Continuous production method of unit honeycomb paper core

A technology of honeycomb paper core and production method, which is applied in the direction of cardboard items, etc., which can solve the problems of inconvenient operation for workers, health damage of workers, and large occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

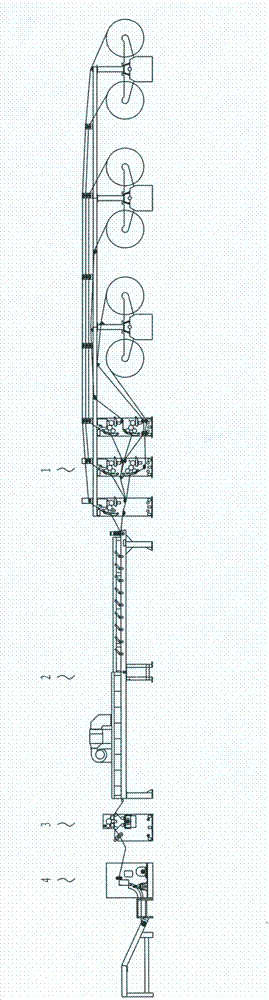

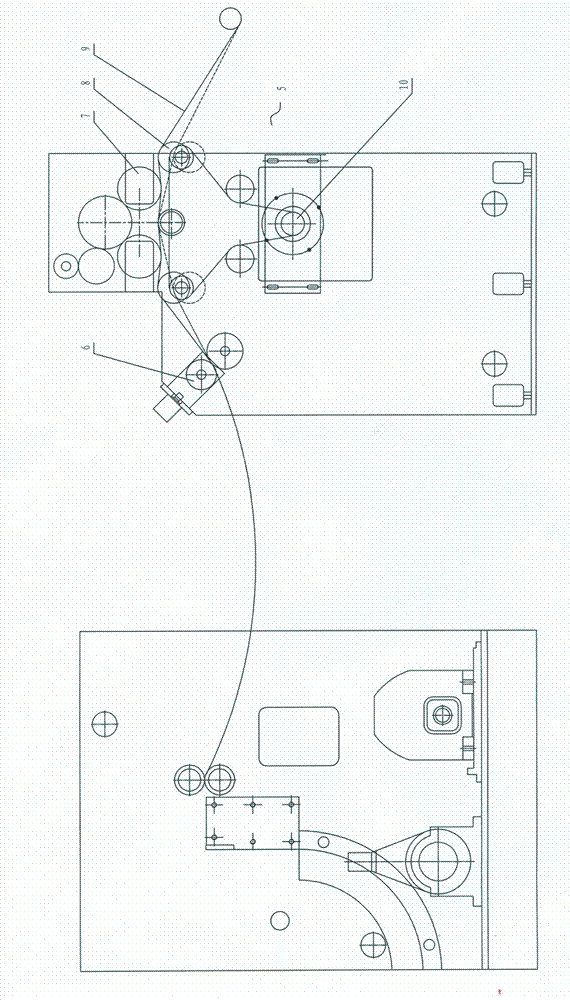

[0017] With reference to accompanying drawing, the continuous production method of this kind of unit honeycomb paper core, its production method is:

[0018] 1) Multiple rolls of core paper are loaded at the same time, and glue lines are applied vertically to the core paper;

[0019] 2) After the core paper is glued, the multi-layer core paper is compounded and dried;

[0020] 3) After the multi-layer core paper is composited into the paper core board, the intermittent gluing device is used to apply glue to the paper core board intermittently, that is, the fixed-length glue is applied to the paper core board, and when the required thickness of the unit honeycomb paper core For a honeycomb paper core with a size of 60mm and 180 sheets of paper, in the case of composite paper on six sheets of paper, it only needs to apply glue for 1800mm, and then cut the glue for 60mm; the formula z=ab / n (a: the required unit Thickness of honeycomb paper core, b: number of sheets of unit honey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com