Hot punching device for runner of MIM (Metal Injection Molding) part

A technology of injection molded parts and hot punching, which is applied in the field of MIM injection molded parts flow channel hot punching device, which can solve the problems affecting the appearance and function of injection molded parts, the melting of injection molded parts body, and the crack of injection molded parts body, so as to improve the quality and process in one step In place, the effect of smooth incision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

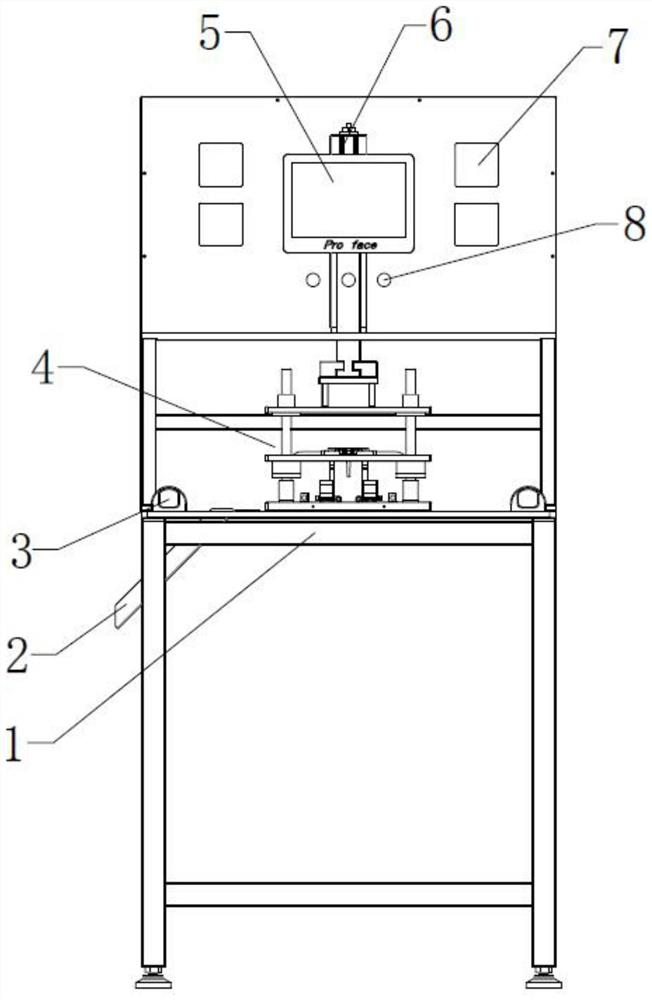

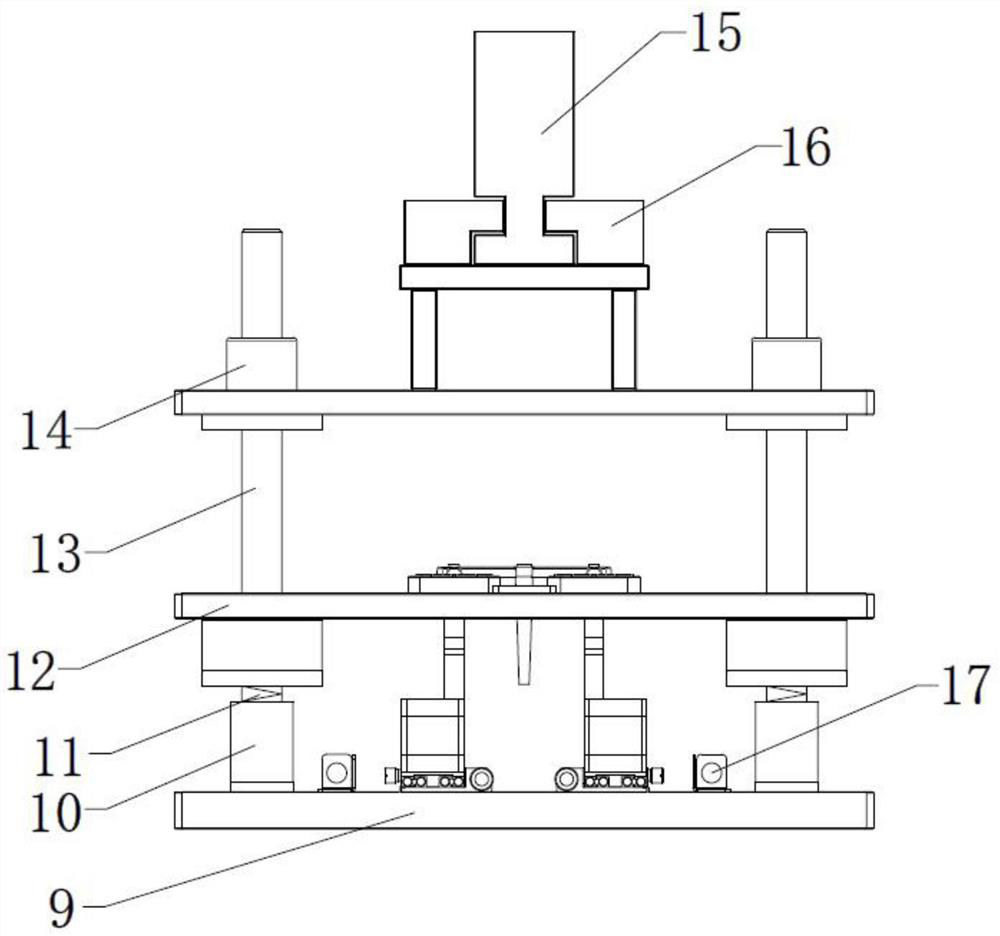

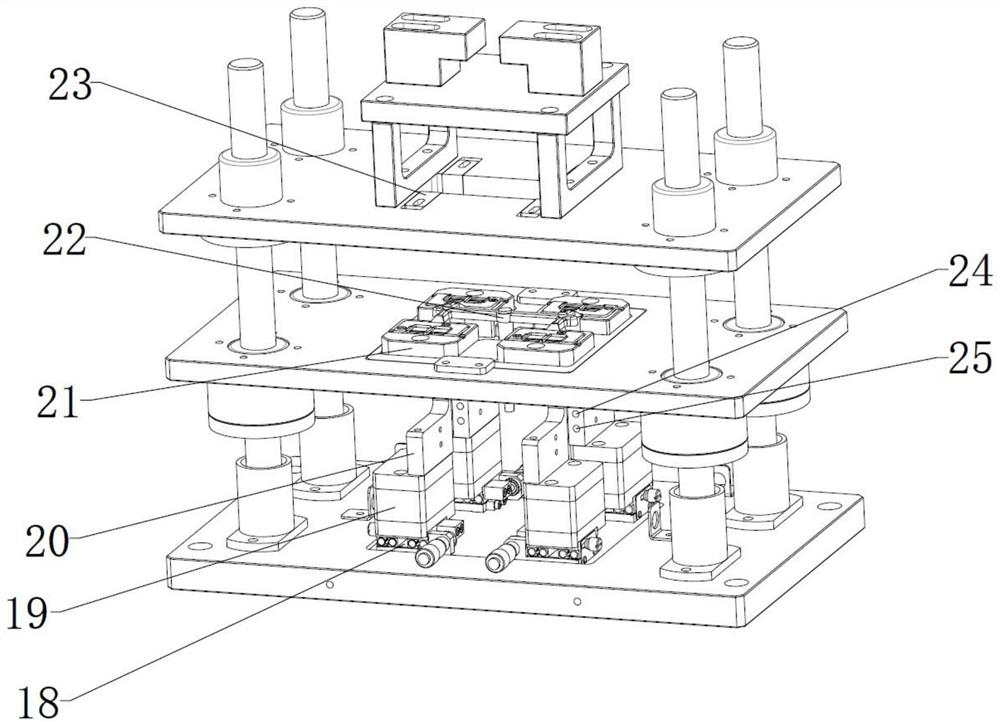

[0025] Such as figure 1 A punching device suitable for small MIM injection molded parts is shown, including a device table 1, an operating part of the device and a main structure 4 of the device. The device table is a desktop frame, the main structure is installed on the device table, and the electric control part of the device is installed above the main structure, including human-computer interaction parts such as touch screen 5, operation button 8 and temperature control table, The touch screen can set the parameters of the action of the mechanical arm 6, and the temperature control table 7 can control the temperature of each cutter. Two touch switches 3 are arranged on the device table, and a hole is provided and a slideway 2 is installed through the hole, which is used for throwing and placing the excised runner, and a barrel is arranged at the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com