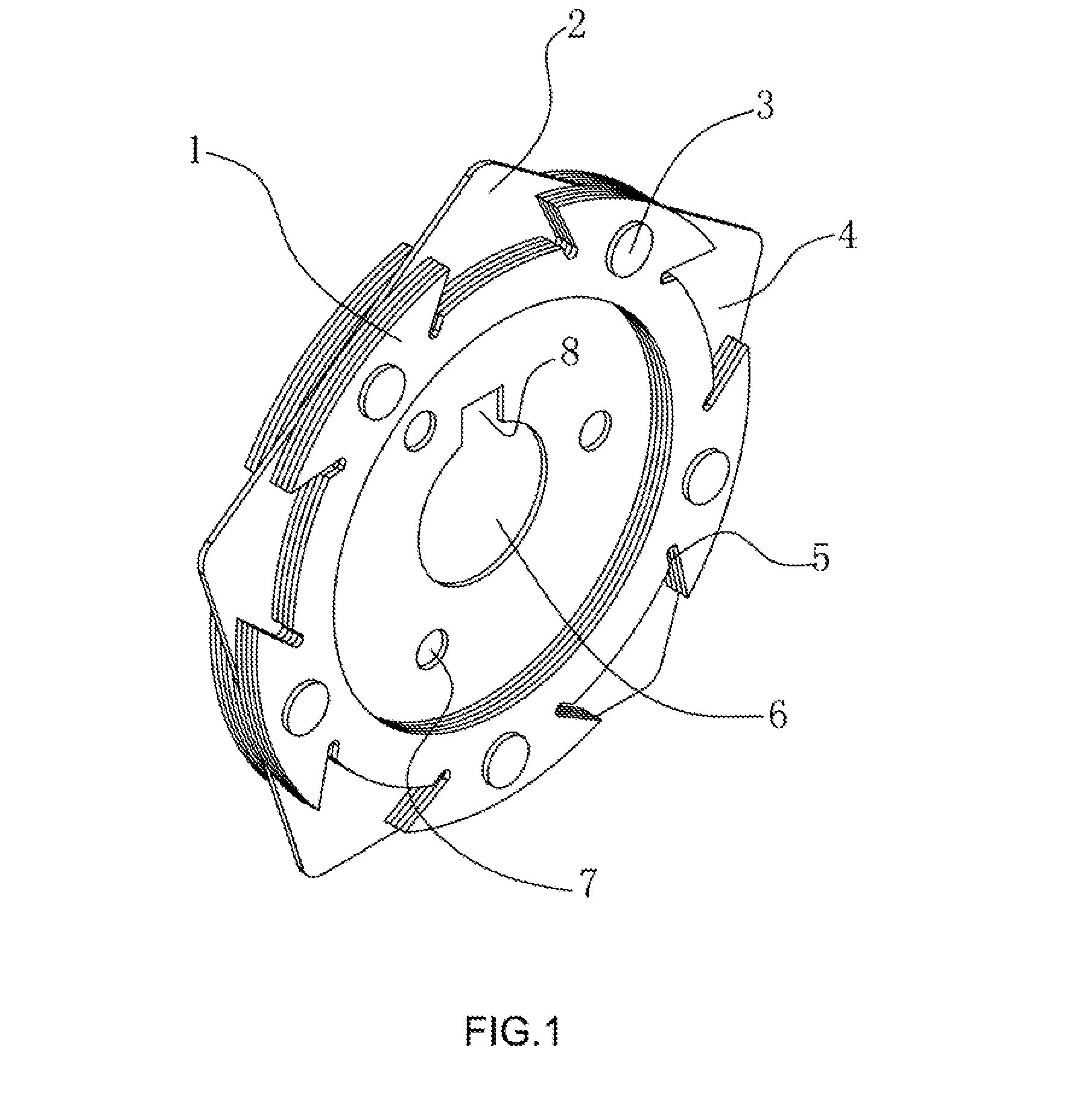

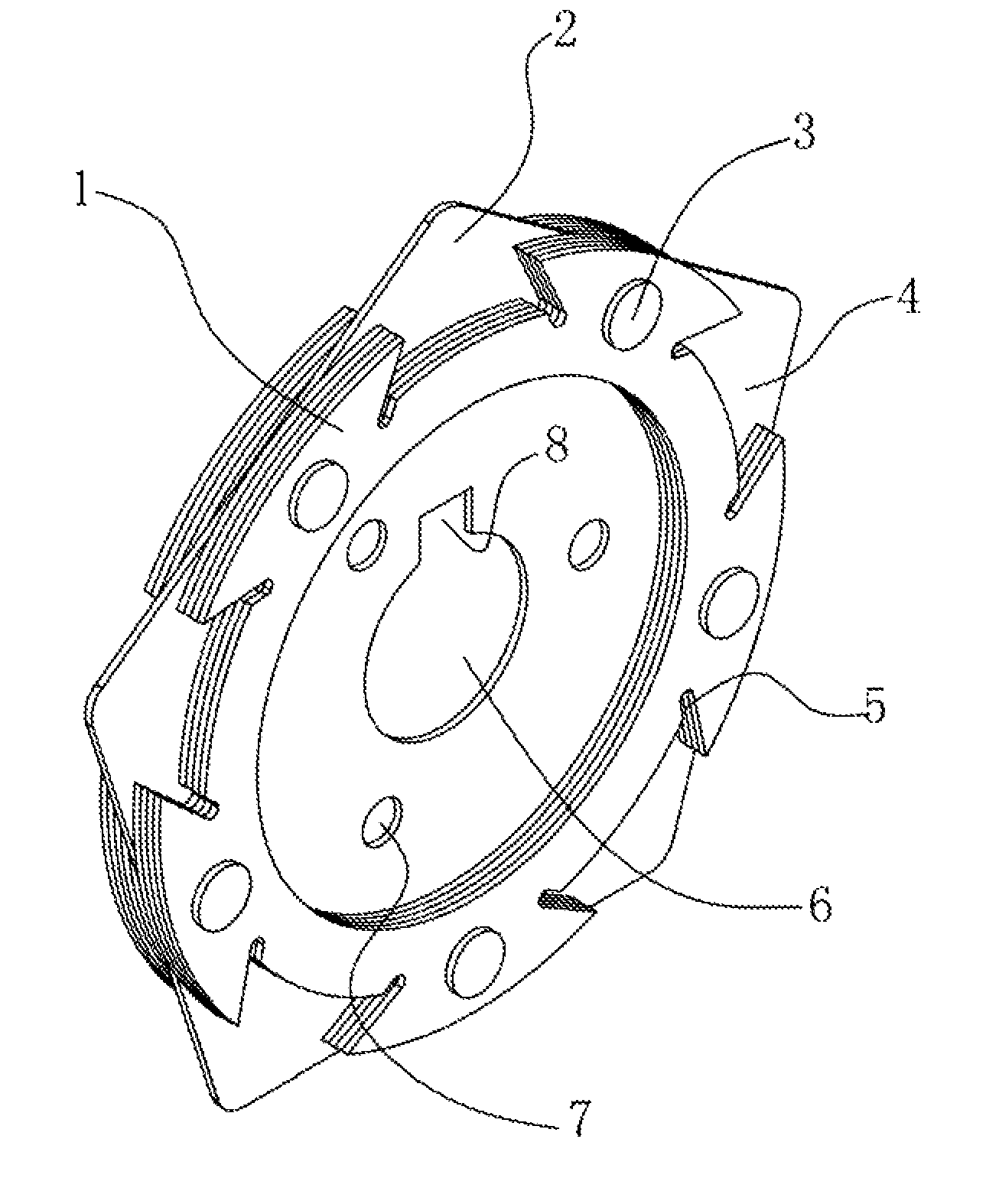

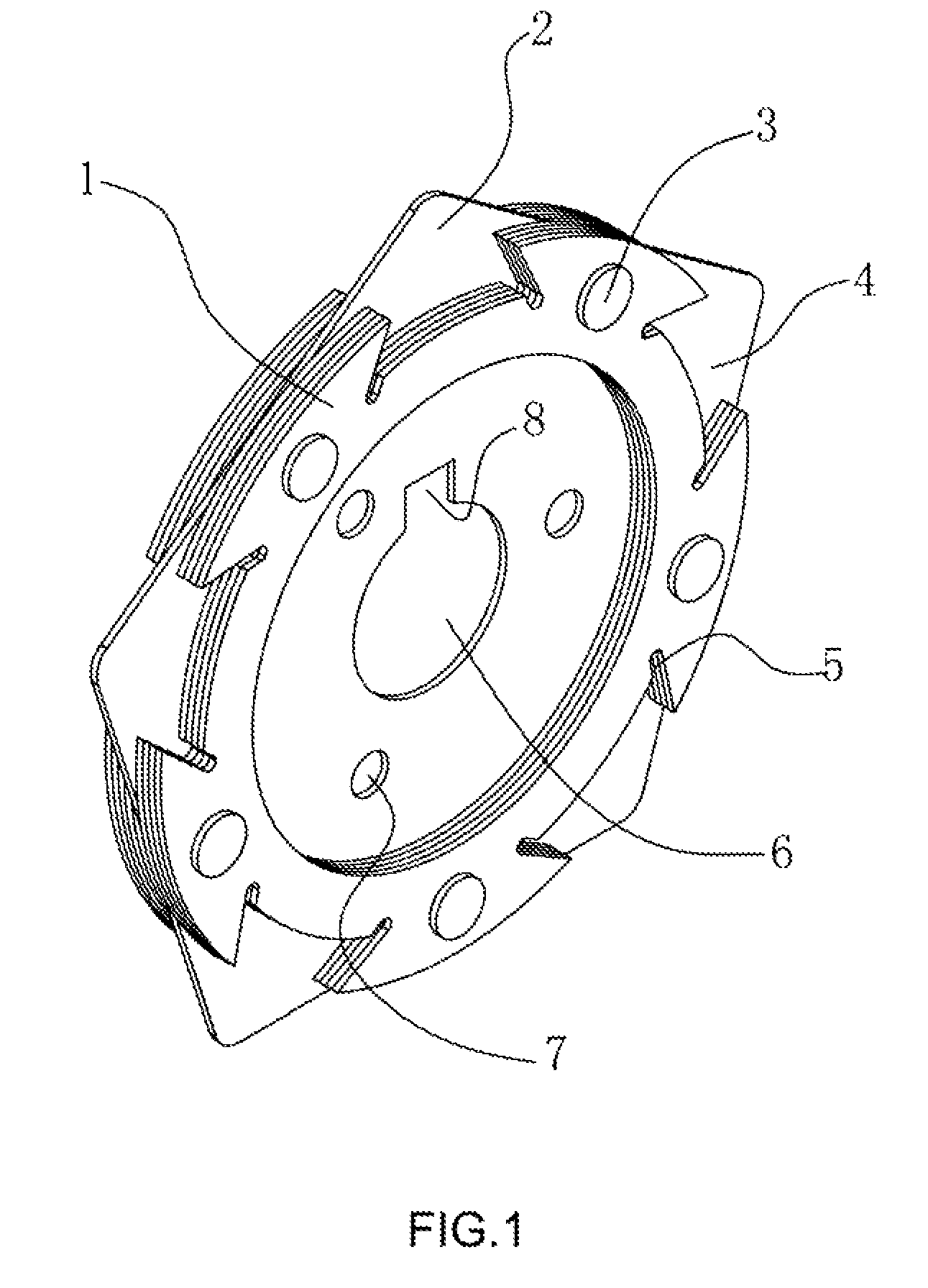

Punching Sheet-Type Flange

ActiveUS20130202351A1Solve problemsLess interferenceYielding couplingFlanged jointsPunchingDie casting

A punching sheet-type flange formed by overlapping and fixing punching sheet-structure assemblies, comprising a substrate (2) and multiple flange sheets (1) fixed with the substrate (2). The substrate (2) and the flange sheets (1) are of a punching sheet structure. The flange sheets (1) are annular, and connection slots (4) are arranged on the periphery of the flange sheets (1). The flange sheets (1) are arranged on both sides of the substrate. The substrate (2) combines with the flange sheets (1) to form the flange. The substrate (2) and the flange sheets (1) are formed by punching processing. The number of the flange sheets (1) is adjustable. The flange sheets (1) having the complex structure can be processed, thereby accommodating connecting parts of different structures. Connection slots (4) enable convenient assembling and replacement. The flange solves the difficulty in die casting of flanges having complex structures, and solves the problem of flange thickness being not adjustable.

Owner:ZHEJIANG LINIX MOTOR

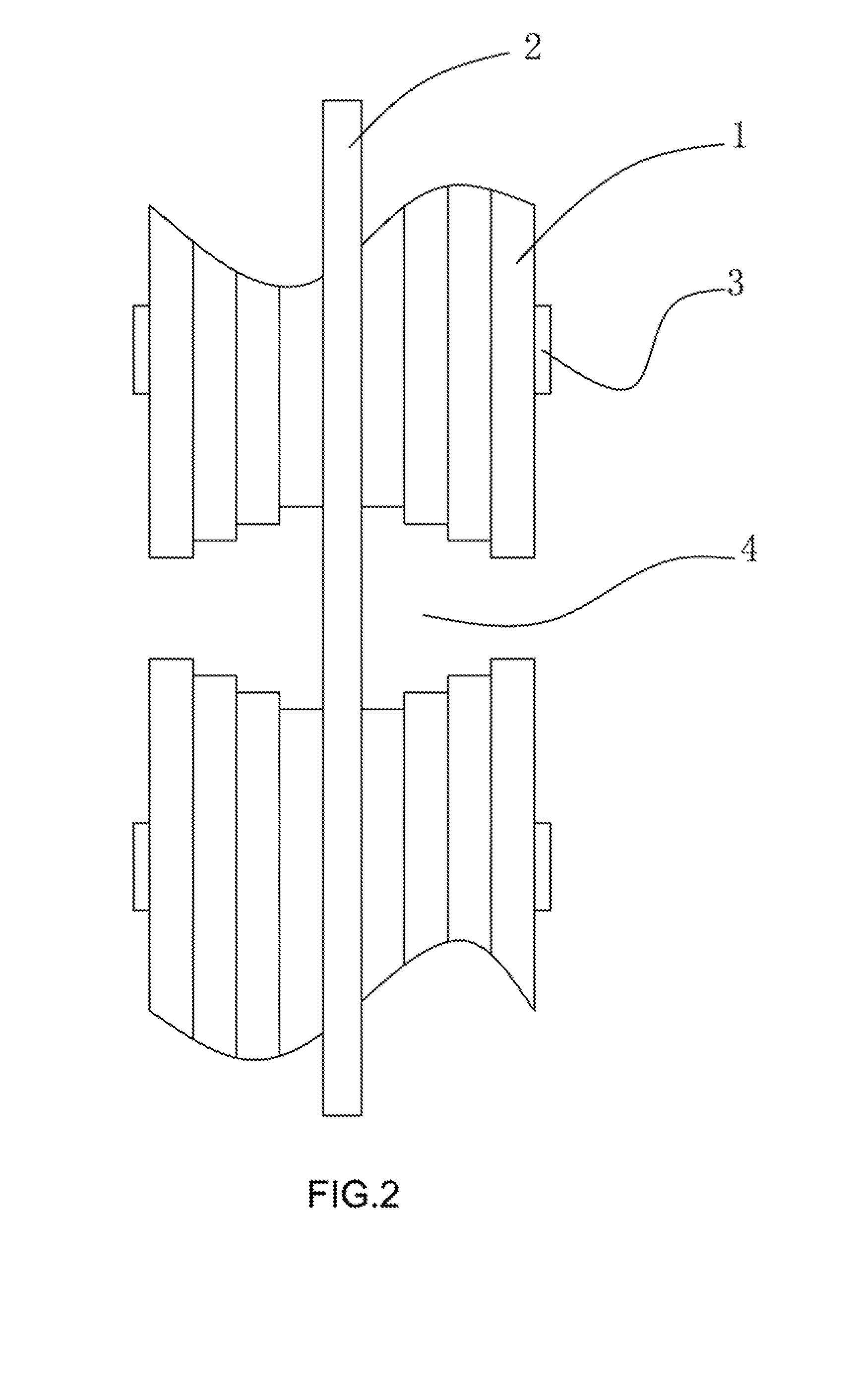

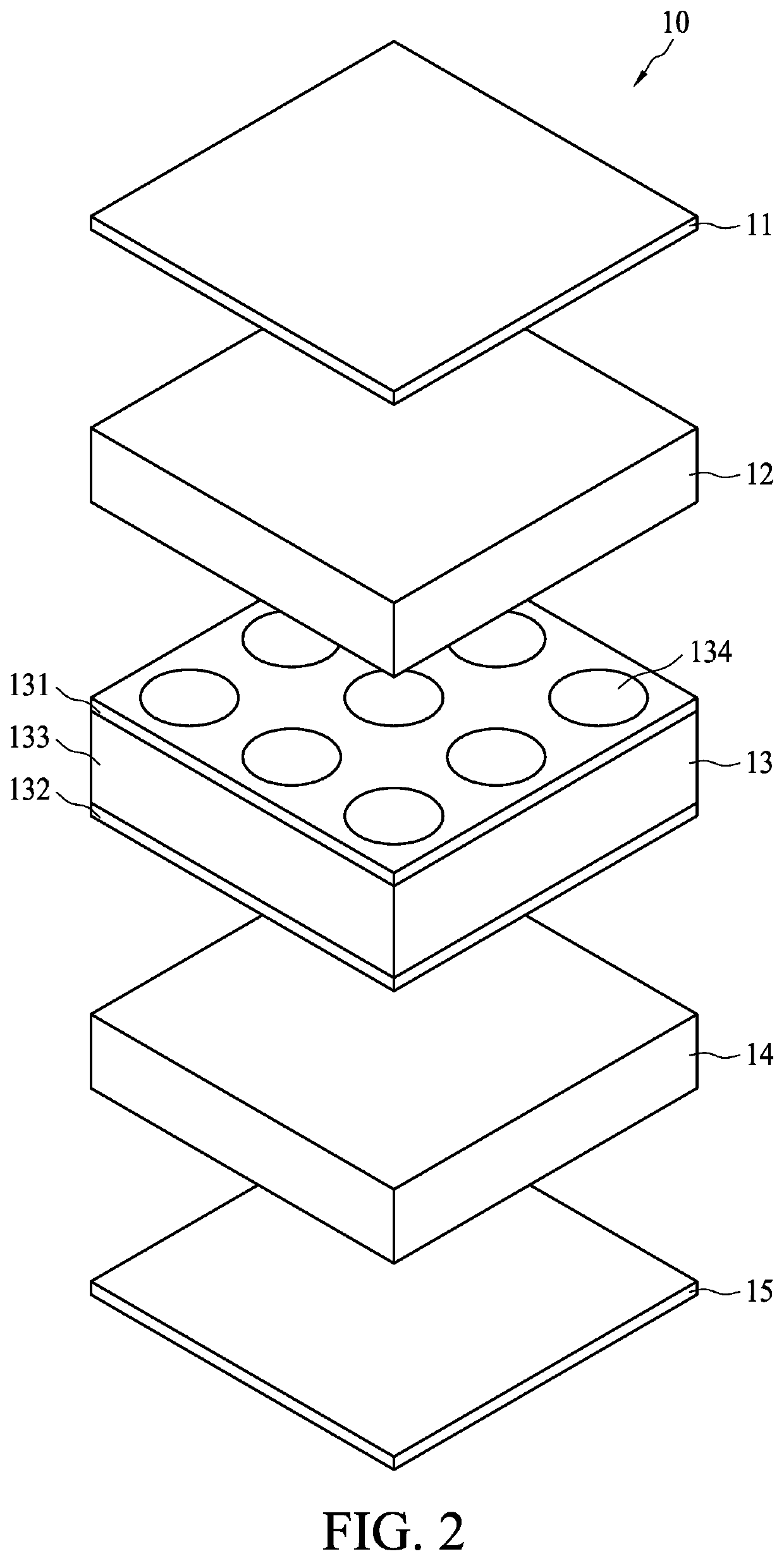

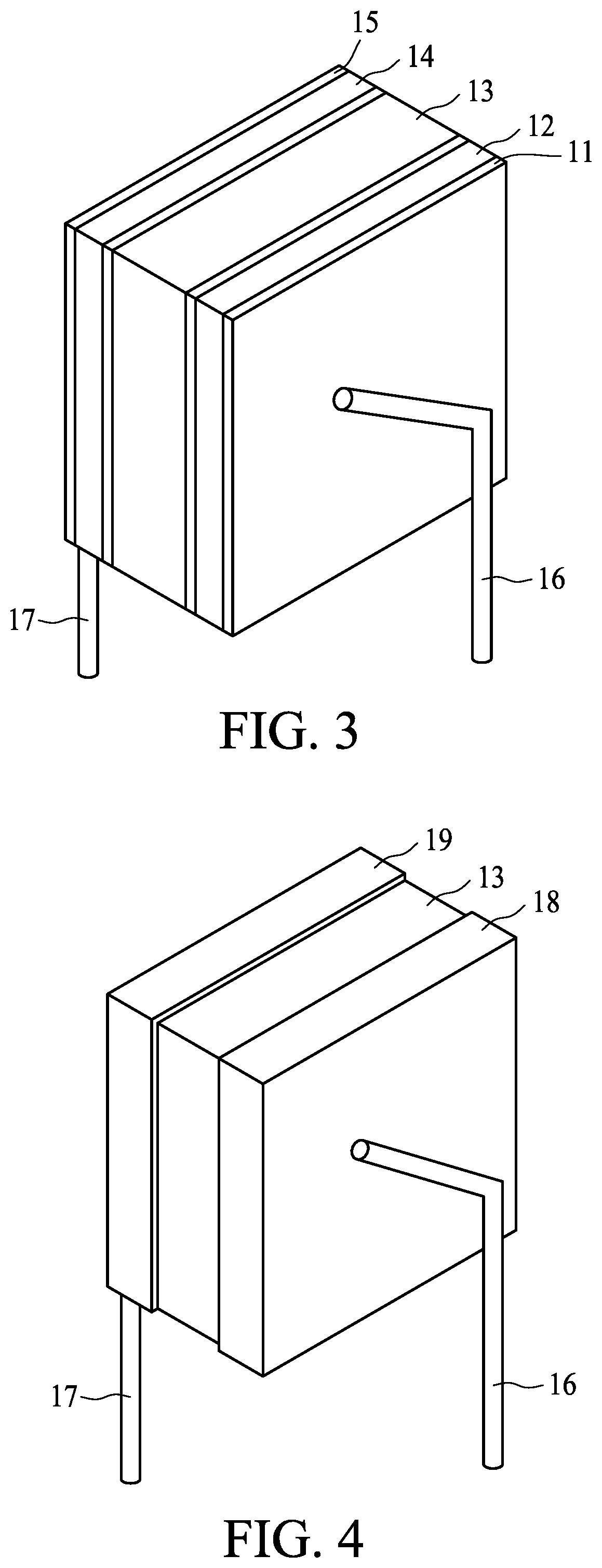

PTC device

ActiveUS10892072B1Simple processSimple structureResistor terminals/electrodesPositive temperature coefficient thermistorsElectrically conductiveSi substrate

A PTC device comprises a laminated substrate, a first PTC material layer, a second PTC material layer, a first metal layer and a second metal layer. The laminated substrate comprises a first conductive layer, a second conductive layer and an insulating layer laminated between the first and second conductive layers. The first PTC material layer is disposed on the first conductive layer, and the second PTC material layer is disposed on the second conductive layer. The first metal layer is disposed on the first PTC material layer, and the second metal layer is disposed on the second PTC material layer. The insulating layer has a through hole filled with PTC material to form a PTC connecting member of which one end connects to the first PTC material layer and another end connects to the second PTC material layer.

Owner:POLYTRONICS TECH

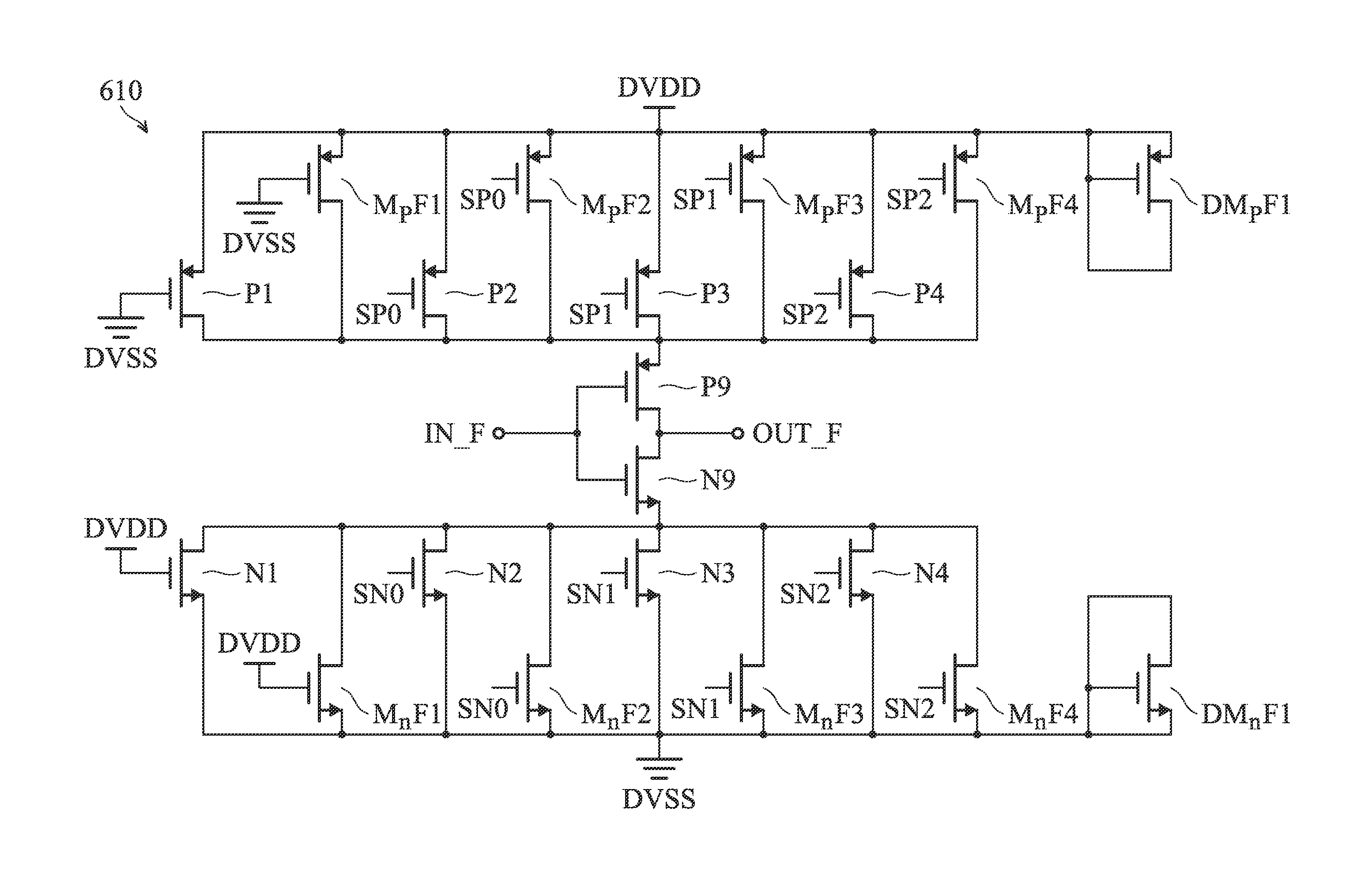

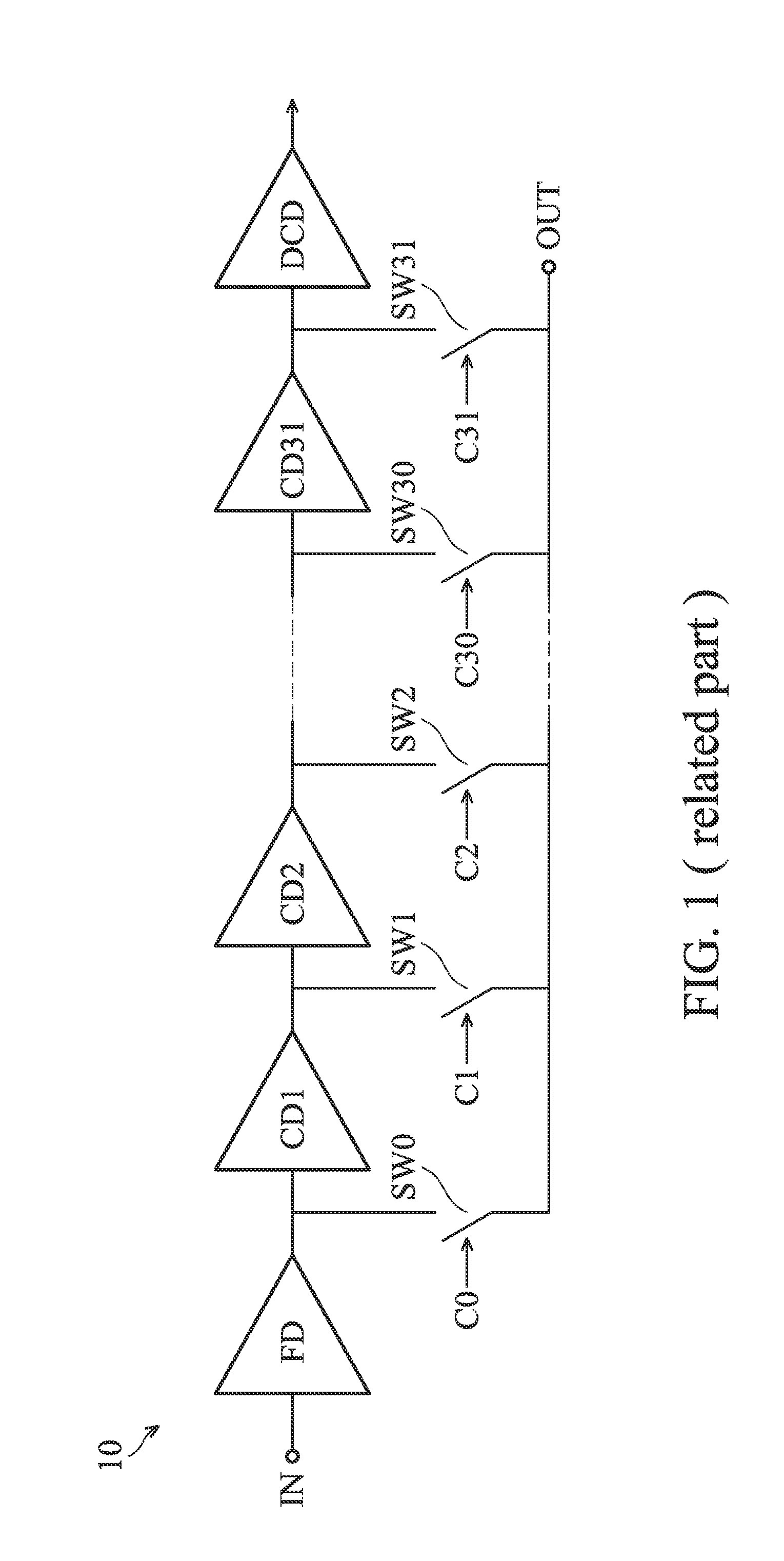

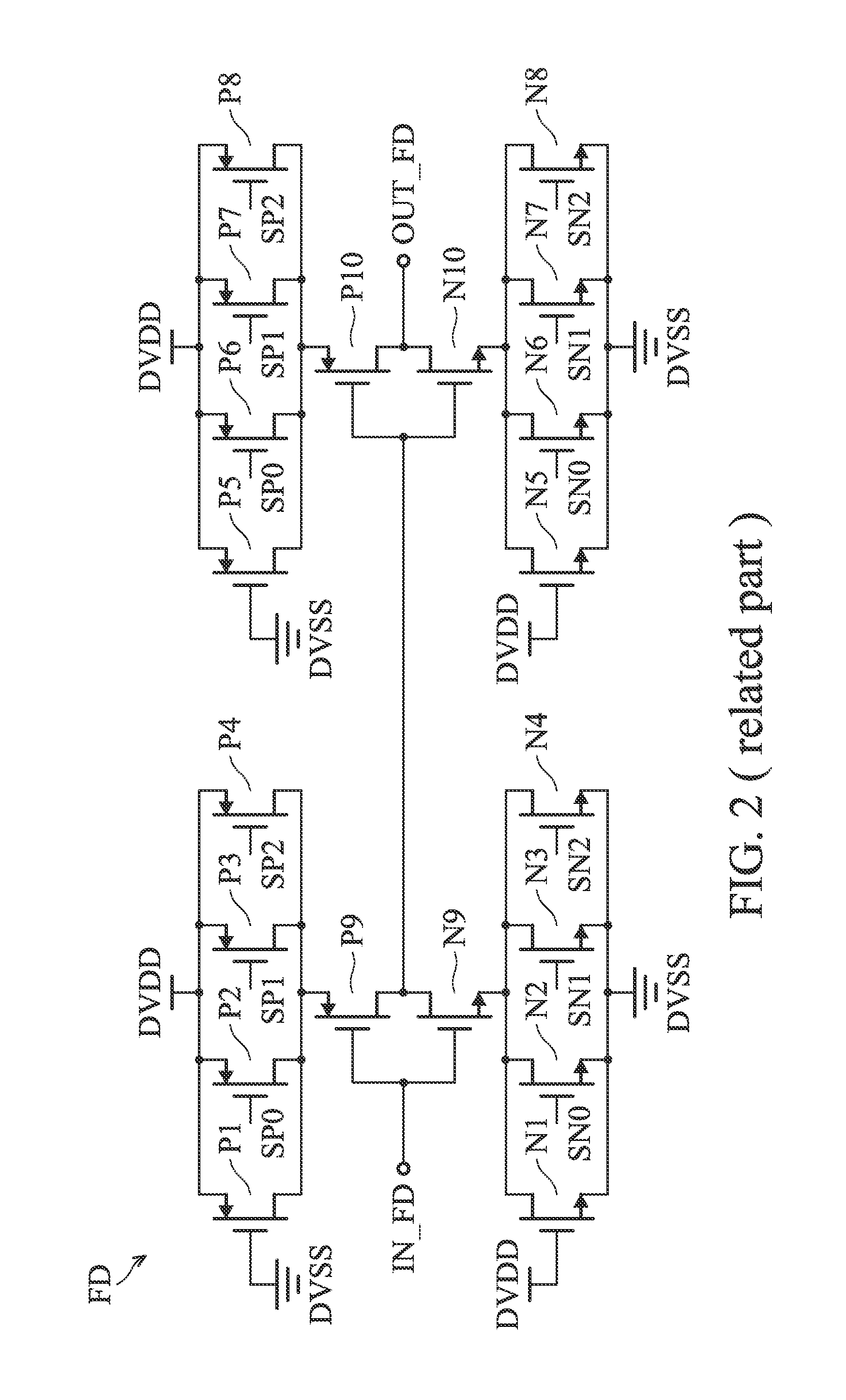

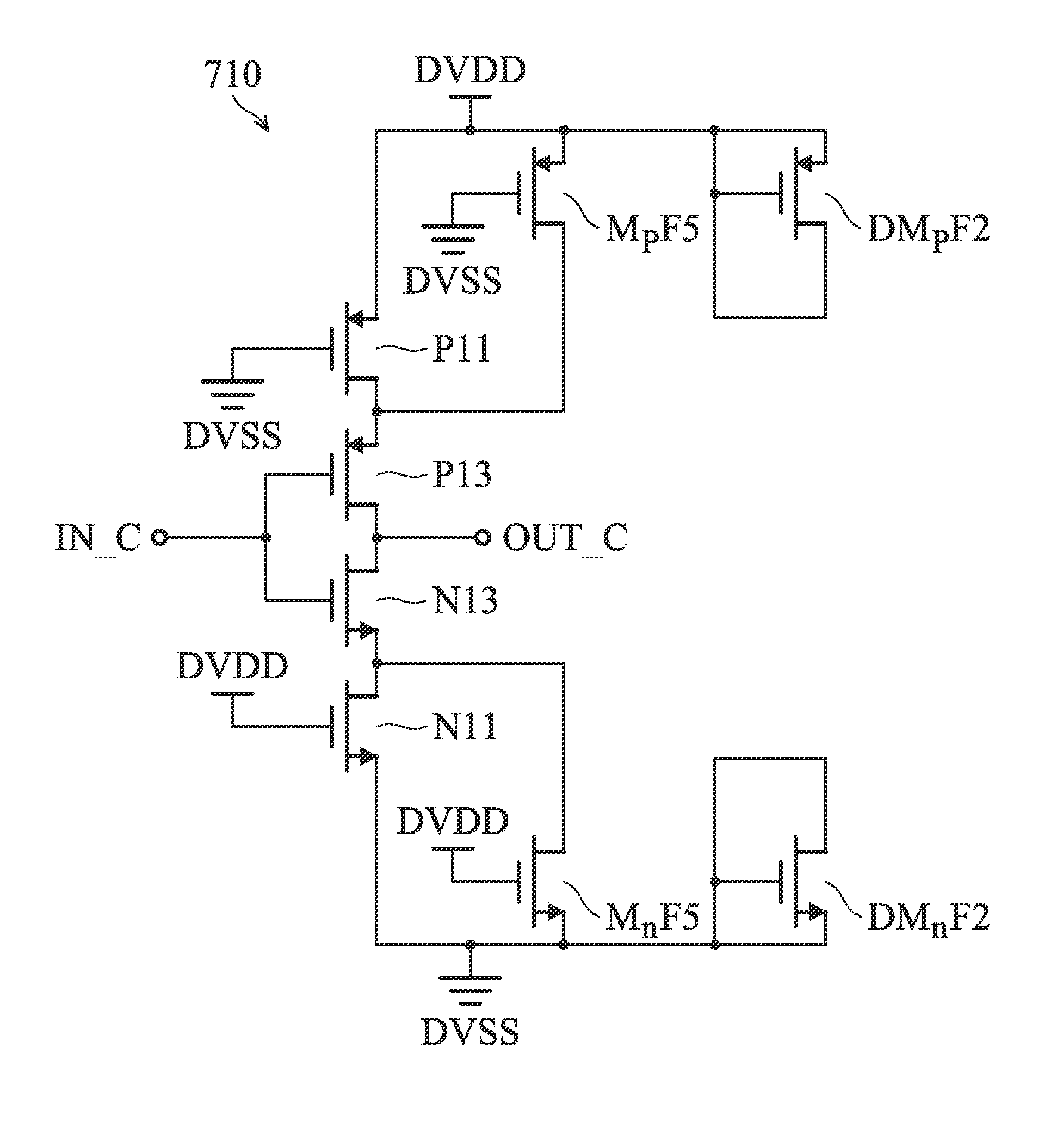

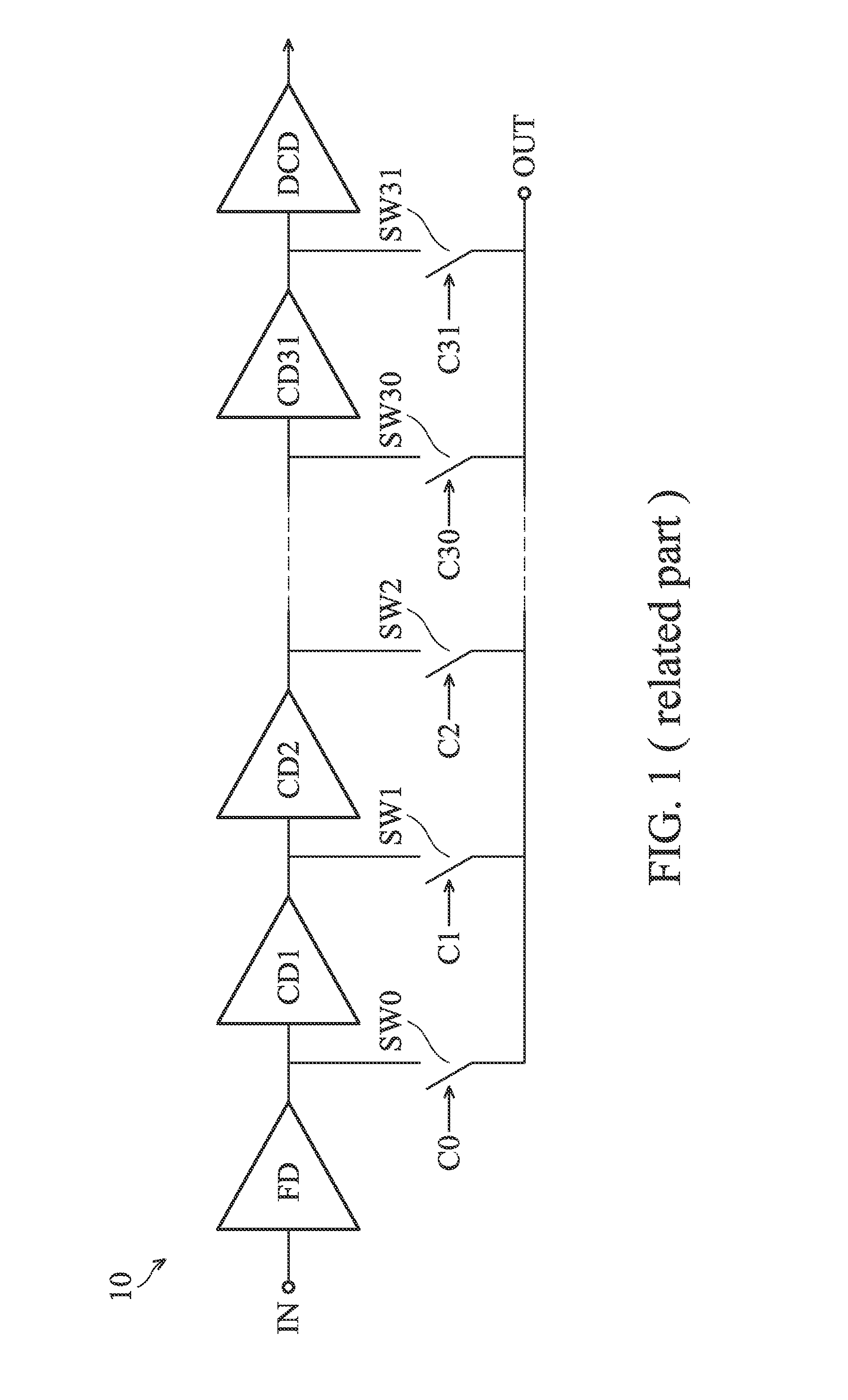

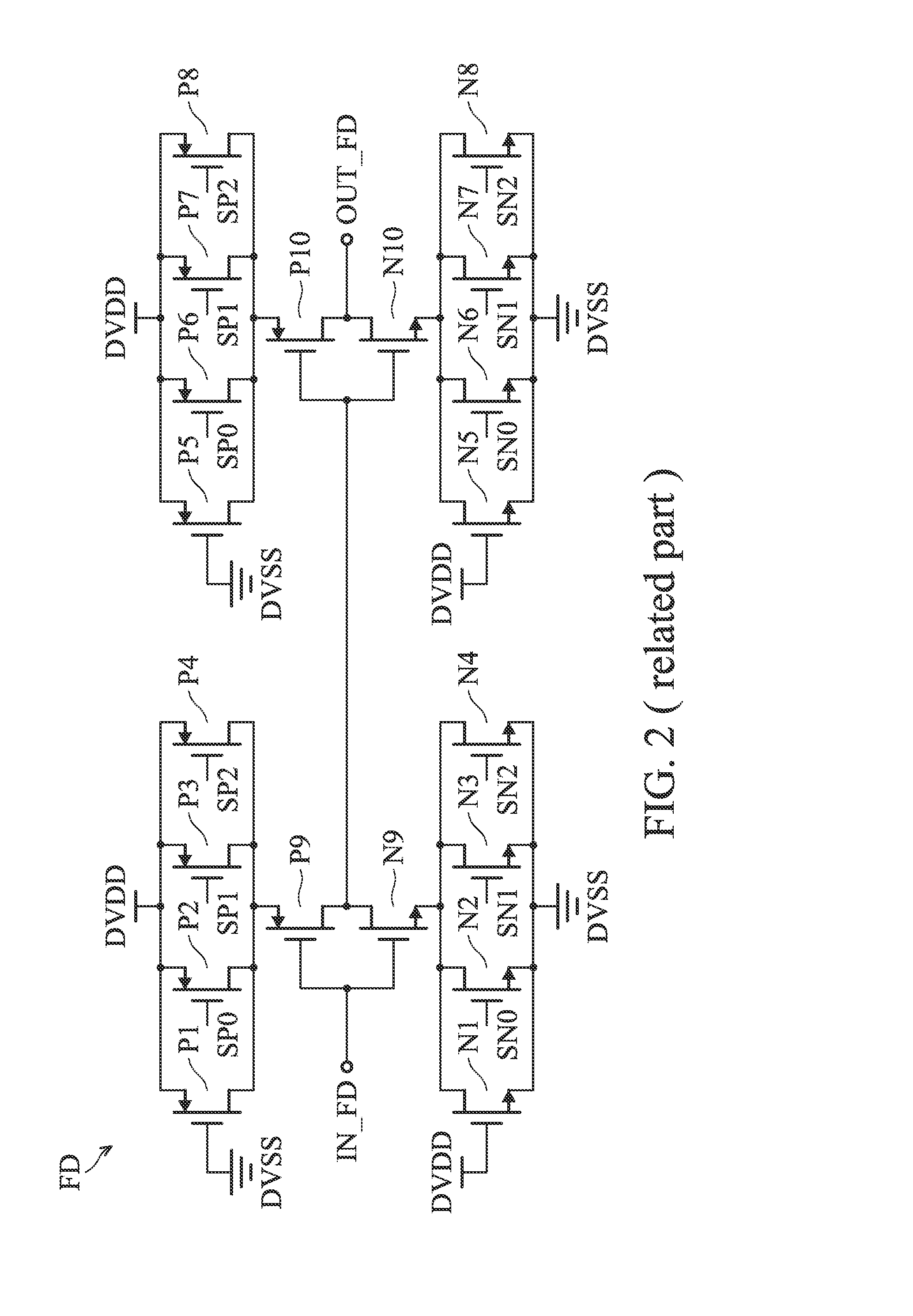

Delay line circuits and semiconductor integrated circuits

ActiveUS9432012B2Short design cycleUniform delay stepTransistorSemiconductor/solid-state device detailsSemiconductorTransistor

A delay line circuit is provided and includes a fine delay unit and coarse delay units. Each fine delay circuit includes a first PMOS transistor; a first NMOS transistor; second PMOS transistors whose widths of gate features of the second PMOS transistor are equal; at least one third PMOS transistor, coupled between the power voltage and the source of the first PMOS transistor, whose width of gate features is smaller than the widths of the gate features of the second PMOS transistors, second NMOS transistors whose widths of gate features of the second NMOS transistors are equal; and at least one third NMOS transistor, coupled between the ground voltage and the source of the first NMOS transistor, whose width of gate features is smaller than the widths of the gate features of the second NMOS transistors.

Owner:VIA ALLIANCE SEMICON CO LTD

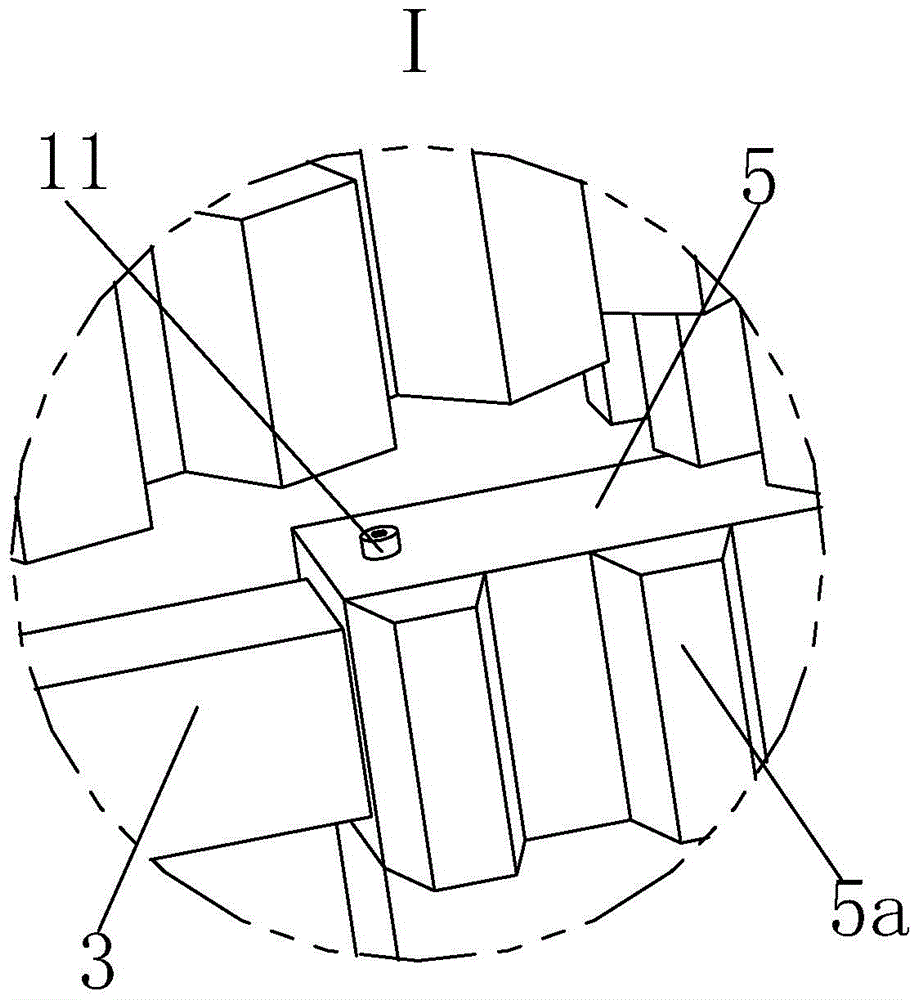

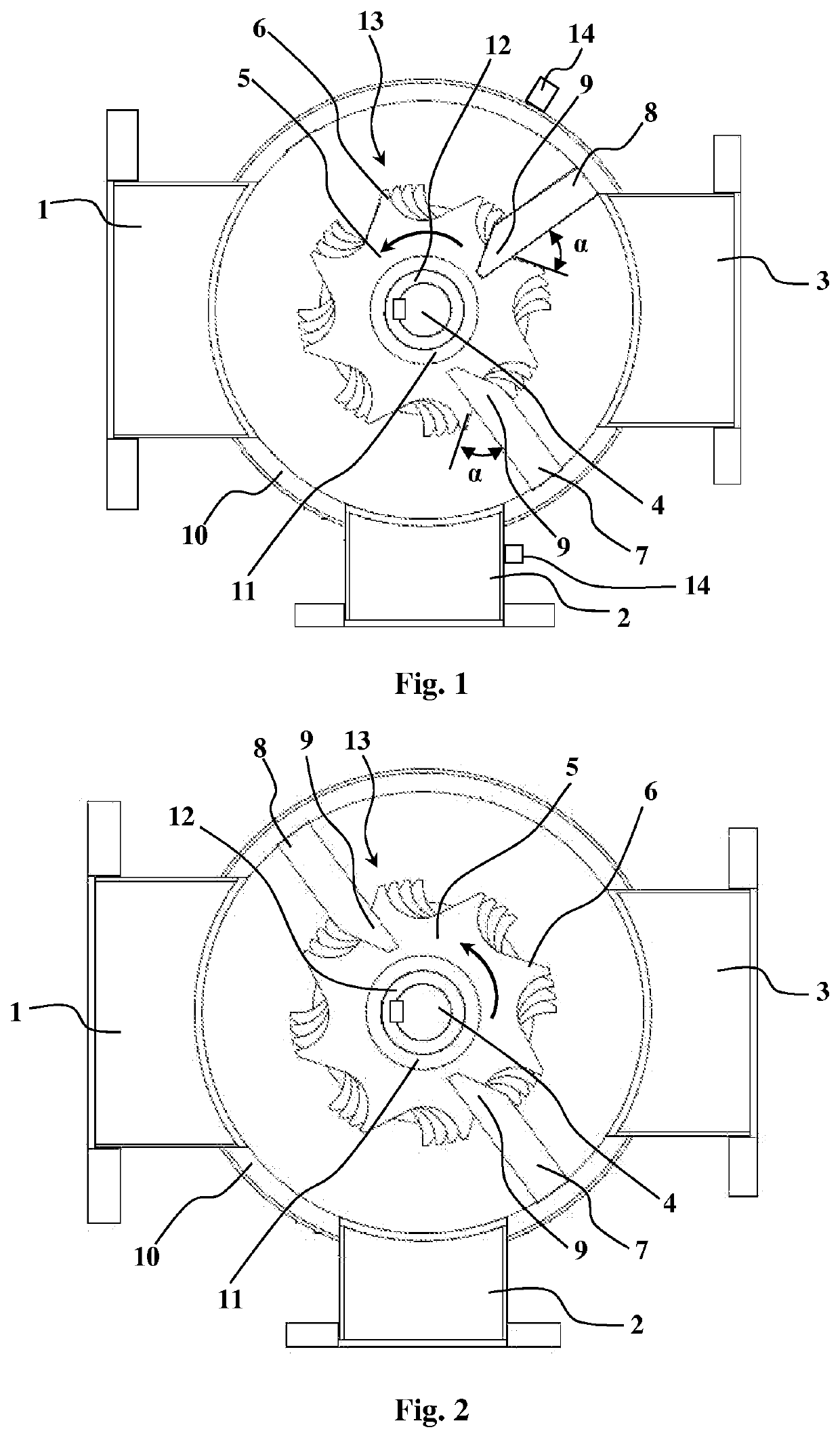

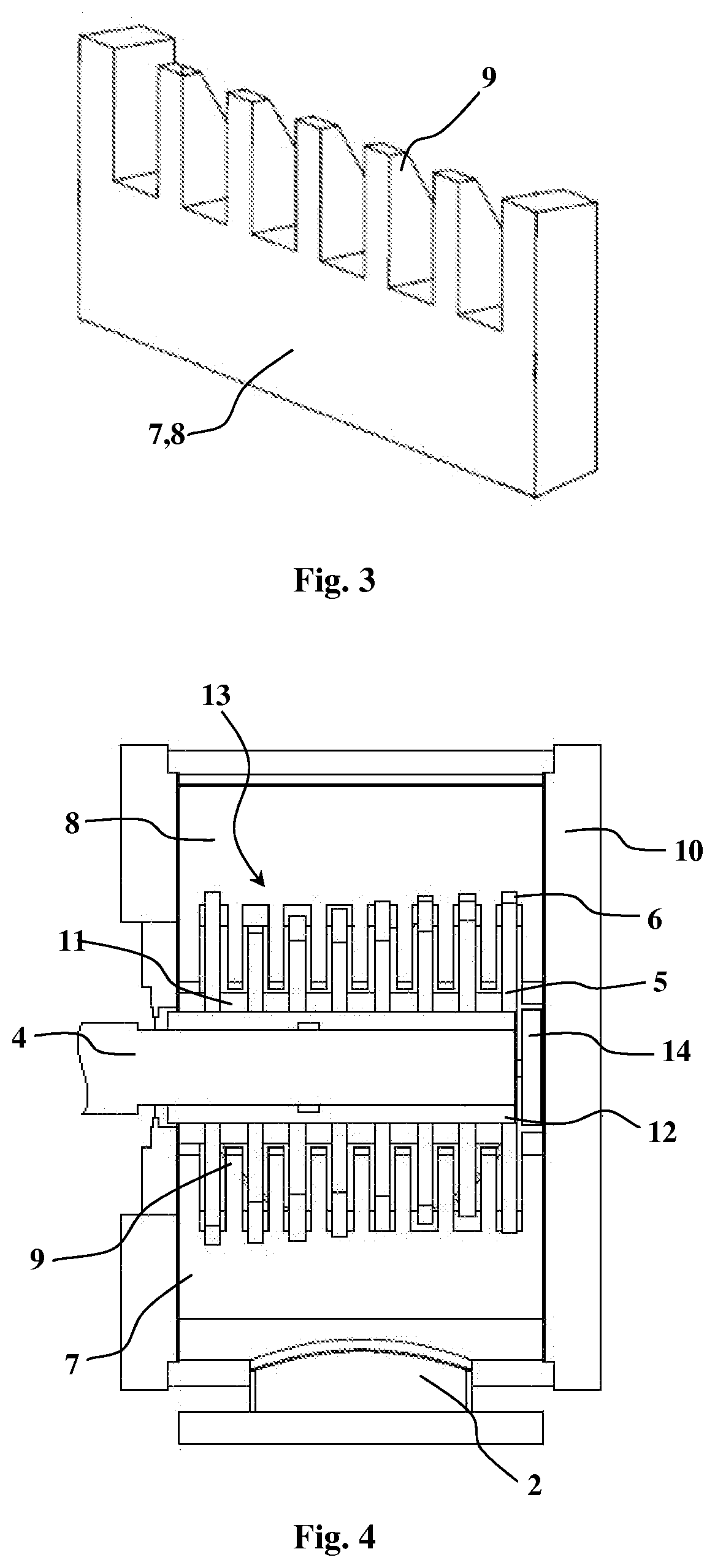

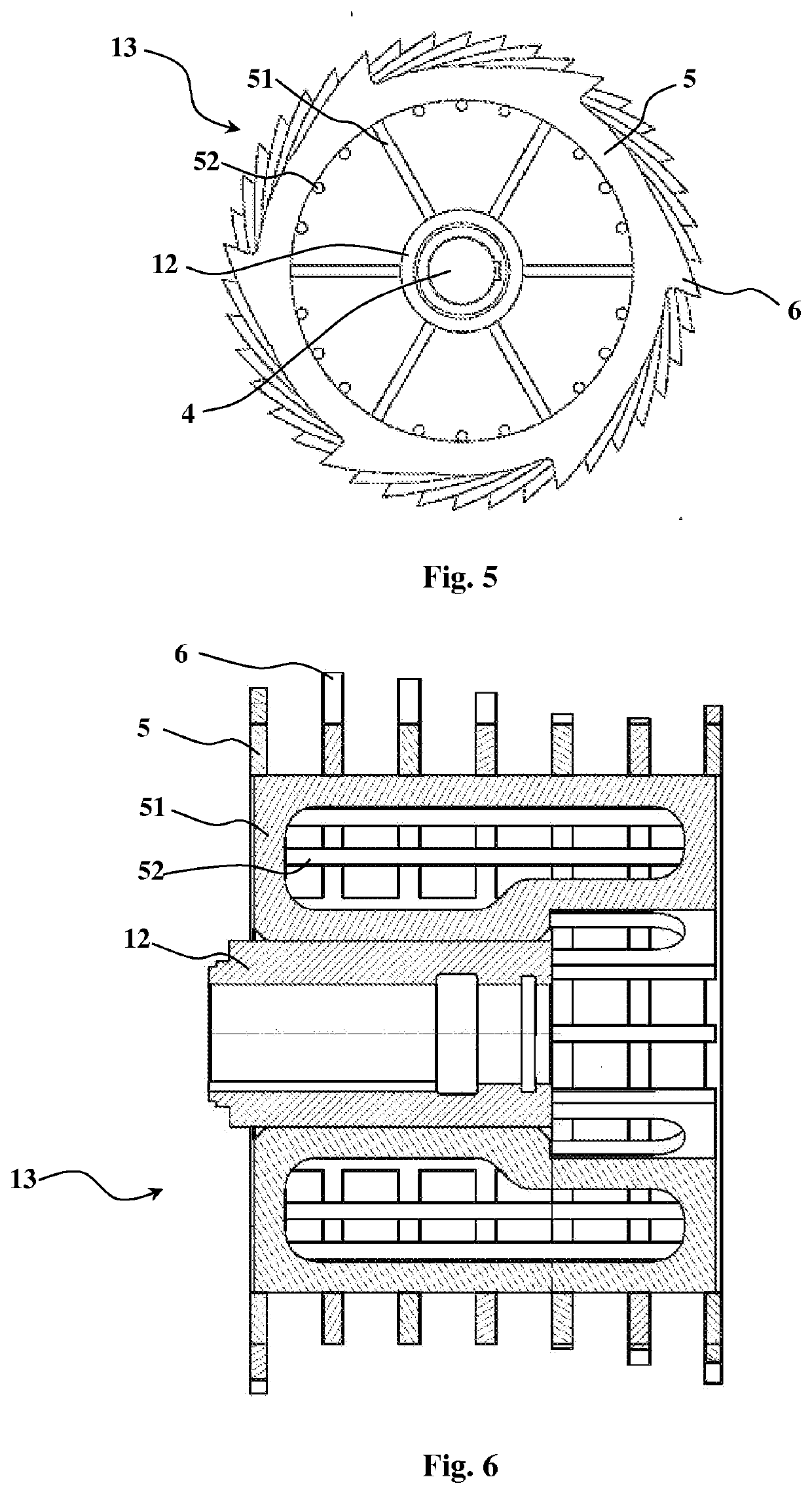

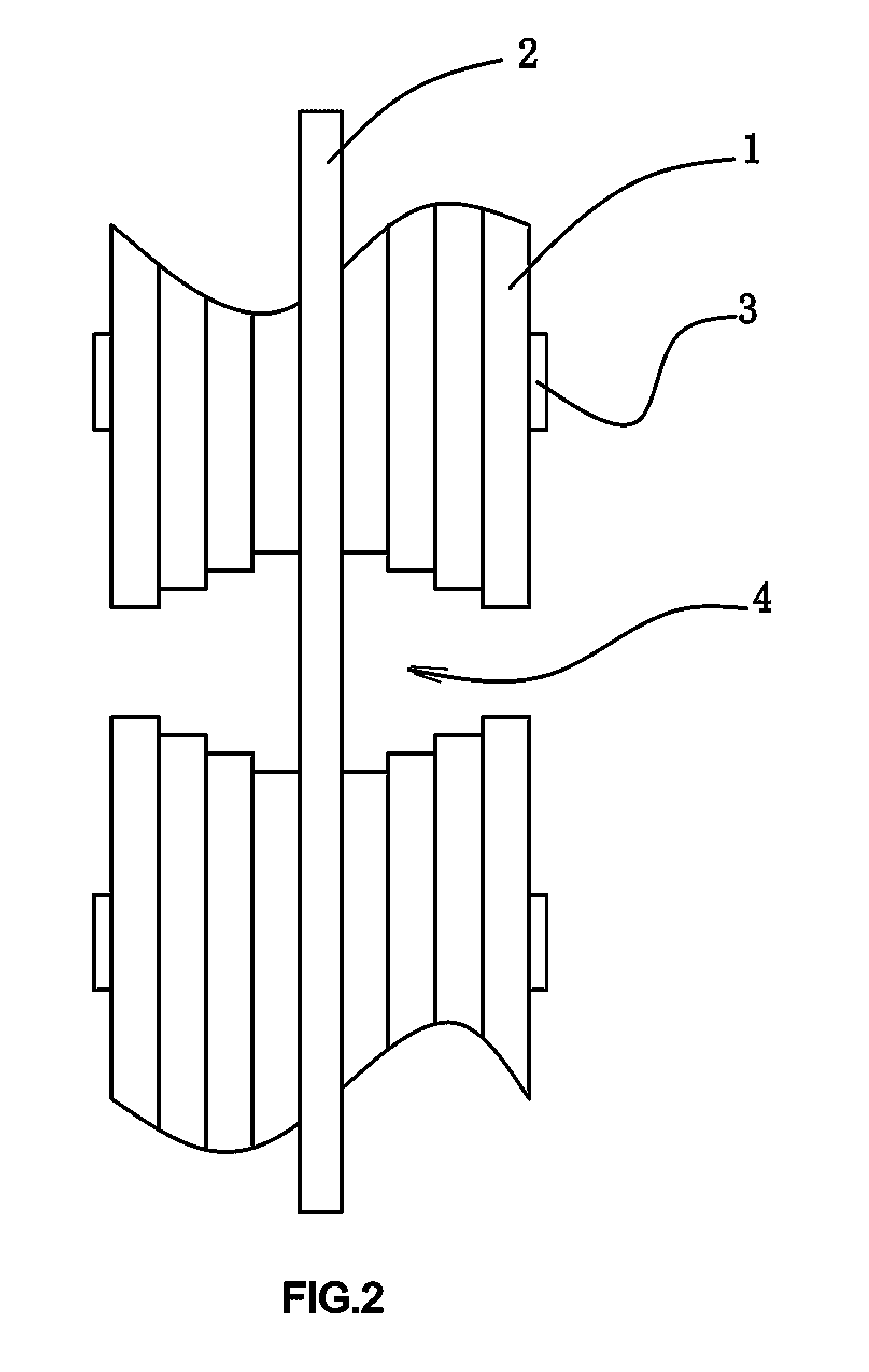

Separation device

ActiveUS20200222942A1Reduce energy consumptionReduce flow resistanceFibrous raw materialsGradingCircular discEngineering

A separation device having a housing (10) with a feed conduit (1) and a reject conduit (2), between which conduits (1, 2) and an accept conduit (3) of the housing (10) is a rotor unit (13) having a shaft (4) transverse to the through-flow direction of the separation device, which shaft rotates discs (5) attached to the shaft (4), the outer surface and / or side surfaces of which discs are jagged, i.e. they have protrusions (6) and / or notches and / or these surfaces are substantially rough and the teeth (9) of at least two sieves (7, 8) attached to the housing (10), extend between the discs (5), the first sieve (7) being between the reject conduit (2) and the accept conduit (3) and the second sieve (8) being between the feed conduit (1) and the accept conduit (3).

Owner:ANDRIZ OY

Method for dredging silt and harnessing river

The invention relates to a method for dredging and management, which belongs to the techniques of environment protection and hydraulic engineering. The method comprises the following steps of: protecting dikes along both shores of a river by a light and hard shell dike method; arranging a nose dike in the middle position of the gradually-wide section of the river along the upstream end of a longitudinally ridged sand sill; according to the shape of the sand sill, hard shell sheet piles gradually extending to the downstream along both sides of the nose dike to form an aequilate river surface; inserting sheet piles, connecting the sheet piles into a whole, throwing the dredged mud into a range surrounded by the hard shell sheet piles, and then gradually forming a man-made island; marking a helix-shaped man-made bay on the downstream of the gradually-narrow section of the river to form a fixing sand point on the sudden-widen river; and then planting and fixing sand on the man-made island. The invention aims to satisfy the functions of flood discharge, tide suppressing, irrigation, water storage and navigation, and also can establish stable man-made islands and marsh parks. The invention has the advantages of dike stabilization, reduction of sand accretion, utilization of natural energy, and increase of earth resources, and is suitable for various types of river management.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Low resistance stacked annular contact

ActiveUS20140131781A1Equal lengthEqual widthTransistorSemiconductor/solid-state device detailsMetal interconnectEngineering

An integrated circuit contains lower components in the substrate, a PMD layer, upper components over the PMD layer, lower contacts in the PMD layer connecting some upper components to some lower components, an ILD layer over the upper components, metal interconnect lines over the ILD layer, and upper contacts connecting some upper components to some metal interconnect lines, and also includes annular stacked contacts of lower annular contacts aligned with upper annular contacts. The lower contacts and upper contacts each have a metal liner and a contact metal on the liner. The lower annular contacts have at least one ring of liner metal and contact metal surrounding a pillar of PMD material, and the upper contacts have at least one ring of liner metal and contact metal surrounding a pillar of ILD material. The annular stacked contacts connect the metal interconnects to the lower components.

Owner:TEXAS INSTR INC

Delay line circuits and semiconductor integrated circuits

ActiveUS20150349765A1Short design cycleUniform delay stepTransistorSemiconductor/solid-state device detailsSemiconductorTransistor

A delay line circuit is provided and includes a fine delay unit and coarse delay units. Each fine delay circuit includes a first PMOS transistor; a first NMOS transistor; second PMOS transistors whose widths of gate features of the second PMOS transistor are equal; at least one third PMOS transistor, coupled between the power voltage and the source of the first PMOS transistor, whose width of gate features is smaller than the widths of the gate features of the second PMOS transistors, second NMOS transistors whose widths of gate features of the second NMOS transistors are equal; and at least one third NMOS transistor, coupled between the ground voltage and the source of the first NMOS transistor, whose width of gate features is smaller than the widths of the gate features of the second NMOS transistors.

Owner:VIA ALLIANCE SEMICON CO LTD

Punching sheet-type flange

ActiveUS9464673B2Solve problemsLess interferenceYielding couplingFlanged jointsTransmitted powerEngineering

A sheet-type flange for transmitting power is formed by a substrate and a multiple of flange sheets. The substrate has a central axle hole with a square key slot and a multiple of fixed holes distributed around the axle hole. The multiple of flange sheets are annular and have connection slots arranged on a periphery of the flange sheets, as well as the multiple of flange sheets are arranged on both sides of the substrate respectively. The substrate and the multiple of flange sheets are fixed together by rivets.

Owner:ZHEJIANG LINIX MOTOR

Method for preparing sealing strip of scroll compressor

ActiveCN102585436BImprove mechanical propertiesImprove insulation performanceSealing arrangement for pumpsMachines/enginesFiberThermal expansion

The invention provides a method for preparing a sealing strip of a scroll compressor. The sealing strip prepared by using the method has high strength, a small thermal expansion coefficient, a small abrasion rate and long service life. The preparation method comprises the following step of mixing the following components in parts by weight: 20-30 parts of polybenzimidazole, 40-50 parts PEEK (Polyether-Ether-Ketone), 5-10 parts of carbon fiber and 3-5 parts of molybdenum disulfide, and carrying out hot-press forming.

Owner:NANJING COMPTECH COMPOSITES CORP

High-hydroscopicity non-woven fabric edge cutter

The invention provides a high-hydroscopicity non-woven fabric edge cutter, belongs to the technical field of machinery, and solves the technical problems of non-uniform width and the like of the edge-cut non-woven fabric obtained by an existing non-woven fabric edge cutter. The high-hydroscopicity non-woven fabric edge cutter comprises a rack, wherein the rack is rotationally connected with a cloth collecting roller, the cloth collecting roller is provided with edge cutting grooves close to two ends, the rack is provided with two sets of cutting assemblies in one-to-one correspondence to the edge cutting grooves, each set of cutting assembly comprises an upper sliding seat, a lower sliding seat and a cutting line connected between the upper sliding seat and the lower sliding seat, the upper sliding seat is in sliding connection onto a top plate of the rack, the lower sliding seat is in sliding connection onto a bottom plate of the rack, the cutting line is vertically arranged, and theupper sliding seat and the lower sliding seat can synchronously move to enable the cutting line to penetrate through each edge cutting groove or keep away from the cloth collecting roller. The edge cutter provided by the invention has the advantage of uniform width of the high-hydroscopicity non-woven fabric after edge cutting.

Owner:浙江明盛达医用材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com