Laminaria japonica cutting equipment

A cutting equipment and kelp technology, which is applied in metal processing and other directions, can solve the problems of kelp curling and cutting knives easily scratching the conveyor belt, and achieve the effects of reducing damage, improving cutting quality, and ensuring cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

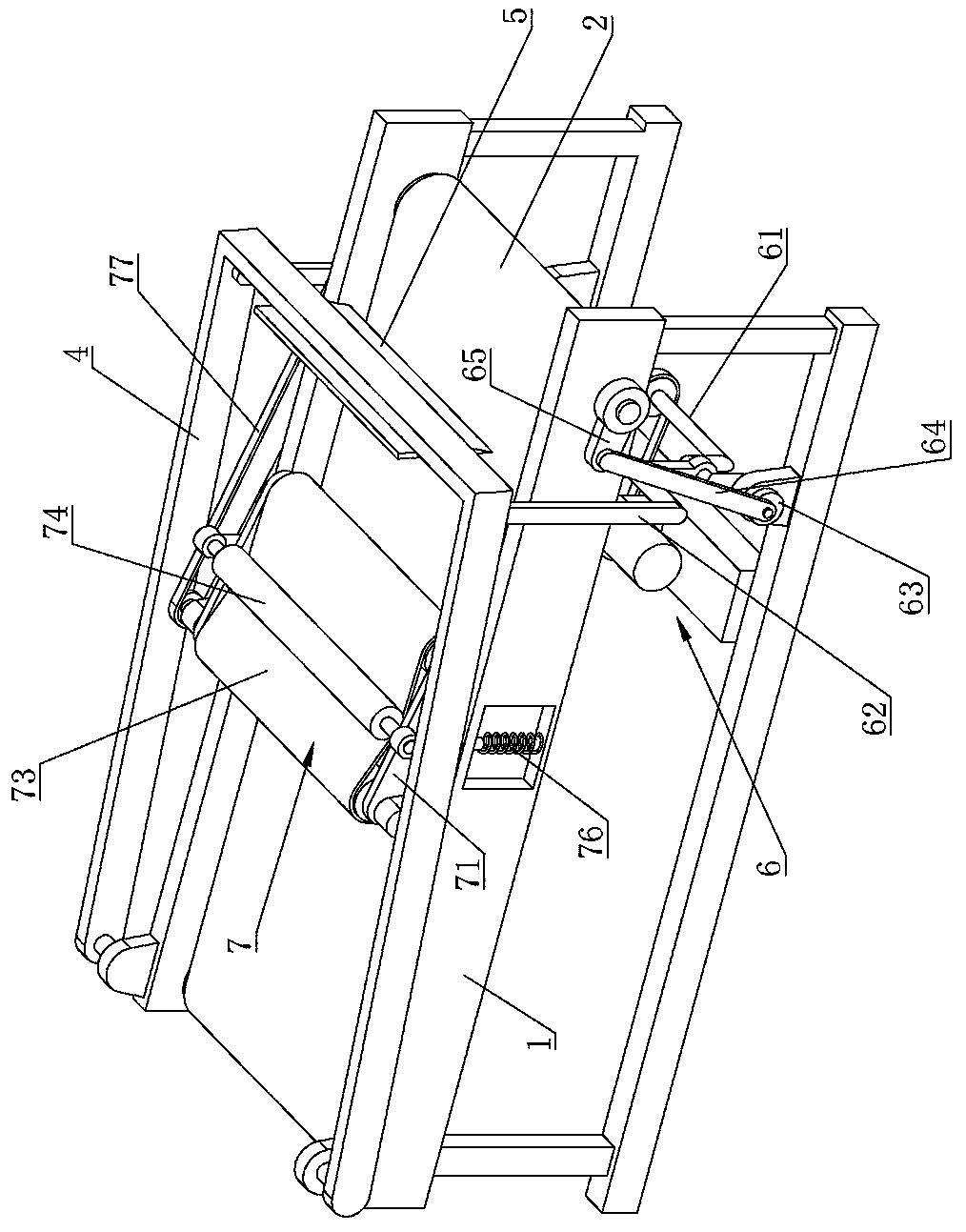

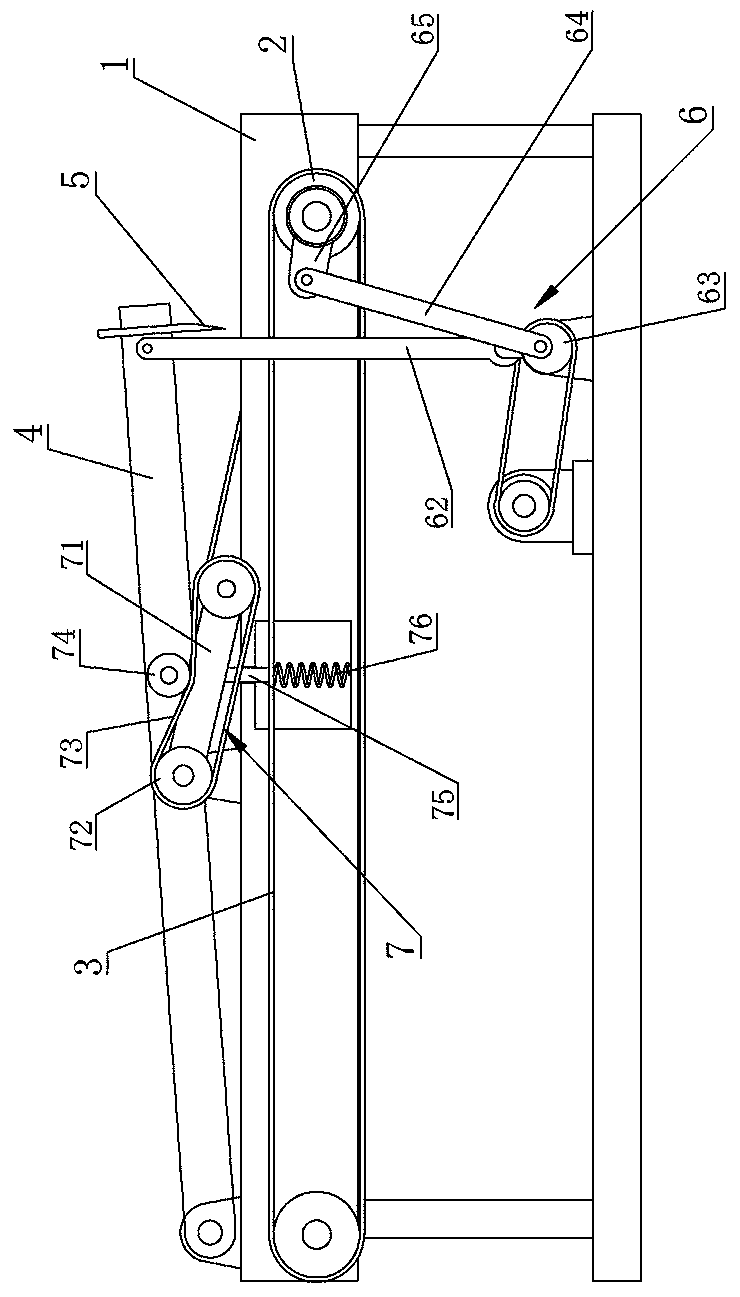

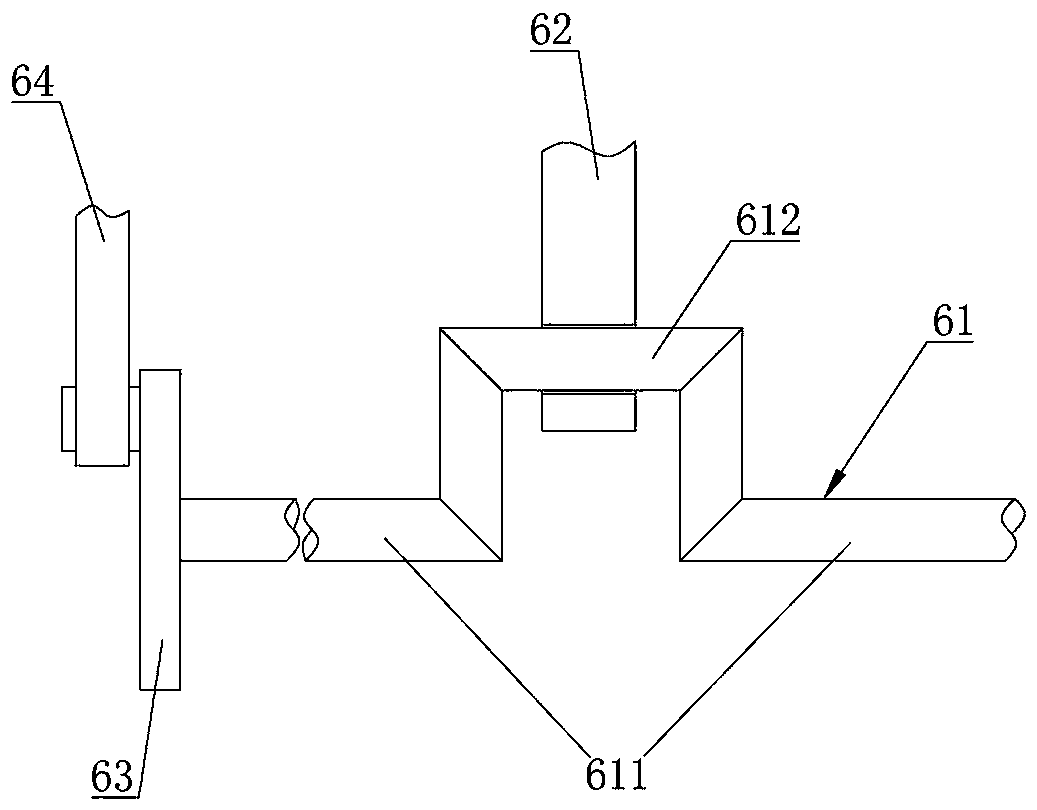

[0025] Example: such as Figure 1 to Figure 4 Shown, a kind of kelp cutting equipment comprises frame 1, the conveying roller 2 that is arranged on frame 1 front and rear ends, the conveyer belt 3 that is wound between the two conveying rollers 2 before and after, is arranged on the cutting machine above conveyer belt 3 Knife 5 and driving mechanism 6 that drives cutting knife 5 to move up and down and conveying roller 2 to rotate. The driving device at least includes a main shaft 61, the main shaft 61 rotates below the installation frame 1, a support frame 62 that drives the cutting knife 5 to move up and down is connected between the main shaft 61 and the cutter 5, and the upper end of the support frame 62 is fixedly connected with a cutting tool. The knife 5 is hinged at the eccentric position of the main shaft 61 at its lower end. The frame 1 is provided with a knife rest 4 , the front end of the knife rest 4 is hinged on the support frame 62 , and its rear end is hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com