PPR pipefitting uniform cutting device

A cutting equipment and uniform technology, applied in the field of uniform cutting equipment for PPR pipe fittings, can solve the problems of manpower consumption and low work efficiency, and achieve the effects of saving time, improving work efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

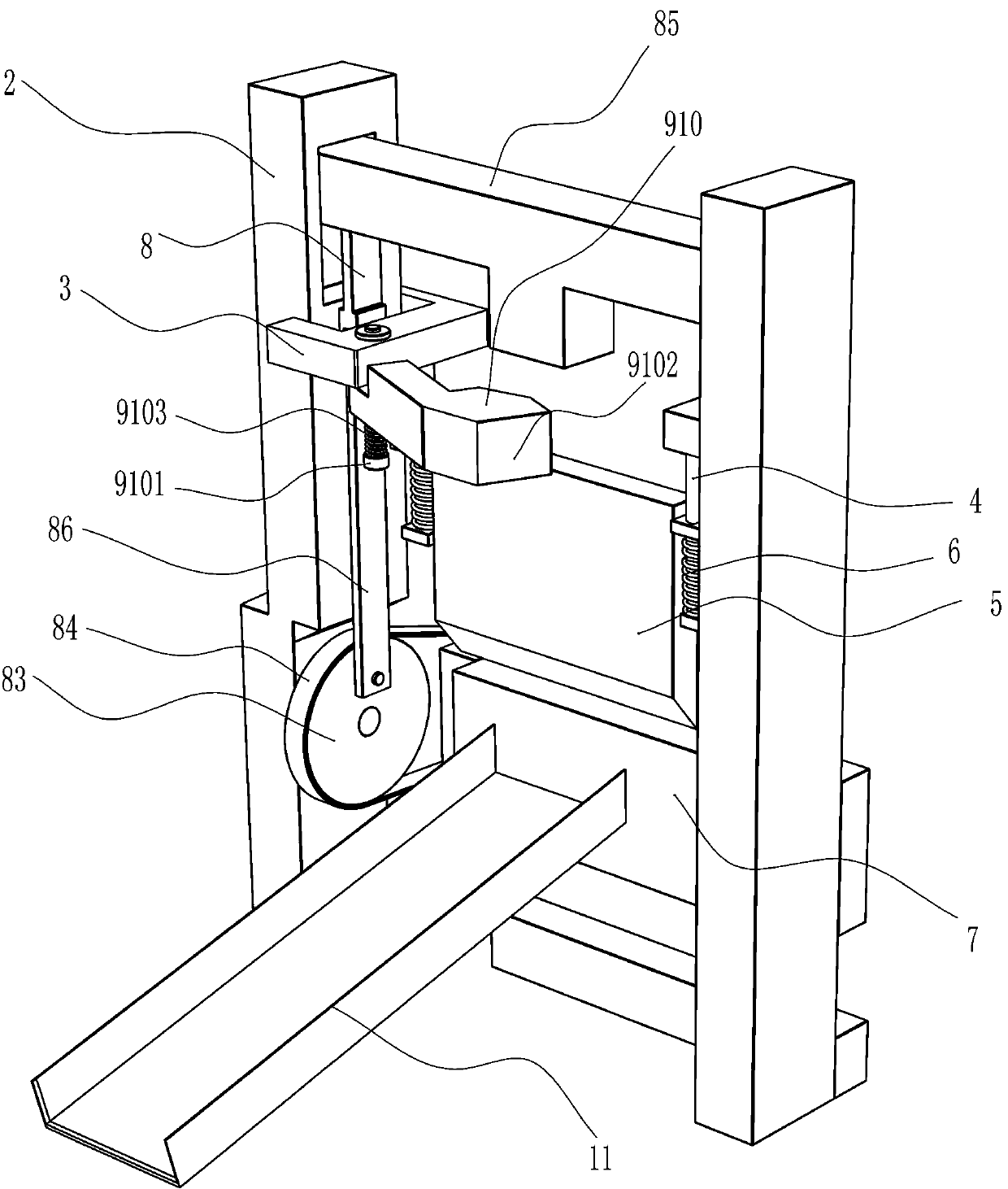

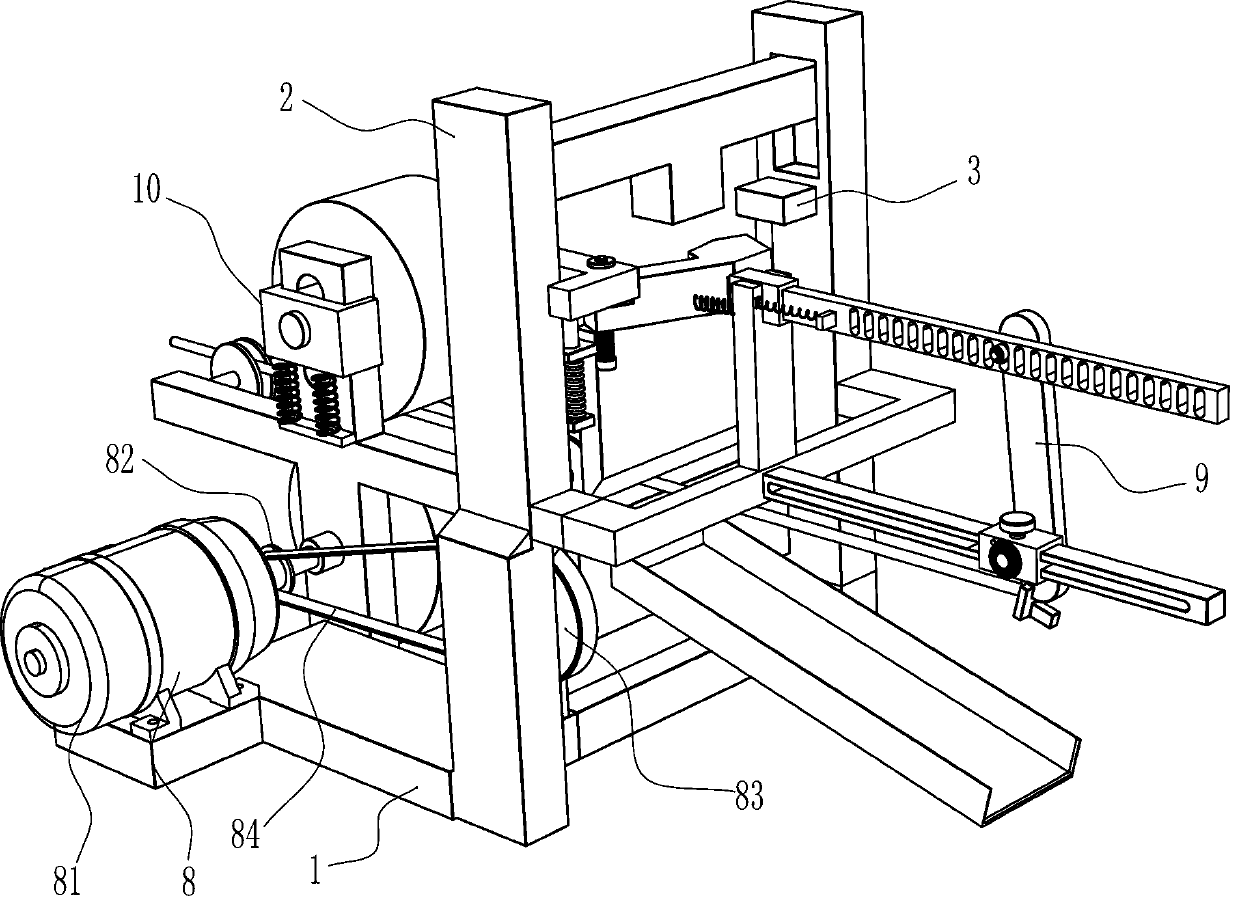

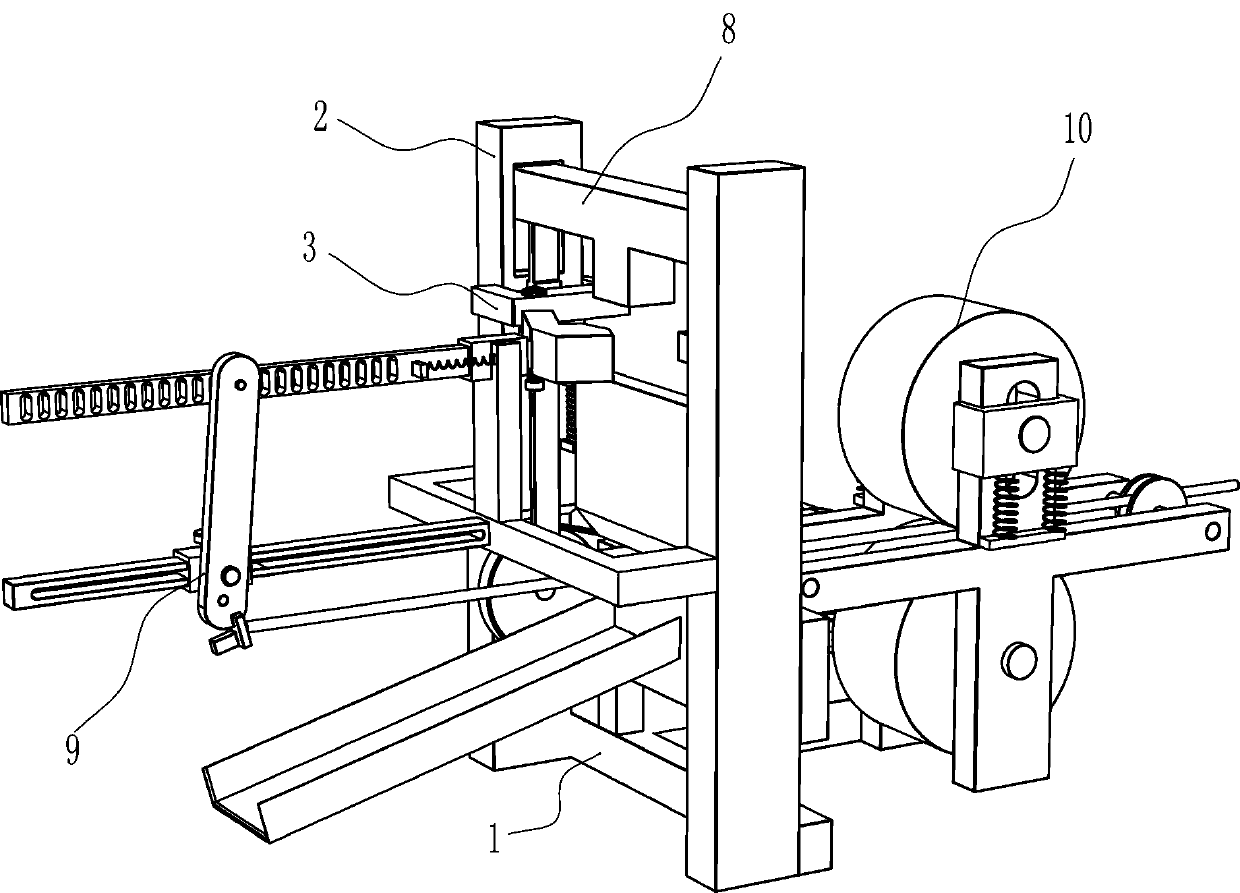

[0022] A uniform cutting equipment for PPR pipe fittings, such as Figure 1-4 As shown, it includes a base 1, a rack 2, a fixed block 3, and a guide rod 4. The base 1 is connected with a rack 2. The upper left and right sides of the rack 2 are connected with fixed blocks 3, and the bottom of the fixed block 3 is connected The guide rod 4 also includes a cutting knife 5, a first return spring 6, a knife seat 7, a power mechanism 8 and a distance mechanism 9. The cutting knife 5 is slidably connected between the guide rods 4 on both sides, the cutting knife 5 and the guide A first return spring 6 is connected between the rods 4, a knife holder 7 is connected to the lower part of the frame 2, and the knife holder 7 is located under the cutter 5, and a power mechanism 8 and a distance mechanism 9 are provided between the base 1 and the frame 2. .

[0023] The power mechanism 8 includes a geared motor 81, a small pulley 82, a large pulley 83, a flat belt 84, a T-shaped sliding frame ...

Embodiment 2

[0028] On the basis of Example 1, such as Figure 5 As shown, it also includes a feeding assembly 10. The feeding assembly 10 includes a cross 101, a lower feeding roller 102, a guide wheel 103, a sliding seat 104, an upper feeding roller 105 and a tension spring 106. The left and right sides of the top rear side of the base 1 Both crosses 101 are connected, and the lower feed roller 102 is rotatably connected between the lower parts of the crosses 101 on both sides. The output shaft of the reduction motor 81 is connected with the drive shaft of the lower feed roller 102. The upper part of the cross 101 on both sides is slidably connected with a sliding seat 104, the upper feeding roller 105 is rotatably connected between the sliding seats 104 on both sides, and a tension spring is connected between the sliding seat 104 and the cross 101. 106.

[0029] When placing the PPR pipe fittings, the PPR pipe fittings can be placed on the knife holder 7 through the two guide wheels 103. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com