Nonmetal thin material shearing machine

A non-metal, shearing machine technology, used in metal processing and other directions, to achieve smooth loading and unloading, high quality of finished products, and small swing space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

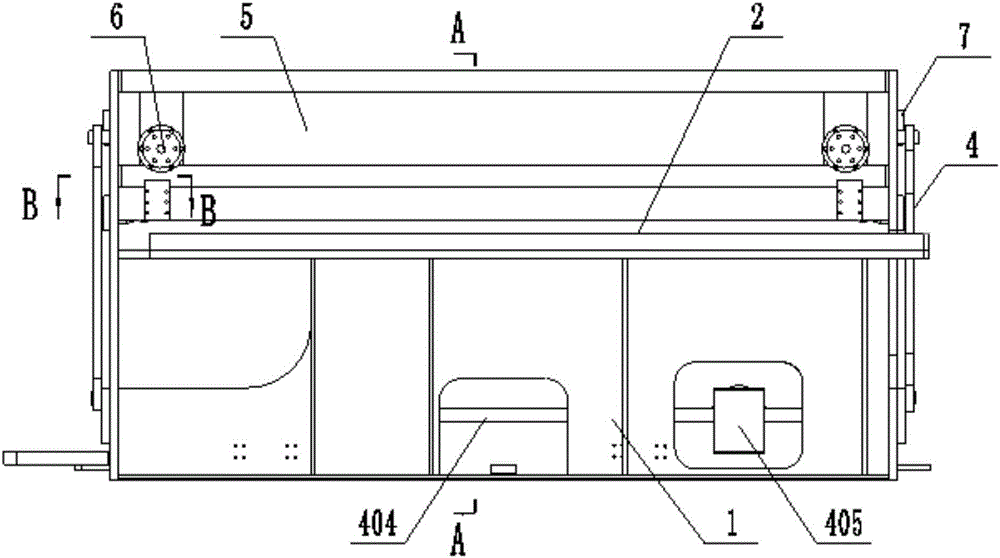

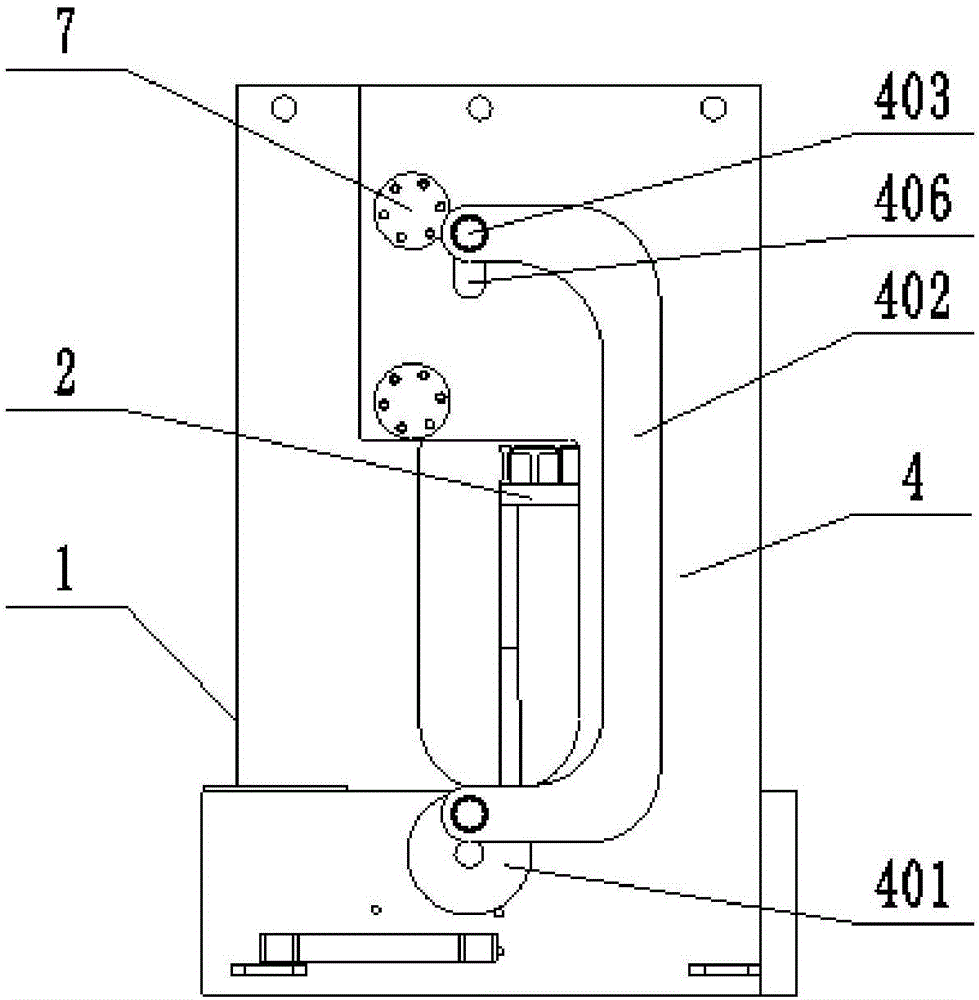

[0046] Such as Figure 1 to Figure 5 As shown, a kind of non-metallic thin material shearing machine of the present embodiment comprises frame 1, workbench 2 and upper knife rest 3, and frame 1 has left and right two wallboards, is respectively left wallboard 101 and right wallboard 101. Wallboard 102, workbench 2 and upper knife rest 3 are located between two wallboards, on workbench 2, lower blade is installed through lower blade seat, and upper blade is installed on the upper knife rest, and the installation structure of blade is prior art The conventional method is the same as that of the common shearing machine, and will not be repeated here.

[0047] In front of the upper knife rest 3, a front panel 5 is installed between the left wallboard 101 and the right wallboard 102, and a front roller assembly 6 is respectively arranged at both ends of the front panel 5, and the front roller assembly 6 is provided with a front roller 640; Both ends of the front surface of the fra...

Embodiment 2

[0052] After long-term practice and summary, when the non-metallic thin material shearing machine in Example 1 is used to shear rubber, the thickness of the sheared rubber is between 0.5 and 2.5 mm, and the gap between the upper and lower blades is between 0.01 and 0.03 mm. During this period, the cutting quality can reach the best. In this example, the rubber of 1mm is taken as an example, the gap between the upper and lower blades is adjusted to 0.02mm, and the equipment in Example 1 is used to cut 1000 times, and no knife jamming occurs. The shearing surface of the sheared rubber is inspected and observed after zooming in. The incision is flat and smooth, without creases, and the shape of the incision is consistent in the length direction, and the overall quality is high.

Embodiment 3

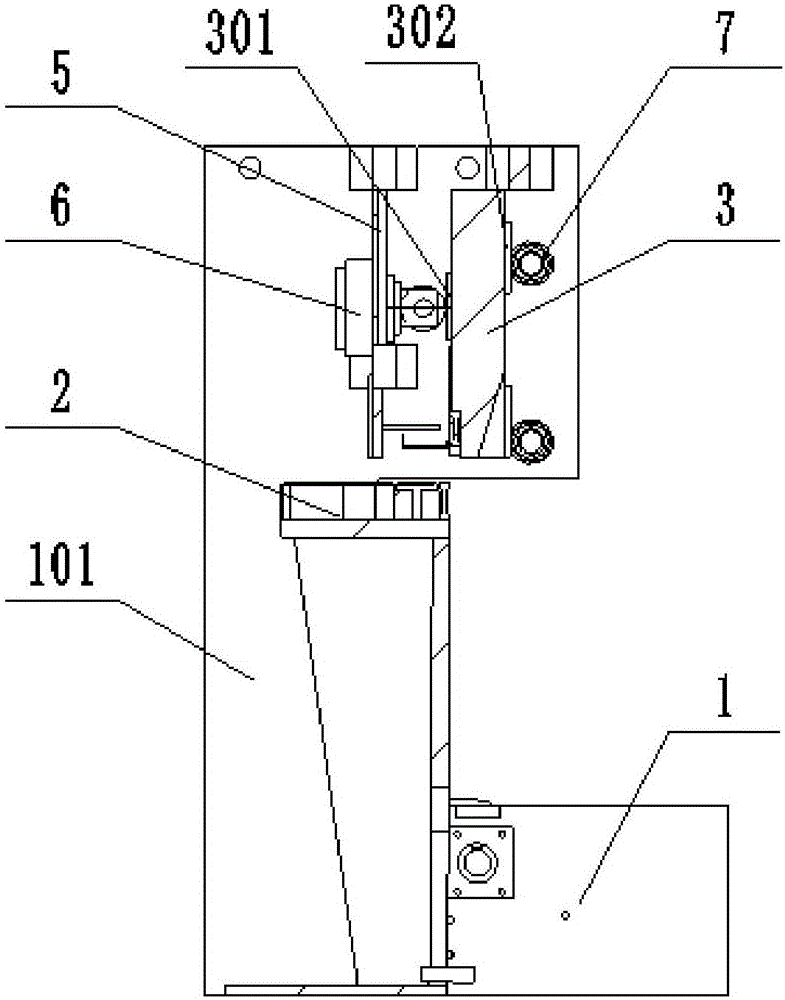

[0054] A kind of non-metal thin material shearing machine of the present embodiment, on the basis of the structure of embodiment 1, the structure of the front roller assembly 6 has been optimized and improved, specifically, as Figure 6 , Figure 7 and Figure 8 As shown, the front roller assembly 6 includes a mounting base 610, a guide rod 620 and a gland 660, wherein the mounting base 610 is installed on the front panel 5, and a through hole is provided in its center, and the rear end of the guide rod 620 is located in the through hole. Among them, the front end of the guide rod 620 is provided with a U-shaped groove, the front roller 640 is located in the U-shaped groove, and is connected to the guide rod 620 through the roller shaft 630, and the roller shaft 630 is fixed by the set screw provided at the front end of the guide rod 620, Thereby avoid roller shaft 630 to drop; Gland 660 is covered on the other end of the through hole of mounting seat 610 by bolt, and spring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com